Ecology of consumption. Lifehack: Submersible pumps used to supply water from wells drilled on the site require periodic lifting...

Submersible pumps used to supply water from wells drilled on site require periodic lifting for preventive maintenance and minor repairs. Also, the rise of pumping equipment is also associated with the replacement of an outdated unit with a more powerful device.

However, the operation of removing a submersible pump from a well pipe is not always successful. It also happens that the pump gets stuck tightly in the pipe. Well owners who are faced with such a problem for the first time do not know how to remove the pump from the well without breaking the cable.

From simple to complex

For deep-well pumps that have a large diameter and short length, the connection of which is carried out via a flexible polyethylene hose, and these are most often vibration pumps, during lifting a situation may arise when the electric cable of the pump gets caught between the pump housing and the wall of the casing pipe.

Such pumps are most often lifted by a cable and a hose, but the cable, the entrance to the pump body, which is located below the level of the hose connection and the cable fastening, is simply tightened periodically. At the moment when the cable is most weakened and has excessive length, it fixes the rise of the entire structure. The small distance between the housing and the wall into which the cable enters becomes a big obstacle to removing the equipment to the surface.

In fact, this is the simplest of all possible cases of jamming during lifting. The problem here can be solved quite simply - just lower the pump a little into the well and at the same time tighten the cable. After tensioning the cable, continue lifting, ensuring the tension of all elements - hose, cable and cable.

When can a pump get stuck?

In most cases, well owners have problems removing pumping equipment that has already been working in the mine for some time.

Lifting a deep-well pump is necessary in the following cases:

- carrying out repair work;

- Maintenance;

- replacement with a more powerful or new pump;

- replacing the flush pump with a permanent one.

Much less often, the pump jams in the barrel when trying to lower it to the bottom of the well. The reasons for getting stuck in this case are, as a rule, a mismatch between the size of the pump and the diameter of the casing pipe or the entry of a foreign object into the column that interferes with the descent of the unit.

These two reasons can be easily eliminated: the size and model of the pump is selected before the descent begins, and a foreign object that has fallen into the casing is removed or pushed down.

To prevent the pump from getting stuck when lowering, it is necessary to observe safety measures: carefully inspect the unit and make sure that all its parts are in good condition, avoid getting foreign objects (stones, tools, packaging) into the pipe, use a reliable cable and clamps.

Using a surface pump instead of a deep one will avoid problems that arise when lowering and lifting equipment inside an aquifer well.

Broken cable

The situation when the cable breaks and the entire structure slides down happens quite often. Typically, a metal cable does not break, just the fixing elements loosen over time due to corrosion of the metal, the threads are not able to fix the fastening and the cable is released. For the metal of a steel rope or cable, alloys that are not subject to corrosion or structures that have an additional protective sheath of plastic are usually selected. But an ordinary steel cable, being constantly in a state of tension, can develop abrasions and active corrosion at the point of fixation, because the pump experiences vibration during operation, which is transmitted to the cable.

In this case, it is recommended to continue lifting if the well is shallow and the pump is light in weight, using a hose or pipe as the main lifting device. The upward feed should be smooth, without sudden interceptions or jerks. The use of a cable as a lifting element is unacceptable! With this method, it is necessary to prevent the pump from rotating around its axis, since if the pump jams, a pipe or hose may become disconnected, which will further aggravate the situation.

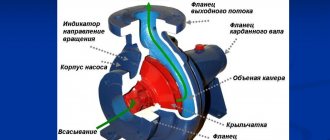

A broken pump at the bottom of the well is also not the best option for the job, but if the power cable is intact and still attached to the pump body, then the chances of lifting the equipment increase significantly. For centrifugal pumps, screw pumps and vibration models, the cable usually has an entry into the housing slightly below the outlet and almost at the level of the cable mounting holes.

For lifting, a device made from a piece of metal pipe and welded wire, on the one hand, and a lifting cable on the other, can be used here. The cable is threaded into the pipe to the bottom, with a wire welded and bent into a hook. The hook is lowered along the cable and, having reached the lowest point on the pump body, is inserted into the eyelet for the cable. This operation is somewhat similar to winter fishing, when the bait is slightly twitched to attract fish, and the lifting hook, with small up and down movements, should enter the eye and engage the pump.

Causes of jams and their elimination

Often, mine owners have problems with the process of lifting a pump that has worked for a certain period of time.

Occasionally, jamming occurs when lowering it down the shaft. So, the reasons for getting stuck can be:

- the difference in the size of the device, the diameter of the casing pipe;

- penetration of a foreign object interfering with immersion.

Very often the following reasons are recorded, which indicate that the device is jammed in the wellbore:

- saggy rope, electrical cable;

- the well silted up onto the sand;

- there are deposits on limestone in the mine;

- pipe walls are damaged;

- debris has entered;

- the instrument was distorted inside the casing;

- rope separation.

If the pump is stuck in the wellbore, then specialists with experience and the required equipment will help in this matter and can safely remove the stuck pump. But sometimes, it is possible to try to remove the unit yourself, identifying and eliminating the jam factor.

Cable slack when lifting

A common reason when a device gets stuck in a well is a sagging electrical cable that carries power through it. A direct sign of an accident is that when the device is removed from the wellbore, no upward movement occurs, even if force is applied. It is possible that both the electrical cable and debris may sag around the body.

If the pump is stuck in the wellbore due to a sagging cable, then the device must be carefully immersed, then pick up the weak area of the electric cable and try to lift it again. It is necessary to control the process, eliminating sagging of the cable, electrical cable and hose to which the unit is attached.

To eliminate such a case, the pump's electrical cable is attached to its hose using clamps, which require replacement the next time the device is pulled out.

When pulling the device out of the well, it is important that the hose and cable are lifted from the outside of the well together.

Silting a well onto sand

Excavations with a sand bottom become silted due to infrequent or incorrect use. This causes the equipment to become trapped in sludge. It is possible to pull out the device using alternating tension and lightening the cable. It is important to slowly rock it in different directions, so the device will be freed from layers of silt.

If the wells are not used for a long time, the sludge may harden, so before removing the unit from the mine, you need to wash it out first. You will need to take a fire hose that supplies water down the well. The sludge softening process takes 2-48 hours.

To check that the pump is free of sludge, you need to try to pull it out from time to time by rocking it. If you cannot remove the device, soaking the sludge should be continued.

The pump may become clogged with sludge if it has not been cleaned for a long time. Cleaning hydraulic equipment and well filters every year will prevent silting and jamming of the device.

Deposition in a limestone well

The device can also get stuck in limestone excavations due to long-standing mining activities. These wells do not silt up; the units get stuck in them due to the significant deepening of the body. As a result, there is a motionless, long-term retention of water in a circle.

Calcium and iron salts present in life-giving moisture combine with oxygen and settle. This sediment is characterized by increased density, accumulating both on the edge of the device and on the components of the pipeline systems it serves.

Cleaning a well when limestone sediment has formed in it is pointless, since such sediments have an increased density. The process of pulling out equipment is identical to that of a well stuck in sand. When manipulation is performed, it is recommended to turn on the hydraulic machine. This is necessary so that the formed limestone sediment pumped by the water is eroded in a short time.

Citric acid can also be used as a folk method. It is diluted in water and poured into the well. The action of acid causes the decomposition of salt deposits. This procedure is used only on pumps; subsequent use is not intended, since acids harm the mechanisms of the device inside.

Damage to casing walls

There are situations where the factor of a broken pump lies in the deformation of the casing due to the strong pressure of the soil.

When, when pulling the unit out of the well, a certain knocking sound with obstacles occurs, the reason is in the casing. Deformation is possible due to soil shift, defects or inadequate tightness of riveted seams.

The pump can be pulled out by rotating its housing.

Entry of foreign objects

Penetration of various debris into the well leads to jamming of the device. Applying serious persistence to lift stuck equipment can result in it falling into the well. When the pump falls down, it is impossible to pull it out. In this regard, it is advised to contact specialists who service and repair units.

Pump distortion inside the pipe

The factors for equipment curvature are as follows:

- the electric cable sagged;

- the cable intended for lifting was strongly pulled;

- lifting of a cable or hose, which resulted in an uneven position of the device.

To avoid an accident, you need to lighten the cord and lower the equipment to the bottom at the original point. Then pull it up again. The cable with cable and hoses must be at the same level; too much tension on one of them will lead to bending.

Broken lifting cable

To fix the problem, use the following options:

- Pull out the pump using a hose or cable, if there is no breakage.

- A hook is attached to the rope and the structure is hooked. While pulling out, correct the situation with the remaining cables.

- A hook is welded onto the edge of a metal rod, like a corkscrew.

- Then it is immersed, screwed into the body, and it is pulled out.

The disadvantage of the procedure is that the device will not be suitable for use.

How to remove the pump from the well if the cable breaks:

Siltation of the well

A well in clay soils or a sandy layer is most often susceptible to silting. The situation when soil gets through the drainage holes into the casing pipe and settles, preventing the equipment from being lifted, is most often typical for wells that have been maintained for a long time without maintenance.

For circulation or screw pumps, this is quite painful, since they have quite impressive dimensions, and the sludge does not just settle, but is tightly compacted between the pump body and the walls of the casing pipe. In this case, when it was not possible to pull out the pump the first time, it is necessary to apply the tactics of gradual release from the bottom sludge.

The pump is alternately raised and lowered, first by 5-10 mm, and then. When the dirt plug begins to become saturated with water and erode, gradually releasing the pump housing.

Options for clearing jams

A more than justified question for dacha owners who were initially faced with the question of how to get the pump out of the well? If an obvious factor of failure is reliably detected, it is possible to choose a more effective elimination option. There are a number of techniques on how to get a pump out of a well if it is stuck.

Lifting when the cable is slack

If there is no movement when lifting the device, even with increased effort, the problem is a sagging cable.

It is easy to lift stuck equipment; you should immerse it downwards and pick up the area where the cable is slack to free the housing from the loop. Carry out the process slowly, avoiding breaking the power cable and hanging the hose. To prevent freezes from happening again, the electrical cable is connected to the water hose and secured with clamps.

When pulling out the hose and cable, their output should be synchronous, this will prevent them from sagging.

Extraction when flooding the bottom

If the mine is heavily flooded, the unit is raised, smoothly rocking it from side to side. Thanks to such procedures, the sludge that has accumulated around the device is washed away with water in a short time.

To properly lift the pump from the excavation, jerking is not allowed, as they can jam or break the rope. It will take 15 minutes to remove the unit.

Extraction during reverse siltation of the bottom

When the installation deepens significantly, this leads to backfilling of the structure's shaft. Layering of salts in life-giving moisture is observed on the shell of the unit, inside on the walls of the casing, which leads to a decrease in the diameter of the device. Pulling in this case is not easy and dangerous.

Flushing the well with life-giving moisture will not bring success and will not get rid of lime deposits. To lift the equipment, it swings.

Pulling out a working device is done by:

- Lifting is carried out using the fastening rope until the casing string narrows.

- Dive to the initial distance, repeat the manipulation - taking out and immersing the device until the silt barrier is eliminated.

- Clean the shaft, periodically removing the equipment.

Lifting when casing is damaged

If there is strong soil pressure, poor quality installation materials are used when a well is being erected, the casing column and the tightness of the joints may malfunction. When the device gets stuck in the well, pulling is done using circular movements.

Entry of a foreign object between the casing and the casing

The problem of small stones, pieces of metal or fasteners getting into the cavity between the casing and the well wall can lead to very serious consequences, such as cable breakage or deformation of the casing at the junction of the pipes.

Most often, a small stone or fastener element falls into the well during repairs or installation of equipment. The operation of the electric motor with slight vibration can facilitate the passage of such a foreign object through the cavity until the moment when it does not completely fix the motor.

There are two main extraction methods:

- pushing a foreign object to the bottom of the well;

- releasing the pump with a powerful jerk.

The first method allows you to free the equipment if it is possible to lower the housing down a few centimeters. It is important here that it is possible to “swing” at least 1-2 cm, so that the structure begins to move, and the stone gradually moves along the body. Raising 2-3 cm to the next place of stupor should alternate with lowering the structure by 1-1.5 cm.

The second method must be used very carefully. A sharp jerk can damage the cable, so if the fixation is rigid and the movement cannot be traced, it is recommended to lift it with a uniform force, literally “dragging” the pump along the well.

Lifting a unit from an idle well

In some cases, it becomes necessary to remove a device with your own hands from a well that has not worked for 2-3 years. It should be taken into account that in such a well the sludge level can rise above the unit. If you try to lift such a pump, it may immediately jam. To fix the problem, you can act on your own, but it is better to call a specialist. The owner can try to remove the pump by shaking it up.

To do this, you need to evenly tighten and then loosen the cable on which the pump unit is installed. Sometimes it is possible to free the pump from the sludge in this way. If this succeeds, water will penetrate into the resulting gap and wash away the silt. This will make the task of lifting the device easier. During operation, you must not use force, as this may lead to a break in the cable with the pump. If after dismantling the equipment the water in the well remains clear, then such a well can be used.

Sometimes, when trying to lift a unit from a silted well, the pump falls to the bottom. Then you need to use a crampon to lift the apparatus from the well.

When the pump falls to the limestone bottom, it is best to call in specialists with the appropriate equipment. They will determine the presence of damage to the pipes, the condition of the pumping unit, and the presence of foreign objects in the well.

Specialists have many different devices that will help you quickly get rid of the problem. If during inspection it becomes clear that a ball of cable has formed in the well, then it can be removed using various traps. Most often, specialists use a cat or a special brush. The hook helps to grab and wrap up pieces of cable that appear after a break. If pipes are damaged, they are removed with a special catcher. Then the pump unit itself is lifted.

What to do if the pump cannot be removed

If the electric pump cannot be removed to the surface after all operations (it has become detached from the pressure pipeline, hose with cable), proceed in the following ways:

They continue to use the well source. The bodies of most centrifugal electric pumps are made of stainless steel, and the internal parts are made of polymers or corrosion-resistant metals. The materials are designed to supply drinking water, so the presence of fallen electric pumps at the bottom of a well for many years is unlikely to affect its quality.

The greatest danger to humans is oil, which is present in the mechanism of almost all pumping units; over time, it can leak through a damaged housing. Also, stainless steel in budget models, usually of low quality, can become rusty over time, affecting the quality of drinking water.

The body of the vibration pump is made of aluminum, which is not susceptible to corrosion, the internal parts consist of rubber and steel, and the mounting bolts are also steel - they are susceptible to corrosion over time.

The well is being mothballed and a new one is being drilled. If the owner cares about his health, the service life of the old well source is coming to an end, you can drill a new well relatively inexpensively - in these cases, the old one is mothballed or liquidated.

Breaking an electric pump with a drill. The operation is permissible if the pump is stuck in deep artesian wells with internal steel casing and the pressure pipe is torn off, if the unit prevents the source from filling with water. It will not be possible to push the electric pump deeper - a standard artesian has a tapering channel at the bottom.

After the electric pump is destroyed by a drill, its small parts fall into the artesian water basin through a filter pipe that does not have a lower cap. Over time, the oil will wash out and small parts will sink to the limestone bottom.

Rice. 14 Example of removing a pump along with a casing pipe

How to prevent pump lifting problem

Pulling a deep well pump out of a well with your own hands if it comes off is not at all difficult if you follow all the recommendations of specialists.

The catchphrase is: “Forewarned is forearmed.” To prevent unpleasant situations from occurring, you need to follow a number of simple rules that can save equipment, time and money.

- Work only with strong cables. You can't skimp on this item. Choose quality products and fasteners.

- The hose must be intact. Buy one of sufficient length, even if the one included in the kit does not meet the required parameters. This will reduce the risk of breakage significantly.

- Choose the right size. The unit should be one third of the diameter of the pipe. Otherwise, congestion during lifting cannot be avoided.

- Set the header. This will ensure “protection” of the well from unwanted “guests”: garbage, bottles, stones, boxes.

Do's and don'ts when removing a stuck pump in a well

When removing the pumping device from the well, sudden actions should not be allowed. Excessive force applied to the pump can simply break the cable holding it.

It is recommended to check the strength of the cable and the reliability of its attachment to the pump at the stage of installing the equipment in the well. If the cable that comes with the pumping equipment does not inspire you with confidence, purchase another one. It is advisable to use a steel cable with a special anti-corrosion coating, or a fairly reliable synthetic analogue.

Galvanized steel cable

You should not try to pull out a pump that is stuck in a well using a grapple. Such a device can get stuck in the well, exacerbating the problem. And of course, you should not try to break through a plug of silt or push a pumping device deeper into the well. Using a heavy crowbar can render the pump unusable.

There are several methods that are used when removing a stuck pump.

- Stretch the cable and tap it taut with a hammer from time to time. Vibrations from the cable will be transmitted to the pump and the plug or deposits may be destroyed. You should not hope that such a technique will lead to instant results. It may take you several days to pull out the well pumping device, centimeter by centimeter.

- If you use any additional devices to remove equipment from the well, be sure to carefully secure them by the head or other strong object near the well with a cable.

- To push a stuck pump deeper into the well, it is better to use a pipe with a cross-section slightly smaller than the diameter of the well. A metal bracket is welded to the upper end of such a pipe, which is secured with a strong cable. Pass the cable, hose and cable from the pump through this pipe. Carefully lower the structure down until it touches the jammed area and, gradually increasing the amplitude, try to push the pump deeper.

Unfortunately, practice shows that in about a third of cases where a pumping device is jammed in a well, it is not possible to remove it on your own. There is only one way out - contact specialized organizations that will inspect the well using special equipment and may try to pull out the stuck pump.

If, when trying to remove a stuck pump, you still break the fastening cable, then the well will have to be drilled again using a drill. But even when using a drill, there is no guarantee that it will destroy the pump along with the obstacle or push it down. In this case, the well will have to be drilled again.

In the worst case scenario, the well will have to be drilled again