Such a tool as a hair dryer is little known to ordinary people. But those who use it for its intended purpose claim that it is very convenient and practical, in particular when performing home repairs. The cost of branded models is quite high. They provide various modes that can significantly simplify the workflow. However, as practice shows, many of the “bells and whistles” are absolutely unnecessary, and in order to perform basic heating of materials, you can make a construction hair dryer with your own hands, while significantly saving on the purchase.

General information and purpose of the device

A construction hair dryer is a professional tool that produces a stream of hot air. The temperature of such an air stream sometimes reaches 650°C. The most important characteristic of construction hair dryers is the range of power that the hot air blower can produce. The more power it has, the wider the tool can be used for different types of work.

The functionality of construction hair dryers is quite diverse and allows you to perform specific operations without much effort:

- remove old paint and varnishes of any texture;

- remove glue, and therefore thoroughly adhered coatings: wallpaper, linoleum, plywood, etc.;

- wax coating of furniture products;

- defrost all kinds of pipes, including plastic ones;

- weld plastic and film;

- bend plastic pipes;

- carry out quick drying of any painted surface or leakage;

- light the coals for the barbecue.

It is worth noting that this is absolutely not all the work that can be performed using this equipment. Depending on the needs of the owner, a hair dryer can be used for many repair tasks.

Equipment diagram and structure

In terms of its design, a technical hair dryer is significantly similar to household models that are used to dry hair. Among the main components in this unit, it is worth noting the mandatory presence of a housing, a heating element and a device that redirects hot air masses to the required location.

Compared to other thermal devices, a hair dryer does not have an open flame. This feature allows you to reduce the level of fire hazard of the unit and eliminate the need for burning flammable materials.

The device can be distinguished by the presence of the following structural parts:

- Electric motor.

- Heating element.

- Fan.

A hot stream of air is supplied through a metal nozzle narrowed at the end; as a result of such a narrow focus, a powerful stream is formed. For full-fledged work, a construction hair dryer should be equipped with various attachments, which can be easily made independently from available materials. Thanks to them, it will be possible to change the shape of air flows based on the types of work the device is used for.

How to calculate and wind a spiral for a hot air gun

To produce a construction hair dryer with your own hands, you need to be able to calculate a nichrome spiral, in other words, determine how long a wire of a certain cross-section will be required for a spiral made from it to produce some kind of power. The duration of the continuous operating cycle of the tool depends on this indicator, and based on this, the ability to perform large volumes of work with it. Depends on the power and heating temperature. But it will also be influenced by other technical operating parameters of the hair dryer, for example, productivity or the volume of air supplied per unit of time (in most cases per minute).

Calculation of the appropriate length of nichrome wire

Having obtained the required power of a technical hair dryer, and for housework it can be from 800 to 1500 W, you need to calculate how long the wire needs to be taken for winding the spiral. To do this, you need to make a series of sequential calculations:

- Find the current by dividing the power by the voltage. For example, if you need to get 900 W of power from a 220 V household power supply, the current should be equal to I = P/U = 900/220 = 4.09 A.

- Determine what resistance the spiral must have. Why divide the voltage (U) by the current (I). We purchase R = 220/4.09 = 54 Ohm.

- The length of a nichrome wire having a resistance of 54 Ohms is determined from the formula R=? · L/S, where R is resistance, ? is an indicator of the resistivity of the material (for nichrome it is in the range of 1–1.2), and L and S are the length and cross-sectional area of the wire. Let's say wire diameter D = 1.00 mm. Then its cross-sectional area will be equal to S = 3.14 · D 2 /4 = 0.785 mm 2. Therefore, the length of the wire is determined as R · S / ? = 54 · 0.785 / 1.1 = 38.54 m.

The thinner the wire, the less it will be needed to produce a hot air gun of the same power. The data obtained by calculation must first be checked in the work. After all, the wire usually has deviations in chemical composition or uneven thickness along its entire length. Before cutting it from the coil, it is necessary to measure the resistance of the measured piece with a device for measuring electrical (ohmic) resistance.

Nichrome spiral winding

In order to wind a spiral from nichrome wire, you must first determine the length of the cylindrical rod or tube onto which you will wind it. This is very easy to do, knowing the diameter of the spiral and the length of the wire that will be needed to do this. It is imperative to take into account that after winding the spiral rings are slightly springy, thanks to which its diameter will be slightly higher than the size of the rod .

Having formed the length of the rod, you need to make the simplest device. There are several options for such devices. For mechanized winding you will need:

- bench vice;

- electric drill with controlled speed;

- two wood blocks with a cross section of 20 x 50 mm;

- coiling rod (mandrel).

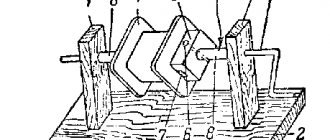

The simplest device for mechanized winding of a nichrome spiral consists of the following parts: 1 - a vice, 2 - a block of wood, 3 - a nichrome thread, 4 - a mandrel, 5 - an electric drill

Semicircular grooves are cut into the bars, forming a hole of sufficient diameter to accommodate a coiling rod with wound wire. The rod itself is placed in the drill chuck, and a nichrome wire is attached to its end. The structure is clamped in a vice very tightly to hold the bars and allow the wire to pass between them when winding.

For manual winding, a similar principle is used, but instead of a drill, a wrench is used, and the free end of the mandrel consists of a support surface with a bearing. You can slightly modify the design by removing the vice and placing a rod at both ends for winding onto the bearing assembly.

Video: hand-winding a spiral from nichrome wire

When winding a spiral you need to follow certain rules:

- winding must be carried out without stopping and without loosening the tension of the thread;

- do not guide the thread by hand, but only with wooden blocks, in order to avoid serious cuts;

- do not allow the wire to bend, which may not break immediately, but will quickly burn out at the bend;

- It is necessary to select the length of the rod for winding with a margin and taking into account the possibility of securing it in a vice or on supporting surfaces.

When winding, the turns should be placed tightly to each other. It is better to then stretch the spiral to the required length.

In order to make a construction hairdryer with your own hands, you don’t need complicated devices and tools. You just need to be smart and come up with the most convenient design possible. It is best that your homemade product is made taking into account the needs that have arisen, and also with a view to using it for the future. After all, a hot air gun will probably be useful to you in the future for construction, repair or installation work.

It's been a long time coming

What you need to make your own hair dryer

To assemble a hair dryer yourself, you need to prepare in advance the appropriate components that will be used during the assembly process. To do this you will need to provide:

- An old casing from a regular hair dryer. However, it should not be plastic; only a ceramic design will do.

- Metal blades that will be installed on the fan. They can be cut from a tin sheet.

- Nichrome spiral.

- Power cables. The cross-section of the wire should be more than 4 mm, since the load on the device is expected to be large.

- Pieces of rubber pipes. Their use on a hair dryer allows you to protect your hands well from burns.

- A standard metal nozzle that is flattened at one end. This simple shape is used for most applications, allowing for easier melting and reheating.

- A straight round tube that will be used for soldering and welding.

- Means providing personal protection. In this case, gloves are sufficient.

What symptoms develop in a drug addict who takes a hairdryer?

Using a hairdryer provokes a massive release of neurotransmitters: dopamine, norepinephrine, serotonin. This explosive mixture causes intense positive experiences. A person in a state of intoxication experiences a whole range of sensations. Symptoms of the pathological process and addiction immediately after taking the drug are as follows:

- Improved mood. The person feels in seventh heaven. Self-confidence increases. Unmotivated euphoria develops. This condition persists throughout the acute period. Until the effect of the drug wears off.

- Increased performance. The addict is literally ready to move mountains. He works tirelessly, constantly busy with some kind of business. This is the result of stimulation of the central nervous system, a powerful effect on the brain. Of course, such mobilization of the body will not take place without consequences. It’s a matter of time before the “recoil” begins.

- Loss of appetite. A person can go without food for up to several days. This does not affect your well-being in any way. Then an increased need for food may develop.

- Psychomotor agitation. Anxiety, increased physical activity. All these are symptoms of acute drug poisoning. Intoxication is characterized by nervousness of the addict. He walks around the room, moving his arms. Constantly in motion, cannot stop. If you are forced to sit in one place, anxiety increases.

- Insomnia. There is no need for sleep at all. The action of amphetamine as a drug against narcolepsy is based on this positive (partial) effect. At the same time, with inadequate dosages of the drug, persistent insomnia develops. It is difficult to overcome, especially if amphetamine enters the body for a long time and systematically.

- Speech activity. It comes to the point of talkativeness. The addict talks constantly and cannot stop.

- Tremor. Trembling of fingertips, hands, chin, head. Develops as a result of the influence of toxins on the central nervous system. If you do not take drugs for a while, the symptom goes away on its own.

- Panic attacks. Attacks of unconditional, strong fear. The man is tossing about, excited. Constantly looking for something, cannot find a place for himself. Panic attacks can develop spontaneously after stopping the hair dryer. This is a long-term consequence that is caused by an imbalance of neurotransmitters in the brain.

- Blood pressure surges. Objective sign. BP is sometimes high, sometimes low. This is dangerous because untrained vessels may not be able to withstand such a load. A stroke or heart attack is possible and even probable.

- Tachycardia. Increase in the number of heartbeats. Up to 100-120 beats per minute and more. Develops against the background of stimulation of the cardiovascular system and peripheral nervous system. It fades away gradually over several days.

- Pupil dilation. Mydriaz. In this case, the eyes do not respond to light at all. The pupils remain the same dilated even in a very bright room. By this sign, relatives can recognize drug addiction.

- Dry mouth. Towards the end of the pathological condition. When the intoxication subsides.

- Increase in body temperature. Hyperthermia.

After the addict recovers from the acute condition, additional manifestations develop:

- Weakness. Inability to do anything. Even just walking, because the muscles feel weak. Like the rest of the body.

- Drowsiness. Desire to lie down. It persists during the day with the same strength. It was as if the person had not slept for several days in a row.

- Thirst.

- Depressive mood. Lowering the background mood. Dysthymia persists for several days. With long-term use of amphetamine, especially without a break - much longer. Suicidal thoughts and even attempts are possible.

The effect of a hairdryer as a psychostimulant drug. But the substance quickly depletes the central and peripheral nervous systems. Therefore, one cannot count on his safety. In addition, tolerance to the substance develops within a matter of months. To achieve the desired and desired effect, drug addicts increase the dosage of the drug.

Self-assembly of the structure: step-by-step process

To produce a full-fledged construction power tool from a household model of a hair dryer, the device must be appropriately modernized by changing its design.

First of all, the hair dryer body is disassembled, and all plastic parts are removed. During operation, they can not only melt and emit a pungent odor, but can also lead to short-circuiting of wires as a result of melting and liquid plastic entering the structure of electrical elements. It is advisable to replace them with textolite or ebonite parts.

After this, the no longer suitable heating element is replaced with a ceramic part. A nichrome spiral must be wound onto the installed ceramic element. In this case, the turns should be arranged as tightly as possible, since their number determines the heating temperature of the tool - a denser arrangement provides greater heating. During the process, it is important to consider some aspects:

- The ends of the wire must be brought out.

- There should be no contact of the nichrome turns with each other, as this may cause a short circuit.

- Excessively dense laying of turns on a home-made household appliance is also unacceptable, since electrical equipment in a residential area is not intended for serious industrial loads.

To make a heating element, you can use the housing of powerful halogen lamps and nichrome spirals. Lamp glasses have good resistance to high temperatures. The twisted wire should be placed in the glass housing structure. Since solder is not possible for nichrome, the connection is made by securely screwing the ends of the nichrome wire to the transformer wiring. After which everything is carefully isolated.

You should also wrap the finished heating element with foil. In this way, reflected radiation is created, which increases the power of the power tool and minimizes its heat loss. An alternative to using a lamp body is fiberglass, which can be wound on a nichrome spiral, and a durable steel tube placed on top to vent hot air out.

After this, a rubber tube is placed on the handle of the product, which will protect the hand from overheating of the ceramic. The optimal solution may be to use fabric corrugation. For example, it can be taken from vacuum cleaners. It has a rubberized structure, which prevents it from heating up from the outside.

Then the wire should be connected to the transformer, initially setting the almost finished product in fan mode. It is important to follow the rule: first of all, the air supply is turned on, and then the heat; when turned off, the actions are performed in the reverse order. It is noteworthy that in order to provide additional air supply, it is recommended to use an aquarium compressor with sufficient power.

The disadvantage of such a device is limited movement, since the wiring and transformer are quite difficult to drag, therefore it is recommended to make holders on stands. When working with homemade devices, you must always remember the safety rules.

Hairdryer from a soldering iron

There are many cases where home craftsmen were able to make a soldering device from an ordinary hair dryer, a hair dryer, and even a soldering iron. But in the latter case, serious alterations have to be made. The fact is that a soldering iron initially does not have special air supply devices, and creating them is much more difficult than a heating element.

Regardless of which of the devices listed above you decide to use as the basis for making a do-it-yourself soldering device, you need to make sure that the finished hair dryer can maintain the set temperature.

If you find a good hair dryer with a thermostat, then be prepared to make certain changes to its design. And this will inevitably lead to the fact that the temperature scale on it will not display the real indicators created by the device on the printed circuit board.

Therefore, we advise you to first test your homemade soldering device using a contact digital thermometer. If, after numerous tests, the temperature remains in the range of 190-240 degrees, then this means that your hair dryer is ready for use. If you observe some deviations, then you will have to additionally work on its design and bring the temperature indicators to optimal levels.

The most difficult thing is to make a soldering device from a soldering iron. The fact is that here you will not only have to stabilize the temperature, but also somehow solve the problem of air supply, and for this you will have to do everything from scratch.

- To create such a device for soldering, you will need a heating element, which is placed in a glass tube, and air will be supplied through it from the other end.

- You will have to get rid of the soldering iron tip.

- For proper operation, air must enter the tube directly through the coil, which, in turn, will heat it.

- The second end of the tube should be slightly longer than the first. Subsequently, you will connect a hose to it to pump air. As suitable mechanisms for this task, you can choose a converted aquarium compressor, a home-made bellows from a plastic bottle, or you can completely abandon such devices and pump air through your mouth.

Since the most problems arise when creating such a hairdryer (setting the temperature, the inability to adjust the heating intensity), you will have to spend a lot of time and effort on making it, but even in this case you will not be sure that such a hairdryer will maintain the parameters you set . It is best to use a regular cheap hair dryer as a base, and you can use a soldering iron for other purposes.

Nozzles for a hair dryer

The scope of application of this equipment is determined by the shape of the nozzle used, which is necessary for a specific type of work. The nozzle is also called a nozzle, nozzle or nozzle. Each product has its own purpose, according to which it is selected.

- The flat nozzle allows you to remove old paint, wallpaper, and deform plastic.

- The round nozzle is used for processing copper pipes.

- A reflector nozzle with a rounded bend is used when bending polymer pipes.

- Using crevice nozzles you can weld PVC sheets.

- The side nozzle with built-in glass protection allows you to clean window frames without overheating and breaking the glass.

- The cutting appearance of the nozzle has the appearance of a flattened pipe. Thanks to it, foam plastic is cut.

- The mirror nozzle is used for welding plastic.

Safety when using a hair dryer

To protect yourself from injury, you need to know how to use a hair dryer correctly.

- Sharing use of the device and gas equipment is unacceptable. Particularly in kitchen areas, where there is the presence of open air and flexible hoses. Improper operation and sparking may cause a gas explosion.

- It is prohibited to use a construction hair dryer to work with paint and varnish materials in an unventilated area. When heated, harmful components scatter, which are hazardous to health.

- When removing paint, you must first find out what its origin is, as there is a possibility that it contains toxic lead.

- When using a construction hair dryer for any task, it is necessary to provide for the availability of fire extinguishing means in advance.

- The work process should be carried out wearing gloves and long sleeves to protect against possible burns.

- When removing paint from windows, you should use a special nozzle that protects the glass. But a homemade device naturally does not provide for it. Therefore, it is better to purchase it or remove the paint without using a hair dryer. Since during operation there is a high probability of glass breaking and flying fragments.

- When working with such equipment, you must ensure that there are no children or animals nearby.

First, the hair dryer is checked from a safe distance. If the device functions properly: the coil heats up to a red state, air is being pumped, then this indicates that the device can be used. To try it out in practice, use something of lesser value.

Making a hair dryer with your own hands at home is not easy, since it requires certain skills and knowledge of designing electrical appliances. If you do not take into account the list of necessary requirements, then equipment breakdown is not completely ruled out. To prevent this from happening, you can watch the video tutorials below on creating devices of this type.

Design, types and principle of operation

One of the distinctive features of the mechanism is the simplicity of the construction hair dryer. Main working elements of the tool:

Heating element for a construction hair dryer. It is presented in the form of a spiral, which performs the function of heating the incoming air to a set temperature. In different models, the heating level can fluctuate in the range of 50 - 700 degrees.- Frame. As a rule, the air heating regulator is located on it.

- Fan. Performs the function of cooling the air flow.

There are several types of technical hair dryers on sale:

- Domestic. It has the ability to switch power in three modes. The operating temperature range ranges from 50 to 500 degrees. With its help, you can perform such types of work as removing old paint, gluing vinyl wallpaper, gluing plastic surfaces, etc. Tools of this type have a simple design and an affordable price.

- Professional. Has the ability to smoothly switch power. Capable of delivering both hot and cold air flow. The maximum heating temperature reaches 700 degrees. The design is equipped with an indicator that prevents the tool from overheating. This type of hair dryer can be used when performing roofing work, laying floor coverings, soldering copper pipes or welding plastic products.

- Industrial. Has the highest power. Its design may have a second nozzle through which a flow of cold air is supplied. Its price is quite high, but the cost pays off in a short time.

The operating principle of the tool resembles the functioning of a hair dryer, which is used to dry hair. This must be taken into account before making a hair dryer with your own hands.

It is designed to change the structure of the working material. To do this, a jet of hot air is used, which is supplied under strong pressure.