What is a hydraulic press?

A hydraulic press is a device that significantly increases the initially applied force. It is called a press conventionally, because in industry this apparatus is intended for the production of parts by stamping.

The most common example of a hydraulic press is a jack. A hydraulic jack allows a person to apply little effort but lift a heavy load. Brakes, shock absorbers, drives and pumps work the same way.

The hydraulic press gained popularity due to the fact that a huge flow of energy is transmitted through thin and flexible hoses, which further simplifies the work.

Purpose

The equipment is widely used in many fields of activity, and its purpose is to perform the following work:

- — lifting cargo to a small height (for example, during loading or unloading operations);

- — stamping;

- — straightening of structures;

- — gluing under pressure;

- - Carrying out repair work at home.

The type of press, force, drive and other parameters depend on the type of work this device is intended for.

Operating principle of a hydraulic press

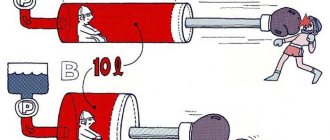

The principle of a hydraulic press is based on the law of communicating vessels. For example, there are 2 connected containers of different sizes. By pouring the liquid there, it will be evenly distributed. If the state of rest is disturbed and the pressure in the smaller vessel is increased, then in the larger vessel the applied force will increase in proportion to the difference in size. The device obeys the rule: the gain in strength is equal to the loss in distance.

Blaise Pascal came up with the idea of how the hydraulic press works, but called it a “machine for increasing strength.” Previously, the benefits from such a machine seemed negligible, but now engineers used Pascal's developments to make the work easier.

The diagram shows a simple hydraulic press, consisting of pistons of large and small diameters installed in communicating cylinders, with liquid under the pistons. A small diameter piston with an area S 1 is subjected to a force F1; let us determine the force F2 that a piston with an area S2 can overcome.

The pressure under piston 1 can be calculated using the formula: p1=F1/S1

The pressure under piston 2 will be determined by the relationship: p2=F2/S2

According to Pascal's law, pressure applied to a liquid is transmitted to all points of this liquid equally in all directions.

Basic rules for operating a hydraulic hand press

Having decided why you need a press, you can purchase the model you like. However, for effective and durable operation of the device, it is necessary to adhere to certain rules for operating the device. First of all, attention is paid to the correct installation of the tool. All necessary information on this issue is described in the accompanying document for the device, which is provided by the manufacturer.

It is necessary to check the fluid level in the cylinder before each operation.

Let's look at the basic recommendations that should be followed to avoid frequent breakdowns of the press and the need to repair it. Before each use and during operation, it is necessary to check the level of working fluid in the cylinders. The amount of pressure that the hydraulic cylinder is capable of creating will depend on the filling of the vessel. It is necessary to regularly lubricate rubbing and moving structural elements.

The condition of the sealing rings is periodically checked. Over time, these elements lose their elasticity. Before starting work, you should check that the part to be processed is securely fastened.

During operation of an industrial press, malfunctions may occur. Information about the possible causes of their occurrence and rules for eliminating them is contained in the instructions for the tool.

Types of hydraulic presses

According to the All-Russian Classification of Fixed Assets, a hydraulic press belongs to group No. 5. This also includes all metalworking press-forging machines and hammers.

Classification by type of cylinder arrangement:

- horizontal;

- vertical.

Classification by type of work:

- stamping;

- bending;

- forging;

- for flanging and beading.

Classification by bed type:

- columned;

- rack-mounted

Classification by type of execution:

- With a closed frame – the frame has holes for fixing the press on the table; used for bending, straightening, pressing/pressing.

- With an open frame - for processing parts of non-standard shape and awkward design; performs similar operations.

- Universal – have a full range of functions; The hydraulic pump can be used manually.

- Press out machines – used for installation/dismantling, pressing out/pressing. Its small size allows it to be used more often in any conditions.

Modern presses cannot do without CNC. By setting the operating mode and choosing the pressure, you can forget about constant monitoring of the machine - the microcomputer will do this.

How to use a hydraulic press?

Each hydraulic press has design features, so the manufacturer sells the machine along with detailed operating instructions for the hydraulic press. But even after reading it, anyone who wants to work on it will not be allowed, because you need to know not only the instructions, but also the general rules on labor safety with hydraulic presses. Here are some of them:

- Only persons who have undergone instructions and a medical examination can operate the hydraulic press.

- You cannot work on a hydraulic press without special clothing.

- You should always be on the lookout for possible fluid leaks.

- Do not keep your hands near the work area.

- When finished, close the valve and wipe the tool.

More detailed guidance can be found in labor protection for working with hydraulic presses.

How to assemble a press with your own hands

To make your own hydraulic press, you first need to make a drawing of the future device. The width of the bed opening depends on what materials will be further processed on this equipment. Initially, the metal is cut according to the values specified in the drawing and, if necessary, holes are also drilled in accordance with the diagram. The base of the structure is welded from a square pipe, the seams are welded on the bottom and top sides. A metal plate is fixed on top by welding, then it is necessary to make a movable work table. The structure is tightened on the sides with bolts and nuts, tension springs are secured, and a jack is installed.

What to rely on when choosing a hydraulic press?

The abundance of models and manufacturers allows you to choose a hydraulic press to suit your specific work needs. It is better if the characteristics of the unit are slightly better than required. Plus, you need to pay attention to the permissible service life.

Important Specifications

- The size of the products you will have to work with.

- The strength of the pressure developed.

Further choice depends on these indicators. For example, a 10-ton tabletop press is not suitable for a truck service center, and a small workshop in a garage does not need a 100-ton machine.

The technical specification indicates the force of the hydraulic press. Having understood what parts you have to work with, you can choose the optimal installation taking into account the standard gradation:

- passenger cars and trucks – up to 45 tons;

- industrial enterprises: from 75 tons and above, depending on the material for work.

Pay attention to the height/width of the hydraulic press and the stroke of the working piston. This determines how large a part can be pressed using a hydraulic press.

Features of hydraulic presses that are worth paying attention to

- Automatic rod return.

Speeds up the workflow and increases convenience. - Chrome shock.

Increases the service life of the hydraulic press, protecting it from corrosion. - Safety valve.

It will protect the operation of the press by releasing excess pressure in the system. Excessive load is fraught with serious consequences. - Reliability of the bed.

Durable material is only 50% of the reliability of the design. It is important that all seams are carefully sealed, otherwise the force of the press will eventually break the frame. - Winch mechanism.

Needed to adjust the work table when working with massive elements. - Moving the table and cylinder.

The mobility of individual hydraulic press parts increases the convenience of working with non-standard sizes. - Pressure gauge quality

. The force exerted on a part can only be assessed using a pressure gauge, so make sure it shows accurate data and is made of reliable materials. It is better to go with a glycerin pressure gauge, which suppresses vibration.

Misconceptions when working with hydraulic presses

There is an opinion that hydraulic presses do not need safety elements. This is not true, because pressure drops in the system can occur even due to a banal change in weather. If the cylinders are made of low-quality metal that reacts to small temperature changes, the liquid can quickly heat up. Without noticing this, the worker will run the hydraulic press to maximum, causing not just a breakdown, but a danger to himself.

When choosing a hydraulic press, you need to take into account not only current needs, but also future ones, because then you won’t want to purchase a new unit.

Where to buy a hydraulic press from the manufacturer?

The Sterlitamak Machine Tool Plant has been supplying us with high-quality hydraulic presses of its own production for a long time. The weight of the product is certified and checked by the workers of STK LLC

Which hydraulic press to buy: tabletop or floor-mounted

When choosing a floor or tabletop type of device, you should first decide what the press is for.

The floor device is impressive in size. The instrument is located on the floor. It is used for processing large parts. The floor type hydraulic press is often chosen by large service stations whose main activity is car repair. Thanks to this device, the productivity of technological processes increases. In addition, the presence of a hydraulic press helps to expand the range of services provided.

Helpful advice! To quickly carry out technological processes that require high power, it is more advisable for a service station to purchase a hydraulic press with an electric drive.

Floor-standing hydraulic presses are designed for processing large parts

Floor-standing hydraulic presses are selected based on the characteristics of the hydraulic cylinder and the design parameters where it is installed. An important factor is the maximum force that the tool can exert on the workpiece being processed. This criterion varies between 5-20 tons. The effective operation of a floor press depends on the distance that the rod travels, acting on the part.

Important! When choosing a hydraulic press, you should study the technical parameters of the tool, which are displayed in the equipment passport.

Features of Tabletop Hydraulic Press for Garage

The tabletop press is more stable. It features an extended range of desktop adjustment. This provides the ability to process parts of different sizes.

A tabletop hydraulic press is often chosen for a home workshop or garage. The maximum load capacity of the device reaches 12 tons. This tool is characterized by its small size and weight, which makes it easy to use. It can be installed on a workbench, which will save usable space.

Tabletop hydraulic press is ideal for the home workshop

When choosing a device, you should focus on the size and weight of the device, the type and characteristics of the working platform, which has different designs and dimensions. The design can be equipped with grooves for mounting additional elements. An important question is how much a press costs. A floor instrument can be purchased for 30 thousand rubles. The price of a tabletop hydraulic press averages 10-20 thousand rubles.

Some models have the ability to move the press along the frame relative to the rod. The tool may include shock-absorbing elements. They are necessary to compensate for the excess pressure that is exerted on the structure.

Related article:

Knife sharpening machines: a convenient way to keep your work tools in order

For which instruments can they be used? Main types of structures. How to choose the right one. Review of popular models of sharpening devices.

When choosing a hydraulic press of any type, you should also take into account the material of manufacture and the thickness of the base plate of the device where the part is installed during its processing.