An engine breather (breathing valve) is a device for equalizing the pressure in a closed container relative to atmospheric pressure. In other words, the breather valve allows the closed container to communicate with the atmosphere. In internal combustion engines, the breather equalizes the pressure inside the engine crankcase.

During the operation of the vehicle and the operation of the power unit, the pressure in the crankcase may increase, as a result of which crankcase gases escape through the breather, excess engine oil is squeezed out, etc. If the pressure in the engine crankcase is below atmospheric pressure, then outside air enters the crankcase through the breather, thereby eliminating the difference between external atmospheric and internal pressure in the crankcase cavity.

Purpose

What is an engine breather? Before answering this question, it is important to understand what it is intended for. This is directly related to the principle of its operation. The main task of this device is to reduce the pressure in the engine crankcase. When the power unit operates, various gases collect in the crankcase. Gradually they accumulate and create quite a lot of pressure. If you do not bleed them, the engine may stop, the pressure will back up the pistons.

In this case, the gas will seek an exit through any available hole. To prevent this from happening, a breather is installed. This device is also used to ventilate the crankcase. Unnecessary gases are removed from it. Thus, the temperature inside the engine is slightly reduced. The engine breather has two tasks: ventilation and releasing excess pressure. In some cases, the operation of the breather can indicate the presence of problems in the engine. If the rings are stuck or the piston is damaged, gray smoke characteristic of the exhaust will fly out of the hose. This way you can diagnose these faults without disassembling the engine. In normal condition, a slightly noticeable transparent smoke comes out of the breather.

Communities › Do It Yourself › Blog › Modification of the compressor zil.

Hello comrades!

The topic is not new, but it may be useful to someone. Modification of the compressor zil. There was a need for a compressor in the garage. I've encountered several times already that I need compressed air. Running to your neighbor is also not a good idea.

In the store, a compressor with a 50-liter receiver of average quality costs about 30 thousand rubles. Honestly, it’s a pity to give so much money.

I decided to do it myself. The search for the necessary components began.

A week ago I received a ZIL compressor unit. Over the weekend I took it apart partially.

I took out the connecting rod and piston and took them apart.

When operating on a ZIL engine, the compressor is flushed from the engine lubrication system by supplying oil under pressure to the compressor elbows. We don’t have pressure, but we need lubrication. We do the following: in the upper part of the connecting rod, together with the liners, we drill 2 holes of 4 mm each and make a countersunk hole of 10 mm. We also drill 1 hole in the connecting rod cover.

These holes will give us lubrication without pressure. As the connecting rod moves, oil enters the chamber and lubricates the crankshaft. Do the same with the second connecting rod. And we put everything back in place.

Next, lubricate the head with sealant and close it.

The next stage is the oil filler hole in the compressor crankcase and the breather outlet. To do this, I drilled a hole with an M10 thread for filling oil and next to it a hole with an M16 thread and screwed in a fitting for the hose.

As a breather, I installed a classic tank on top of the head. I made a bracket out of a tin can. And he brought it up with a rubber hose.

After the sealant had dried, oil was poured into the crankcase. Filled through the breather. It is more comfortable. Well, that's all. Thank you for your attention.

Comments 111

I did the same last year, the flight was normal www.drive2.ru/b/2446979/

Good stuff. In Chermert I once picked up a good compressor from MAZ for 600 rubles, they just don’t throw it away... a working compressor, put it aside until better times.

Isn't cooling required?

its operating temperature is about 70-80 degrees.

Otherwise you need half an hour of work and it just jams

Isn't cooling required?

requires. The head has channels for liquid cooling. connected the water tank. per hour of compressor operation - water boils in the tank)

At our base, such a compressor worked for 20 years. And they painted paints, halls and lawns, plus they had their own tire service and it was without any cooling and no one had ever even disassembled it. As a result, the office no longer exists, but that compressor seems to still be working for someone else.

Attach an O5 sheet to the connecting rods, a scoop for catching oil and give a slot with a small grinder along the crankshaft, I have it like this

What's wrong with the engine? What about the receiver?

The receiver will be 100 liters from the fire extinguisher. Still looking for the engine.

Dad has the same one in his garage. The father is thinking of throwing it away. Should I take the second one (for small things) to take home?

One hole in the body is redundant, you remove the back cover, remove the valve and hang the hose with the reservoir on the corner, and the breather is ready.

Agree. It's easier to remove the valve. But I didn't do this.

One hole in the body is redundant, you remove the back cover, remove the valve and hang the hose with the reservoir on the corner, and the breather is ready.

the breather must be above the oil level, otherwise it will simply fly out of the block

That's why I made a separate hole for the breather at the highest point. And also a control hole.

did it right

the breather must be above the oil level, otherwise it will simply fly out of the block

The air will come out where it is easier, that is, into the breather and nothing will happen

if it is made separately then yes, otherwise oil will jump out through the factory valve

www.drive2.ru/c/1647677/ Oil does not jump))) Now Zilovsky has already installed

It’s cool, I’m perverted in a different way, I did everything like you took it from the net, and additionally added a pump for coercion. The pump from the vacuum cleaner is powered by an electric magnet, it takes enough oil from the sump-sump to drive it back into the crankcase and lubricate the crankshaft, there is one or more problems - the performance is low, and the oil is driven out. although everything has been changed, both the rings and the liners.

The pump is good, but I don't have one.

OK. Thank you. I also thought about automation, but first I need to do the basics. I will install automatics last.

There will be questions about automation, just ask, I ate an elephant on this, and there was no one to ask, simple electricians helped.

There are already questions. Firstly, what kind of coupling should be welded into the receiver to screw the pressure switch into it.

I took the simple route. The compressor itself stands in a hole in the garage, and the receiver and automation are at hand. So I installed all the automation on the receiver. The fitting you need is the same as the one you will have on the pressure switch. One more tip: it is advisable to install a metal tube from the compressor to the receiver; the hoses will simply explode from overheating and pressure. In principle, if it doesn’t work for long, then the hose will come off, but in practice I know from myself that this is unlikely to end with this small one. if there is a working compressor.

I also had a three-way valve near the receiver, like a tank switch on a goat. This is to quickly pump the wheels. And while he pumps it into the receiver...

can you tell me how much oil is needed in it...otherwise I threw it into the same one, probably too much, and the oil seal was squeezed out from the pulley side)

300-400 grams are needed. And the oil seal was squeezed out most likely due to the fact that the breather was not made. When the compressor operates, pressure builds up in the crankcase, and if there is nowhere for it to escape, it presses on the oil seal.

oh...1.500 rpm. 3 sq. seems... so decent. but it works for me from 220V. I start it with a cord. I have 2 pulleys on it. I wind a rope around one and pull it... it starts right away... I have a report. here.

here's the beginning... now fully assembled and on wheels... www.drive2.ru/c/2286166/

Wow. This turns out to be stationary.

I’m making one for myself too, but I haven’t decided on the lubricant yet.

What kind of engine will it be?

so far 1.1 kW 1000 rpm, but it is weak, there is also 2.2 but I don’t know the rpm

1.1 will be rather weak. If only you try it at 380. And if from 220 volts then 2.2 kW will be the norm. And in terms of rpm you need about 3000.

380 is enough, but 380 is not. 2.2 would be enough for me and 1500

I’m making one for myself too, but I haven’t decided on the lubricant yet.

lubrication scooping system and slot on the crankshaft I’m so happy so far

How much oil should be poured into the crankcase?

About 300-400 grams

I did it a little differently. I welded a tray from a 4 mm sheet and made a gasket from paronite. I drilled the connecting rod caps and bearings from below. I cut a thread in the lids, screwed in a copper tube, bent it and sawed it off. A bent copper tube is needed so that the connecting rods themselves draw oil from the sump. And I also made an oil dipstick =)

Why do you need to clean the valve?

The external conditions created during the operation of the breather valve often lead to the accumulation of dust and dirt in it, which interfere with its normal functioning. Because of this, excess or, conversely, insufficient pressure occurs, leading to oil leakage. If situations arise when oil is thrown through the unit, first of all you should check whether it is clogged. To prevent oil from being thrown out, you need to remove the valve for cleaning or replacement. The breather should be replaced with a new one in cases where it is too contaminated, and before installing a new unit, it is recommended to thoroughly clean the place where it is installed, which will avoid rapid contamination again.

Breathers of other important components of the car also need to be cleaned in a timely manner to prevent car malfunctions. Important The breather is an important element that helps the car operate properly, but to prevent breakdowns it is recommended to clean or change it in a timely manner. A faulty valve can lead to various problems: risk of gearbox leakage; rapid wear of synchronizers and much more. Regular cleaning of the valve will help protect the oil from deterioration in its lubricating and protective properties, and therefore will extend the life of the iron horse for a long time.

Author:

Maxim Markov

Many novice motorists often hear the expression “engine breather,” but not everyone knows what it is and what it is needed for. This article will talk about what an engine breather is, its installation locations and its main purpose.

What is a breather and its main purpose?

Engine breather, what is it? In order to answer this question, you need to understand its purpose. A breather (breathing valve) is a device through which a closed container communicates with the atmosphere, thereby maintaining the required pressure. During the operation of the engine, various gases accumulate in it, and if they are not released in time, then the operation of the internal combustion engine may stop, and the breather is responsible for this. In other words, it maintains the required pressure inside the engine crankcase.

By itself, it performs the function of a valve, which, at increased pressure, bleeds air from the engine. In a car, this device is installed in the following places:

Now it’s worth considering the installation location in more detail.

Breather: description, purpose, cleaning, installation, photo, video.

There are different designs. Quote: Tramp from 31 Aug. Hello everyone, I guess I've already bothered you with my compressor.. Just returned from the garage.. Solved the problem of air etching from one of the heads..

I simply tightened the valve cover better and tighter...

Why do you need to clean the valve?

I also noticed one feature. When the compressor initially starts, it pumps 2 cylinders, that is, you put your hand on each cylinder and it sucks...

Upon reaching 4 atmospheres, one of the cylinders seems to cut off and does not suck in air at all, the compressor threshes on 1 cylinder and barely reaches 6 atmospheres. By the way, it cuts off the cylinder on which the piston was changed, the piston was installed from a KAMAZ compressor. Well, at the end of the work it strongly bleeds air from the filler hole..

The exhaust valve is stuck and does not fit tightly. On the one hand, it unloads before starting, but this is a mess. Quote: Mikh lych from 01 Sep. Quote: Electric from 01 Sep. Quote: uvl77 from 01 Sep.

In normal condition, a slightly noticeable transparent smoke comes out of the breather. Why do you need to clean the valve?

Breather installed in an internal combustion engine

Most often, the device is located next to the oil filler neck; a hose comes from the outlet pipe, which is connected to the air filter housing. Also, in addition to controlling the required pressure, the breather prevents the engine device from getting dirt and moisture into it. Due to the fact that oil constantly circulates through it, dirt and dust accumulate in it, so it is necessary to monitor its normal operation and clean it on time.

There is an expression “engine breather”, which manifests itself in the fact that exhaust-like smoke pours out of all open openings of the internal combustion engine, and at the same time, oil and fuel consumption increases. The main reasons for this malfunction may be:

- occurrence of piston rings;

- contamination of the ventilation system;

- malfunction of the cylinder-piston group.

The consequences that such a breakdown can lead to: rupture of the crankcase exhaust hose, rupture of the valve cover, breakdown of internal combustion engine parts (engine knocking), and there have also been cases when the pan was torn out.

In case of such breakdowns, we will immediately talk about expensive repairs, and sometimes you will even have to buy a new engine. By the way, today it is possible to buy a contract engine. This is a type of used internal combustion engine that was brought from abroad and has not been driven in our country.

Operation and repair of a piston compressor

A compressor is quite complex technical equipment; as it is used, it has the right to wear out and break. In this article we will consider all methods of maintenance and operation to maximize its life. Repair the compressor yourself

, if it is still broken, perhaps.

The reliability of compressor equipment largely depends on timely and high-quality maintenance. A large number of breakdowns of piston compressors are a consequence of poor quality cleaning of compressed air (abrasive dust, water, and other impurities). The use and timely replacement and cleaning of filter elements will delay compressor repairs for a long time.

The main reasons why an air piston compressor fails:

To ensure high-quality maintenance, operation and repair of the compressor with your own hands, it is necessary to solve all the above points.

The main difference between maintenance and repair of a compressor is that during repairs a forced replacement of certain parts is carried out, and during maintenance, parts are replaced as necessary, depending on their actual condition.

Operating principle and components

A compressor is a device for increasing pressure and moving gas to the required source (spray gun, grinders, impact wrenches, airbrushes and any other pneumatic equipment). The main equipment in demand in body repair has become a piston, oil-type compressor. In piston engines, the volume of the working chambers changes with the help of pistons that perform reciprocating motion.

They have different numbers of working cylinders and are distinguished by the following structural arrangement:

The main design flaws: incomplete balance of their moving parts, the presence of a large number of friction pairs, etc. All this causes failure and subsequent repairs.

Before you repair the compressor yourself, you need to study its technical structure. The photo below shows a diagram of a single-stage compressor, piston group.

On the housing near the electric motor there is an automation unit called a presostat. Using it you can adjust the compressor. It is possible to lower or increase the pumped pressure.

Reciprocating compressor malfunctions

If any defects are detected (knocks, jamming of rubbing parts, strong heating, increased consumption of lubricant, etc.), it is necessary to carry out repairs.

It is important to determine the type and scope of repairs at the stage of diagnosing the condition of the object before repair. Compressor malfunctions can be divided into two groups: technical malfunctions (working part, piston group and electrical equipment malfunctions). Below are the most common breakdowns:

Compressor (electric motor) does not start

The compressor does not turn on, the most common problem. The main and trivial thing that can happen in this breakdown is that there is no voltage in the network. The first thing you should check is the plug and wire supplying the electric motor for breaks. Using a special “tester screwdriver”, check whether voltage is supplied to all phases. Check the fuse if there is one. Make sure the starting capacitors are working (single-phase compressors have a voltage of 220V).

Pay attention to the pressure level in the tank (receiver). Perhaps the pressure is sufficient and the automation does not start the compressor; as soon as the pressure drops to a certain level, the electric motor will start automatically. This is not a breakdown; many people forget about this nuance and worry ahead of time.

The check valve can also become a problem if the compressor does not turn on. Also, a faulty automation unit (pressostat) affects the breakdown (on, off), the button on the unit itself may have become unusable.

If the electric motor does not start, hums, hums, does not gain the required speed, or stops during operation, this does not always mean it is broken.

Breather in gearbox

Why do you need a breather in the gearbox? Just like with an internal combustion engine, this device is designed to control the pressure in the unit. If the “breathing valve” is heavily contaminated, this will affect the operation of the gearbox, and as a result, the wear of bearings and synchronizers will increase. Also, if the valve is severely clogged, the pressure in the gearbox will increase, and as a result, oil will begin to leak through the seals.

Breather in bridges

There is also oil inside the axles connecting the wheels, and for their normal operation and maintaining optimal pressure, a breather is also provided. This mechanism acts as protection against dirt and moisture getting inside while the car is moving. If the valve is significantly clogged, the oil inside the bridge will leak. In order to prevent this, you should clean the breather and check that its cover moves in all directions.

Preventative work

Some motorists are wondering: why clean the breather? This is done in order to avoid problems with the operation of car components; it is necessary to clean the breather in a timely manner. Such actions will allow you to maintain the permissible pressure level, and as a result, stable and trouble-free operation of the car. It is recommended to carry out cleaning at every technical inspection (MOT), and in some cases even more often. The cleaning process itself looks like this:

- Removing the pipes and hose. All pipes and hoses coming from the “breathing valve” are removed; in some models you will also need to remove the air filter housing;

- removing the breather cover;

- cleaning work. Now you can begin cleaning the valve cap and tube.

- installation work. Assembly is carried out in reverse order.

This is how cleaning is done. The procedure is quite simple, and you can do it yourself with your own hands, without the need to visit a service center.

Based on all the above information, it is time to draw conclusions. The breather in a car engine plays an important role for its stable and normal operation. And in order to avoid problems with its operation, it is necessary to carry out preventive cleaning of accumulated oil in a timely manner. If this is done in a timely manner, then there will be no problems with the operation of the engine.

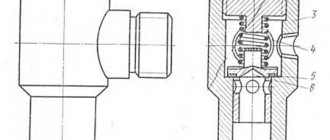

The claimed technical solution relates to the field of compressor engineering and is intended to remove gas leaks from the compressor. The compressor breather contains a housing closed at one end with a lid. It differs in that a glass is inserted inside the body, which is equipped with a damper. The technical result provided by the claimed technical solution is to ensure the durability of the device and ease of use. 1 n.s.p. and 4 salary files, 1 ill.

The claimed technical solution relates to the field of compressor engineering and is intended to remove gas leaks from the compressor.

Prior art.

There is a known breather, which is part of an internal combustion engine (USSR author's certificate for IZ 909247, F02B 37/00 F02B 39/14, 1982 [1]), which consists of a housing closed with a lid in which the packing is located.

The disadvantage of this analogue is the presence of packing in the breather. This is because the padding wears out quickly and requires constant monitoring and periodic tightening.

The specified analogue [1] is, in terms of the totality of essential features, the closest analogue of the same purpose to the claimed technical solution. Therefore, it is accepted as a prototype.

Disclosure of the proposed technical solution.

The technical result provided by the claimed technical solution is to ensure the durability of the device and ease of use.

The essence of the claimed technical solution is that the compressor breather contains a housing closed at one end with a lid. It differs in that a glass is inserted inside the body, which is equipped with a damper.

The above essence is a set of essential features of the claimed technical solution, ensuring the achievement of the declared technical result of “durability of the device and ease of use.”

Compressor breather

1. COMPRESSOR BREATHER, containing a cylindrical body with a cover and a coaxially located pipe with holes, around which a fibrous packing is placed, fixed between the annular ribs and installed between the stops, with one of the stops located on the body and the other on the pipe, from The main thing is that, in order to increase the service life of the packing, make it easier and faster to clean, the packing is made in the form of threads of the same length, and the holes in the pipe are made in the form of jagged cutouts located on the side housing cover 2. Breather according to item ^ The only difference is that the stop on the pipe is made in the form of a nut. 8 CO o el with 1 906592 2 all threads 9 are arranged in parallel. The invention relates to machines, forming figures in the form of a co-, structure and axial cylinders can be used. Upper ribs 6 in compressor construction. connected to each other by ties 10. A compressor compartment is known, the containing ribs 7 are also connected by a cylindrical tightening body with covers 10. The lower ribs 7 are pressed against the core and coaxially located upper stops in the form of a nut 11 on a nut with holes, around which there is a pipe 3. On the inner wall Fiber packing is placed, protrusions 12 are reinforced behind the body 1, the upper ribs are fixed between the annular ribs and are installed between the supports, against which the ra 6 rest. “where one of the supports is located on the body, and the other on the pipe LI]. The proposed device works. The disadvantages of the device are: as follows. insufficient efficiency in removing dust, the need for frequent oil changes, 15 When the compressor operates, gases from the crankcase are difficult to maintain and large, barites are knocked out through pipe 4. impulses outward, and air from the The purpose of the invention is to increase the sromosphere through the same pipe 4 ka of the packing service, to facilitate and accelerate its cleaning. 20 in the crankcase. In a dusty atmosphere, dust gets into the crankcase, and the compressed air is achieved because the debris quickly wears out. It is installed that the packing is made in the form of a thread on pipe 4, the breather retains the same length, and the holes in the pipe trap dust into soot. When the suction occurs, made in the form of toothed cutouts located on the side of the cover 25, the air passes through the lower ribs 7, then through the packing 8, the top. The stop on the pipe is made in the form of a rib 6, cutouts 5 and nuts along the pipe. to the compressor. Dust will settle on the packing. Fig. I shows the breather, vert8. When exhausted, soot moves into the scaling section; in fig. 2 - section A-A in Fig.I; in fig. 3 - view of the packing in the 30th direction and settles on the packing 8 in the area of the upper ribs 6, and during the cleaning period, in axonometry. accumulated in the area of the upper ribs 6, the Breather contains a cylindrical and accumulated in the area of the lower ribs housing 1 with a cover 2, R of which 7 dust is thrown down in a stream coaxial to the housing? gas attached. pipe 3, the second end of which is connected by a screw thread to pipe 4 35 of the compressor crankcase. In the place where the packing 8 becomes clogged with dust deposits, cleaning is carried out. connection to the cover, pipe 3 is made with To do this, the breather is removed from the pipe using through toothed cutouts 5. Between 4, nut II is screwed together and the lower pipe 3 and body 1, below the cutouts 5, the upper annular ribs 40 are placed, the ribs 7 are removed out together with the threads 9 in a stretched state (Fig.Z), 6 and lower ribs 7, between which, when they are extended and located in a fibrous packing 8, is located in the form of coaxial cylinders with backfill in the form of pieces of threads 9, rum between the rows. Dust accumulated in threads of the same length, fixed at the ends 45 9, spills through these gaps towards a pair of ribs - one upper one - and the threads are cleaned. Then there is one of the same size at the bottom, so the breather is assembled in the reverse order. that when the ribs are spread apart (Fig.Z) 906592 6 Fae i Editor S. Yurkovetskaya Order 2465/DSP Compiled by V. Lobanov Techred L. Iikesh Circulation 568 Proofreader E. Sirokhman Subscription VNIIPI of the USSR State Committee for Inventions and Discoveries 113035, Moscow, Zh-35, Raushskaya embankment. , 4/5 Branch of ShTP "Patent", Uzhgorod, st. Proyektnaya, 4 Divytisya