In production areas, loading or unloading operations, transportation of fine and bulk materials is carried out using screw conveyors, they are also called screw conveyors. This equipment has proven itself to be trouble-free and reliable.

A screw conveyor is a continuous device, which is an open or closed chute within which a screw rotates. The auger is driven by an electric motor. Blades are used to move materials downhill or horizontally. It depends on the type of conveyor. Due to their versatility, such conveyors are widely used in industry.

Varieties

Based on the type of housing, experts divide screw conveyors into two main types:

- open;

- closed.

Based on the type of screw used (the number of independent spirals), a distinction is made between single-pass and double-pass. In the direction of rotation of the screw - left and right.

Based on the orientation of the housing, devices are divided into:

- vertical screw conveyor;

- inclined;

- horizontal conveyor.

Inclined and vertical screw conveyors are usually constructed in a closed enclosure to prevent the load being moved from falling.

Screw spiral conveyors are also distinguished according to such parameters as:

- performance;

- blade diameter and pitch;

- conveyor length;

- rpm, etc.

Closed conveyor

Such mechanisms consist of a closed tube within which a screw rotates. The blades are made solid or shaped. This is determined by the required productivity and the type of material being moved. There is a hole at the inlet end of the pipe; it has a receiving tray through which the load is poured into the mechanism. At the opposite end it has an outlet; it is equipped with a pipe that directs the flow in the desired direction. The pipe is equipped with a damper that prevents random objects and precipitation from entering the mechanism.

This design can easily be sealed, so it is ideal for transporting fine bulk substances with increased dust formation. They are suitable for work both in closed production or warehouse premises, and in open space. A vertical auger also requires a closed circuit. They are characterized by high productivity and low losses of transported cargo.

The downside is the complexity of maintenance and repair; access to the auger parts requires complete disassembly of the device.

Open screw conveyor

An open screw conveyor has a simpler design. It is a gutter or a piece of pipe with the top cut out. An auger rotates in the middle of the chute, moving material through it. This design is used mainly in rooms where the cargo is protected from atmospheric phenomena and the ingress of foreign objects.

It is recommended to use them for low-dust materials that do not emit strong or unpleasant odors.

The advantage is easy access to device parts for maintenance and repair. The disadvantage will be that the conveyor is located exclusively horizontally (or with a minimal slope), otherwise there is a danger of cargo spilling.

Screw Conveyor Design and Performance

The process of assembling a screw conveyor consists of constructing a body from several separately manufactured sections. Often, cylindrical sections are bolted together (however, the shape and dimensions of the body are determined at the calculation stage). The modular structure of the sections allows you to adjust the length of the equipment: each section has flanges. They allow you to conveniently connect sections to one another, as well as install end walls with bearing and sealing units. During the design and calculation of the screw conveyor, the screw conveyor is designed and installed up to 40 m long. The conveyor screw can be with a right or left spiral stroke. The screws are produced in single, double or triple thread. Grain mass or other products are poured into the chute through a special hatch located in the equipment cover. The transported material rubs against the walls of the chute, and gravity, in turn, prevents the product from rotating along with the screw.

Completed projects

Construction of elevators, grain complexes. Production of elevator equipment.

Screw conveyor design

The design of the screw conveyor consists of internal unloading and loading units, a large spiral and connecting flanges. The type of grain screw conveyor is selected depending on its purpose in production and the amount of grain that will need to be moved. A specific screw has a certain winding density and diameter and is the main working body of the screw conveyor. The productivity of a screw conveyor depends specifically on the diameter of the screw and the diameter of the pipe. The gear motor is the driving element of the conveyor screw, which drives the machine.

The cylindrical screw conveyor is one of the most common. Its tube-shaped body is rigid, and the unit itself is compact and easy to use. It is suitable for almost all industries. Let's pay attention to its features and additional functions:

- Conveyors are straight, with adjustable angle, and vertical.

- Stationary or mobile.

- Housing and screw material ─ stainless or galvanized steel.

- Equipped with dispensers.

- Speed adjustment and reverse rotation of the auger are possible.

An open type conveyor is a chute or half of a pipe within which a screw rotates. The rectangular container can also be an open conveyor body. The mechanism can only be used indoors, as it is not sealed: moisture and dust may enter. It is desirable that the materials being moved are odorless, do not fly apart, and do not create dust during transportation.

There are two types of screw conveyors: stationary and mobile and, of course, they differ and have their own characteristics. But in general we can highlight several main advantages:

- compact equipment, mobility, ease of use and light weight;

- The design of the unit is easy to maintain and repair;

- high efficiency and productivity;

- the conveyor allows you to transport cargo to hard-to-reach places in all planes.

Small and dusty cargo is completely stored inside the housing, which minimizes product losses. Inclined units will help save space, because they require less space with the same length (compared to horizontal conveyors). The screw conveyor consists of separate parts and is connected to each other by flange connections. In this way you can easily change the length of the conveyor. Stainless steel, from which all parts of the units are made, prevents oxidation of the transported product.

The compact dimensions of the mechanisms make them possible to integrate into various types of production.

Screw screw conveyor design

The main unit and working body of the screw conveyor is a screw auger. The second main element is the body, which prevents the transported load from falling apart.

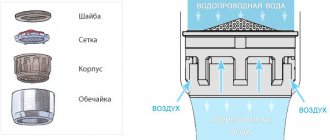

The screw conveyor consists of the following parts:

- a receiving compartment in which the transported material accumulates;

- unit body - closed pipe or open half-pipe;

- working auger;

- drive electric motor;

- transmission (V-belt or gear);

- outlet pipe.

Propeller blades are most often made of steel sheet. In some cases, cast iron is used to move abrasive substances. The blades are mounted on a central shaft; it is made of steel pipe. At the ends, the shaft rests on rolling bearings, protected from dust and abrasives by seals. If the conveyor is long, intermediate support bearings are installed to protect the shaft from sagging.

The gutter is welded from sheet steel segments. The seams between the segments serve as additional stiffening ribs, increasing the geometric stability of the entire structure. A gap of half a centimeter to a centimeter is left between the walls of the vertical screw conveyor pipe and the blades to reduce rotational resistance.

Corresponding pipes are installed at the inlet and outlet ends of the pipe. They are equipped with valves.

Installation of screw conveyors

In order for the screw conveyor to work productively and without annoying failures, attention should be paid to the correct choice of location for its installation and installation and configuration of the unit.

The device should be placed on a level, reliable base to prevent it from falling or being systematically soiled.

A very important stage in preparing the unit for operation is its installation. The installation requirements outlined in the assembly manual must be strictly followed. Such work should be entrusted to qualified assemblers who already have experience in working with under-face mechanisms. Violation of the assembly order, installation dimensions and other errors can lead to the following consequences:

- shocks and vibration when turned on and during operation;

- drop in rotation speed, torque, performance;

- accelerated wear of main parts, frequent repairs;

- reduction in service life.

It is recommended to carry out the assembly and installation of horizontal and vertical screw conveyors in two stages.

The first one is preparatory. within its framework the following operations are performed:

- checking the packaging according to the shipping lists of the manufacturing plant;

- re-preservation of mothballed units and parts;

- initial assembly of large units from individual parts;

- preparation of the installation site, including electrical installation work.

After completing the preparation, you can move on to the main stage, which includes work such as:

- installation of lifting and rigging devices;

- supply of large-unit assemblies to the installation site;

- installation of the unit base;

- installation of other parts with mandatory control of inclination angles and installation dimensions;

- checking the correct assembly, turning the screw manually;

- connecting power supply, setting operating parameters and fine adjustment.

First, a test run is carried out without load. If everything is working normally, the blades do not touch the pipe, no extraneous sounds or impacts are heard, you can test the device under load.

Types of auger screws used in conveyors

The screw is the main working part of the device. Its shape and material used for manufacturing depend on the specific purpose of the unit.

The main screw designs used are as follows:

- Solid. Stamped steel segments are connected into a single spiral and installed on the shaft using welding or threaded connections. Used for transporting fine and medium-grained powdery substances that are not prone to caking. The pipe is filled with a load by 30-40%, the rotation speed is from 50 to 120 rpm.

- Tape. It differs from a solid screw in that there are gaps left on the shaft side. They provide lower productivity due to the fact that the load partially falls back through the slots. This design is used for media prone to caking and ensures their mixing and crushing of compacted lumps during transportation. Can handle gravel, crushed stone and similar materials. The gutter filling rate is 24-40%, rotation speed is from 25 to 100 rpm.

- Bladed. The propeller is divided into separate blades. They walk at equal pace. Simultaneously with the supply of material, the blades loosen and mix it. Used for feeding lump materials, the chute is filled by 25-35%, rotation speed is from 40 to 100 rpm. Also used for moving wet media such as cement mortar or moistened clay. In this case, the filling is 15-25%, the rotation speed is from 30 to 60 rpm.

- Shaped The solid profile of the screw is complemented by shaped cutouts and protrusions on the outer edge. Performs a number of operations at once, such as moving, grinding, stirring. Suitable for concrete, asphalt and clay mixtures. The gutter is filled by 15-30%, rotation speed is 30-60 rpm.

Working principle of a screw conveyor

A conveyor with a screw mechanism operates as follows:

- bulk material enters the storage hopper or directly into the inlet pipe;

- the rotating propeller blades capture portions of the cargo and push it towards the outlet pipe;

- upon reaching the outlet, the load leaves the mechanism through it.

The screw is driven into rotation by a drive device consisting of an electric motor and transmission. On some models designed for work in places where there is no power supply, the conveyor can be equipped with an internal combustion engine. The transmission is a belt drive or gear reducer.

The screw conveyor can be equipped with an electronic control system, the sensors of which monitor the level of the product in the output storage and control the rotation speed of the electric motor and the transport screw, maintaining the level within the specified values.

The conveyor, equipped with a screw mechanism, is designed for long or continuous operation.

Occupational Health and Safety

To avoid malfunctions of equipment and accidents that could damage the safety of material assets and the health of personnel, you should strictly follow the requirements of safety regulations when working with screw-type conveyors:

- regularly check the qualifications of personnel authorized to work on auger equipment;

- equip the mechanism with a fence that prevents unauthorized access to the work area;

- when using inclined screw conveyors, the entire area of its projection must be fenced;

- use personal protective equipment, protective gloves, a respirator (when working with dusty materials), safety glasses, durable overalls and shoes;

- when moving dusty materials, it is necessary to regularly check the quality of sealing of all pipeline joints in order to prevent the formation of an explosive suspension; in addition, exhaust ventilation must be working in the room;

It is strictly unacceptable to carry out service and repair work without turning off the power to the unit.

Application of screw conveyors

There are a number of areas in which screw conveyors are used: agricultural enterprises, large production complexes and processing plants, warehouses. For example, screw conveyors are used in the process of loading operations at granaries, grain elevators and mill enterprises, cereal factories, sugar factories, etc. To produce equipment used in food industry enterprises, stainless steel and technical polymers are used, which prevent the oxidation of transported products.

They are also installed in the premises of flour mills and bakeries, feed factories, etc. for transporting raw materials within workshops. Not a single large enterprise in the chemical, coal, or mining industries can do without such equipment. Screw conveyors transport raw materials at enterprises producing building materials and mixtures and in machine-building shops. It is not recommended to use such equipment for transporting materials with a sticky consistency, dense or highly abrasive materials.

How to choose a conveyor for granular materials

A screw conveyor for granular materials should be selected based on the following parameters:

- required performance;

- characteristics of the transported products: granularity, humidity, tendency to stick together and form dust;

- lift height;

- travel distance;

- mobility.

For such materials, a solid auger is usually used; for horizontal movement, open chutes are used; for inclined and vertical movement, closed chutes are used.

Mobile screw conveyors, as a rule, are produced with low and medium productivity. To move large volumes, it is more reliable to mount the conveyor on a permanent basis.

Methodology for calculating key indicators

To produce screw conveyors, it is necessary to perform a large amount of design and technological preparation. It includes the production of product drawings, the construction of its kinematic diagram, and engineering calculations.

To calculate a screw conveyor, it is necessary to take into account the main parameters. These include:

- Spiral pitch t. depends on the specific gravity ρ of the transported substance; with increasing density, the step must be reduced.

- Shaft rotation speed n. For light loads, the speed reaches 120 rpm; for dense and viscous loads, the speed must be reduced to 30 rpm.

- Screw diameter d. also decreases with increasing specific gravity and viscosity.

- The gutter filling rate ψ, depending on the density of the material, ranges from 15 to 40%.

- C - correction for the elevation angle, for horizontal devices C = 1, for vertical screw conveyors the value is taken from the tables;

The performance of the screw mechanism is calculated using the formula:

Engine power sufficient for reliable operation of the conveyor with a given performance is determined by:

- mass of the shaft with blades;

- weight of the load in the pipe;

- linear speed of movement;

- a number of correction factors for friction.

Finally, the power is determined taking into account the efficiency of the gearbox and adding the standard power reserve required to start a conveyor filled with cargo.

Screw conveyor - design and device

The design of the screw conveyor may vary depending on the model, but the operating principle is the same. The installed helical screw moves the loaded material as a result of its rotation. The device is powered by turning on an electric motor. The design is also equipped with a gearbox and drive shaft, which are responsible for transmitting traction force. The efficiency of the material transportation process depends on the design of the installed propeller (bladed, belt, solid or shaped), its diameter and pitch variability. The shape of the screw matches the type of load being moved. The direction of the spiral (left- or right-handed) also affects the performance of the conveyor. Augers can withstand high loads and intensive work, but the conveyor model must be selected based on the type of material being transported.

Cylindrical screw conveyors have a modular structure that allows you to adjust the length of the equipment. The housing modules are fastened to each other using intermediate flanges, and the installation of intermediate supports makes it possible to extend the spiral. Troughed conveyors have a sectional body, the length of which can be increased in accordance with production needs. Such equipment is equipped with intermediate supports and couplings.

Scope of application of screw conveyors

Screw conveyors are used in many industries, wherever it is necessary to move bulk materials:

- food industry enterprises, confectionery factories, large bakeries, elevator complexes, grain grinding plants;

- agricultural enterprises associated with the production, storage and processing of grain, production of combined animal feed;

- mining industry, production of building materials;

- chemical industry enterprises - supply of raw materials and finished products;

- heating systems - for supplying granulated fuel and removing waste;

- woodworking and metalworking - for removing shavings and sawdust.

Typically, screw conveyors are used for material with a grain size of up to 20 mm. Larger ones are more convenient to transport using belt conveyors. Vertical screw conveyors allow you to quickly and cost-effectively convey bulk materials to a height of up to 30 meters

Characteristics, design and application of screw conveyors

Screw conveyor (screw conveyor) - a screw conveyor is a stationary transport device, the working part of which is a screw (screw), which imparts forward motion to the material.

The screw conveyor is designed to move materials of bulk, dusty, powdery consistency or fine-grained materials (fraction size does not exceed 20 mm). With the help of such equipment, grain, sugar, flour, sand, lime, cement, sludge, sawdust, metal shavings, chemical materials, etc. are transported. Movement is carried out in three positions: horizontal, vertical and inclined, with an inclination angle of up to 20°.

CHARACTERISTICS OF SCREW CONVEYORS

Screw conveyors come in different lengths - from several meters to tens of meters (usually horizontal up to 40 m, and vertical up to 30 m) and have different electric motor power - from 1.5 to 55 kW. This equipment is very popular due to its ease of design and maintenance, overall dimensions, the ability to move materials in a sealed state without contact with the environment, and the convenient process of intermediate unloading. The disadvantages include high energy consumption, high wear rates of the screw and chute, and increased abrasion of the transported material.

APPLICATION OF SCREW CONVEYORS

There are a number of areas in which screw conveyors are used: agricultural enterprises, large production complexes and processing plants, warehouses. For example, screw conveyors are used in the process of loading operations at granaries, grain elevators and mill enterprises, cereal factories, sugar factories, etc. To produce equipment used in food industry enterprises, stainless steel and technical polymers are used, which prevent the oxidation of transported products.

Screw conveyor

They are also installed in the premises of flour mills and bakeries, feed factories, etc. for transporting raw materials within workshops. Not a single large enterprise in the chemical, coal, or mining industries can do without such equipment. Screw conveyors transport raw materials at enterprises producing building materials and mixtures and in machine-building shops. It is not recommended to use such equipment for transporting materials with a sticky consistency, dense or highly abrasive materials.

AUGER CONVEYOR - DESIGN AND DEVICE

The design of the screw conveyor may vary depending on the model, but the operating principle is the same. The installed helical screw moves the loaded material as a result of its rotation. The device is powered by turning on an electric motor. The design is also equipped with a gearbox and drive shaft, which are responsible for transmitting traction force. The efficiency of the material transportation process depends on the design of the installed propeller (bladed, belt, solid or shaped), its diameter and pitch variability. The shape of the screw matches the type of load being moved. The direction of the spiral (left- or right-handed) also affects the performance of the conveyor. Augers can withstand high loads and intensive work, but the conveyor model must be selected based on the type of material being transported.

Cylindrical screw conveyors have a modular structure that allows you to adjust the length of the equipment. The housing modules are fastened to each other using intermediate flanges, and the installation of intermediate supports makes it possible to extend the spiral. Troughed conveyors have a sectional body, the length of which can be increased in accordance with production needs. Such equipment is equipped with intermediate supports and couplings.

Advantages and disadvantages of using screw conveyors

Screw conveyors have a number of important advantages:

- High safety of use. The absence of external moving parts minimizes the risk of personal injury.

- Small dimensions make it possible to easily integrate the device into production lines and technological installations, and move loads between rooms and between levels.

- Closed-type units are indispensable when working with substances that are toxic and prone to dust formation. All connections are easily sealed with gaskets.

- Suitable for moving both heated and cooled loads.

- The simplicity of the design determines the affordable prices for such equipment.

They also have a number of disadvantages:

- Changing the structure of transported cargo. In the conveyor, it experiences friction against the walls and blades, and can grind and wear out.

- Movement distance limited by design features.

- Rapid wear of working parts and housing, especially when working with abrasive materials.

Characteristics of screw conveyors

Screw conveyors come in different lengths - from several meters to tens of meters (usually horizontal up to 40 m, and vertical up to 30 m) and have different electric motor power - from 1.5 to 55 kW. This equipment is very popular due to its ease of design and maintenance, overall dimensions, the ability to move materials in a sealed state without contact with the environment, and the convenient process of intermediate unloading. The disadvantages include high energy consumption, high wear rates of the screw and chute, and increased abrasion of the transported material.