Magnetic mass for welding is a special device that provides reliable fixation on metal surfaces. This allows you to comfortably perform welding work on complex surfaces where the use of classic alligator clips is impossible. There are many design options that depend on the work conditions. The structure of this device is not particularly complicated. For this reason, some craftsmen prefer to use homemade magnets for welding.

What's happened?

This device is mounted on the working plane of the workpiece . Thanks to the active magnetic field, a strong fastening is achieved, creating a closed electrical circuit - the main condition for the formation of an electric welding arc.

The tool is especially popular among novice welders - it will take a few minutes to familiarize yourself with the principles of the work. Experienced specialists use magnetic mass for welding machines for critical work - welding large-diameter pipes or connecting load-bearing units made of profile materials.

Design of magnetic contact and its characteristics

Consists of two nodes:

- Cable holder . The ground cable of the welding equipment is attached to it using a bolted connection.

- Magnetic node . The size of the magnet depends on the design features. Some models are equipped with a mechanism that regulates the pressure of the magnet on the working plane. Professional devices have switches.

The parts are connected to each other by a rigid fastening. The main characteristics of the devices are:

- Dimensions and weight. Depends on the manufacturer and specific model. The average weight is 1-1.2 kg.

- The force of attraction to the surface. Varies in the range from 2 to 50 kg.

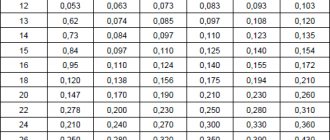

- Welding current strength. The maximum value of the parameter is measured in amperes. For entry-level models, it does not exceed 200 A. An advanced tool is capable of operating at 400-500 A.

- Execution type. They produce special clamps for corners with gap adjustment.

Safety regulations prohibit connecting a cable without a special lug, which is clamped with bolts.

Types of magnetic holders

Types of gas burners: their advantages and disadvantages

Today, the welding equipment market offers various modifications of magnetic holders, which differ not only in shape, but also in their operating principle:

Magnetic square. This is the simplest monolithic special design. welding fixtures, which provide the ability to position the workpieces to be welded at a certain angle.

Magnetic clamp. This device is flexible and allows you to set any desired angle.

Latch. Such devices can be either monolithic or complex configurations, with an adjustable angle. The main feature of this holder is the “fastener release” function. When you press the button, the action of the magnets weakens, as a result of which the device is quite easily rebuilt. The switchable magnetic clamp can be used quite effectively when working with powerful corners.

Holder angles are also distributed according to power. Standard low-power devices are used for light metal samples, and angles with powerful magnets are used for heavier metal structures.

Advantages and disadvantages

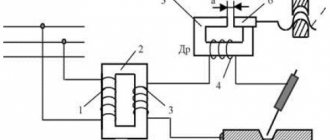

Electric welding is the most common method of joining metal products. The quality of the future connection depends on the integrity of the electrical circuit .

That is why the invention of the device in question aroused serious interest among specialists.

The popularity of magnetic mass for welding is due to the following advantages:

- Reliable fixation will allow the welder to concentrate on work without being distracted by adjusting the clamp.

- The working mechanism is a permanent or switchable magnet. Subject to compliance with operating conditions, it can serve for an unlimited period.

- You do not need any consumables to use the holder.

- Even compact models have a contact patch sufficient for reliable closure.

- The device is resistant to sudden voltage changes or temperature changes.

- The magnet can be attached to any place to create comfortable conditions for making the connection.

Despite the large number of advantages, there are a number of disadvantages:

- Before use, it is necessary to prepare the surface. The procedure involves removing dirt and foreign particles.

- There is no possibility of attaching to small parts, for example, a circle with a small cross-section.

- It is impossible to work with non-ferrous metals because they are not magnetic.

How to improve the ground terminal?

This problem is usually encountered by novice welders. Purchase a budget manual arc welding inverter for welding at home: for a fence, gate, canopy, etc. Such an inverter, costing 6-10 thousand rubles and more, is equipped with a “Crocodile” clothespin. In addition to other negative aspects of such a clothespin, which were already mentioned above, it most likely has steel jaws coated with a thin layer of galvanic copper (to give the impression that they are copper). It’s very easy to check whether it’s copper or steel; you just need to hold a magnet. If it is magnetic, it means it is steel. Usually, food-grade stainless steel in an unhardened state is not yet magnetic, but that’s a completely different story (read the article “How to determine what kind of metal”).

What are the dangers of steel jaws? They will get hot - steel is a much worse conductor than copper or brass. To prevent this from happening, you can remake a cheap clothespin that costs 40-50 rubles. (if, of course, you have some copper or brass in your household, for example, a plate or tube, a busbar).

What should be done? You need to unscrew the original jaws, which are held on by bolts, and use them, like a template, to make other jaws. It is enough that in cross-section they represent the Russian letter “P”. Without much effort you will get a good contact on a low-quality clothespin!

How to use?

The technology for using the device is not complicated. First of all, the welding cable is connected, after which installation begins .

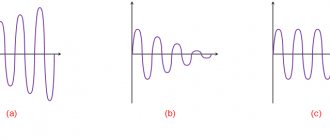

Most units are equipped with switches that activate a magnetic field. At rest, the magnet will not be attracted to the surface.

One person is required for commissioning. After contact with the working plane, the device must be activated. Upon completion of these steps, the clamp is in operating mode.

After completing the work, perform the above steps in reverse order. Do not try to separate the switched-on device from the part - many models have quite high tear strength. In addition, this may damage the latch.

Upon completion of work, you should immediately clean the contact surface of the magnet from metal shavings, since they negatively affect the force of attraction.

Choosing or making a holder: tips and tricks

A more reliable and durable welding element, which allows you to hold the electrodes during the soldering process, is a holder with a threaded fixation. It allows you to select the level of inclination of the electric cathode at any angle.

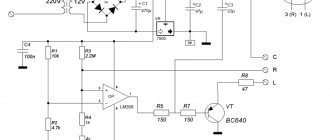

Electrode holder designed by V. Anikin.

Select a holder that allows you to fix the electrodes taking into account the welding current required for the operation of the equipment. When planning a job that involves traveling, you should carefully consider a backup version of the welding fixture. You should not skimp on this device if you need to perform professional welding under prolonged loads. This will increase the service life of the holder.

If the choice is made on a device holder designed for 200 amperes, then when welding using such an inverter operating at a current strength of 300 amperes, this device will only be enough for two days. During the welding process, a characteristic smell of plastic will appear, burnt when the electrode holder is heated and there is weak contact between the device and the welding electrode. This will lead to burning of the holder clamp, which will then fail, becoming unsuitable for further use.

When choosing a holder, you should take into account its amperage, which increases as the weight and size of the device increases. Convenience of work can be ensured by selecting a holder if a current strength close to the working current of the welding inverter is required. Holders corresponding to 200-500 A are often available for sale.

Is it worth buying?

The answer to this question can only be given by the master performing the work. For a novice welder who has just started his professional career, this device can make life significantly easier.

If a specialist works primarily with non-ferrous metals, a magnetic clamp will most likely not be useful.

Experienced workers have a set of various clamps for all occasions, including this device.

The cost of the device is quite high. If you have knowledge in the field of electrical engineering, you can try to make it yourself. The technology and manufacturing process will be discussed below.

Magnetic mass for welding. Advantages and disadvantages

Like everything else in the world, this device has both positive and negative sides. Let's look at the pros and cons of magnetic mass for welding. Some of the points below will only make sense in comparison to the clothespin.

Just a second, attention! Have you ever wondered why a semi-automatic welding machine fires? We answered this question to one of our colleagues...

Pros:

- Easy to use

- Can be used in places where there is nothing to attach a clothespin to

- Reliability of the hook - no need to be distracted, the mass is firmly fixed on the surface

- Unlimited use

- When securely fixed, the mass does not heat up

Minuses:

- Constant contamination of the magnetic surface with metal shavings and scale. Requires regular cleaning with a wire brush.

- The need for preliminary cleaning of the junction of the mass with the metal for tight fastening and to eliminate the possibility of heating the mass.

- A magnetic field. It is impossible to perform high-quality welding in close proximity to the magnetic mass. It's all about the magnetic fields that every now and then set the welding arc in motion...

- A serious drawback is that it is impossible to fully use the magnetic mass when working with non-ferrous metals. You understand why. Of course it can be used, but if you just put the mass on the welding surface.

As you can see, there are both pros and cons. But it normal! Many will find significant positive aspects for themselves that will cover the negative ones.

How to do it yourself?

Experienced craftsmen try to reduce all costs for the purchase of auxiliary and working equipment to a minimum. Due to the simplicity of the design, no special equipment or complex tools are needed for manufacturing .

To assemble a homemade device, you should prepare the following equipment:

- Magnet . The working part of the unit. It must have sufficient power to securely attach to metal. Magnets from old car speakers with a power of 10-15 W are ideal for this purpose.

- Two washers . Their size must correspond to the diameter of the magnet.

Sometimes it can be difficult to select washers for the size of the magnet. It is much easier to make washers yourself from sheet metal.

- A set of hardware for fixing the welding cable.

Algorithm for performing the work:

- One of the washers will make contact with the working plane. It is necessary to make a hole in it corresponding to the size of the bolt head.

- The cap is cut to the thickness of the washer.

- After preliminary preparation, the structure is connected by welding. The product should resemble a mushroom, in which the threaded part of the bolt plays the role of a leg.

- A magnet is placed on the mushroom. Place a second washer on the reverse side.

- A welding tip is attached to the thread, and the entire structure is secured with nuts.

Functionality testing is performed only in the field. The quality criterion will be the correct functioning of the welding machine.

Do-it-yourself welding machine compound is a great way to save money, as well as a means to test your DIY construction skills.

A properly assembled device will last no less than the factory clamp.

Recommendations on how to extend the life of an alligator clip

The main design feature of such a welding compound is a spring, which ensures quick fastening to the metal. It is also the “Achilles heel” of the device.

Understanding the operating principle of a crocodile-type mass allows you to extend its life and not ruin it after two or three welding jobs. What is it about. On any clamp there is a strip (copper-plated or brass) that transfers contact from one clamping jaw to another. If you do not monitor its condition and incorrectly connect the mass to the metal, it may deteriorate. A common malfunction is that a contact that fits with a wire to one clamping jaw may slip through the spring to another. As a result, the spring begins to heat up, which leads to a loss of its hardness and springing properties (in metallurgy, this process is called tempering), aimed at reliable fastening of the clamp to the surface of the metal product. Because of this, the mass is destroyed at a rapid pace. To maintain working condition, you need to monitor the condition of the strip: it should not touch the metal when connecting. The photos clearly demonstrate what is meant.

Incorrect contact

Correct contact

Buy a crocodile for professional work. What positive aspects does it usually have:

- the design is correct (the strip is recessed so that it cannot be touched)

- quality materials,

- more powerful spring;

- larger girth (sometimes it is simply not replaceable).

Take with a reserve of 400 -500A.