Some time ago, we bought a pair of inductive converters in China with the hope that, despite the simplicity of the design and the small number of radio components, it would be possible to later use this device in the workshop, for example, as an aid in loosening stuck bolts or for hardening small-sized metals. As it turned out, 100 W of power is very little for these purposes, however, the device works very well and effectively, no worse than a homemade one.

Features of EasyTherm induction heaters

- 3 (three) heating modes: temperature, time and temperature-time. (The temperature-time mode allows you to simultaneously control the heated part by temperature and time, eliminating the possibility of destruction of the part as a result of local overheating)

- Possibility of heating parts with a diameter from 10 mm to 5 m, weighing from 0.1 kg to 10 tons

- Capable of heating sealed bearings, lubricated bearings, shielded bearings, etc.

- Possibility of heating parts up to 400 °C!

- Possibility of both manual and remote control

- The heater can be made of a special shape, which will allow it to be evenly heated over the entire surface of parts of a complex configuration, without leading to their warping or local non-heating

- Availability of automatic demagnetization function upon completion of the heating process

- Possibility of continuous operation without the use of additional cooling

- The warranty period for EasyTherm induction heaters is 3 years!!!

The main advantages of induction heaters compared to traditional methods of heating parts are high heating speed (saving time when heating), ease of use, constant control during the heating process , as well as environmental friendliness and safety of the process.

DIY induction heater

An induction heater is a very necessary thing for blacksmiths, turners, mechanics and home craftsmen. With its help, you can always heat and even melt metal without problems and easily; you do not need expensive heat carriers such as coal and gas, you just need to connect electricity to the device. Non-contact heating of the metal occurs with high-frequency currents, scientifically called radio-frequency waves. The device is widely used for heat treatment, hardening and bending of parts, non-contact melting, soldering and welding of metals. In jewelry, for thermal processing of small parts. In medicine for disinfection of medical instruments. At a car service center, a mechanic warms up rusted nuts. The inductor is also installed in induction boilers used for heating residential premises.

This figure shows the working diagram of an induction heater, which you can easily make with your own hands.

Induction heater circuit

The device consists of a high-frequency master oscillator assembled on two powerful field-effect transistors. The operating voltage of the generator depends on the power of the installed field-effect transistors. With IRFP250 transistors, the device can be powered with voltage from 12 to 30 volts. And if you install IRFP260 transistors, then the supply voltage can be raised from 12 to 60 volts.

The power of the inductor will increase significantly, the heating temperature of the metal will increase to more than 1000 degrees, which will make it possible to melt metals. During operation, the transistors will become especially hot, so they need to be installed on large heating appliances and a powerful fan installed. At idle, the inductor consumes at least 10A, and in good condition, at least 15A; naturally, a high-power power supply of at least 20A is required.

This picture shows the circuit board of an induction heater.

You will also need 10K resistors R1, R2 with a power of 0.25 Watts. Resistors R3, R4 with a resistance of 470 Ohms of at least 2 Watts. Diodes D1, D2 are ultra-fast UF4007 or the rest are the same for the highest current up to 1A. Zener diodes VD1, VD2 with a power of at least 5 Watts with a stabilization voltage of 12V, for example 1N5349 and others. I pulled out chokes L1, L2, sized 27x14x11 mm, yellow with a white stripe, from computer transformers. For each choke you need to screw 25 turns of copper wire with a diameter of 1 mm, preferably in varnish insulation; if you can’t find it, a single-core wire in PVC insulation will do, it doesn’t really affect the speed.

Metal film capacitors C1-C16 0.33 uF 630V, connected in parallel in 4x4 rows, there are only sixteen pieces in the block. It is better not to install with low operating voltage, they will overheat. Leave a small distance between the condensers for excellent cooling by air flow.

I decided to seal the throttles with silicone sealant so that they would not dangle.

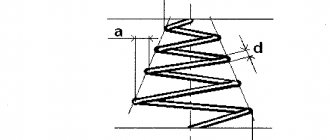

I made the main part of the heater, the inductor, from a copper tube with a diameter of 6 mm and a length of 1 meter. You can buy one at any automobile store like “Gazovshchik” and where they sell gas equipment for cars. We wind the copper tube onto a piece of polymer pipe with an outer diameter of 40 mm; a similar pipe is used in plastic heating. We make five turns, the distance between the top edge of the first turn and the bottom edge of the fifth turn should be 40 mm. We bend the ends of the pipe as in the figure and secure it to the heating devices using 2 terminal blocks for a wire with a cross-section of 16 mm?.

During operation, the inductor will become very hot from the hot part, which can lead to damage to the copper tube, so it needs to be cooled. I put silicone tubes on the ends of the copper tube and connected the car windshield washer pump. I bought a pump from a VAZ 2114 and silicone tubes at a car store. The normal hydraulic cooling system has failed.

To cool the heating devices and the capacitor unit, I installed a powerful fan from the processor. For power supply from 12 volts, such cooling is in reality sufficient. If you want to increase the voltage from 12 to 60 volts in order to get the highest power from an induction heater, set up much more powerful heating devices and a very efficient fan, for example from the interior heater of a VAZ 2107. It is best to make an iron curtain that protects the heated part and a copper inductor from the flow cold air forced by the fan.

Since the induction heater consumes a large current of about 20A, all traces on the circuit board should be improved with copper wire soldered on top.

And now the most curious thing... I tested the induction heater from a twelve-volt car battery. I simply don’t have any other power source capable of delivering high currents. The blade of a utility knife became red hot in 10 seconds. And this is an effective result, if you take into account that the inductor is powered by only twelve volts!

Friends! If you wish, assemble an induction heater with your own hands. My advice to you... Immediately install IRFP260 field-effect transistors, large heating devices and a powerful fan from the VAZ 2107 interior heater; to power the inductor, first of all, use a powerful power source, preferably from 24V to 60V with a current of at least 20A.

Radio components for assembling an induction heater

- Transistors T1, T2 IRFP250 are better than IRFP260 2 pcs.

- Resistors R1, R2 10K 0.25W 2 pcs. R3, R4 470R 2W 2 pcs.

- Ultrafast diodes D1, D2 UF4007 2 pcs. or similar

- Zener diodes VD1, VD2 for 12V 1W 1N5349 or similar 2 pcs.

- Capacitors C1-C16 0.33mf 630V 16 pcs.

- Chokes from a computer power supply are yellow with a white stripe, size 27x14x11 mm, 2 pcs.

- Terminal block for wire with a cross section of 16 mm? 2 pcs.

- Copper wire in varnish insulation d=1 mm length 2 meters

- Copper tube d=6 mm, length 1 meter

- If the heating device is larger, it is better to have 2 pieces.

- Windshield washer pump from VAZ 2114 1 pc.

- Silicone tube 2 meters

- The more powerful the fan, the better. I recommend from the interior heater VAZ 2107 1 pc.

Friends, I wish you good luck and a great mood! See you in new articles!

I advise you to watch a video on how to make an induction heater with your own hands

Disadvantages of Traditional Heating Methods

Traditional bearing heating methods, which include blowtorch heating, oil bath heating, oven heating and hot plate heating, have several serious disadvantages:

Blowtorch and hot plate heating

Lack of temperature control

Heating in oil baths

- Low heating rate

- Grease leaks from the bearing

- Danger during operation (hot oil)

- The heating process is not environmentally friendly

Heating in heating furnaces

- Low heating rate

- High energy consumption

- Grease leaking from the bearing

Main parts of the EasyTherm heater

- Control panel TM, which is a touchscreen LCD display for entering heating parameters and monitoring the process. The panel is equipped with a USB output for downloading graphs and heating dynamics data.

- Replaceable induction rod.

- Connector for connecting a temperature sensor.

- Place of installation of the sensor (IMPORTANT! First of all, we are interested in heating the internal diameter, so the sensor should be installed as shown in the image).

- Pull-out rails for large parts.

- U-shaped core.

- The heater body (it is in this that the coil is located, unlike analogues, which allows you to increase the working area of the U-shaped circuit).

When choosing a heating method, you can say with complete confidence that the induction heating method is highly effective, economical and efficient!

Dealer certificates

| Dealer certificate for the supply of TM Induction equipment - induction heaters. | Dealer certificate for the supply of PowerRAM equipment - mechanical and hydraulic pullers. |

On our website you will find all the necessary information about induction heaters of the Easytherm series, as well as about special-purpose heaters TM-Induction and equipment for mounting and dismantling female parts (hydraulic and mechanical pullers Powerram). Our company’s specialists will help you select the optimal equipment to solve your production problems and provide detailed advice on its use.

Call us at 8 (800) 505-45-20, write to us by email

Do-it-yourself working diagram of a metal induction heater

When a person is faced with the need to heat an iron object, fire comes to his mind first. Fire is an old-fashioned, ineffective and slow way to heat metal. It spends a large share of energy on heat, and smoke always comes from the fire. How cool it would be if all such problems could be avoided.

Today I will show you how to assemble an induction heater with your own hands with a ZVS driver. This device heats most metals using a ZVS driver and the power of electromagnetism. Such a heater is highly efficient, does not create smoke, and heating such small metal products, such as, say, a paper clip, is a matter of a few seconds. The video shows the heater in action, but the instructions provided are different.