Density of materials

Unit

The density of aluminum and any other material is a physical quantity that determines the ratio of the mass of the material to the occupied volume.

- The unit of measurement for density in the SI system is kg/m3.

- For the density of aluminum, a more descriptive dimension g/cm3 is often used.

The density of aluminum in kg/m3 is a thousand times greater than in g/cm3.

Specific gravity

To estimate the amount of material per unit volume, such a non-systemic, but more visual unit of measurement as “specific gravity” is often used. Unlike density, specific gravity is not an absolute unit of measurement. The fact is that it depends on the magnitude of gravitational acceleration g, which varies depending on the location on Earth.

Dependence of density on temperature

The density of the material depends on temperature. It usually decreases with increasing temperature. On the other hand, specific volume—volume per unit mass—increases with increasing temperature. This phenomenon is called thermal expansion. It is usually expressed as a coefficient of thermal expansion, which gives the change in length per degree of temperature, for example mm/mm/ºC. Change in length is easier to measure and apply than change in volume.

Specific volume

The specific volume of a material is the reciprocal of density. It shows the volume of a unit of mass and has the dimension m3/kg. Based on the specific volume of the material, it is convenient to observe the change in the density of materials during heating and cooling.

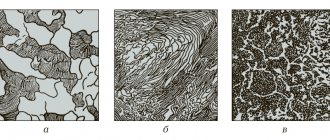

The figure below shows the change in specific volume of various materials (pure metal, alloy and amorphous material) with increasing temperature. The flat sections of the graphs represent temperature expansion for all types of materials in solid and liquid states. When a pure metal is melted, there is a jump in the increase in specific volume (a decrease in density); when an alloy is melted, it rapidly increases as it melts in the temperature range. Amorphous materials, when melting (at the glass transition temperature), increase their coefficient of thermal expansion [2].

How to find out the weight of aluminum sheets?

Naturally, the most accurate method to determine the mass of an aluminum sheet is to weigh it.

But this can be done using fairly simple calculations. True, regardless of the calculation method used, a theoretical weight indicator is always obtained - close to the real value, which is obtained by weighing, but slightly different from it. There are the following methods for calculating the mass of an aluminum sheet: As indicated above, the result of the calculations is the theoretical weight. This is primarily due to the fact that any calculations use the dimensions of the product: width, thickness and length. They are measured, or data from the GOST reference book for aluminum sheets is used. In any case, the actual dimensions will differ from those obtained by any of these methods. This is due to the following reasons.

The main one is hidden in the imperfection of today's technologies for the production of rolled metal, any kind at that. It is impossible to manufacture a product of exactly the specified size. It is for this reason that all GOSTs (for any assortment), which regulate production requirements and the assortment (list of standard sizes) of products, indicate possible deviations in dimensions. For aluminum sheets, such requirements are specified in GOST 21631. Here are all standard sizes of industrially manufactured products and deviations in their length, thickness and width. In documentation and reference books for sheets, the dimensions that meet the requirements according to the assortment are indicated, without taking into account possible deviations from them.

That is, when buying an aluminum sheet with the dimensions indicated in the accompanying documentation, you can be absolutely sure that at least one of the packages does not correspond to those specified. The tolerance, if it fits within the framework possible by GOST, will be insignificant, and, accordingly, the error in the theoretical calculation of weight is small. Although, if it is necessary to count a fairly large amount of rolled products, missing or extra tons may “come out”.

By the way, according to the first calculation option, a theoretical indication of the weight of 1 meter of sheet is selected according to GOST. It is also calculated taking into account the standard dimensions of the aluminum assortment.

Measuring the product can improve the situation a little, but not always. As a rule, it is made along one wide and long side, and the thickness is determined in one place on the edge with a micrometer or caliper . But readings from opposite edges may vary. And in the interval between the angles of length and width they can also “float”. The same applies to thickness; it will vary by some hundredths of a millimeter along the entire perimeter of the aluminum product.

The next point that affects the accuracy of the calculations is what data on the density of aluminum was substituted into the formulas for calculating the weight. Since the weight is determined by multiplying the volume of the sheet by its density. The weight designation for 1 meter from the GOST reference book and documentation was calculated taking into account the indicator 2.85 g/cm3 (2850 kg/m3). This value refers to the density of compositions B95.2, B95.1, B95 and a number of others. But there are a great many types of aluminum and its compositions, and each has its own value. It may be slightly different from the table weight. And in this case, the weight indicator of 1 meter taken from GOST will differ even more from the real one.

To make it possible to adjust the theoretical mass of the tables, GOST specifies conversion factors for certain brands of aluminum compositions. Having found the required one, we multiply the reference weight indicators by it.

Aluminum Density

Theoretical density of aluminum

The density of a chemical element is determined by its atomic number and other factors such as atomic radius and the way the atoms are packed. The theoretical density of aluminum at room temperature (20 °C) based on the parameters of its atomic lattice is:

- 2698.72 kg/m3.

Density of aluminum: solid and liquid

A graph of aluminum density versus temperature is shown in the figure below [1]:

- As the temperature increases, the density of aluminum decreases.

- When aluminum transitions from solid to liquid, its density decreases abruptly from 2.55 to 2.34 g/cm3.

The density of aluminum in the liquid state - molten pure aluminum 99.996% - at various temperatures is presented in the table.

How to find out the weight by the specific gravity of 1 square meter?

As mentioned above, it is advisable to calculate the mass of the sheet using tables.

Therefore, if they are at hand, then it is best to follow the advice in the chapter described above. If not, then this one. First, measure the length, thickness and width of the sheet. Before calculating the weight of an aluminum sheet, you need to find out its specific gravity of 1 square meter. Why first find out the volume of 1 sq. m.:

V=LхHхT, where:

In our case, L and H products are 1 square meter in size. equal 1 meter, then the formula looks like this:

V = 1x1xT.

Then we find from the tables the density of the composition (P) from which the sheet is made. If the density is indicated in g/cm. cubic meters, then convert to kg/m. cube – multiply the tabular data by 1000. If you don’t have a reference book at hand, then substitute the density of aluminum – 2700 kg/m. cube We determine the specific gravity: m=VхP.

This weight is 1 sq. m. will be in kilograms. Then we multiply it by the length and width of the product. As a result, we get the desired weight. The calculation can be made without intermediate determination of the specific gravity of aluminum. It is described below. Just once you know the specific gravity of an aluminum sheet, you can, if necessary, use it again as a universal constant to calculate the mass of sheets of the same composition and with the same thickness, but with different lengths and widths .

Aluminum alloys

Effect of doping

Differences in the density of different aluminum alloys are due to the fact that they contain different alloying elements and in different quantities. On the other hand, some alloying elements are lighter than aluminum, others are heavier.

Alloying elements lighter than aluminum:

- silicon (2.33 g/cm³),

- magnesium (1.74 g/cm³),

- lithium (0.533 g/cm³).

Alloying elements heavier than aluminum:

- iron (7.87 g/cm³),

- manganese (7.40 g/cm³),

- copper (8.96 g/cm³),

- zinc (7.13 g/cm³).

The effect of alloying elements on the density of aluminum alloys is demonstrated by the graph in the figure below [1].

The lightest and heaviest aluminum alloys

- One of the lightest aluminum alloys is the foreign cast alloy 518.0 (7.5-8.5% magnesium) - 2.53 g per cubic centimeter [1]. The domestic alloy AMg11 (AL22) contains even more magnesium - from 10.5 to 13.0%. Therefore, we must think that it is even lighter, but we do not have exact data!

- The heaviest aluminum alloys are foreign cast alloys 222.0 and 238.0 with a nominal copper content of 10%. Their nominal density is 2.95 g per cubic centimeter [1].

- The lightest wrought alloy is 8090 aluminum-lithium alloy with a nominal lithium content of 2.0%. Its nominal density is 2.55 g per cubic centimeter [1].

- The heaviest deformable aluminum alloys are alloy B95 and foreign alloy 7175: 2.85 g per cubic centimeter [4].

Density of industrial aluminum alloys

The densities of aluminum and aluminum alloys that are used in industry are presented in the table below for the annealed state (O). To a certain extent, it depends on the state of the alloy, especially for heat-hardening aluminum alloys.

Influence of alloying elements of aluminum alloys on density and Young’s modulus [3]

Aluminum-lithium alloys

The famous aluminum-lithium alloys have the lowest density.

- Lithium is the lightest metal element.

- The density of lithium at room temperature is 0.533 g/cm³ - this metal can float in water!

- Every 1% lithium in aluminum reduces its density by 3%

- Every 1% lithium increases the elastic modulus of aluminum by 6%. This is very important for aircraft construction and space technology.

Popular industrial aluminum-lithium alloys are 2090, 2091 and 8090:

- Alloy 2090 has a nominal lithium content of 1.3% and a nominal density of 2.59 g/cm3.

- Alloy 2091 has a nominal lithium content of 2.2% and a nominal density of 2.58 g/cm3.

- Alloy 8090 with a lithium content of 2.0% has a density of 2.55 g/cm3.

Weight calculation using GOST tables

This method is more accurate and makes it possible to minimize the likelihood of a mathematical calculation. This is ensured by the fact that the tables indicate the weight of one linear meter for the standard width and thickness of manufactured aluminum sheets. At the same time, GOST contains several tables - each takes into account a certain accuracy of rolled metal production.

All these calculated values were carried out by specialists, taking into account permissible deviations in dimensions and manufacturing accuracy, and in terms of theoretical ones they are considered the most accurate. The likelihood of making a mistake is reduced due to the fact that there are fewer calculation operations than with other calculations.

To find out how much an aluminum sheet weighs, you need to select the necessary table based on the accuracy of its production, if these data are indicated. If this data is not available, then we focus on the table, which is intended for products made with acceptable accuracy in thickness and width, since these products are the most popular.

We select in the table the weight of 1 meter, which corresponds to the width and thickness of the product being determined. Then we multiply it by the length of the entire rolled metal product or one product. This is the mass of the aluminum sheet. To make the calculations more accurate, you need to take into account the brand of the composition from which the sheet is made. The tables contain data for V95.2, V95.1, V95 with a density of 2.85 g/cm3. If the sheet is made from a different composition, but you know the brand, we look for the required conversion factor to GOST. Multiply the sheet weight value you determined by it.

GOST does not indicate coefficients for all aluminum compositions. For those not designated, there is a general one: aluminum of another alloy - 0.95. You can use it or try to find the density of the composition from which the calculated sheet is made in other reference sources. If the value you determine is not equal to 2.85 g/cm3, we make an amendment:

- We divide the calculated weight by 2.85 g/cm3.

- Multiply this value by your density.

If the product is of non-standard width, then it can be done this way. We look in the table for a definition of the weight of 1 meter for width, which is as close as possible to the size of your product. We divide it by the reference width, and then multiply it by the data on the calculation sheet. As a result, your product weighs 1 meter. Next we calculate as stated above.