Description of the basic operating principle

Now we sell equipment for chrome plating, both domestic and foreign. Foreign developments are distinguished by their convenience and efficiency in operation, as well as their compactness. But they are much more expensive than their Russian counterparts.

As for the configuration, it usually consists of:

- working stand;

- pressure gauges (preferably a whole set);

- spray bottle;

- pistol

It is these parts that carry out both the blowing of products for processing and other work processes. Domestic analogues are much cheaper. But they often lack the ability to perform decorative finishing.

When such equipment is used for chrome plating, the description of the process will look like this:

- Any paintwork previously applied must be completely removed. Any contamination must be removed. Grinding and degreasing are carried out.

- After this, move on to the primer layer.

- Heat treatment of products helps improve adhesion to other materials.

- The next step is to use a spray gun to apply the chrome layer.

- Varnish or self-adhesive film is used to provide additional protection.

Thus, the metal receives maximum protection from corrosion processes. Chemical metallization also helps to cope with this problem. It is performed with special reagents, which are also used in the chrome plating process. The procedure promotes the formation of a thin layer of chromium. The main characteristic is a high level of protection. Just like the chrome plating equipment itself.

On video: equipment for chemical metallization.

Principle of operation

On the modern market you can purchase both foreign and domestic equipment for chrome plating. The first, although compact, convenient and efficient in operation, is quite expensive. The set of such equipment includes a working stand, a set of pressure gauges, a spray gun and a gun, with which the workpiece is blown. Domestic equipment used for chrome plating of parts costs much less than foreign equipment, but does not allow decorative processing (with its help you can only imitate its results).

Professional installation for chemical chrome plating. All controls and controls are conveniently located on the front panel

Chrome plating when using such equipment is performed as follows.

- Before chrome plating, the surface to be treated is cleaned of paint and varnish coatings, any contaminants, sanded and degreased.

- Then a layer of primer is applied to it.

- To improve the adhesion of the applied primer to the metal, the latter can be subjected to heat treatment.

- After this, a layer of chromium is applied to the surface of the cooled product using a spray gun.

- To protect the coating applied as a result of chrome plating, you can use varnish or self-adhesive film.

A coating applied in this way cannot provide reliable protection of the metal from corrosion. Chemical metallization, performed using special chemical reagents for chrome plating, can effectively solve this problem. As a result of this procedure, a thin layer of chromium is formed, characterized by high protective properties.

Pseudo-chrome plating and real processing

Using paint that contains up to 75 percent chromium is one of the simplest metal processing options. But this decision does not apply to metallization in the full sense of the word. They simply use paint on the surface of the product that requires treatment.

With this method of chrome plating, an ordinary paint brush or spray bottle will become indispensable assistants. However, there is also chrome spray paint on sale, which simplifies the painting process.

If the work is done according to all the rules, the result will last for at least five years. This result is achieved by any chrome plating installation. But, if such a layer is damaged, then corrosion will quickly begin to penetrate inside the product.

If you carry out truly effective metallization with your own hands, then you need to use:

- source of direct electric current;

- electrolyte for chrome plating;

- a special container where galvanic processes will take place.

This is a minimum set, without which chrome plating becomes completely impossible.

Installation for chemical metallization "META-CHROME/PRO 1"

The unit is lightweight, compact in size, easy to transport and equipped with filler necks that allow you to fill in chemicals. reagents without the need to remove pressure tanks

- Installation dimensions - 410 mm x 600 mm x 1100 mm

- Installation weight - 14 kg

- Dimensions of the container with chemical reagents - 340 mm x 340 mm x 250 mm

- Weight of con-ra with chemical. reagents - 10 kg

Equipment complete set:

- Equipment for chemical metallization "META-CHROME/Pro1"

- Device “HP-Pro” for obtaining ultra-pure water

- Spray gun H-4000 HVLP (1.3 mm) for application. primer and varnish

- Set of latex gloves (20 pairs)

- Air gun for removing residual water

- Set of supply flexible pipelines

- Telemetric conductometer COM-12

- Coloring toner (1 bottle x 20 ml)

- 100 without targeted advertising booklets

- User guide

- Chemical trial kit reagents per 20 sq. meters

- FREE TECHNICAL SUPPORT

Installation for chemical metallization "META-CHROME/s" including a trial kit for 20 sq. meters - 144,985 rubles.

Chemical chromium plating technology

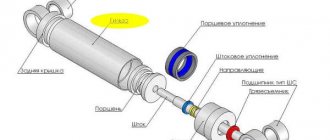

The algorithm for chrome plating, which is carried out by galvanization, can be described as follows:

- The product for processing is placed in a special bath, which is pre-filled with electrolytic solutions.

- Afterwards everything is connected to the current source, with a plus sign.

- Any chromium-based workpiece is connected to the negative contact at the power source.

- The chrome billet absorbs the electricity. It goes into the electrolyte, to an additional product. Next, the ions that make up chromium are separated. They are passed through the surface of the electrolyte, and then taken over by the part being used. It is sometimes difficult to get a set with them.

- Chromium ions settle on the surface and bind to it at the molecular level. The result is the formation of a layer that provides maximum protection.

It is the chemical type of metallization that contributes to the creation of the most reliable protective layer.

This technology allows you to apply a layer of not only chromium to the surface, but also of other metals, including: aluminum, silver, zinc. The installation for chemical metallization remains the same. It is important to use a suitable current source, then the speed of the process for chrome plating parts will be appropriate.

But we must remember that the process of chemical metallization involves the release of substances harmful to human health. Therefore, to carry out the procedure in a domestic environment, only non-residential premises should be used. Personal protective equipment will also not be superfluous.

Equipment for chrome plating

The market offers a variety of equipment for applying a chrome layer, both domestic and foreign. Private foreign entrepreneurship prompted developers to create compact installations that can be easily placed in a garage or small workshop.

Non-professional equipment only imitates high-quality chrome plating, but the quality is not so good. The work is carried out in the following sequence:

cleaning of old coating; grinding; degreasing; applying a primer; chromium spray application; drying; protection from damage with varnish.

Electrolytic (galvanic) chromium plating is widely used in production. For this purpose, special baths, electrical installations, ventilation systems, washing and drying installations are used. The hot method of applying chromium uses furnaces and vacuum units.

But regardless of the type of equipment used, during the chrome plating process, physical and chemical reactions occur, which are accompanied by the release of decomposition products.

Thermochemical metallization

At the end of the last century, gilding of metal was carried out using thermochemical metallization technology.

This is another way to apply metal coatings for additional protection. Its main features, as well as for the equipment for chemical metallization itself, are as follows:

- A special composition is applied to the metal, in which metal dust is combined with a binder component. It is usually based on wood resins. Their selection varies.

- The product is placed inside a muffle furnace when the raw materials harden.

- Inside this structure, a sufficiently high temperature is maintained, when exposed to which the connecting element simply begins to burn out. Metal dust melts. Thus, a dense layer is formed for additional protection.

This chemical metallization is currently used in several variations. The first of them is based on the main principle according to which a layer of metal is applied to the surface of the product while constantly maintaining high pressure. The product itself is located inside an oven heated to a certain temperature.

An option is possible when a layer of metal is pre-sprayed onto the surface of the product. After this, the product is placed in a kiln for firing.

This chemical metallization is also available in a more simplified, home version:

- Metal dust is applied to the surface in one layer.

- Melt the dust using a regular construction hair dryer. This promotes the formation of a thin layer on the surface.

- Grinding and subsequent polishing with your own hands allows you to make the surface as smooth and even as possible, meeting all requirements.

Chemical metallization by this method requires the use of the following materials and technologies:

- composition for finishing coating;

- a machine with which everything is polished;

- hair dryer to create a flow of air with increased temperature;

- spray bottle for applying metal powder.

A set of tools is easy to obtain in a specialized store.

Technological features of chemical metallization

Chemical metallization can be carried out for various purposes, the main of which is to improve the decorative characteristics of the processed product. In addition, the coating obtained by chemical metallization makes it possible to hide such defects of the treated surface as small pores and microcracks. In some cases, this technology is used to restore the surface.

If we summarize the goals of using this processing method, they all consist of improving the characteristics of the material from which the product is made. Such characteristics include, in particular:

- decorative properties;

- corrosion resistance;

- hardness;

- wear resistance, etc.

At the same time, by applying a metal layer to the surface using a chemical method, it is possible to obtain a coating with the required characteristics.

The chemical metallization process is divided into several stages, which can be easily carried out in any paint and varnish production.

The main task that needs to be solved when performing chemical metallization is to provide optimal conditions for the occurrence of redox reactions. When such conditions are provided, atoms are released from the composition of the chemical substance, the redox potential of which is at a higher level. Of course, such a process is difficult to control visually, but its result - a change in the color of the treated surface - will be noticeable immediately.

The technology itself for performing metallization using a chemical method is as follows: special chemical reagents are applied to the product, which begin to react with each other. As a result, a thin layer of metal is formed on the treated surface. A metal coating obtained by a chemical method can be made not only in a specific color, but also have several shades with smooth transitions between them. The method of catalytic chrome plating of products, known to many specialists and home craftsmen, by the way, is also performed using chemical metallization technology.

If you watch the implementation of chemical metallization on video, you will notice that this method is not complicated. From the outside, this method of applying metal coating resembles simple surface painting.

Classification

Chromium plating can be done in several ways:

- Galvanic. There are two types - diffuse, electrolytic. The first option involves applying chrome using a galvanic brush. The electrolytic type involves the use of a chromic anhydride solution into which the workpiece is immersed.

- Vacuum. The workpieces are placed in a vacuum chamber into which chromium vapor is supplied, which deposits on the metal surfaces, creating a protective layer.

- Chemical. The technology does not require the use of electric current. The mixture for treatment is prepared from sodium citrate, phosphorus, sodium hydroxide, and glacial acetic acid.

- Catalytic method. It can be classified as a chemical treatment. A working composition that does not contain acids is applied to the surface of the parts. It consists of silver in an alkaline ammonia solution. Additionally, a reducing agent is used - hydrazine or formalin.

- Thermochrome plating. The products are heated and coated with a working mixture - chromium powder or ferrochrome.