According to fire safety rules (FPR), appropriate fire-fighting measures are carried out during the organization of hot work. The rules determine that responsibility for carrying out activities and monitoring compliance with fire safety standards lies with the head of the enterprise or an individual performing the duties of the management of the enterprise in which hot work will be carried out.

The responsibility for the entire organization of fire safety measures and the preliminary preparation of premises falls entirely on the management of the institution. The manager undertakes to take all measures to prevent all possible violations leading to fire and explosion hazards.

Types of hot work

Fire regulations define the following types of hot work:

- gas welding;

- electric welding;

- soldering;

- cutting of metal products.

Of the listed types, welding and cutting of metal products are considered to be the most flammable. Fire hazards arise from splashes of molten metal generated during welding or cutting.

Steam and gases, when combined with oxygen contained in the air, can form mixtures that lead to an explosion at a certain concentration.

Sparks and splashes of metal cause charring of tow, roofing felt, gauze and cardboard in the form of a trace. Although the lifetime of the spark is about three to five seconds, during this time the process of smoldering begins in the cleaning cloth, which can lead to fire. Sparks from welding can ignite oily rags at a distance of up to 10 m, and tow - up to 16 m.

Fire safety requirements during hot work include 3 stages:

- preparatory;

- compliance with fire safety during the hot work stage;

- control at the final stage.

Personal protection for the welder

Occupational safety requires special equipment for people working with welding equipment. Kit includes:

- A wide apron or clothing made of dense fabric (canvas, tarpaulin, leather, split leather) with fire retardant impregnation. It must withstand the arc temperature for 50 seconds and not burn out from sparks of hot metal. Costumes are marked with the letter symbols “Tr”.

- Welding gloves or gaiters are made from tarpaulin, felt, leather, and split leather. They are available in the form of mittens, three- and five-fingered. They are impregnated with synthetic resins to prevent smoldering and burns from sparks.

- Boots are regulated by the standard. They should have a dielectric sole, a thickened toe that can withstand heavy loads, and leather that does not burn through high temperatures. Shoes with laces or metal heels are not allowed.

- Protective masks protect the face from heat and ultraviolet radiation. They have a special screen - a light filter, through which the welding zone is visible. They produce models with automatic darkening of the filter, with a forced air injection system to protect the respiratory system from harmful vapors emitted by the melt.

Occupational safety provides for special equipment for people working with welding equipment.

Injuries are an additional risk of fires; a person will definitely get distracted and lose control of the welding area if he gets burned. Personal protective equipment cannot be neglected even with a small amount of work.

General requirements

Hot work is carried out during daytime working hours (the only exception may be an emergency situation requiring emergency intervention). Operating personnel are required to inspect workplaces within three hours after completion of all hot work for signs of fire, smoldering, and the formation of a smoke source. If necessary, you need to take all necessary measures to eliminate them.

In a situation where it is necessary to carry out unscheduled hot work - during non-working periods, on weekends or holidays, then these actions are allowed to be taken only after the order has been issued and announced in advance at the enterprise.

Personnel allowed to carry out hot work must have a certificate confirming their qualifications.

Each employee starting work is required to undergo training and obtain the necessary permission to proceed to unscheduled work. The admission must be accompanied by the signature of the head of the enterprise, who bears full responsibility for the operation.

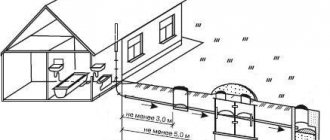

The hot work area can be permanent or temporary. The sector for regular work can be a site or a workshop that includes up to 10 workplaces. Safety precautions require storing oxygen cylinders in a room separate from the work workshop. Each employee's station is equipped with only 1 spare cylinder.

The commission of the department where the planned hot work sites are located is obliged to draw up a report on the compliance of the workplace with all fire safety requirements and measures. It is accompanied by a floor plan with assignment of workplaces to equipment. This act is approved by the signature of the responsible manager, after which it is approved by an order for the enterprise.

Preparatory work stage

According to these safety rules, before starting to carry out flammable work of any kind, it is necessary to carry out preliminary preparation of the entire territory of the premises, technological equipment and other communications of the enterprise.

Management, who is responsible for safety precautions and the entire work process, undertakes to limit the potentially dangerous area and mark it with educational signs.

All mechanisms on which work is planned to be carried out must be disconnected from functioning communications by plugs, or compensatory measures must be taken.

The time during which the plugs were installed must be recorded in a log. The starting equipment is rendered inactive, and measures are taken to ensure that it cannot be launched unexpectedly.

Fire safety measures during hot work require equipping the workplace with a mandatory set of fire extinguishing equipment (a conical bucket, half a cubic meter of sand, a fire extinguisher, an asbestos sheet measuring 2x1.5 m).

Welding equipment requires cleaning from substances that can cause a fire and explosion hazard. The method of ventilation, washing and steaming is determined depending on the type of equipment used.

The room must be equipped with natural or forced ventilation before starting work. All hatches and openings leading to other rooms or to adjacent floors must be tightly closed with partitions. If walls are made or covered with flammable materials, they must be protected with protective panels. They prevent sparks from hitting the surface of the walls during operation.

The workplace must be cleared of flammable and potentially hazardous substances, and cleaning must be ensured throughout the area within a radius of 5-15 meters. Doors leading to nearby departments must be tightly closed and windows must be open.

What is prohibited

When carrying out hot work it is prohibited:

- use faulty tools, equipment or devices;

- if structures that are undergoing repairs or changes are painted with flammable materials;

- use clothing contaminated with technical oil, flammable liquids or fats;

- allow cylinders filled with compressed gases, liquefied or dissolved, to come into contact with open electrical wiring;

- use connections to wires with damaged insulation or uninsulated wires at all;

- When connecting, it is forbidden to use non-standard type circuit breakers;

- use grounding or grounding wires and networks as a return conductor; this also applies to railway tracks, communication networks, technological equipment and metal structures of buildings and structures;

- use tanks and containers operating under pressure unless they have been tested for leaks and strength;

- during hot work, use pumps and devices that monitor and indicate the pressure of the medium;

- It is prohibited to heat the evaporator of gas cutting equipment with flammable liquids;

- it should also not be overheated and suspended while burning with the nozzle upward;

- this also applies to kerosene lamps, which cannot be filled with gasoline or a mixture of gasoline and kerosene;

- when using gas welding, it is prohibited to twist the hoses, clamp them or wring them;

- they are prohibited from being used for purposes other than their intended purpose;

- it is impossible for the pressure in the oxygen cylinder to be less than in the cylinder with a flammable mixture;

- a kerosene lamp must be filled with fuel to 60% of the total volume of the tank.

This is interesting: Fire protection of concrete (reinforced concrete structures): requirements

Stages by which hot work should be carried out

The manager responsible for conducting hot work undertakes to personally verify compliance with workplace safety regulations, the validity of the personnel’s certificates and work permits. In case of compliance, a briefing is carried out, necessarily confirmed by a signature in the log, and permission is given to begin work.

During the work process, the use of faulty equipment is prohibited. An employee whose uniform contains traces of any kind of flammable liquids cannot be allowed to perform work.

At the time of completion of work, all mechanisms and electrical equipment must be disconnected from the power supply, residual gases and/or liquids are released in gas cylinders, and pressure in blowtorches is reduced to zero.

Compliance with technical safety rules when cutting metal

The employee is prohibited from hanging the cutter with its head up during breaks in work or changing the purpose of the hoses. The gas pressure in the fuel tank should not be higher than the oxygen pressure in the torch. The working cutter is responsible for preventing spills of liquids and the possibility of their ignition.

Safety rules require placing flammable substances at a distance of ten meters from the worker’s place of work.

Rules for soldering work

During soldering, the master's workplace must be completely cleared of any kind of materials that could cause a fire hazard.

All flammable materials must be located at a distance of at least 5 meters from the place of work, and be reliably protected by screens and shields made of special non-flammable materials.

Blowtorches designed to operate on kerosene fuel are prohibited from being filled with other flammable substances. When refilling the lamp, the use of open flame is prohibited. The amount of fuel poured into a blowtorch should be no more than three-quarters of its volume.

Every month a routine leak test of blowtorches must be carried out. At least once a year, hydrotests are carried out, the results of which are recorded in the test log.

Types of fire extinguishers

Fire safety requirements imply fire extinguishing means. Fire extinguishers are powder or carbon dioxide. If electrical wiring catches fire, do not use water or liquid foam to avoid short circuits and electric shock.

Powder fire extinguishers are universal, suitable for all classes of fires; for welding they are chosen with the “D” marking. The powder component contains potassium, sodium, and phosphorus salts. White soot, talc, nepheline, and silicon compounds are used as disintegrants. Various modifications of fire extinguishers are available:

- injection (with inert gas or air);

- gas generators;

- self-acting.

Carbon dioxide is distinguished by its ability to lower the temperature when gas is released. They are reliable for gas welding and quickly neutralize oxygen. Carbon dioxide is in cylinders in a liquid state, under pressure.

Fire extinguishers are powder or carbon dioxide.

Carrying out welding work

Fire safety during welding requires the fulfillment of a number of requirements.

When performing electric welding work, only standard electrodes are allowed. Before starting work, they are dried at the temperature specified in the technical passport. Remains are placed in a metal container, which should be equipped with each workplace.

It is strictly forbidden to use electrical wires whose insulation is damaged. From the power supply wires going to the welding installation, a distance of at least half a meter must be maintained from pipelines with oxygen, and more than a meter from pipelines with other gases.

For electric welding equipment, mandatory grounding is required. Wires used in electric welding machines for connection must be connected using special clamps, welding, and soldering.

Measures aimed at preventing potentially dangerous situations

To minimize the risk of fire, prior training is required. It is important for beginners to know:

- how to reduce the risk of fire,

- how to localize a fire when it occurs,

- How to protect yourself from burns while working.

A properly organized workplace is the key to safety.

Fire extinguishing means: a fire extinguisher or a box of sand should be within walking distance; these safety measures are mandatory. Before work, technical measures are carried out: the equipment is inspected, a test run is done to select the desired operating mode.

Rules for storing and using calcium carbide

Calcium carbide is stored in a separate and well-ventilated room.

During storage, the use of fire, including smoking, is strictly prohibited. Fire safety rules when carrying out welding work prohibit the use of open fire. The volume of the container filled with calcium carbide should not exceed half. At the same time, the use of the dusty fraction of calcium carbide and its increased granulation is strictly prohibited.

When working with calcium carbide, it is strictly forbidden to use copper tools and copper as solder for repairing acetylene equipment.

Acetylene generators must be protected from the welding sector during gas welding work. Their distance must be at least ten meters. It is mandatory to place a warning about the prohibition of smoking in the area where the acetylene generator is located when carrying out welding work.

Upon completion of all work, the residues from the cylinders must be drained into a sludge tank or a trench fenced with railings and warning signs.

Bitumen heating and safety

Bitumen is boiled in special boilers, installed so that the edge located above the firebox is higher than the opposite one. The boilers are equipped with a special lid. The dry boiler is filled to three quarters of its full volume.

The boiler installation site is surrounded by a non-flammable side with a height of thirty centimeters. After completing work, workers are required to extinguish the fire and fill it with water.

Fire extinguishing means should be available nearby: sand, shovels, foam fire extinguishers. If the bitumen boiler is installed outdoors, then a canopy made of non-flammable materials is installed on top.

If a leak is detected in the boiler, the fire is extinguished and all work is stopped.