Electric motor for woodworking machine

Asynchronous three-phase electric motors are widely used in various industries, including woodworking. Wood processing machines are usually equipped with low-power electric motors (from 1 to 10 kW) of 220 and 380 volts.

Single-phase motors AIRE

Price on request

Single-phase asynchronous electric motors AIRE are time-tested electric drives that have been successfully used in light industry and mechanical engineering for more than 50 years.

Power: from 0.25 to 2.2 kW (depending on the specific electric motor model).

Electric motors AIR 71st height

from 4 198

up to

5,753

rub.

5AI 71 A2, AIR 71 A2, 5AI 71 A4, AIR 71 A4, 5AI 71 A6, AIR 71 A6, 5AI 71 B2, AIR 71 B2, 5AI 71 B4, AIR 71 B4, 5AI 71 B6, AIR 71 B6, 5AI 71 V8, AIR 71 V8

Asynchronous electric motors AIR 71 belong to micro- and low-power motors, which are used mainly in the production of household machines and equipment, as well as for construction tools and small industrial installations.

The power of AIR 71 electric motors varies from 0.25 and 1.1 kW.

Electric motors AIR 80th height

from 5 200

up to

8,113

rub.

5AI 80 A2, AIR 80 A2, 5AI 80 A4, AIR 80 A4, 5AI 80 A6, AIR 80 A6, 5AI 80 A8, AIR 80 A8, 5AI 80 V2, AIR 80 V2 2.2, 5AI 80 V2 Zh, AIR 80 V2 Zh , 5AI 80 V4, AIR 80 V4, 5AI 80 V6, AIR 80 V6, 5AI 80 V8, AIR 80 V8

AIR 80 electric motors are low-power motors, the scope of which is mainly limited to the production of household appliances and devices, construction equipment and oversized industrial installations.

Power varies (depending on specific model): from 0.37 kW to 2.2 kW

Electric motors AIR 90th height

from 6 900

up to

11,265

rub.

5АИ 90 L2, AIR 90 L2, 5АИ 90 L2 Ж, AIR 90 L2 Ж, 5АИ 90 L4, AIR 90 L4, 5АИ 90 L6, AIR 90 L6, 5АИ 90 LA8, AIR 90 LA8, 5АИ 90 LV8, AIR 90 LV8

AIR 90 electric motors are low-power motors and are used mainly in the production of household appliances and electrical equipment, construction equipment and small industrial installations.

Depending on the model in question, the power of AIR 90 varies from 0.75 to 3 kW.

Electric motors AIR 100th height

from 8 662

up to

14,132

rub.

5AI 100 S2, AIR 100 S2, 5AI 100 S2 F, AIR 100 S2 F, 5AI 100 S4, AIR 100 S4, 5AI 100 L2, AIR 100 L2, 5AI 100 L2 F, AIR 100 L2 F, AIR 100 L4, 5AI 100 L4, 5AI 100 L6, AIR 100 L6, 5AI 100 L8, AIR 100 L8

Asynchronous general industrial electric motors AIR 100 are low-power and are used mainly in the production of household appliances, construction equipment, as well as small industrial plants and machines.

Depending on the specific model, power varies from 1.5 to 5.5 kW.

Electric motors AIR 112th height

from 14 000

up to

18,810

rub.

5AI 112 M2, AIR 112 M2, 5AI 112 M2 F, 5AI 112 M4, AIR 112 M4, 5AI 112 MA6, AIR 112 MA6, 5AI 112 MV6, AIR 112 MV6, 5AI 112 MA8, AIR 112 MA8, 5AI 112 MV8, AIR 112 MV8

General industrial motors AIR 112 are classified as low-power electric motors. They are mainly used for the production of small industrial equipment (fans, pumps) and various installations (conveyors, etc.), and are also used in the field of industrial construction as part of concrete mixers, etc.

The power of AIR 112 engines varies from 2.2 to 7.6 kW (depending on the specific model).

Electric motors AIR 132nd height

from 20 588

up to

26,188

rub.

5AI 132 S4, AIR 132 S4, 5AI 132 S6, AIR 132 S6, 5AI 132 S8, AIR 132 S8, 5AI 132 M2, AIR 132 M2, 5AI 132 M4, AIR 132 M4, 5AI 132 M6, AIR 132 M 6, 5AI 132 M8, AIR 132 M8

General industrial asynchronous motors AIR 132, despite their already quite high power ratings, are classified as low-power motors. They are used in the production of various industrial installations (fans, pumps and smoke exhausters), construction equipment and machinery.

Power, depending on the specific electric motor model, varies from 5.5 to 11 kW.

Electric motors AIR 160th height

from 30 485

up to

RUB 37,903

5AI 160 S2, AIR 160 S2, 5AI 160 S2 Zh, AIR 160 S2 ZH, 5AI 160 S4, AIR 160 S4, 5AI 160 S6, AIR 160 S6, 5AI 160 S8, AIR 160 S8, 5AI 160 M2, AIR 16 0 M2, 5AI 160 M4, AIR 160 M4, 5AI 160 M6, AIR 160 M6, 5AI 160 M8, AIR 160 M8

General industrial electric motors AIR 160 , despite their already quite high power ratings, are classified as low-power motors. They are used in the production of various industrial installations (fans, pumps and smoke exhausters), construction equipment and machinery.

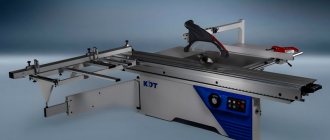

ELECTRIC MOTORS FOR WOODWORKING MACHINES

Asynchronous three-phase electric motors are widely used in various industries, including woodworking. Wood processing machines are usually equipped with low-power electric motors (from 1 to 10 kW) of 220 and 380 volts.

Features of electric motors for woodworking machines:

- compact dimensions along with high power levels;

- increased degree of protection (IP54/IP55) to reliably protect the engine from moisture entering the mechanism;

- only high rotation speed (from 6000 to 3000 rpm).

- increased engine life (minimum 20,000 working hours, subject to timely replacement of bearings every 3-5 thousand working hours, depending on the rotation speed of the electric motor).

Since the main requirement for an electric motor for a woodworking machine is the possibility of long-term and continuous operation, when choosing an electric motor it is necessary to pay special attention to the degree of reliability of the mechanism, the strength of the structure and the resistance of the housing to external influences (chemical and mechanical).

However, in addition to quality characteristics, all electric motors for woodworking machines differ:

1. By type of fastening (feet or flange).

2. By the number of working ends of the shaft:

- electric motors with 1 working shaft end:

- with 2 working shaft ends.

3. By voltage:

- Three-phase electric motors 380V (properly selected electric motors have greater performance than similar single-phase models);

- Single-phase electric motors 220V. Often, woodworking industries do not have the ability to connect the machine directly to a 380V network, and the use of single-phase motors becomes the only option. And this is normal practice, since taking into account all the features of the technological process and correctly calculating the maximum load on the engine, using a 220V electric motor is just as effective and economical.

4. According to climatic design. The climatic design of the electric motor shows in what climatic conditions the electric motor can be used and where it can be located. The electric motors presented on our website have a climatic version: U2/U3 (for use in temperate climates, under a canopy or in enclosed spaces with natural ventilation, without artificial climate control).

5. According to the type of environmental protection, electric motors for woodworking machines are:

- protected;

- closed;

- explosion-proof (explosion protection is required when there is a high concentration of explosive wood dust in the air). All protected electric motors have a high-strength and sealed cast iron casing.

We hope that the information presented above will help you choose and buy the right electric motor for a woodworking machine. However, if you have any doubts or questions, you can always contact our specialists by calling our toll-free number 8 800 555 5836 or email.

220 Volt electric motors

Single-phase asynchronous electric motors are widely used in those units where there is no need to use an increased starting torque. Installed in industrial and household machines - wood processing machines, compressors, concrete mixers, etc. They find their application in drives for small mechanization devices: grain dryers...

Single-phase asynchronous electric motors are widely used in those units where there is no need to use an increased starting torque. Installed in industrial and household machines - wood processing machines, compressors, concrete mixers, etc. They find their application in drives for small-scale mechanization devices: grain dryers, grinding units and low-power pumps. The power supply for such a motor is carried out from an alternating current network with a voltage of 220. In our online store you can buy a single-phase 220V electric motor manufactured according to the Russian GOST standard type AIR, ADME, 5AIE, as well as the European DIN (Cenelec) type AICE, AIS2E, etc.

For ease of operation, the 1-phase motors we supply are manufactured with two stator windings - working and starting. In this case, the working winding is connected directly, and the starting winding is connected through a capacitor; all that remains is to connect the electric motor to a regular outlet. The disadvantages of 220-volt single-phase electric motors include low power factor and efficiency, as well as low overload capacity, which is more than compensated for by high performance, safety and reliability in operation, ease of maintenance, low noise and vibration levels.

We deliver your goods to Rostov-on-Don, Taganrog, Stavropol, Krasnodar, Novosibirsk, Moscow, Chelyabinsk, Samara and other cities of Russia.

agregat.me

Electric motors for woodworking machines (HELZ Ukrelectromash, JSC, Ukraine)

Application area

Electric motors of the 4AMHD series are designed to drive woodworking machines, in which the working tool is mounted directly on the motor shaft. Protection degree IP54. The axial displacement of the rotor shaft does not exceed 0.08 mm. Simultaneous action of radial load and 30% axial load is possible. Electric motors of the 4AMHD series are available with different lengths of the end of the protruding shaft. The average service life before major overhaul is at least 20,000 hours, when replacing bearings after 3-5 thousand hours of engine operation, depending on the rotation speed.

The designation of the 4AMHD electric motor is deciphered as follows:

4 – serial number of the series; A – asynchronous;

X – frame made of aluminum alloy, shields made of cast iron; D – for woodworking machines;

80, 90 – height of the axis of rotation;

S, M, L – installation dimensions along the body length;

A, B – designation of the stator core length (A – first length, B – second length); 2 – number of poles;

P – precision version (increased accuracy);

U or T – climatic version (U – for temperate climates, T – for tropical climates).

Specifications

Rotation speed, rpm

Voltage 220, 380, 220/380, 240/415 V, frequency 50 Hz

Voltage 220, 380, 400, 415, 440, 220/380, 230/400, 240/415 V, frequency 60 Hz

Voltage 220, 330 V, frequency 100 Hz

Climate - U3, T3; increased accuracy (P)

Instructions for use

Indication of safety measures

For the safety of operating personnel, the engine must be reliably grounded, for which the grounding clamp provided on the frame should be used. Tropical engines have two grounding clamps.

When using a cable with a special grounding conductor, the latter must be grounded, for which the grounding screw located inside the current lead should be used.

When connecting the grounding wire, the surface under the cable lug and the lug itself must be thoroughly cleaned of dirt and oxide film. The cross-section of the grounding wire must meet the requirements of the relevant operating rules.

When preparing the engine for operation, the power cable must be connected securely.

After securing the cutting tool, it is necessary to securely secure its guard.

Maintenance of the engine should be carried out only after disconnecting it from the mains and completely stopping the rotating parts.

High Torque DC Motors

High torque permanent magnet DC motors have a low rated speed. Low nominal rotation speeds allow them to be installed in machines and mechanisms without gearboxes. This quite significantly simplifies the design of electric drives and makes it possible to bring the source of motion closer to the executive body of the machine. The rated speed of high-torque motors is usually 1000 rpm. It can work for a considerable time under heavy overloads.

Typically, high-torque motors are produced with a built-in electromagnetic brake, tachogenerator and position sensor. In Fig. Figure 2.3 shows an example of the layout of such an engine.

Figure 2.3. High Torque DC Motor

where: 1 - housing, 2 - permanent magnets, 3 - armature, 4 - electromagnetic brake, 5 - tachogenerator, 6 - position sensor (resolver), 7 - mechanical transmission, 8 - coupling. Brake 4 is used to prevent accidents in the event of a power outage, as well as to quickly brake the moving parts of the machine. Tachogenerator 5 is an engine speed sensor in the feedback system of its control. For feedback when controlling the engine, position sensor 6 is also used, which produces an electrical signal proportional to the angle of rotation of the engine shaft. This | The built-in design allows not only to reduce the overall dimensions of the drive, but also, as a result of simplified connections, to increase the positioning accuracy.

In turn, the presence of permanent magnets makes it possible to reduce the overall dimensions of the excitation system and the motor itself and improve its energy and dynamic characteristics. Thus, the effect of using high-magnetic motors in CNC machines consists of increasing the productivity of the machine and simplifying its kinematic diagram. An increase in engine performance is achieved as a result of an increase in the speed of rapid movements, a large range of speed control and low inertia.

The domestic industry produces high-torque motors of the PVB, PV and DK series for use in electric drives of CNC machines, differing in the shape and material of the permanent magnets and armatures. These differences are caused by the desire to reduce the diameter of the armature and, accordingly, its moment of inertia. The presence of built-in devices, as well as the degree of their protection and overall dimensions are indicated in the designation of the engine type. For example, PBV160LSUZ is a direct current motor (P). execution - closed (B); high-torque, excitation is made from permanent magnets (B). The height of the rotation axis is 160 mm, the second length (b). Has a built-in tachogenerator (C). Climatic modification and placement category UZ.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

Electric motors

are the main components of many mechanisms. The offered devices are ideal for driving woodworking machines. They are distinguished by high quality and reliability. The service life under normal conditions is about 10-15 years.

We always have various types of electric motors in stock.

The main advantages of these devices:

Electric motors

allow you to save a lot of money. After all, they do not run on gasoline, but consume electricity. They do not require special care. Customers who have purchased this product from us leave only positive feedback.

Cost of electric motors

quite affordable. We provide discounts to regular customers. You will enjoy working with us. It's reliable and profitable!

For questions about ordering goods, prices, availability of goods in our warehouse, timing of next deliveries, please contact our managers or place an order right now.

Call: 8, 28-12-13, 28-20-55, +7 (921) 238-21-35,

© PiloramService LLC 2004–2019

The information on the site under no circumstances constitutes a public offer. When using materials from this site, a link to it is required!

Electric motors for machine tools are used in a wide variety of industries, including:

- Woodworking (sawing and planing units).

- Metalworking (drilling, turning, grinding, milling machines).

- Papermaking (guillotines).

- Transport (electric trains, trolleybuses and trams).

- Construction (pumps, crane installations), etc.

When choosing an engine for a particular type of work, you should pay attention to such parameters as:

- power;

- rotational speed;

- number of revolutions on the output shaft;

- possibility of operation from a 220V network (relevant for private enterprises and small manufacturing enterprises that equip workshops in residential or public buildings and do not have access to industrial power grids).

Requirements for electric motors for woodworking machines

On wood processing equipment, engines of very different power are installed (ranging from 1 to 10 kW). Usually these are asynchronous three-phase units, which are not prohibited from being connected to a household network. Electric motors of this class are characterized by:

- compactness combined with sufficiently high power;

- reliable protection of the structure from moisture entering the mechanism;

- high rotation speed;

- significant resource reserve;

- durability;

- the ability to maintain original characteristics after long-term use.

Since the main requirement for such an electric motor is the ability to work daily for several hours when changing modes, manufacturers pay special attention to the degree of reliability of the mechanism, structural strength and resistance of the housing to external influences (chemical and mechanical). When choosing a model, you need to consider the level of workloads.

How to choose a stepper motor to create a CNC machine with your own hands?

The selection of the optimal engine is based on several parameters.

Inductance

The first step is to calculate the square root of the winding inductance. The resulting number is multiplied by 32. The final value is compared with the voltage of the source that powers the driver. These indicators cannot differ significantly from each other.

The motor will run too loudly and overheat if the difference is more than 30%.

High inductance helps maintain high torque. For a motor with high inductance, it is important to select a driver with a high voltage. This is the only way the engine can work fully.

Torque and speed

To choose the ideal motor, you need to draw a graph of speed and torque (more precisely, the dependence of one parameter on the other). The finished graph shows whether the selected motor meets the specified technical parameters.

Geometric parameters

It is recommended to analyze the following indicators:

- Moment of inertia of the rotors.

- Nominal current within a phase.

- Maximum number of static synchronizing torque.

- General characteristics of ohmic-type phase resistance.

IMPORTANT! When choosing a motor, special attention is paid to the flange, shaft diameter and the length of the motor itself.

Requirements for electric motors for metalworking machines

In metalworking production, more powerful units are used, since the load on them is incomparable with that on the engines of woodworking machines. Basic operations are performed on drilling and turning machines. Depending on the scale of the enterprise, they are equipped with engines with a power of 2 to 7.5 kW, which should produce 2000 rpm.

The most common types of electric motors for metalworking machines are:

- Asynchronous. When the load changes, they can maintain a constant spindle speed.

- Stepper with control unit.

- Linear direct drive with frequency converters.

- Asynchronous reversible with power up to 15 kW (for drilling machines). When the load fluctuates, they are able to slightly change the rotation speed.

Since the profitability of production largely depends on the dynamic performance of the mechanism, work is now underway to improve its ability to change the rotation speed when overloaded (currently for the most advanced models this figure is 10-12%). Therefore, many electric motors for machine tools are equipped with complex control systems and speed sensors.