Best Combination Wrench Sets

The design of such instruments combines horn and ring profiles. This provides a wide range of applications, ease of tightening and loosening of threaded fasteners in various conditions.

Jonnesway W26126S

5

★★★★★

editorial assessment

100%

buyers recommend this product

This set contains a large number of keys - 26, which ensures comfortable work with fasteners of all main sizes. The material used is high-strength steel, and chrome plating is provided to protect against corrosion.

Available sizes are 6-32 mm, the total weight of the set is 5 kilograms. The set comes in a fabric case. It can be rolled up and secured with Velcro straps for easy transportation and storage. Tool locations are individually marked.

Advantages:

- ease of carrying;

- rich equipment;

- corrosion protection;

- high strength.

Flaws:

- high price.

Jonnesway W26126S is worth purchasing for both private and professional use. A universal set for working with hexagonal fasteners.

Cobalt 020108-07

4.9

★★★★★

editorial assessment

97%

buyers recommend this product

The high strength of steel allows the keys to withstand heavy loads without the risk of deformation. The cap profile is equipped with a ratcheting mechanism, which facilitates work in cramped conditions and increases labor productivity.

Number of tools - 7, available key sizes 8-19 mm. The set comes in a shock-resistant case with inserts and a metal lock. This guarantees complete safety of the kit during transportation.

Advantages:

- durable materials;

- lockable case with holders;

- reverse key movement.

Flaws:

- large dimensions.

The cobalt set 020108-07 is recommended for outdoor work. Suitable solution for professional use.

Delo Techniki 511120

4.9

★★★★★

editorial assessment

91%

buyers recommend this product

The keys are made of chrome vanadium steel, which provides them with increased hardness and resistance to mechanical loads and environmental influences. To protect against corrosion, all instruments are coated with a special varnish.

Available key sizes are 6-22 mm, the total weight of the set is 1.15 kg. The cap profile has a deviation of 15°, making it convenient when working in confined spaces. The holder is made of plastic and equipped with reliable latches.

Advantages:

- high tool strength;

- corrosion protection;

- ease of use in cramped conditions;

- light weight of the set.

Flaws:

- flimsy holder.

The Case Equipment set 511120 will be useful in everyday life and in the garage or auto repair shop.

Berger BG1144

4.8

★★★★★

editorial assessment

88%

buyers recommend this product

Berger keys are placed in individual pockets of the fabric case. Special holes make it possible to fix it near the workplace for quick access to the tool, and the Velcro strap makes it easy to transport when folded.

The key sizes are 8-19 mm, the total weight of the set is 1325 g. The tools are made from chrome vanadium steel, which guarantees them high strength and reliability. A special coating is provided to protect against corrosion.

Advantages:

- durable steel with rust protection;

- fixation on the surface;

- ease of carrying;

- size markings.

Flaws:

- The short-lived cover wears out quickly.

Berger BG1144 will be an excellent assistant when performing assembly or installation work. The right choice for regular use.

Force 5161

4.8

★★★★★

editorial assessment

87%

buyers recommend this product

Force tools are supplied in a plastic case for easy storage and transportation. The presence of holders reduces the likelihood of loss, and detailed markings simplify selection.

The number of keys in the set is 16, sizes from 6 to 24 mm are presented here. The material used is high-strength steel, resistant to damage and deformation under heavy loads.

Advantages:

- convenient to carry;

- durable materials;

- indication of dimensions;

- extensive equipment.

Flaws:

- rather large total weight - 2.3 kg.

Force 5161 wrenches are designed to service external hex head screws. An excellent choice for outdoor work.

READ ALSO

10 Best Torque Wrenches

Best wrench sets with special profile

Such tools are designed to work with fasteners that have heads with internal hexagons and radial stars. Such elements are often used in mechanical engineering, the furniture industry, and in the assembly of household appliances or computers.

Gross 16400

5

★★★★★

editorial assessment

97%

buyers recommend this product

The keys are made of alloy steel with a hardness of 52-56 HRC. Each of them is equipped with a magnet that ensures reliable contact with the fastener during operation.

Multi-colored powder coating makes it easy to select the right tool and guarantees protection against corrosion. The holder can be placed on a vertical surface or on a clothing pocket.

Advantages:

- laser marking of sizes;

- convenient holder of small dimensions;

- presence of a magnet on the keys;

- durable.

Flaws:

- high price.

The Gross 16400 kit is purchased to work with connections measuring 1.5-10 mm.

Aist 1054309TT

4.9

★★★★★

editorial assessment

94%

buyers recommend this product

The tools are shot-blasted and polished, which ensures resistance to metal fatigue, corrosion, and minor damage. The manufacturing material is complex alloy steel with a high carbon content.

The set contains 7 keys of minimum and maximum sizes T10 and T50. The compact holder simplifies the storage and transportation of the set; it is equipped with a special hole for placement in a convenient place and quick access to the tool.

Advantages:

- good margin of strength and durability;

- small dimensions;

- convenient storage.

Flaws:

- flimsy holder.

The Aist 1054309TT set is designed to work with automotive fasteners at a service station or in a private garage.

Delo Techniki 563591

4.9

★★★★★

editorial assessment

92%

buyers recommend this product

The reliability and durability of the instruments is guaranteed by the use of chrome vanadium steel in their manufacture. Cold rolling and heat treatment of the metal provide them with additional strength.

The set contains 9 imbus keys of sizes T10-T50. Special markings make selection easy. The plastic holder does not take up much space and is equipped with a hole for mounting in any convenient place.

Advantages:

- high strength and durability;

- compactness;

- clear size markings;

- low price.

Flaws:

- The holder wears out over time.

Case Equipment 563591 complies with GOST and DIN requirements - a reliable solution for professional use.

Stanley 0-69-253

4.7

★★★★★

editorial assessment

87%

buyers recommend this product

The set includes 10 L-shaped hex keys. Their all-metal construction is not subject to deformation and can withstand heavy loads. The steel used is not afraid of corrosion, which guarantees a long service life of the kit.

The key sizes in the set are 1.5-10 mm. The small dimensions of the case make it easier to store the set, especially since the instruments are placed in individual holders and do not dangle around the box.

Advantages:

- durable and corrosion resistant;

- compact case;

- Convenient key storage.

Flaws:

- The protective paint chips off quickly.

Stanley 0-69-253 is worth purchasing for long-term use: installation and assembly work.

Matrix 11233

4.7

★★★★★

editorial assessment

85%

buyers recommend this product

The imbus keys included in the kit are made of chrome vanadium steel and are not afraid of deformation under mechanical load. The long length of the tools makes it easier to work with fasteners in hard-to-reach places.

Available sizes: 1.5-10 mm. The compact holder makes it easy to store and carry the set. It is equipped with reliable latches that eliminate the possibility of losing keys.

Advantages:

- small dimensions and weight;

- Ease of use;

- low price.

Flaws:

- short-lived holder.

The Matrix 11233 kit will be useful during assembly work. Economical choice for home use.

READ ALSO

13 Best Hand Tool Sets

Time to turn the nuts - key test

You are here: Technical information »Time to turn the nuts - key test

OBJECT OF OUR ATTENTION

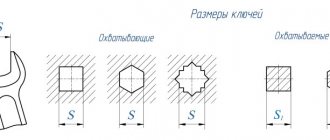

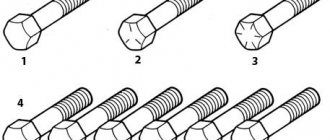

It is impossible to cover all the diversity of the instrument within one study. Therefore, it was decided to conduct comparative testing of identical samples from different manufacturers. We chose open-end wrenches or, as they are also called, combination wrenches. A combination wrench is a wrench with a combination of open and ring jaws. The size chosen for all samples was 13 mm. This is one of the most popular sizes. HEYCO, JOBI, JONNESWAY, KABO, KAMASA TOOLS, KING TONY, RUSSIA and TONA. This set is not accidental. The sample is such that the study includes both samples from world-famous manufacturers who position their tools as professional, and keys whose manufacturers wished to remain in the shadows.

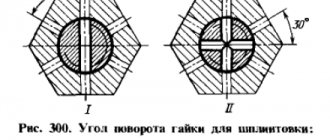

WHAT THEY SHOULD BE

Combination keys must be manufactured in accordance with GOST 16983-80, which establishes the design and main dimensions of these keys. GOST 16983-80 provides for the production of keys with opening sizes from 5.5 to 55 mm (29 standard sizes). Combination keys must be made of steel 40HFA (GOST 4543-71). It is allowed to use steel of other grades with mechanical properties in a heat-treated state no lower than those of 40HFA steel. GOST 2838-80 (reissue 1985) contains technical requirements that must be observed in the manufacture of wrenches. This GOST requires that the hardness of keys with a throat size of less than 36 mm be 45.5 ... 51.5 HRC. The hardness of the handles may be less by 5 units compared to the lower hardness limit indicated above. GOST 2838 provides for strength testing of keys, which consists of applying a torque of a value corresponding to the standard size of the key. For a combination wrench with a throat size of 13 mm, the maximum test moment should not exceed 51.5 N*m for an open jaw, and 72.6 N*m for an annular jaw.

TESTS

A set of experiments took place on the basis of the laboratory “Testing of Materials and Structures” of the Department of “Applied Mechanics” of MSTU. N.E. Bauman. All work was carried out by qualified specialists in accordance with the tasks set by the editors.

GEOMETRY OF COMBINATION KEY

Structurally, a combination wrench consists of two heads and a rod connecting them (handle). One head forms an open throat. The design and dimensions of combination keys must comply with the parameters established in GOST 16983-80 (reissue 1985). The recommended design and dimensions of the key handle are given in the appendix to GOST 16983-80. Measurements were taken of 10 main sizes of 36 keys from the above companies. The measurement results showed that the sizes of keys from all companies basically correspond to those specified in GOST 16983-80, with the exception of length. According to GOST, the length should be from 137.5 to 142.5 mm. For keys from all companies this figure is higher. This is especially true for the companies BARCLAY, HEYCO, JOBI, JONNESWAY, Kabo. It should be noted right away that such a deviation does not impair consumer properties and should be considered only as a design feature. In particular, wrenches with an increased handle length make it possible to develop a torque of about 30 N*m, without the use of extensions, with no noticeable negative impact on the human hand. At the same time, wrenches with a short handle length allow you to work comfortably in hard-to-reach places.

DETERMINATION OF HARDNESS

An important parameter of wrenches is the hardness of both the working surfaces of the jaws and the handle. The higher the hardness of the material, the higher the strength of the key, so the keys are subjected to heat treatment. In accordance with GOST 2838-80 (reissue April 1985), the hardness of wrenches should be in the range from 45.5 to 51.5 HRC. The handle can have a hardness 5 HRC less than the hardness of the areas near the jaws, that is, from 40.5 HRC. There are several methods for measuring hardness, but the most widely used are methods for assessing hardness by the resistance of the test metal to the introduction of another harder body (diamond tip) into it. Hardness measurement is a very common type of mechanical testing of metal. The most widely used method in production conditions is the method of determining the Rockwell hardness number. The criterion for assessing hardness is the depth of the indentation (hole), measured during testing. A steel ball or a diamond cone is used as a solid body introduced into the metal. The sizes of the ball and cone are standardized. The hardness number of the wrenches was measured using the Rockwell method at five points. Of which three were located on the mouth of the key, and two on the handle.

STRENGTH TESTS. STAGE 1

Two keys from each company were tested, and the strength tests were carried out in two stages. The first stage of testing is provided for by GOST 2838-80 and GOST 16983-80 and consists of loading the keys with a maximum test torque for an open jaw of 51.5 N*m and for an annular jaw of 72.6 N*m. During strength testing, the key was mounted on a hexagonal, high-hardness mandrel. In our case, the mandrel is made of HVG steel and has a hardness of 58 HRC, which corresponds to GOST 2838-80. The nominal dimensions of hexagonal mandrels comply with the requirements of GOST 6424-73. The mandrel is installed in the grip of the testing machine, connected to the torque measuring device. An extension is placed on the handle of the key being tested and the key is loaded smoothly five times to the maximum test torque. After the tests, a visual inspection of the key is carried out and the condition of the working surfaces of both jaws and the handle is assessed. When the open jaw was loaded with a torque of 51.5, all the keys passed the test without noticeable damage to the working surfaces, with the exception of one of the keys from an unknown company, appearing in the test called NO NAME, which collapsed at a torque of 50.0 N*m due to the separation of one of the horns . When the annular jaw was loaded, all the keys, without exception, passed the test without noticeable damage to the working surfaces and remained fully operational.

STRENGTH TESTS. STAGE 2

Since all samples, with the exception of one, passed the first stage of testing, strength tests were carried out with a maximum moment of 107.3 N*m. This type of test is provided for by GOST 2838-80 for wrenches of group A. Note that according to GOST, combined wrenches require compliance with groups B and C, that is, these requirements are deliberately excessive and are not mandatory from the point of view of the standard. Loading was carried out three times in each direction. The results are given only for an open jaw, since when the annular jaw of keys from all companies was loaded with a moment equal to 107.3 N*m, no damage to the working edges or other elements of the keys was noted. All keys in this case remained fully operational.

TESTS TO FAILURE

The purpose of these tests is to determine the magnitude of the breaking moment, comparing it with the maximum moment and the consequences of failure. Two keys (No. 1 and No. 2) from each company were subjected to these tests, and the same keys were subjected to a strength test with a torque of 107.3 N*m. Open throat tests were carried out provided that at least one sample passed the strength test with a moment of 107.3 N*m. Tests for the annular throat were carried out on two samples without exception. Moreover, tests to failure for the annular shed are the most revealing. Only by them it became possible to judge the quality of this part of the key. This is due to the fact that during previous tests of the annular throat, all samples withstood the loads applied to them and reached this stage of testing without any losses. During testing, the wrench was installed on a hexagonal mandrel having a hardness of 58 HRC, the wrench size was 13 mm. The mandrel was fixed in the grip of the testing machine. An extension was placed on the handle, through which the key was loaded manually until it was destroyed. The torque corresponding to destruction was recorded by the torque meter of the testing machine. After the tests, the key was inspected and the condition of its elements was assessed.

TESTS FOR CYCLIC LOADING OF A THREADED CONNECTION

The purpose of these tests is to evaluate the nature of the interaction of the working edges of combination wrenches with the edges of nuts when tightening a threaded connection. The test object is an M8 nut of low strength with a hardness of 3-4 HRC units. The nut was mounted on a mandrel, the hardness of which averaged 22 HRC units, that is, the mandrel was much stronger than the nut. After that, the nuts were loaded five times using a combination wrench with a torque equal to 30 N*m. The magnitude of the moment was taken from preliminary tests, which were carried out by influencing the key without an extension with a hand wearing a cloth glove.

BUSINESS OF TECHNOLOGY

TEST RESULTS : the main geometric dimensions correspond to those specified in GOST 16983-80. The length indicator is slightly exceeded. The cross section of the handle is lenticular. HARDNESS: one of the lowest hardness values in comparison with samples from other manufacturers. Hardness 37.6 HRC near the jaw and 35.8 HRC at the handle. Both values are significantly lower than the limit established by GOST 2838-80. Also, “DELO TEKHNIKI” keys are characterized by a significant deviation in hardness values from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. When the samples were loaded with a moment of 107.3 N*m, medium-sized dents formed on the working edges, and the coating also came off in these places. Despite this, both samples passed the test. When tested to failure, the working surfaces suffered significant damage. As a result, the nominal size of the key's mouth increased to 14.0 mm and the key rotated relative to the mandrel. The minimum breaking moment was 135 N*m, which is 2.62 times higher than the maximum moment (51.5 N*m). This is a good result. RING EDGE: When testing the annular opening, no noticeable damage to the working edges is observed. In this case, the destruction of the key occurs due to large plastic deformations of the handle in the area of the annular jaw. The minimum breaking moment is 202 N*m, which is 2.78 times higher than the maximum test moment for the annular throat (72.6 N*m). COATING: The protective and decorative coating is not strong enough, as it has separated from the base. INTERACTION WITH THE EDGES OF THE NUTS: noticeable plastic deformations of the edges of the nut have occurred. PRICE: 50 rub.

SUMMARY “Delo Tekhniki” showed good results in strength tests. However, they have one of the lowest hardness values and an insufficiently durable protective and decorative coating.

BARCLAY

TEST RESULTS GEOMETRY: geometric dimensions correspond to those specified in GOST 16983-80, with the exception of the length, which is 48% greater than required. The cross section of the handle is lenticular. HARDNESS: in terms of this parameter, the keys showed themselves to be the best. The hardness of the keys is not only high, but, most importantly, it is constant along the length of the key and from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. Loading the keys with a torque of 107.3 N*m for the first sample was completed successfully. The second sample collapsed due to the separation of the horn when a moment of 105 N*m was reached. Tests to failure were carried out on only one sample. At the same time, a torque of 117 N*m was reached. The destruction occurred due to the separation of the horn from the key head. The crack started in the concentrator area. In addition, the working edges received significant plastic deformations due to the cutting of part of the metal. The minimum breaking moment was 105 N*m, which is 2.04 times higher than the maximum moment (51.5 N*m). RING JOINT: when testing the annular jaw, no noticeable damage to the working edges is observed; the destruction of the keys occurred due to the rupture of the handles near the annular jaw. The minimum breaking moment is 259 N*m, which is 3.57 times higher than the maximum test moment for the annular throat (72.6 N*m). This is one of the best indicators relative to other models participating in the test. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: subtle plastic deformations of the nut faces. PRICE: n.d.

SUMMARY High, stable hardness along the length of the key and from key to key. A very good result for an annular throat and not bad for an open one. Overall the result is very good.

N0 NAME

TEST RESULTS : the main geometric dimensions satisfy GOST 16983-80. Length slightly exceeded. It is 21% more than required. The handle has an I-section. HARDNESS: hardness near the throat is below the lower limit established by GOST 2838-80. Handle hardness is normal. There is also a very significant scatter of hardness numbers from key to key, which indicates the imperfection of the technological process in the production of these keys. OPEN JOINT: NO NAME wrenches performed the worst in open jaw strength tests. When loaded with a torque of 51.5 N*m, key No. 1 passed the test. The second sample collapsed already at a moment of 50.0 N*m due to the separation of one of the horns. The crack started in the concentrator area. At the same time, the working edges did not have time to obtain noticeable plastic deformations. An attempt to load the open mouth with a torque of 107.3 N*m ended unsuccessfully. The failure of the sample occurred at 54 N*m, which is only 1.05 times higher than the test moment. The destruction occurred, as in the first sample, due to the separation of the horn. Thus, the minimum failure moment was 50 N*m, which is less than the maximum test moment for an open mouth (51.1 N*m). This indicates that the key did not pass the strength test and does not meet the GOST requirements for this parameter. Tests to failure were not carried out with these samples, because failure occurred at significantly lower moment values than these tests imply. RING EDGE: When testing the annular opening, no noticeable damage to the working edges is observed. The destruction of key No. 1 occurred due to a rupture of the ring, No. 2 due to a rupture of the handle near the annular jaw. The minimum breaking moment is 172 N*m, which is 2.37 times higher than the maximum moment for the annular throat (72.6 N*m). This is one of the lowest results. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: when interacting with the nut, medium-sized plastic deformations occur on its edges. PRICE: 20 rub.

SUMMARY The result is disappointing. The only sample that showed strength results below GOST requirements. There is no need to talk about the result of hardness measurements. We strongly recommend that you refrain from purchasing such samples.

GEDORE N7-13

TEST RESULTS : the main geometric dimensions correspond to those specified in GOST 16983-80. Length slightly exceeded. It is 20% more than required. The handle has an I-section. HARDNESS: the hardness of the throat is slightly lower than that required by GOST. 44.7 HRC vs 45.5 HRC. The hardness of the handle is also insufficient. There is a scatter in hardness values along the length of the key and from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. The keys also withstood a loading moment of 107.3 N*m, although they suffered significant plastic deformations. Both specimens took part in ES tests to failure. The destruction occurred due to large plastic deformations of the working edges of the jaw, as a result of which the nominal size of the key jaw increased to 13.8 mm and the key rotated relative to the mandrel. In addition, the handle in the head area was severely deformed. The minimum breaking moment is 110 N*m, which is 2.14 times higher than the maximum moment (51.5 N*m). This is a very good indicator. RING FROM: when testing the annular jaw, no noticeable damage to the working edges is observed; the destruction of the key occurs as a result of strong curvature of the handle in the area of the ring head in a plane perpendicular to the middle plane of the key. The minimum breaking moment is 147 N*m, which is 2.02 times higher than the maximum test moment for the annular throat (72.6 N*m). COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: when interacting with the nut, subtle plastic deformations of the edges are observed. PRICE: 7.3 euros.

SUMMARY The result is not bad. The impression was spoiled by the low hardness of the handle, although it can be strengthened if desired.

HEYCO 00410

TEST RESULTS : geometric dimensions correspond to those specified in GOST 16983-80, with the exception of the length, which exceeds the required by 31%. The handle has an I-section. HARDNESS: the hardness of the keys meets the requirements of GOST 2838-80 and differs in the average variation from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. The keys also withstood a loading moment of 107.3 N*m, receiving minor plastic deformations. Both samples were tested before failure. The destruction occurred due to large plastic deformations of the working edges of the jaw, as a result of which the nominal size of the key jaw increased to 13.8 mm and the key rotated relative to the mandrel. The minimum breaking moment was 135 N*m, which is 2.62 times higher than the maximum moment (51.5 N*m). This is a very good indicator. RING EDGE: no noticeable damage to the working edges is observed; the destruction of the keys occurred due to a rupture of the annular opening. The crack formed in the depression (stress concentrator). The minimum breaking moment was 256 N*m, which is 3.53 times higher than the maximum test moment for the annular throat (72.6 N*m). As with the open throat, the result is very good. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: there are no plastic deformations of the nut faces. PRICE: 8.59 euros.

SUMMARY Without a doubt, this key showed the highest results in all respects. It should be noted that this also applies to price. This sample can be recommended for use for professional purposes: in car service centers and service stations.

JOBI DU 30C

TEST RESULTS : geometric dimensions satisfy GOST 16983-80, with the exception of the length, which exceeds the required by 26%. The handle has an I-section. HARDNESS: the hardness of the keys is significantly less than the requirements of GOST 2838-80. This sample also has the maximum spread of readings from key to key compared to samples from other manufacturers. In simple terms, you can run into both a more or less tolerable sample and a sample of extremely low quality. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. When testing the open jaw with a torque of 107.3 N*m, key No. 1 fell slightly short of 107.3 N*m. It collapsed when a moment of 106 N*m was reached as a result of separation of the horn from the head. A crack has formed in the concentrator area. Key No. 2 passed the test, receiving noticeable plastic deformations of the working edges. Only one sample was tested to failure. Its destruction occurred when the torque reached 126 N*m. The reason was large plastic deformations of the working edges of the jaw, as a result of which the nominal size of the jaw increased to 14.1 mm and the key rotated relative to the mandrel. The minimum moment of failure was 106 N*m, which is 2.06 times higher than the maximum test moment for an open mouth (51.1 N*m). RING JOINT: when testing the annular jaw, no noticeable damage to the working edges is observed; the destruction of key No. 2 occurred due to large deformation of the handle near the annular jaw and rupture of the ring. The destruction of key No. 1 occurred due to a rupture of the handle near the annular jaw. The minimum breaking moment is 150 N*m, which is 2.07 times higher than the maximum test moment for the annular throat (72.6 N*m). A very low figure compared to other models participating in the test. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: when interacting with the nut, no noticeable plastic deformations occur on its edges. PRICE: $0.45.

SUMMARY A significant drawback is the hardness of the key, which is lower than the requirements of GOST, as well as the low strength index of the cap part compared to samples from other manufacturers. Advantages: good strength of the open mouth and low price.

JONNESWAY W26413

TEST RESULTS : geometric dimensions correspond to those specified in GOST 16983-80, with the exception of the length, which exceeds the required by 29%. The cross section of the handle is lenticular. HARDNESS: the hardness of the throat is slightly lower than the hardness required by GOST. Handle hardness is normal. There is a scatter of values from key to key, but it is not large. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. When trying to load the samples with a moment of 107.3 N*m, moments of 103 N*m and 104 N*m were achieved, respectively, for the first and second samples. The destruction occurred due to large plastic deformations of the working edges of the jaw, as a result of which the nominal size of the jaw increased to 14.1 mm and the keys rotated relative to the mandrel. No additional failure testing was conducted for this grade. The minimum moment of failure was 103 N*m, which is 2 times higher than the maximum test moment for an open mouth (51.1 N*m). RING JOINT: when testing the annular jaw, no noticeable damage to the working edges is observed, destruction of the keys is due to large deformation of the handle near the annular jaw. The minimum breaking moment is 235 N*m. This is 3.24 times higher than the maximum test moment for the annular throat (72.6 N*m), which is a good result. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: very small plastic deformations of the edges of the nut are observed. PRICE: $2.5.

SUMMARY Overall a good result.

KABO PKW-131

TEST RESULTS : geometric dimensions correspond to those specified in GOST 16983-80, with the exception of the length, which exceeds the required by 48%. The cross section of the handle is lenticular. HARDNESS: in terms of this parameter, the keys showed themselves to be the best. The hardness of the keys is not just high, but, most importantly, it is constant along the length of the key and from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. When testing the open throat with a torque of 107.3 N*m, a torque of 100 N*m and 94 N*m was achieved, respectively, for the first and second samples. The destruction of the samples occurred due to the cutting of the notch on the working edges of the jaw, as a result of which the nominal size of the throat increased to 14.0 mm and the keys rotated relative to the mandrel. The minimum failure moment is 94 N*m, which is 1.82 times higher than the maximum test moment for an open mouth (51.1 N*m). RING JOINT: when testing the annular jaw, no noticeable damage to the working edges is observed, destruction of the keys is due to the rupture of the handles near the annular jaw. The minimum breaking moment is 254 N*m. This is 3.5 times higher than the maximum test moment for the annular throat (72.6 N*m), which is a good indicator. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: noticeable crushing of the nut edges due to the presence of a notch on the working edges of the key. PRICE: $4.06.

SUMMARY This wrench is a leader in hardness; a plus also includes the high strength of the annular jaw. The highlight of this wrench - a special profile notch, which allows you to unscrew bolts with worn edges - played a negative role in the test for the maximum load of the throat. Therefore, for power loads we recommend using the cap part.

KAMASA-TOOLS K1263

TEST RESULTS : the main geometric dimensions correspond to those specified in GOST 16983-80. Length slightly exceeded. It is 21% more than required. The handle has an I-section. HARDNESS: the hardness of the throat is slightly lower than that required by GOST. 44.8 HRC vs 45.5 HRC. The hardness of the handle is high and meets the requirements of GOST 2838-80. Also, hardness values have a low scatter from key to key, which is a good indicator. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. When the first sample was loaded with a moment of 107.3 N*m, the working faces received noticeable plastic deformations, but the sample passed the test. When testing the second sample, a moment of 100 N*m was reached, after which a loss of throat size occurred due to small plastic deformations. One sample participated in further testing. Its destruction occurred when a moment of 112 N*m was reached due to large plastic deformations of the working edges of the jaw, as a result of which the nominal size of the throat increased to 14.3 mm and the keys rotated relative to the mandrel. The minimum failure moment is 100 N*m, which is 1.94 times higher than the maximum test moment for an open mouth (51.1 N*m). RING EDGE: When testing the annular opening, no noticeable damage to the working edges is observed. The destruction of key No. 1 occurred due to a rupture of the ring (a crack formed in the cavity), the destruction of key No. 2 occurred due to large plastic deformations of the handle near the annular jaw. The minimum breaking moment is 235 N*m. This is 3.24 times higher than the maximum test moment for the annular throat (72.6 N*m), which is a good indicator. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: when interacting with the nut, noticeable plastic deformations are formed on its edges. PRICE: $4.

SUMMARY The samples showed good results.

KING TONY 1060-13

TEST RESULTS : geometric dimensions correspond to those specified in GOST 16983-80, with the exception of the length, which exceeds the required by 26%. The handle has an I-section. HARDNESS: the hardness of the keys meets the requirements of GOST 2838-80 and is characterized by small variation, both along the key and from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. During further testing, moments of 106 N*m and 107 N*m were achieved. The destruction of the samples occurred due to large plastic deformations of the working edges of the jaw, as a result of which the nominal size of the jaw increased to 13.8 mm and the keys rotated relative to the mandrel. The minimum moment of destruction is 106 N*m. This is 2.06 times higher than the maximum test moment for an open mouth (51.1 N*m) and is a good result. RING JOINT: when testing the annular jaw, no noticeable damage to the working edges is observed; the destruction of the keys occurred due to large deformation of the handle near the annular jaw. The minimum breaking moment is 233 N*m, which is 3.21 times higher than the maximum test moment for the annular throat (72.6 N*m). Good result. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: there are no plastic deformations of the nut faces. PRICE: $1.92.

SUMMARY Very good results in all respects. Only HEYCO performed better, but the price of the latter is almost 6 times higher. Keys from KING TONY will take their rightful place both in auto repair shops and among ordinary motorists.

RUSSIA

TEST RESULTS : the main geometric dimensions correspond to those specified in GOST 16983-80. Length slightly exceeded. It is 21% more than required. The cross section of the handle is lenticular. HARDNESS: the hardness of the keys does not meet the requirements of GOST 2838-80 and has a significant variation along the length of the key and from key to key. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. During further tests of the open jaw, the destruction of key No. 1 occurred due to separation of the horn from the head, key No. 2 due to large plastic deformations of the working edges of the throat, as a result of which the nominal size of the throat increased to 14.0 mm and the key rotated relative to the mandrel. Moments of 106 N*m and 104 N*m were achieved. The minimum failure moment is 104 N*m, which is 2.02 times higher than the maximum test moment for an open mouth (51.1 N*m). This is an average result. RING JOINT: when testing the annular jaw, noticeable damage to the working edges is observed; the destruction of the keys occurred due to the rupture of the ring. The minimum breaking moment is 268 N*m, which is 3.69 times higher than the maximum test moment for the annular throat (72.6 N*m). Compared to other models, a very good result. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: no noticeable plastic deformations of the faces of the nuts are observed. PRICE: 35 rub.

SUMMARY Good results in strength tests. However, the hardness is much lower than GOST requirements.

TONA 406.6

TEST RESULTS : the main geometric dimensions correspond to those specified in GOST 16983-80. Length slightly exceeded. It is 17% more than required. The cross section of the handle is lenticular. HARDNESS: hardness both near the mouth and the handle corresponds to GOST. There is a scatter in the hardness values for the handle for different samples. OPEN JOINT: when the open jaw was loaded with a moment of 51.5 N*m, both samples passed the test without noticeable damage to the working surfaces. When trying to load the first sample with a moment of 107.3 N*m, a value of 106 N*m was achieved, after which the sample collapsed, as there was a loss in the size of the pharynx due to large plastic deformations of the working faces. The second sample also received noticeable plastic deformations, but passed the test. The second sample was subjected to additional testing to failure, during which a torque of 135 N*m was achieved. Further loading of the jaw was impossible, since its nominal size increased to 14.1 mm and the key rotated relative to the mandrel. The minimum moment of destruction was 106 N*m. This is 2.06 times higher than the maximum test moment for an open mouth (51.1 N*m), which is a good result. RING JOINT: when testing the annular jaw, no noticeable damage to the working edges is observed; destruction of the keys is due to large plastic deformations of the handles near the annular jaw. The minimum breaking moment is 191 N*m, which is 2.63 times higher than the maximum test moment for the annular throat (72.6 N*m). This is a good result. COATING: the protective and decorative coating is durable and has not lost its original qualities. INTERACTION WITH THE EDGES OF THE NUT: as a result of the impact on the nut, subtle plastic deformations of its edges occur. PRICE: $4.2.

SUMMARY Overall, the keys performed well.

https://autodela.ru.

Best Adjustable Wrench Sets

This type of tool is suitable for turning nuts, bolts and other large parts. Their feature is the ability to change the working diameter. As a rule, it is carried out using a worm or screw gear.

Milwaukee 150/250

5

★★★★★

editorial assessment

97%

buyers recommend this product

The worm mechanism and size indicator provide smooth and precise adjustment of the position of the parallel jaws of the tool, which reduces the likelihood of slipping and speeds up the work process.

The length of the keys is 150 and 250 millimeters, the total weight of the set is just over 700 g. The ergonomic design of the handles and a special insert contribute to a secure grip. The chrome-plated surface protects tools from corrosion and extends their service life.

Advantages:

- fine adjustment;

- anti-slip handles;

- carrying strap;

- high strength and corrosion resistance.

Flaws:

- not a small price.

The Milwaukee 150/250 kit is good for working in awkward positions or hard to reach areas.

Heyco HE-50839000100

4.8

★★★★★

editorial assessment

92%

buyers recommend this product

The working part of Heyco tools is made of chrome vanadium steel and treated against corrosion, which guarantees long service life of the keys. The diameter of the pharynx is adjusted using a special wheel, the maximum available size is 30 mm.

The total weight of the set is 1 kg. Ergonomic plastic handles with non-slip coating make it easy to hold keys. Laser marked metric and imperial scales make adjustments easy.

Advantages:

- strength;

- size markings;

- fine adjustment;

- corrosion resistance.

Flaws:

- rapid contamination of the mechanism.

Heyco wrenches are useful for installing and dismantling connections. A universal set for use at home or on the go.

Licota ACK-384012

4.8

★★★★★

editorial assessment

88%

buyers recommend this product

The kit includes a standard adjustable and adjustable wrench. The rough surface makes it easier to hold when wet and increases comfort while working. The metal is not afraid of heavy loads and corrosion.

Packaged dimensions 140x375 mm, weight almost 1 kg. The presence of holders provides convenient storage of keys. An additional recess allows you to place fasteners, measuring tape or other necessary accessories at hand.

Advantages:

- durable materials;

- presence of lodgements;

- corrosion resistance and durability.

Flaws:

- the weight is too big.

Licota ACK-384012 will be useful when assembling or dismantling structures. An excellent solution for service station or housing and communal services workers.

Which set of wrenches is better to buy?

When choosing a set of keys, you should pay attention to the available sizes - the compatibility of tools with fasteners depends on them. The most common sizes are from 8 to 24 millimeters. For professional use, it is better to buy a set that can work with connections with a diameter of 6-32 mm.

The material used to make the working parts will determine the strength characteristics of the tools and their resistance to large mechanical loads. More reliable are keys made of high-carbon steel with admixtures of molybdenum, chromium, and vanadium. However, during operation they may be exposed to aggressive environments, moisture and other factors.

The most undemanding to storage conditions are tools with chrome or powder coating.

We should not forget about the features of the holder. Its design affects the ease of storage, transportation, selection of keys by size, etc. Using a case with holders is one of the most reliable ways to place a set of tools. However, for frequent carrying, it is better to buy a set in a fabric case.

Universal wrenches

Classic instruments are being replaced by new, more advanced and reliable devices. Thus, universal wrenches are designed to facilitate the process of mounting/dismantling fasteners. They have a multi-functional head that can grip bolts of various shapes and sizes, locking them in a convenient position.

In modern apartments and houses, people try to use every centimeter as efficiently as possible, and there is not always space to store a whole bunch of tools. With a universal wrench, you can quickly tighten a bicycle wheel, and in a few minutes you can go fix the plumbing.

Disadvantages of such products... The design of multi-tools is not always durable. If the device can perform several tasks at once, you have to sacrifice something, because the adjustable head or jaws take on a greater load.

4 stages of sheet metal fabrication- Features of Ziplock bags

- How to choose reliable spare parts for household appliances

A good alternative is double-sided wrenches, and options with an adjustable design will be a good replacement for the type of product described above.

However, it is worth understanding that we are talking about housework, and not about the professional activity of, say, a pipeline fitter - specialists use large kits that contain everything they need to fix any problem.