Choosing a receiver

The selection of an air receiver for a compressed air preparation system should be approached with special attention.

Incorrectly selected parameters for pressure and volume of the air collector may not correspond to the same characteristics of the compressor and the pneumatic network will not operate at full capacity or will work intermittently. In addition, any compressor units and power equipment are pressure devices. Accordingly, these devices are high-risk units, and if they are connected incorrectly, emergency situations may occur.

By design, any receiver is a sealed container, the internal volume of which, even for the largest models, does not exceed 2000 liters. When choosing an air collector, in addition to technical characteristics, you should take into account the design features of this device and operating conditions.

From this article you will learn:

- Receiver classification

- How to correctly determine the volume of the air receiver for a compressor?

- Basic criteria for choosing a receiver for a compressor installation

- What happens if you choose the wrong receiver?

Receiver selection

The technical requirements for compressor receivers are quite stringent. As high-pressure equipment, they may pose a potential hazard . The most important characteristics that determine the permitted parameters for using the tank are:

- operating pressure;

- temperature range;

- indicators of relative air humidity.

The rules for the design and safe operation of pressure vessels regulate the volume, frequency and method of their control tests for density and strength. They must be sealed, without visible defects and traces of external or internal corrosion.

From a technological point of view, an air compressor with a receiver is needed to ensure the operation of certain pneumatic equipment. What is important here is the required gas flow with the required pressure. This takes into account the operating mode with probable peak loads. All these indicators determine the minimum volume of the receiver capable of ensuring a stable supply of air.

How to choose a receiver for a compressor that you already have? Use special tables or calculation calculators.

On a note! Simplified methods are based on averaged experimental data. It is believed that the cylinder for a compressor cannot be less than the volume of gas produced by it in 8 seconds of operation at normal loads.

An alternative option for selecting capacitive equipment is based on compressor power. It gives the simplest dependency:

- 5 kW – up to 100 l;

- 10 kW – up to 300 l;

- 20 kW – up to 550 l.

All other values are obtained by interpolation.

Stationary receivers

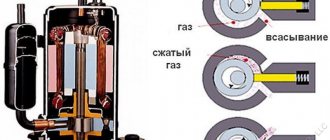

In the first case, the receiver is a separate sealed tank, for which a special stand or legs are provided (Figure 1).

Such models are placed on a pre-prepared base, most often a concrete floor or slab. The base must be level and strong to withstand weight pressure and possible vibrations. Stationary receivers are used in enterprises where the production of compressed air is required on an ongoing basis.

Why do you need a receiver in a compressor?

The receiver included in the supercharger provides a solution to several complex problems, in particular:

- Guarantees stable pressure of the working medium transported to consumers.

- Provides gas transportation at a time when the compressor begins to operate intermittently, or an additional consumer is connected to the air supply system.

- Cleaning the compressed air mixture from accumulated moisture.

- The accumulation of gas in this container leads to a decrease in vibrations in the compressor. This in turn reduces the level of force loads affecting the foundation.

- To carry out work that involves producing a large amount of gas normally, the installed vessel may not be enough, so instead of purchasing and installing a stronger compressor, an additional tank is installed on the old compressor.

- The receiver ensures that the compressor is turned on at a certain frequency, and this leads to a decrease in electrical energy consumption.

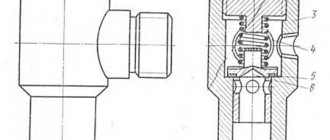

Filters are installed on them, which purify the gas from moisture; in addition, the design of the receiver includes condensate drains and shut-off valves. It is used to connect the compressor to consumers.

For the manufacture of receivers, corrosion-resistant steels 10HSND or 16GA2F are used, meanwhile, in rare cases, polymers or high-strength elastomers are used for low-power units.

Manufacturers produce two types of containers - horizontal and vertical. The first version is used for mobile type compressors, the second version is used for stationary compressors.

Each of the versions has its own advantages and disadvantages. For example, in a vertical design it is easier to drain water, while horizontal ones are more compact in size and require shorter pipelines.

Mobile receivers

If the room area is limited, or compressed air is required at remote sites, in such cases, mobile compressor units with a built-in air collector are used (Figure 2).

In this case, the receiver on the trolley is located in a horizontal position, together with the piston compressor on top.

There are other design features. So, there are receivers:

- Vertical design.

Vertical air collectors are most often stationary models, the installation of which significantly saves space in a cramped room, especially if several receivers are connected to the compressor. Due to their vertical arrangement, condensate is removed from the bottom of the tank faster and more fully. However, the vertical location of the receiver requires a sufficient height of the premises where it will be used. - Horizontal receivers

allow you to place an electric motor, pump and auxiliary equipment (in case these are mobile units). Such models have compact dimensions and less weight than vertical ones, so they can be installed on a chassis and transported to the desired location. A characteristic feature of this arrangement is the minimum length of connecting pipelines and maximum resistance to external influences.

Do-it-yourself additional receiver for a compressor

Some work performed in a home workshop or garage requires compressed air. And a situation may arise when a household compressor cannot cope with the task. In this case, the situation can be resolved by installing an auxiliary receiver on the existing unit. This device can either be purchased at a specialized store, for example, car spare parts. There you can buy a receiver for the KAMAZ pneumatic system, or make it yourself.

Most of the receivers offered are made for a specific model and are distinguished by a high price. Depending on the planned size of the DIY container, you can use either a propane cylinder or a fire extinguisher body.

3Main criteria for choosing a receiver for a compressor installation

Based on the foregoing, the main criteria when choosing the desired model of air collector for an enterprise’s pneumatic network will be the following parameters:

- Internal volume. There are models of receivers with a volume from 5 liters (household models) to 2000 or more liters (industrial use). When selecting equipment, you should use the calculation methods according to the formula given above, or compare the volume of the receiver with the power of the compressor. On average, the receiver volume should be 30-50 percent of the compressor capacity.

- Receiver design (horizontal, vertical) and installation type (stationary or mobile model with compressor).

- Operating pressure. For enterprises where compressed air is used periodically, it will be sufficient to purchase a receiver for storing compressed air under pressure up to 10 bar. For industrial use, you should select models that can withstand 15 bar or more.

- Bandwidth. This parameter determines how many liters of the working medium the air collector passes through itself in a certain period of time (most often it is measured in liters/per 1 minute). The higher the need for compressed air at an enterprise, the greater the throughput capacity of the receiver should be. To increase the throughput of vertical receivers in the pneumatic network, a parallel arrangement is used.

Price on request

Request CP

Write by email

We offer receivers with pressures of 10-16-40 bar and tank volumes from 3 to 900 liters. Receivers with a volume of 250-500-900 liters are always available. Go to section >>>

Selection of an air receiver for a compressor.

Capacity, l/min

Specify the compressor capacity. The interval can be from 100 to 100,000 liters per minute.

Air temperature at the compressor inlet, °C

This is usually the ambient temperature

Air temperature at the compressor outlet, °C

For screw ones, the outlet temperature will be from 30°C to 45°C. For piston compressors usually from 70°C to 90°C

Compressor power, kW

Enter power from 4 to 315 kW

Calculate

Reset

= 0 (l)

We recommend watching:

If you want to get the most complete information about air receivers and are ready to plunge into the boundless abyss of the Internet for this, wait, let’s try to save your time. Especially for you, we have prepared two videos about air collectors, in which we cover in detail all the topics related to receivers (first video). We also talk about how to correctly calculate the required receiver volume for a compressor (second video).

The air receiver is one of the most important elements in any pneumatic network. The main characteristics of the air collector are its volume and the maximum permissible compressed air pressure. As a rule, the volume ranges from 20 liters to 50 cubic meters, and the pressure from 10 to 50 atmospheres. The air receiver is installed after the compressor primarily in order to “facilitate” its operation, reducing the number of transition modes (such as turning on, turning off, going to idle), since it is during frequent transitions of the compressor from one state to another that the greatest number of breakdowns. Screw compressors of medium and high power in this case are the most vulnerable. That is why the correct calculation of the required volume of the air receiver and its subsequent installation ensures stable operation of the air compressor and extends the service life of the latter. So, how to correctly calculate the volume of the air receiver for a single compressor? We offer two options. — First method: Simple. One third of compressor capacity. Manufacturers of compressor equipment usually recommend installing an air receiver in compressor data sheets, the volume of which is equal to a third of the compressor’s capacity. That is, if our compressor produces 3000 liters per minute, then a receiver with a volume of one cubic meter should be enough. It should be noted that this is a rather crude method of selecting a receiver, which does not take into account the maximum compressed air pressure, air temperature, or compressor power. — Second way: Beautiful and scientific. This option for calculating the volume of the receiver is the most preferable, since in this case all the necessary parameters of both the compressor and compressed air are taken into account. Below is a formula that allows you to quite accurately determine what the volume of the air collector should be.

Example. If we have a screw compressor with a capacity of 6 cubic meters per minute (power about 37 kW), then we will need the following: - Convert cubic meters to liters per second. We get a productivity of 100 liters per second. — Let’s take the standard maximum temperature at the outlet of the compressor: +40°C, convert it to Kelvin, and get 313K. — The maximum cycle frequency is the maximum number of times the compressor is turned on and off per minute. It is recommended to select this value depending on the compressor power. Table 1 is provided to help.

| power, kWt | Stop/start, h-1 |

| 4 — 7.5 | 1 / 40 |

| 11 — 22 | 1 / 35 |

| 30 — 55 | 1 / 30 |

| 65 — 90 | 1 / 25 |

| 110 — 160 | 1 / 20 |

| 200 — 250 | 1 / 15 |

— Pressure difference is the minimum and maximum pressure of compressed air in the receiver. For example, the compressor should turn off at an air pressure in the receiver of 8 bar, and turn on at a pressure of 7.5 bar. The difference is 0.5 bar. — The air temperature at the compressor inlet is usually +30°C. Convert to Kelvin and get 303K. Now we substitute all these values into the formula

and we get the answer: 1550 liters. This means that for a 6cc compressor with a maximum air pressure of 8 bar, an air receiver with a volume of 1500 liters will be sufficient.

4What happens if you choose the wrong receiver?

If the receiver parameters are incorrectly selected (volume, throughput, pressure), the following situations may arise in the pneumatic system:

- Increased load on the compressor, dryer and other equipment

- Emergency compressor shutdown. The situation arises when the on and off modes are frequently changed, as well as due to the use of a smaller receiver.

- The appearance of loads on the electrical network, and as a result - short circuits, power surges and increased electricity consumption. The situation arises due to frequent mode switching.

- Reduced pressure in the line. Occurs when the maximum permissible consumption of compressed air is reached and the production equipment is simultaneously connected to the power grid.

- Long-term operation of the compressor at increased loads. Occurs because the receiver volume is too large as the compressor continues to produce compressed air to fill the tank. In this case, premature wear of couplings, bearings, seals and other parts occurs, and as a result, overheating of the compressor unit.

Determining the volume of the compressed air receiver

When equipping a production enterprise with compressor equipment, the correct selection of all components, especially such as a receiver, dryer, and filters, is important. Incorrectly selected system elements lead to large pressure losses, condensate reaching the consumer, and increased energy consumption. In this article we will pay attention to the question of how to choose an air receiver and methods for determining the required volume.

First of all, we will explain what an air collector is and why it is needed. Modern air collectors are a container that serves to store a supply of compressed air; they are usually cylindrical in shape. The second important function is to smooth out pulsations, since the air from the compressor flows unevenly. Depending on the method of placement, they can be either vertical or horizontal. The choice of volume is varied from several liters to several tens of cubic meters, while the range of operating pressures is also quite wide. As a rule, all receivers are equipped with a pressure gauge and a safety valve. Depending on the area of use, either painted or galvanized receivers are used. Some manufacturers provide a special viewing window, which is used to inspect the internal surface and clean it from contamination.

The choice of compressed air receiver is determined by the type of compressor installed and its characteristics (performance, pressure). It should be noted that for piston and screw machines the calculations are somewhat different. Quite often there is advice that the required volume is equal to 1/3 of the machine’s productivity, which is suitable for screw-type machines. For piston units, it is better to use a universal calculation formula or special online receiver volume calculators.

Formula for piston compressor:

Vres = (Veff x p(a)) / (4 x Zs x ∆p)

where: Vres – receiver volume Vef – flow rate (m³/hour) Zs – number of compressor starts ∆p – pressure drop (bar)

Formula for screw compressor: