Description

Hydraulic lifts are specialized technical devices that are used to lift loads to a certain height. Such mechanisms are involved in different areas. Hydraulic lifts are used in industrial facilities, warehouses, auto repair shops and construction sites. These technical devices differ from each other in design features and other characteristics. But regardless of the type, all such lifts operate thanks to a built-in hydraulic drive.

Working principle of hydraulic lift

These technical devices raise and lower loads thanks to fluid pressure, which creates the force necessary to move the platform.

Hydraulic lifts stand out from similar devices with a different operating principle in several ways:

- the fluid pressure in such devices is sufficient to lift large and heavy loads;

- the working platform rises and falls slowly and smoothly, preventing the load from accidentally falling;

- wide variety of designs.

The latter feature allows you to select a hydraulic lift that fully meets specific tasks and meets operating conditions.

How does a hydraulic drive work?

The very word “hydraulics” implies in advance that the operation of this design will be carried out due to fluid pressure (and not, for example, compressed air, as in pneumatic drives). Simply put, when the hydraulic mechanism is turned on, its “insides” are filled with a special liquid, which creates the necessary pressure, which produces a lifting force.

But everything is in order. The standard hydraulic drive consists of the following elements:

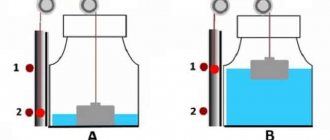

- communicating working cylinders into which fluid (hydraulic oil) flows;

- a working piston that raises the working platform as pressure increases;

- tank or other container in which oil is stored;

- a pump that transfers fluid from the tank to the cylinders;

- a safety valve that protects the hydraulic system from overloads associated with excess pressure;

- a hydraulic valve used to change the fluid flow when raising and lowering the platform;

- a filter system that serves to clean the oil entering the tank.

Boris Damchuk

auto RU

The operating principle of the hydraulic drive is incredibly simple. When turned on, the pump supplies oil from the tank to the cylinders (or vice versa), passing it through the hydraulic distributor. According to the principle of communicating vessels, the liquid level in both cylinders is equal, which means the pressure will be the same at all points. If the pressure level in the system exceeds a safe standard, the safety valve is activated, after which the excess oil is sent back to the tank.

More on the topic: Advantages of a chain lift

After finishing work, the used oil is drained and filtered, after which it can be used again once or twice.

For stable operation of the hydraulic drive, all elements of the circuit described above must be in working condition and free from leaks and other damage. Oil used several times must be replaced with a new one - otherwise, the pressure created will be too weak, which can lead, at best, to high energy costs to maintain the operation of the drive, and at worst, to an unplanned lowering of the working platform during work.

It’s hard to believe, but such a system is really capable of producing a force that is sufficient to lift multi-ton loads, which is why it is widely used in various lifting devices, ranging from ordinary jacks available to any motorist, to industrial lifts used in large enterprises . Let's look at some types of these devices.

Types of structures

Depending on the design features, hydraulic lifts are divided into the following types:

- Console. The design of hydraulic lifts of this type provides for 2 vertically oriented guides along which the loading platform moves, driven by the pressure of hydraulic cylinders. Such models are compact in size. Cantilever hydraulic platforms are capable of lifting over four tons of cargo.

- Scissor type (lift table). Universal models with a platform driven by a drive system. The latter is formed from crossed and interconnected metal slats or beams. Scissor-type devices are distinguished by enviable technical characteristics. These models are capable of lifting loads weighing up to 15 tons to a height of up to 18 meters. Thanks to this feature, scissor-type devices have found application in many areas. But more often, lifts are used in warehouses, production or during construction.

- Telescopic. The loading platform for models of this type rises along vertical posts under the pressure of the working fluid. Telescopic hydraulic lifts are also used in a variety of applications, including service stations and construction sites. These devices are available in different configurations, from compact to powerful models capable of lifting up to 15 tons to a height of 12 meters.

In addition to the above, there are highly specialized types of hydraulic lifts on the market:

- Lifting platforms. These devices are mainly used for lifting and lowering heavy and bulky cargo. Lifting racks are mainly used in warehouse, industrial or retail facilities.

- Low profile lift tables. When fully lowered, the platforms of these devices form a flat surface with the floor. This feature makes loading heavy items easier.

- Inclined hydraulic lifts. One of the types of overpasses, which is used for driving cars onto various hills. Also, models of this type can be used to adjust the angle of inclination of the working platform, tilting heavy loads, moving carts and other purposes.

Scissor lifts

Perhaps the most functional lifting devices today, characterized by maximum ease of operation, small dimensions, good load capacity and low price. In this design, the hydraulic drive drives the lever system, which is shaped like scissors; moving along special grooves towards each other, they thereby straighten and lift the working platform with a load:

- the matter is rarely limited to scissors alone, since they often cannot provide the required lifting height - for example, when storing goods on the upper shelves of shelving structures. Lifts with two, three, four and five scissors are manufactured especially for this purpose, which can operate at significantly higher heights, although with less reliability. As for reliability, there are designs with a parallel arrangement of scissors (for lifting one or even several platforms), the use of which, although not conducive to working at height, provides additional stability and load-carrying capacity of the device;

- Scissor lifts can also be stationary or mobile. Stationary ones are mounted directly into the floor for long-term use in one place - for example, servicing a specific loading and unloading area. Mobile ones - they are also called hydraulic carts - can quickly move around the enterprise, which is especially convenient when there are a large number of work areas or extended storage systems.

Scissor lift

We recommend to buy

More on the topic: Where is a mine hoist used?

Application area

According to the area of application, hydraulic lifts are divided into the following types:

- For multi-level parking. Here, lifts are used to transport cars to and from the parking lot to road level.

- For service stations. In this case, the devices are used to lift the machine to the level necessary for free access to the node units under the bottom.

- For construction and renovation work indoors. Models of this type are compact in size and highly mobile. Such lifts are equipped with a platform, the dimensions of which are sufficient to accommodate people and tools.

- For warehouses. Lifts of this type are mainly characterized by their compact size and high mobility.

- For industrial workshops. The most powerful lifts are used here, designed to move loads weighing several tens of tons.

- For loading on planes and trains. Lifts of this type are equipped with an open or closed platform.

Section one design and device Chapter I

GENERAL INFORMATION

§ 1.

General structure and classification of car lifts and towers

Device. Car lifts and towers are lifting machines for vertical or inclined movement of goods and people from one level to another in cradles and work platforms installed on working equipment in the form of articulated knees (for lifts) or a telescopic mast (for towers). Most lifts and towers are mounted on a vehicle chassis. Some lifts are trailed and do not have their own movement mechanism. Let's take a closer look at the structure of the lift and tower.

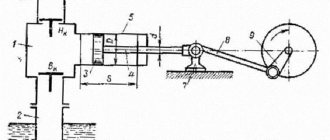

The lift (Fig. 1, a) has working equipment in the form of one, two (or more) articulated knees 2, 3. A working platform (cradle) is attached to the head of the upper knee 4. The lower knee is hinged on a turntable 6. The knees rotate relative to each other and the platform at a certain angle using hydraulic cylinders 1.5 and levers. The platform rotates relative to the chassis in a horizontal plane on the slewing support device 7 using a rotation mechanism. The cradle, when turning the knees, maintains a vertical position with the help of a tracking mechanism. The spatial movement of the cradle is carried out by several (in this case, three) mechanisms: changing the angles of inclination of the lower and upper knee and rotating the platform.

The lift's chassis is a car. The chassis is reinforced by a support frame 9 with additional supports 8 to ensure the stability of the machine.

The lift is equipped with control systems and safety devices. The lift mechanisms are driven by the car engine.

Some lifts are installed on a self-propelled trolley (chassis), which is delivered to the work site in the form of a trailer to a tractor. The PPK-14 lift is trailed and does not have its own movement mechanism; other lifts are equipped with a simple mechanism for moving around the work site at low speed (up to 3 km/h). The mechanisms of trailed lifts are usually powered by a 380 V industrial network.

The tower (Fig. 1, b) is a telescopic mast 13 with a cradle at the top; Designed for vertical lifting of people only. The work platform does not move in space, and the tower has a limited service area. Therefore, towers are usually used in urban environments to service the lighting network and public transport contact lines. The tower support frame is much simpler than the elevator support frame. The towers are mounted on the base of the vehicle and are driven by its engine. These machines, like lifts, are equipped with control systems and safety devices.

Classification of lifts. Lifts are classified according to the following criteria:

According to their intended purpose, they are general purpose and special. General purpose machines are used for various construction and installation works: painting the external surfaces of buildings and structures, electrical installation work, thermal insulation, sanitary work. Special-purpose machines are used to perform a certain type of work and are equipped accordingly, for example, for fire-fighting operations, installation of power lines;

According to the design of the working equipment, one-, two- and three-leg lifts are distinguished;

according to the possibility of rotating the working equipment, they are full-rotary (360°) and part-rotary “360°”;

according to the design of the chassis - automobile and trailed;

by type of drive of working movements - hydraulic, electrohydraulic and electromechanical.

1 In the future, instead of the full term “car lift”, the abbreviated term “lift” will be used, since the book does not describe other types of lifts.

Rice. 1. Lift (a) and tower (b)

contents .. 1 2 3 ..

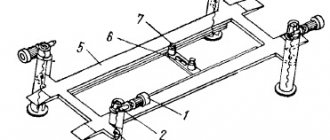

Scissor (parallelogram) car lifts [ edit | edit code]

The advantage of these lifts is that they save space when not in use when installed with recessed ladders. The equipment has hydraulic power drives, which determines the noiselessness and reliability of the design.

Synchronous operation of the sides of the lift is ensured using electronic automation or through the operation of high-precision hydraulics.

The design can be used in conjunction with equipment to perform other operations, for example, adjusting wheel alignment angles.