Functionality of compressor lubrication

To achieve stable operation of the device, it is necessary to find out exactly what kind of oil to pour into the piston air compressor. This fluid must perform various functions that ensure stable operation of the device during normal maintenance. Failure to perform any function will reduce the performance of the device and may even cause it to fail. The most important properties of a piston compressor fluid are:

- Protection of parts from increased wear.

- Excellent heat dissipation.

- Reducing engine knock.

- Sealing of the working compression chamber.

What is the difficulty here?

The main problem of piston compressors is maintaining the cylinders in which the main working process takes place in proper condition. Despite the fact that oil is necessary for lubrication of other elements (the crankshaft, for example), it is the type of cylinder that determines the choice in favor of one or another brand of oil.

The objectives of lubricating oil are as follows:

- seal the compression chamber (this will increase the efficiency of the compressor);

- protect metal elements from corrosion;

- reduce friction (which will also increase efficiency);

- reduce wear rate.

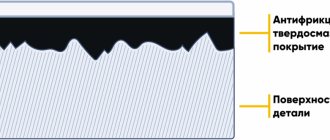

The main load on the lubricating film occurs at the top and bottom points of the cylinder - this is where film rupture can occur. In addition, the oil in the cylinders is constantly exposed to high temperatures and high pressure.

Due to the fact that the quality of the oil film directly depends on the purity of the oil, it is recommended to pump only purified substances through the compressor. Otherwise, contaminants in the form of microparticles will settle on the oil film, leading to accelerated wear of all compressor elements.

What kind of oil should I put into a piston compressor?

To lubricate piston compressors, mineral-based oils are used in accordance with the DIN 51 506 classification. As a rule, such oils are called “compressor” oils. Among Russian brands, the most popular is KS-19 compressor oil.

At the same time, small mobile compressors are often lubricated with engine oil. However, this practice is not always justified:

- Compressor oil has a high ignition temperature, which makes replacement with motor analogues not entirely complete;

- Also, compressor oil is cheaper than almost any motor oil, so it makes sense to replace it only if you already have motor oil and do not need to buy it.

What main oil parameters should we be interested in?

When choosing compressor oil, two parameters are considered basic: viscosity and ignition temperature. The optimal oil viscosity for a piston compressor is about 20 cSt (centistokes) at a temperature of 100 degrees. The ignition temperature must be no lower than 230 degrees, since when the volume of the working chamber of the cylinder is compressed, the temperature can increase very significantly.

The amount of oil required to operate a compressor depends on its model, power and other parameters. The optimal oil volume is indicated in the technical documentation of the compressor, and it is highly recommended not to ignore this indicator.

Compressors are quite often used by many industrial organizations. They allow you to optimize the operation of many modern systems.

Correct selection of liquid

In order for the device to show high performance, you need to select compressor oil for piston compressors, and all its parameters must necessarily meet the individual requirements of the device.

The most important indicators of such a liquid are:

- Viscosity degree.

- Thermal-oxidative parameters.

Consumption depends on operating temperature.

It increases as it increases. This is what causes frequent lubricant changes. What oil to pour into a piston air compressor to reduce heat transfer performance is usually decided taking into account the brand of liquid and the manufacturer’s recommendations. Professionals advise using only fluids intended for a specific model. The oil brand is indicated in the technical description of the device. The manufacturer indicates the best option. Today the most popular lubricants are:

The last type differs from others in its properties. Its kinematic viscosity is affected by the operating temperature. If it is 40 degrees, the viscosity value approaches 150 sq. mm/s. If the temperature reaches 100 degrees, the viscosity begins to decrease. Its value becomes equal to 10.6 square meters. mm/s. If a problem arises about what kind of oil to fill into an air compressor, Eco mak brand, Shell Corena P 150 liquid can be considered the ideal option.

Selecting the right type

It is not always possible to immediately select the right type of lubricant for pouring into a piston compressor. The most important parameter in the classification is its viscosity. For screw motor devices, sealing properties are considered the main ones. The permissible viscosity value is 7 mm2/s, at an ignition temperature of +180 degrees.

Which is better: mineral water or synthetic water?

This problem occurs quite often. Some people prefer synthetic products, while others consider mineral lubricants to be of better quality. It all depends on the frequency of use of the device. If the compressor turns on rarely, it is better to fill in mineral water, especially since it costs much less. In addition, its operating temperature is +80 - +90 degrees. Mineral liquid has a short service life.

The properties of a synthetic product are much better. High viscosity makes it possible to fill the lubricant into any compressor. Even when the temperature reaches its maximum values (+200 degrees), the structure of the liquid remains unchanged and the engine does not detonate. Therefore, this product belongs to the universal group.

Synthetics allow you to work at low temperatures. The service life of such a liquid is several times longer. Of course, the cost of synthetics is much higher, but the quality of such oil compensates for all costs. The liquid is actively used in workshops where the compressor operates constantly.

Review of popular oils

Of course, compressor lubricant can be called a specific material.

It is designed for a specific job. Manufacturers recommend using only certified, high-quality products. They can be replaced with other materials, of which several types are considered the most popular. The most popular of them is “Arian K-12”. Mineral water designed for the operation of a piston compressor. Oil hardens when the temperature drops below - 25 degrees. Viscosity ranges from 11 to 14 mm2/s.

BP Enersyn GCS 180. Synthetics. Can be used at high temperatures. Thanks to special oxidation inhibitors, it protects parts from corrosion.

Mobil Rarus 429. Refers to universal products.

Can be used in any compressor. It has excellent viscosity and ignites at high temperatures. The lubricant is designed for a long service life. "Arian K-28". Universal mineral oil. The degree of viscosity is in the range of 26-30 mm2/s. The liquid contains virtually no sulfur. Due to the absence of various mechanical impurities, the liquid can be used at a temperature of -10 degrees.

"VDL 100 Fubag". Special product for filling into piston compressors. Thanks to special additives, the lubricant protects parts from oxidation when temperatures reach high values. The liquid prevents the appearance of burning on the surface of parts.

Explanation of markings

In Russia, a special designation for lubricant is used. To choose the right type of oil, you need to know what the designation means.

Very often, KS-19P brand liquid with the following designations is used to fill the compressor:

- “K” - compressor;

- “C” - made from sour crude oil;

- “p” - it contains special additives;

- 19 is the viscosity value when the temperature reaches 100 degrees.

Recommendations from professionals

It is advisable to fill the device with lubricant specified by the manufacturer. It provides maximum performance and fully complies with the characteristics of the device.

The oil level must exceed the required volume. These devices do not have a separate lubrication system. Oil enters directly into the system after the connecting rod captures lubricant from the crankcase.

Compressor oil is a complex synthetic or mineral composition that simultaneously performs different functions. Labeling is important, since each brand has its own characteristics necessary for a specific situation. For example, if the required viscosity is not present, the filled oil can cause rapid equipment failure.

Differences in classification and method of application

When choosing the most suitable type of material, attention should be paid to its classification. There are several main groups:

- For simple operation when the temperature does not exceed 160 degrees Celsius.

- Moderate mode. This type of substance is the most widely used and can be used at temperatures up to 180 degrees Celsius.

- Severe conditions are typical for powerful pumping stations that can be operated continuously for a long period. In this case, the maximum temperature is 200 degrees Celsius.

- Oils for extreme operating conditions are extremely rare; they do not lose their properties when the temperature rises to 200 degrees Celsius and above.

Difficulty in classification arises due to the fact that different manufacturers apply different standards when producing similar materials.

When servicing a domestic device, you can follow GOST 1861-73. He indicates two main types of consumables:

- K-12 is an oil to which a depressant additive is added.

- K19 is a design option that is made 100% from residual oil with the addition of various additives.

There are simply a huge number of foreign versions on the market, which are characterized by more attractive properties. Their classification and method of application depend on what standards and production technologies the manufacturer uses.

Download GOST 1861-73

Oil for air piston compressor

Oil performs various important functions that ensure stable operation of the compressor. Failure to do at least one of them reduces productivity and sometimes causes breakdowns. Let's list its functions :

- lubrication of rubbing parts;

- cooling of parts that heat up during operation;

- sealing gaps;

- reduction of detonation;

- creating tightness in compression chambers.

Low tightness or seals reduce the efficiency of the compressor, but in the absence of lubrication or cooling of parts, an expensive unit quickly fails due to wear of parts, so the oil level in the air compressor must always be at the proper level.

What functions does compressor oil perform?

It performs a whole range of functions - and all of them are “vital” for the stable operation of the compressor. Interruptions with at least one of them lead to a decrease in productivity, and in some cases, to breakdown. Let's list all the functions:

- lubrication of rubbing compressor parts, reducing wear;

- cooling of parts exposed to heating during operation by heat removal;

- reliable sealing of gaps;

- reduction of detonation during engine operation;

- creating high tightness in compression chambers.

If low tightness or lack of sealing of gaps simply reduces the efficiency of the compressor, then the lack of lubrication or cooling of parts leads to the fact that an expensive device quickly fails as a result of wear.

Compressor oil prices

Special formulations

What kind of oil should I pour into the compressor?

A piston air compressor has special requirements. The lubricant must be in close contact with the highly heated compressed gas. Thus, the product must be safe even when heated to temperatures of 170°, 180°C and more. It should include only high-quality additives that eliminate the risk of carbon deposits on moving parts. Also, the substance must have high resistance to temperature oxidation, otherwise the likelihood of compressor failure increases. Due to long-term use, its density increases as the liquid evaporates and contamination increases. Because of this, a fire is possible, so the oil in the air compressor must be changed regularly.

Methods for supplying lubrication in compressors

The lubricant can be supplied to the contact zone in a variety of ways. Among the features of this moment we note the following:

- The piston or screw type of mechanism is in most cases lubricated by gravity. In this case, the compressor design may include a cooling circuit.

- All seals and packing rings must also be lubricated. In this case, classic spraying can be carried out using moving elements, or the substance can be supplied under pressure to increase the effectiveness of the procedure. To do this, the substance is mixed with the air flow.

As a rule, the lubrication method determines what viscosity the substances are most suitable for.

An example is the case when, during normal spraying, an oil with a high viscosity is suitable.

Mineral or synthetic

Opinions are divided on what kind of oil to pour into the compressor: some praise mineral oil, while others say synthetic oil is better. Mineral is cheaper and is usually used when the compressor is used infrequently. In this case, there is a temperature limit - no more than 90 °C. Higher temperatures may cause ignition or detonation. The oil service life is short - 2-4 thousand hours, depending on the brand and manufacturer.

Synthetic oil has different properties:

- High viscosity allows its use for any screw compressors.

- Heating to 180−200 °C does not disrupt the structure of the substance and does not lead to detonation. Therefore, it is considered universal.

- It performed well when working in low temperatures: it can be used outdoors in winter.

- Service life is up to 8000 hours, which is 2-4 times longer than mineral.

Synthetic oil is more expensive than mineral oil, and they prefer to buy it when the compressor is used frequently and actively.

Types of compressors and corresponding oils

Piston and rotary, the oil comes into contact with the pumping medium only on one side of the piston. Filtration required.

- Screw compressors – direct interaction with the material.

- Turbochargers are the most challenging environment for lubricants.

- Refrigeration compressors – compatibility between refrigerant and lubricant must be ensured. Compressor oil should not lose its properties due to a sharp change in refrigerant temperature.

- The gas compressor is the main task, the ability to separate (filtrate) the lubricant from the air (gas). Selection according to gas compatibility.

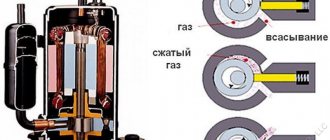

To appreciate the variety of types of compressor units, take a look at the illustration:

Each design requires a special lubricant; there is no unification. Recommendations for consumables are in the passport documentation or the manual for routine maintenance.

Selection by characteristics

Read the labeling carefully. The main thing is to have heat resistance and high thermal-oxidative stability. Moving parts become hot during high temperature operation and the use of a low-quality product may cause a fire. These characteristics must be indicated on the container.

In the case of screw models, it is especially important to create tight gaps, so the use of oil with a viscosity of less than 7 mm²/s is unacceptable. In this case, the operating temperature is not so important, but it is still not recommended to use brands in which this indicator is 90 °C. Otherwise, the oil will have to be changed much more often than indicated in the passport in order to increase the service life of the compressor.

When studying the markings, pay attention to the designations. As a rule, the options are standard: SAE 20, SAE 40, SAE 60, etc. You can also find the following markings: SAE 20W, SAE 30W. Here the letter W indicates that the oil can be used in the cold season. At temperatures of -20 °C or -30 °C, the viscosity will ensure high-quality pumping.

Composition and performance characteristics

To ensure trouble-free operation and long service life of the mechanisms, the lubricant must meet the following requirements:

- Ensure temperature stability by effectively cooling the moving internal components of the compressor;

- Prevent the formation of coke-like deposits during oil heating;

- Have a stable viscosity indicator over a wide range of operating temperatures;

- Maintain the tightness of the joints of the parts, filling all the gaps;

- It is good to lubricate rubbing parts to avoid abrasion and overheating.

To achieve the above requirements, compressor oils have the following performance and technical characteristics:

- The viscosity coefficient at t = 100ºC varies in the range from 7 to 30 centistokes;

- Low degree of evaporation, including at elevated operating temperatures;

- Ability to perform its functions at high temperatures of mechanism components and pumped substances. According to the requirements of technical standards, the ignition temperature of compressor lubricant should be from 190 to 270ºC;

- Chemical neutrality. It must not react with the pumped gases. When used in refrigeration units, compressor oil must be inert towards refrigerants.

Based on their composition, compressor oils are divided into mineral-based varieties. These are either pure mineral oils or have a certain percentage of additives that provide anti-corrosion properties, oxidative stability, and increase the service life of fuels and lubricants.

In recent years, synthetic and semi-synthetic oils made from hydrotreated or essential oils have become widespread. Their main advantage compared to mineral oil is their improved technical characteristics. This concerns the fluidity rate, the lower solidification threshold, and the ability to work for a long time in particularly difficult conditions.

Manufacturers

Not many companies produce compressor oils. Their products differ in cost, viscosity, pour point and other parameters. What kind of oil does an air compressor use? Here is a list of a number of manufacturers:

- "Arian K-12". Used in medium and high pressure piston compressors. Contains 0.3% sulfur; hardens at -25 °C, viscosity varies from 11 to 14 mm² / s. It's inexpensive.

- BP Enersyn GCS 180. Synthetic oil for piston compressors. Can be heated to high temperatures without harm. Contains oxidation inhibitors to prevent corrosion. Dear.

- Mobil Rarus 429. Universal oil suitable for screw and piston compressors. Thanks to the high level of purification, good viscosity and high flammability temperature are ensured. Extremely low rate of coke deposit formation, which extends service life. Dear.

- "Arian K-28". Universal mineral oil. High viscosity - 26−30 mm²/s, thanks to which it can be used in screw compressors. Sulfur content is minimal. There are absolutely no mechanical impurities, which allows the product to be used at temperatures from -10 °C. Inexpensive.

- VDL 100 Fubag. Oil for piston compressors. A large number of special additives prevent oxidation of moving parts even at high temperatures. Also, no fumes form on them. Dear.

Compressor oil: what is the difference from motor oil

A fairly common question is what is the difference between motor oil and special compressor oil. In general, we can say that synthetic compressor oil belongs to motor oils. This is due to the fact that both versions are used in difficult operating conditions: changes in load, temperature and many other parameters.

It is not recommended to use conventional oils for a screw compressor for a number of reasons, among which we note slightly different performance characteristics.

In addition, mineral oil for internal combustion engines has the worst properties. This is due to the fact that they do not tolerate overheating and are characterized by worse performance characteristics in comparison with synthetic versions.

The above information determines that synthetic motor oils can be used for compressors, but only in case of short-term operation. If the device operates constantly, then attention should be paid to special lubricants that have more attractive properties.

Marking

Not everyone understands the Russian markings - KS-19p or Kp-8 S. So, the letter “K” says that this is a compressor product, and the letter “C” means that sulfurous oils were used in production; the letter “p” indicates the presence of additives in the composition; the number means viscosity at 100 °C.

These indicators correspond to GOST.

- Coking capacity - no more than 0.5%.

- Viscosity at 100 °C - 11−21 mm²/s.

- Lack of alkalis and acids that dissolve in water.

- Mechanical impurities - no more than 0.007%.

- The mass fraction of sulfur is no more than 0.3%.

- Flash point - 21−245 °C.

Compressor technology

Compressor technology is used in various fields. The following models are more common:

- Piston - consists of a piston and cylinder with discharge and suction valves.

- Screw - with two screw rotors that rotate synchronously.

- Jet - includes a jet device, a spool valve, a nozzle with a channel, used in the oil and gas industries.

- Membrane - has an elastic lamellar organ that is used when pumping liquid.

- The axial one is a body with guides, and the rotor is with working blades.

- Centrifugal - with a rotor and wheels, has conventional and prefabricated diaphragms, as well as devices for directing gas flows.

Regardless of the design, there is always an oil blower supplying lubricant, cooling and sealing material.

Compressor life

Manufacturers often forget to indicate this parameter, and deliberately so. After all, the duration of operation of the unit can only be determined experimentally. However, there are indirect signs of determining the motor resource. In piston models, this is the crankshaft rotation speed. The faster the shaft rotates, the more the head heats up and the faster it wears out. It is correct to compare compressors of the same performance.

Belt driven compressors last longer. Belt drive provides high performance at low speeds. Compressors with belt transmission of torque belong to the semi-professional class and are capable of creating up to 16 atm.

Changing the oil in the compressor must be done. It is quite difficult to calculate how many hours a unit has worked, especially if it works daily. It is recommended to change the oil twice a year. During this time, it usually manages to change color.

Not everyone knows what kind of oil to put in a piston air compressor or whether it needs maintenance. To clarify this issue, let's start with the concept: what is an air compressor?

Technologically, this is the complete opposite of the internal combustion engine. We are talking about a piston design, because membrane compressors operate on a completely different principle.

Any mechanical unit requires lubrication, otherwise its service life will tend to zero. To simplify the analysis, compare the compressor with a conventional internal combustion engine.

A piston engine works on the following principle: pressure is generated in the cylinders (due to the combustion of the air mixture), the pistons move, and with the help of the crankshaft they transmit torque to the power take-off shaft.

In a compressor, everything is the other way around: the shaft rotates (using an external drive), the pistons move in the cylinders, and pressure is created. For the sake of it (pressure) the whole structure works.

Compressor oil compatibility table

| Ether* | PAG | PJSC | Group III synthetic oil | Mineral oils of group I and group II | Silicone base oil | |

| Ether* | Yes | No | Maybe | Maybe | Maybe | No |

| PAG | No | Yes | No | No | No | No |

| PJSC | Maybe | No | Yes | Maybe | Maybe | No |

| Group III synthetic oil | Maybe | No | Maybe | Yes | Maybe | No |

| Mineral oils of group I and group II | Maybe | No | Maybe | Maybe | Yes | No |

| Silicone base oil | No | No | No | No | No | Yes |

It is impossible to answer for sure whether one oil will be compatible with another, since it is always worth considering incompatibility with additives and the degree of contamination of the oil during operation. When changing oil in compressors, we strongly recommend draining the old oil and flushing the system, regardless of what base oils are included in the old and new oils, since there is always the possibility of incompatibility. This conservative recommendation is also based on a risk-benefit model when it comes to tank size; tanks tend to be small in size. So, due to the fact that the container contains a small volume of oil, i.e., its loss in the process of removing its residues will be minimal, draining the oil and flushing the system should be carried out taking into account all risks and compatibility aspects.

The risk of contamination can be reduced not only by draining the old compressor oil, but also by flushing the system and replacing filters. To get the most out of your new compressor oil, it's not enough to simply add oil to the system, which is why we recommend going through the replacement procedure from start to finish, including draining the oil, flushing and replacing filters.

This procedure not only reduces risks, but also improves equipment performance.

In some cases, the services of technical specialists may be required. If the question arises about removing carbon deposits and varnish deposits, it is worth thinking about the incompatibility of oils. In this case, it is necessary to flush, possibly using solvents, replace seals, etc.

We bring to your attention recommendations for washing. These can be used as requirements to complement OEM requirements.

Why pour oil into the compressor?

At first glance, it may seem that the pistons in the compressor can operate without oil. There are modern materials that have a minimum coefficient of friction (Teflon, fluoroplastic, etc.).

For example, piston-type automotive compressors do not use separate lubricant. However, there is a huge difference in the volume of air pumped. Let us remember the elementary laws of physics: when gases are compressed, a large amount of thermal energy is released.

Simply put, the piston group gets very hot during operation: the higher the pressure in the receiver, the stronger the heating. It is for this reason that the compressor cylinders are equipped with air cooling fins.

- Oil has good thermal conductivity (albeit less than ordinary water), so washing the piston group to some extent helps remove heat.

- No matter how low the coefficient of friction of the piston rings, heating still occurs. If you leave the compressor without lubrication, the metal may become hot, it will “lead”, and the geometry will be disrupted.

- In addition to the pistons and cylinders themselves, the piston group consists of many elements: connecting rods, crankshaft, and possibly a gearbox. These elements require lubrication, and according to the classical method (as in an internal combustion engine). That is, the compressor has a crankcase in which lubricant splashes.

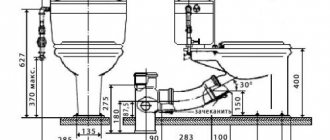

To understand the principle of operation of a piston compressor, consider its structure:

The crankshaft (1) rotates freely using bearings (2) . The need to lubricate these components is not even discussed: without it, work is impossible. The connecting rod (3) and piston pin (4) do not have rolling bearings. Just like in an internal combustion engine, liners are installed. If these friction pairs are not lubricated, the compressor will seize within a few minutes.

To prevent air compressor oil from leaking out of the housing, a seal (8) . What about the piston (5) ? If the rings are not sealed, fumes from the lubricant will enter the working chamber (6) . And then through the valves (7) the contaminated air will enter the working line.

Topical. (for compressor oil)

in CAMP KS-19 costs 800 rubles for 10 liters guys, why try to replace it with diesel at such a low cost? I thought it was expensive. 400r in terms of 5L. Is diesel cheaper?

All that remains is to find a small displacement, I should buy 2-3 liters in total.

But it's interesting. Why do people die from motor vehicles? Why does the engine compressor on a ZIL/KAMAZ not die, but the garage piston one does?

What is the physics of the phenomenon?

+1. I don't understand, it's somehow strange. I want to write “what nonsense!?” but I don't write.

what kind of carbon deposits are there in the compressor?! Is something burning there?!

Those. are the conditions HARDER than in an internal combustion engine? so what? I understand that in the compressor there will be 160. Yes, at least 200. Why, is it less in the internal combustion engine? The engine itself will cool down, I understand that. But at the point of sliding through the oil, and that layer of metal that first meets the fire - is it heated to less than 160 or something?

I don’t argue that the oil in the compressor is heavy. but is it really easier for him in an internal combustion engine?

ok, special means special.

where can I buy it cheaper?