Steel comes in different grades and specifications. It varies in shape and type of finish. The World Association of Steel Manufacturers identifies more than 3.5 thousand of its varieties, which have their own unique properties. It is widely used in construction, infrastructure development, household appliances, transport production and other areas. If you visit our website, you will find a large number of rolled metal products there: fittings, pipes, profiles, sheets, rolls, wire, mesh, etc.

But optimizing the properties of steel is not only about changes in the chemical composition. The process of its production also has a significant impact on steel products, even in cases where the grade and characteristics are the same. The key difference is the method of its production: cold or hot rolling.

Differences between hot rolled and cold rolled steel

It is important to note that their main difference is the production process. Hot refers to a process that takes place under high heat, while cold refers to a process that takes place at normal temperatures. While these methods have an impact on performance as well as general application, they should not be confused with the formal specifications and grades of steel that determine metallurgical composition and characteristics. Steels come in a variety of grades and specifications, both hot-rolled and cold-rolled, including basic carbon and other steel alloys.

It may seem obvious, but certain types of steel are more suitable for certain specific applications. Therefore, understanding which one to use will help prevent waste of raw materials. And you can also save money and time spent on additional processing. Understanding the differences between hot and cold rolled steel products makes it easier to choose one or the other.

Differences between cold rolled and hot rolled steel

Cold rolled and hot rolled steel, what are the differences?

- Hot rolling is performed after the workpiece is heated to a temperature that exceeds the recrystallization limit of the alloy. In this case, the temperature regime must exceed 60% of the temperature at which the metal melts. Heating steel leads to its plasticity. This simplifies the rolling process and requires less energy, even taking into account the heating of the slab.

During the hot rolling method, new grains are formed in the structure of the steel alloy, which maintain the necessary ductility of the steel. Dimensional control directly during hot rolling is difficult due to the formation of scale on the surface of the metal product and thermal expansion.

- Cold rolling involves plastic changes in the shape of a metal workpiece at normal temperature. The blanks for cold-rolled metal products are hot-rolled sheets. Before rolling, its surface is cleaned of scale by shot blasting, acid etching, or a combination of both.

During cold rolling at temperatures less than 30% of the melting temperature of the alloy, hardening appears in the upper layers of the workpiece after contact with the rolling mill. These are strain hardenings that increase the strength of rolled metal and reduce its ductility. To neutralize this effect, additional heat treatment of cold-rolled steel is carried out. Tempering increases ductility and reduces the hardness of finished rolled metal.

Hot rolled steel

This production cycle occurs according to the following scheme: steel is rolled at a fairly high temperature, over 900 ° C, which exceeds the recrystallization temperature inherent in most metals. This simplifies its molding and allows you to obtain products that are simple and easy to work with.

To produce hot-rolled steel, manufacturers take a large steel billet. It is heated and pre-treated, using flattening over the entire area. After this, it is kept for a certain time under the influence of high temperatures and passed through a series of rollers to achieve its final dimensions. Hot steel passes through these rolls at high speed. After this, the rolled steel is rolled into coils and cooled. The rods or sheets are separated and prepared for storage or transportation.

The steel contracts slightly as it cools. Since this happens after processing, its final shape is practically not controlled. Therefore, hot-rolled steel is mainly used where exact dimensions are not critical, for example, on construction sites and railways.

Hot rolled steel can be identified by the following parameters:

- rough surface - remnants of cooling from extreme temperatures;

- slightly rounded edges or corners of rods and sheets - due to shrinkage;

- slight distortions in thickness observed in different places of the product.

How to do it

As you can guess from the name, hot-rolled steel is obtained by passing the workpiece through special machines at high temperatures. Heating occurs up to 1000 degrees Celsius, which is more than the recrystallization temperature of the steel alloy.

This is done so that the metal loses its rigidity and becomes more ductile. In this form, it can be given any desired shape. In addition, due to greater variability, in this way it is possible to create finished parts and elements of a much larger size.

For production, this also means a cheaper process, since molding occurs in one cycle and there is no need to reheat and re-run the workpiece. This speeds up the process of releasing finished products, which means improves productivity and reduces costs.

What are the advantages of hot rolling steel?

Hot-rolled steel usually requires much less processing than cold-rolled steel, which reduces its cost. Because hot-rolled steel is allowed to cool to room temperature, it lacks the internal stresses that sometimes arise from mechanical hardening or tempering.

Hot rolled steel is useful in applications where dimensional error is less important than product strength and where surface quality is not a key factor. If surface roughness is a concern, it can be removed by sandblasting, grinding or acid bath etching. Once the roughness has been removed, you can also apply paint or other protective coatings of various types to the surface.

Advantages and disadvantages

The difference in production gives the rental not only a difference in characteristics, but also various pros and cons.

Hot rolled steel

Pros:

♦ Inexpensive cost – cheap brands are used, so the price is reasonable.

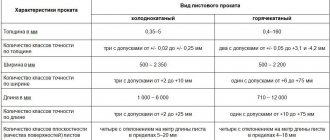

♦ Wide range of thickness – up to 200 mm. With a maximum thickness of cold-rolled sheets of only 50 mm.

♦ High corrosion resistance.

Minuses:

♦ It is impossible to obtain uniform thickness, exact size. The need for additional processing to get rid of scale.

♦ Surface roughness and unsightly appearance.

♦ Poor weldability, the metal can “lead”.

Cold rolled steel

Pros:

♦ High quality.

♦ Wide selection of thin-sheet products (including foil).

♦ Smooth, shiny, aesthetic surface.

♦ Good weldability.

♦ Clear shape and very precise dimensions.

Minuses:

♦ Reduced ductility.

♦ More expensive than hot-rolled products.

♦ If the products are not galvanized, then additional anti-corrosion treatment is required.

Cold rolled steel

To obtain cold-rolled steel, it is necessary to subject hot-rolled steel to additional processing. To do this, it is re-rolled at normal temperature in order to obtain more accurate dimensions over the entire area and improve the quality of the surface. Cold-worked steels then become much harder and stronger.

Cold rolling is applicable only to sheet materials; rods or pipes cannot be rolled - they are pulled out. The use of grinding, turning and polishing is used to modify and produce a new product line with improved performance and appearance.

Cold rolled steel can be defined by the following parameters:

- higher quality and finished surfaces with tighter tolerances;

- smooth surfaces, often greasy to the touch;

- pipe products are homogeneous and even;

- the products are regular all around with clearly defined edges and corners.

Cold rolled steel

Cold-rolled sheet, despite the name, does not avoid heat treatment: any cold-rolled sheet is made from a hot-rolled billet. First of all, the workpieces are cleaned from scale and oxide film. There are two cleaning methods: pickling and shot blasting. Pickling involves immersing steel in a 25% solution of hydrochloric or sulfuric acid. This method chemically removes excess elements from the metal surface. Shot blasting means impact on a steel sheet, which allows you to knock off excess particles from the surface. Some industries use a combined cleaning method, which is the most effective.

And only after this the billets are transferred to cold rolling mills. That is why the thickness of a cold-rolled steel sheet does not exceed 5 mm , but the surface of the sheet is much better (smoother).

This completes the immediate production stage and begins the hardening stage . To begin with, the steel is annealed in furnaces at a temperature of about 700 degrees Celsius. This leads to recrystallization of the molecular network of the alloy, due to which it obtains the necessary flexibility and elasticity. After annealing, the sheets are rolled again on the mill, which prevents the appearance of shear lines.

The last stage of processing is called training . It involves compressing the resulting blanks by up to 3%. This procedure increases the hardness and strength of the sheets so that they can perform their intended functions without problems in the future. In addition to the listed standard processing procedures, the material can be subjected to additional manipulations to impart certain properties to it. For example, galvanized cold-rolled steel is coated with a layer of zinc, which provides it with high resistance to corrosion.

Features of cold rolled metal products are:

- high accuracy of geometric characteristics,

- evenness and flatness of the surface,

- homogeneity of the internal structure of the metal.

These advantages of the physical and mechanical properties of cold-rolled steel compared to hot-rolled steel determine the scope of its application :

- in aircraft manufacturing,

- in the space industry,

- in machine tool industry,

- in electrical engineering,

- in the chemical and metallurgical industry,

- in construction for finishing works.

In general, cold-rolled sheet is a sought-after product among enterprises engaged in the production of high-quality metal products in all mechanical parameters. Cold-rolled steel sheet is also a workpiece for the production of various construction and auxiliary products:

- corrugated sheets,

- tinplate, galvanized,

- polymer sheets,

- roofing iron and other things.

What are the advantages of cold rolled steel?

With better surface quality than hot-rolled steel, it is clear that cold-rolled steel is more often used for high-precision applications and where aesthetic appearance is important. But due to additional metal processing of cold finished products, they are more expensive.

Due to their physical characteristics, cold rolled steels are often harder and stronger than standard hot rolled steels. Because the metal is formed at lower temperatures, the steel's hardness, resistance to tensile fracture, and resistance to deformation increase.

This additional processing may still result in internal stress in the material. This can create unpredictable warping if the metal is not released under stress before cutting, grinding or welding.

Classification by brand

Depending on what the final product is planned, alloys are selected for the manufacture of HA sheets:

- 08ps, 08Yu – low-carbon;

- 09G2, 09G2S, 10HSND, 15HSND, 17GS, 17G1S – low-alloy;

- 10, 15, 20, 30, 40 – quality;

- St1, St2, St3, St4 – carbon;

- 30Х, 40Х, 30ХГСА, 15ХМ – alloyed.

Carbon grades are most often chosen for the production of hot rolled sheets. After producing layers from such steel, they can be used in construction, production of aircraft parts, and mechanical engineering. Other grades are used to create sheet metal used as blanks for other types of rolled metal and hardware.