Types of screw mechanical jacks

There are many types of lifting devices for cars, the most popular is the diamond screw jack. A screw jack, the price of which is at an average level, is the most stable and compact.

Car jack

The main advantages are:

- The car is lifted along a vertical plane, without pushing in different directions.

- If the maximum permissible loads are observed, it is durable and does not break.

- It is characterized by increased stability.

- Repairable, folds compactly.

Repair of this type of mechanism occurs without difficulty; the screw part often fails, which can be replaced with a screw-type construction pin. If you have the necessary plumbing skills, it is enough to cut the stud in accordance with the size of the jack and weld a nut on the fastening side. It is possible to make the device yourself, but the time spent is not worth the savings, because the price of a screw mechanical jack starts from 400 rubles.

Mechanical jack

The mechanical jack of the lever-screw type is reliable during operation, thanks to the smallest number of moving elements. The price of such a device on the market is not high, but there are a number of disadvantages. The stability of the device is not at a high level; when lifted, it pushes the car body away from itself. Increased effort is required to lift equipment with such a device, which is not very convenient for women, as well as for long-term work.

In the domestic automobile industry, vertical screw jacks have been used for a long time. The design features a long stroke and smooth force applied to the handle. The lifting height, sufficient for any type of work, made the unit attractive to car enthusiasts.

Vertical screw jacks

Rack-mount screw mechanisms are used less and less due to the high cost and specific purpose of the work. They require the object to be lifted to have special holes for guides. If installed incorrectly, it is easy to damage the car's paintwork.

Bottle devices differ from competitors in having a greater load capacity. There are varieties that can lift up to 5 tons; this solution will help owners of SUVs or minibuses. The design consists of persistent threads with impressive internal elements, which allows you to not worry about durability. The price of the device is high, which makes it difficult to choose between a conventional design; such jacks will help for construction purposes and other purposes.

Bottle jacks

In households, special screw construction jacks are used, which allow you to hold the load at a certain height. Under conditions of frequent use and a larger mass of objects, an electric jack, also of a screw configuration, is used.

Purpose of mechanical screw diamond jack

A mechanical screw jack is a device whose design contains a lifting mechanism with a rotational movement. During work, the device is directly under the load; lifting does not require the use of fastening belts, cables or chains.

Purpose of the hand-held device

Depending on the design features of the device, a screw mechanical jack is used in different areas of business:

- At a service station for car maintenance and repair.

- When laying piping systems in a trench.

- When working with a large load.

- When installing or replacing elements of supporting structures, etc.

A device for lifting heavy objects, or a screw mechanical jack, is produced in several versions, among which the vertical and rack are considered the cheapest.

The devices contain a screw, a steel body and a handle; manipulation of a load weighing up to 1000 kg is carried out by moving the handle. The lever rack-and-screw mechanism is made of special steel in single-screw and double-screw versions, its load capacity is about 3000 kg.

Operating principle of the device

The working cycle of screw lifting mechanisms is to move the screw through a wheel with a worm gear. The lever rotational movement of the working units is converted into a translational movement up/down and holds the load at a height. The safety of operation of a screw mechanical jack is ensured by an automatic static and dynamic locking and braking system.

Screw jack device

Screw jacks are a simple design capable of lifting large masses of loads. The operating principle consists of converting torque into translational movement; the main structure consists of a screw, nut and gearbox.

A device with a loose nut must be used with extreme caution and monitor the level and quantity of its lubricant. Failure to comply with the maximum loads can damage the screw mechanism.

Increased safety during work is achieved by the presence of a self-braking function.

The device of a car screw jack

The gearbox transmits torque to the support nut, where it lifts the load. There is a more modified screw jack device, where lifting rollers are added to the screws and nuts. Modernization is carried out to improve service life, reduce the coefficient of friction for easier lifting of the car.

Vertical devices

The design of vertical screw jacks was developed 30 years ago, and since then it has remained virtually unchanged. The main structural elements of the devices are the screw and the steel housing. Load capacity - up to 1 ton.

Main advantages:

- Insignificant force applied to the handle.

- Large working stroke.

- Load stability.

- High lifting height.

- Low cost.

- Small mass.

Minuses:

- Small support area, low stability.

- Can only be used for lifting vehicles with special lugs.

- Large dimensions.

To avoid “undermining,” experienced car enthusiasts advise additionally placing logs, bricks, etc. under the body of a raised car.

Rack-mount mechanical

Rack-and-screw structures are available with one or two screws and can lift loads weighing up to 3 tons. The operating principle of single-screw devices is the same as that of vertical ones. In twin-screw jacks, the role of the support nut is played by the housing. A second screw with a large thread is screwed into the first screw with a large diameter. When the handle rotates, a screw of a larger circle is brought out, from which a screw with a smaller diameter emerges, due to which the lifting height increases.

Rack-mount screw structures are stable and have a rigid frame. The disadvantages include high weight, and for jacks with one screw - a relatively low lifting height.

Lever-screw

Multifunctional devices used to lift vehicles weighing up to a ton. The main elements are the screw, lower and upper arms. The upper lever has a nut and a catch, the lower one has a support platform and a screw stop. The angle between the lever with a pick-up and the lever with a platform is changed by rotating the handle.

Advantages of the devices:

- Relatively small mass.

- Large working stroke.

- Low starting height.

The disadvantages include low structural rigidity and poor stability.

Screw jacks have a rigid structure and a large support surface; they are universal in use. The disadvantage is the small working stroke.

Diamond jacks

Using screw mechanical rhombic devices, machines weighing up to 2 tons are lifted. The load-bearing component kit includes four levers connected by hinges, which are arranged in a diamond shape. Lowering and raising are carried out by changing the angles of the diamond.

The drive of rhombic mechanisms can be:

- mechanical;

- hydraulic;

- electrical;

- manual.

Using these devices, you can lift a load weighing up to 1.5 tons. The design is small in size, reliable, and allows you to lift loads to a considerable height.

The disadvantage is the rather high price. Combined lever-screw products are a kind of combination of a rhombic and lever jack. They are oversized and have a low starting height. The disadvantages are low stability and insufficient rigidity.

The described types can be classified as devices for use mainly in everyday life. Each variety is represented by models of different power. Thus, the screw mechanism, which is used in construction, has large dimensions and can lift very heavy weight.

Main features of a rack and pinion jack

The list of works performed by jacks can be listed endlessly. The rack and pinion design mechanism stands out from its competitors, which is useful in conditions remote from service when repairing a car.

Rack jack

Rack jack device

The design of the mechanism has increased dimensions; it can hardly fit into the trunk of a passenger vehicle. The technical characteristics and features of the rack jack correspond to the dimensions; the design allows you to lift a load weighing up to two tons to a height of more than 70 centimeters. The mechanism is also used in the form of a winch in rural areas; if you correctly adapt the device, it will help rescue the car from difficult conditions.

Hydraulic jacks

A common type of hydraulic jacks are bottle jacks. The main differences are in dimensions and working load capacity. The larger the jack body, the higher its characteristics and ability to lift loads, and, accordingly, the price. Durability and stability make this type of lifting equipment the most used in car repair shops. The design provides a safety valve that does not allow work to continue if the object weight exceeds 25% of the declared one.

Hydraulic jack and its structure

Repairing hydraulic devices is a simple process in which the main thing is to replace the seals and replenish the fluid level. The disadvantage is the increased initial height, heavy weight, and the ability to work only in a vertical position. A type of hydraulic device is a rolling one, which can often be found in auto repair shops.

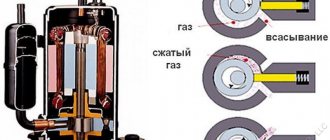

Pneumatic jacks

Pneumatic jacks are also considered a common type of rolling jacks, often used in large auto repair shops. The device consists of a pneumatic cushion that is inflated with compressed air. Inflatable lifting devices are made independently using a tube from a truck, together with a ball valve to gradually release the air.

Pneumatic jack device

For ordinary car owners, a type of pneumatic design is used that can be inflated from a hand pump or exhaust pipe. Such a mechanism will easily lift even the heaviest car to a height of more than half a meter and allow you to replace a wheel or diagnose the chassis.

The best device model

In addition to the vertical and rack-mount devices, models of rhombic and lever-screw type devices are available for sale. Before you find out which 2t diamond jack is better, you need to study the design and technical characteristics of the mechanisms.

The lifting device consists of 4 levers and hinges connected in a diamond shape and can withstand loads of up to 2000 kg. A mechanical jack performs manipulations by changing the angle of the hinge joints.

The advantage of rhombic-type lifts is the presence of a support platform in the upper part of the base; the disadvantages of a manual device include the small stroke of the working elements and the high cost of the product. Rhombic types of jacks lift the load along the entire perimeter of the base of the object due to a power screw and two levers, one of which has a clamp and a nut, the other is equipped with a screw stop and a support platform.

Application of screw type jacks

The scope of application of screw-type mechanisms may vary depending on the type of work and purpose. A varied selection of mechanisms according to their characteristics allows the design to be used in various processes:

- Installation and dismantling of car wheels.

- Maintenance and diagnostics of machines.

- Compression of springs and related mechanisms.

- Laying pipes.

- Lifting loads to the required height and moving them.

Lifting system based on jacks

Screw jack as an adjustable shrinkage compensator

Screw-type lifting devices began to be used for lifting loads about two thousand years ago. At that time, the device featured a minimal number of parts in its design, but worked more efficiently than a lever. The main purpose of screw devices is to replace a broken wheel and provide car service. A screw jack is included in every motorist's kit.

Types and features of automobile horizontal jacks

Today, almost every motorist has a threaded pit jack, which can be used to greatly facilitate the process of repairing a vehicle.

Example of a car jack

There are several types of lifting mechanisms, namely:

- pneumatic;

- hydraulic;

- screw;

- wedge jack.

In order to carry out car repair work, as well as install loads from above and below, screw lifts, a paw and a rotating heel are used. As for the lifting capacity of such a device, it is 10-15 tons, and the unit itself looks like a cylinder with one or more lifting screws that can be pushed in or out - it all depends on the direction in which the gear nut rotates.

Each type of mini-jack has a number of advantages. For example, a screw lift has the greatest reliability during use due to the fact that the load is fixed using a thread, and the nut rotates idle. Significant advantages are also represented by strength, stability and the ability to operate without the use of auxiliary equipment.

Note! The combined lever-screw device has several advantages - low cost, low weight, compact dimensions and impressive lifting height. As for the disadvantages of such lifts, they are represented by a drive handle, which causes inconvenience, as well as poor stability.

Lever-screw jack. Dismantling, installation, construction and repair work almost always cannot be done without the use of rack jacks

The main types of such devices are represented by lever and gear structures that move the rack. In a rack and pinion lift, the drive arm is replaced by a gear, which is driven by a handle. In order to hold the load for a certain time, a ratchet is installed on the axle along with the gears

Dismantling, installation, construction and repair work almost always cannot be done without the use of rack jacks. The main types of such devices are represented by lever and gear structures that move the rack. In a rack and pinion lift, the drive arm is replaced by a gear, which is driven by a handle. In order to hold the load for a certain time, a ratchet is installed on the axle along with the gears.

Note! You can find a tension jack on sale. Despite the name, it is not related to lifting loads; its purpose is to screw and unscrew nuts with a calibrated force.

How to choose a screw jack

The choice of jack is made for each type of specific work. It is necessary to accurately determine whether it is possible to use a manual mechanism, or whether it is necessary to use an electric drive. Manual devices do not require preliminary calculations; when working with electromechanical devices, the mass of loads lifted by a jack is accurately measured. The calculation is made to calculate the power of the structure, taking into account the factors of maximum lifting height, working stroke and initial height. Hydraulic mechanisms will require calculation of the force exerted on the handle and the power of the electric motor.

Basic requirements for mechanisms:

- The load capacity is selected according to the type of car; if the design is used as a universal device, it is important to pay attention to more powerful models.

- The lifting height varies, so it’s worth looking at the numbers; the higher, the better.

- The presence of special grooves or cells for lifting on a car requires the use of a device of the appropriate type, otherwise stability is lost.

The most popular type of lifting equipment is mechanical screw designs, which are characterized by low cost and ease of operation. The rhombic type of mechanisms comes complete with almost every modern car, but there are times when you have to select a device for certain jobs.

When purchasing a jack, you should refer to the technical documentation of the car, where the curb weight is precisely indicated. A power reserve is necessary, but you should not be overly insured, because... more lifting devices have increased weight and dimensions.

Types and design of jacks

A jack is a special device that is used to lift and hold various types of loads. Unlike other similar lifting devices (hoist, winch), the jack is located at the bottom of the load, and no additional structures, chains or ropes are required for the operation of the device.

First of all, the use of jacks is related to the repair of motor vehicles (the most common option is when you need to change a wheel). At the same time, such equipment can be used to work with any other objects. This is especially true when you need to get unobstructed access to the bottom of the load.

The modern market offers a large selection of such equipment. We will talk about the types of jacks and their purpose now.

Types of jacks with photos

If we talk about the main types of jacks, then the following are distinguished:

- rack and pinion;

- hydraulic;

- screw.

There are also other varieties, but these three are the most popular.

Features and types of rack jacks

If we talk about rack-type jacks, then the key load-bearing element in them is the gear rack. A ratchet mechanism moves along it, to which a folding catch is attached. The presence of a switch allows you to change the direction of movement.

It is worth noting: The key feature of such models is that they are capable of lifting loads to a fairly large height. For example, the HI JACK 3T-1350MM model has a rack travel of 135 cm.

Load capacity may vary. Mostly, such equipment is designed to work with objects weighing 3-5 tons. At the same time, there are models capable of handling fairly large cargo (up to 20 tons). The latest models have found wide application in servicing railway transport.

Among the main advantages of such equipment are:

- large working stroke;

- maximum lift height;

- simplicity of design.

It is thanks to this that mechanical type rack and pinion jacks have gained the greatest popularity these days.

At the same time, they are not without some disadvantages. First of all, it is necessary to emphasize their rather large dimensions and significant weight.

Types of hydraulic jacks

If we talk about the types of jacks, then, undoubtedly, the most powerful of them are hydraulic (based on the characteristics of their shape, they are also called bottle-type hydraulic jacks). Such models can easily work with objects weighing 20, 25 and even 50 tons. And this is not the limit. For example, the hydraulic jack DG-100, PRO JACK is excellent for lifting loads of 100 tons.

As a result, this determines the scope of their use: hydraulic jacks of various types are widely used during the repair of trucks and other heavy equipment.

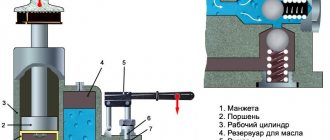

Such equipment consists of such basic elements as a housing, a retractable piston (plunger) and working fluid. The diagram of a bottle-type hydraulic jack looks like this:

In this case, the housing serves two purposes at once: as a guide cylinder for the plunger, as well as an oil reservoir. The piston contains a screw with a lifting foot, so that by turning the screw you can increase the maximum lift height.

The design of a bottle jack, a bottle jack, assumes that the force is transmitted from the drive handle through the lever to the pump. During the upward movement, the liquid flows into the pump cavity and pushes out the plunger (does not flow back thanks to the valves). To lower the load, unscrew the shut-off needle, then the liquid will return to the reservoir.

Among the main types are:

- single plunger;

- multi-plunger.

It is worth noting: Despite its fairly high reliability, such equipment is very demanding. It is necessary to constantly pour oil into the bottle-type jack and check the tightness of the seals. In addition, the device can only be stored in a vertical position.

In addition, it is not recommended to repair a bottle-type jack with your own hands due to the complexity of the design. It is better to seek help from professional specialists who have the appropriate certificates (you can view the documentation on the website).

The main advantages of the model include:

- high structural rigidity;

- good stability indicators;

- maximum load capacity;

- little effort when handling loads.

The disadvantages of a bottle-type jack include a fairly substantial cost and a large initial lifting height.

Rolling jacks

Such devices are used mainly in garages or car repair shops. If you use rolling jacks directly on the road, there is a high probability of equipment breakdown. They are modified hydraulic jacks (featuring a low steel body with small wheels). The handle with the lifting heel is extended by a piston.

DIY screw jack

Assembling a screw jack with your own hands is cost-effective if you save on budget or have specific operating conditions. Self-production will cost less than a ready-made version if you have basic plumbing experience, guided by certain schemes.

For manufacturing you will need several rack pipes, a sheet of metal 4-6 mm thick, and a mechanical rod. The pipes are welded in parallel, the base and top are fastened with a piece of metal. Then a nut is welded and connected to a rod at the bottom of the future jack. Next, you need to complete the structure by attaching fastening mechanisms and a handle.

When making lifting devices yourself, it is important to be guided by the purpose of the mechanism. For basic wheel replacement, a compact screw-type device is suitable, which can easily fit in the trunk of a car.

Correct installation is associated with safe work; the process must be monitored to avoid injury or property damage. When working, it is possible to use a static stand as the main support, for example a large stump.