What it is

Let us answer the question, what kind of fabrics are these that do not burn? Such materials primarily include the long-known, non-flammable asbestos fabric, used at temperatures up to 500℃. Made from the natural layered mineral asbestos, it does not contain combustible organic substances, therefore, in the full sense of the word, it is non-flammable.

On this topic ▼

Workwear and suits with fire retardant impregnation

The second type of fabric from which fire-resistant workwear for welding and protective suits for working in hot shops are made are high-density natural materials made from cotton and linen.

For example, tarpaulin fabric, additional resistance to direct contact with open fire, the high-temperature thermal effects of which is imparted by fire-retardant impregnation with various types of fire retardants.

This fabric is fire-resistant in its properties, as it is capable of resisting flames and high temperatures for a short period, which makes it possible to reliably protect a person wearing protective clothing made from it in the area of direct contact with negative influence factors.

In addition to these most famous examples, there are many other types of both flame retardant and fire resistant textile materials used in a wide variety of fields.

Fireproof fabric

Protection against welding spatter

Burns when working with welding equipment can be obtained not only during flame cutting or welding, but also when working with simple electric arc welding.

welder overalls

Often, novice, inexperienced welders pay little attention to special clothing. But there are many cases of burning and even fire from a drop of molten metal formed during welding. Gaiters are used to protect hands. To protect the body - fireproof jackets, trousers, suits. The most effective is overalls. Special welder's boots are used for the feet. Clothes and shoes must be tailored to fit. You should feel comfortable in it - the productivity and efficiency of your work depends on it.

Read the article: Choosing protective equipment for a welder: overalls, leggings and shoes. Requirements, GOST

Safety precautions when welding at height

Work in rooms where large-scale structures are assembled and work at height have an increased risk of injury.

helmet mask

When performing them, it is necessary to use a special mask used together with a protective helmet. To work safely at height, it is necessary to use a protective belt, which provides the possibility of reliable safety fastening to the structure; boots should not have metal parts.

Types and characteristics

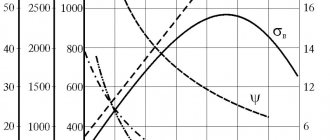

Depending on the component that is the basis for the production of non-flammable or fire-resistant fabric materials, the following types of fabrics are distinguished:

Silica

Also called silicate, quartz. They are made from SiO2 - silica (silicon dioxide), quartz, and other silicates. Such materials work stably up to temperatures of 1250℃, breaking down only above 1700℃. They have a low thermal conductivity coefficient, high electrical insulating properties, and are environmentally friendly.

Fiberglass

These are materials that can withstand short-term heating up to 700℃, sudden cooling down to -200℃, and constantly operated at temperatures up to 550℃. Distinctive characteristics - low weight, high tensile strength, low coefficient of linear expansion, dielectric properties; resistance to ultraviolet radiation, moisture, microorganisms.

Basalt

Made from basalt fibers by melting it. Withstands temperatures up to 700℃. They also produce non-woven fire-retardant basalt material used for structural fire protection of metal structures and filling openings in fire barriers.

Asbestos

Obtained on the basis of fibrous material - asbestos, in combination with various inorganic additives in order to hide and bind the dangerous carcinogenic effects of this natural material when its dust is inhaled.

Carbon

They are produced by weaving from threads made from pure carbon fibers. They are lightweight, stretch-resistant, can withstand temperatures up to 370℃, but are still capable of linear expansion.

Aramid

These are the most innovative fabrics made from polymers - aromatic polyamides. They are extremely durable, even going so far as to make bulletproof vests out of them; resistant to fire, intense heat up to a temperature of 400℃.

Polyester

Made from polyester threads with a high content of phosphorus compounds. When exposed to open fire, they do not ignite, do not melt, and become charred and decrease in size.

As well as various types of sewing and finishing fabric materials subjected to fire retardant treatment by dipping and spraying fire retardants. After such impregnation, it is difficult to set them on fire with low-calorie fire sources; they do not burn, but become charred.

Requirements

At the time of writing, there are no national standards defining the production of non-flammable, fire-resistant fabrics that do not burn well. Therefore, companies that produce this group of textile materials themselves develop technical specifications that regulate the entire production process.

In addition, specifications are a mandatory document provided by the manufacturer for certification fire tests of serial products, necessary to obtain a fire safety certificate.

Testing non-flammable fabric for flammability

Requirements and test methods relating to the main characteristic - the flammability of fabrics - are set out in the following fire safety standards:

- GOST R 50810-95, which classifies decorative textile materials based on the flammability test method.

- NPB 257-2002. This document regulates testing methods for flammability, smoldering, flame sustained and residual combustion of textile materials - curtains, drapes, bedding, upholstery.

Such tests involve exposing selected tissue samples to the flame of a laboratory gas burner or a smoldering cigarette; and the results obtained objectively show how well their fire protection treatment was carried out with fire retardant solutions.

Purpose

Fabric materials based on asbestos, due to its carcinogenic properties, are practically no longer used in the production of fire-retardant elements of overalls for firefighters and metallurgists, but are widely used as asbestos-technical, fire-resistant heat-insulating products, including in aggressive chemical environments.

Polyester, as well as some varieties of aramid fire-resistant fabrics, serve as the starting material for curtains used for the stage of theaters and clubs; for restaurants, hotels. Wherever there are a lot of people constantly or regularly, there is a possibility of draperies, drapes, curtains coming into contact with ignition sources.

On this topic ▼

Fire retardant impregnation: requirements and procedure for processing materials

Furniture manufacturers also use these types of fire-resistant fabrics as furniture upholstery, which cannot be set on fire by a fallen smoldering cigarette.

For mittens included in the sets of special clothing for firefighters, workers in hot shops of metallurgical and energy production, carbon, silica, basalt fire-resistant materials are used, as well as fiberglass, which is the surface layer of both hand protection means and workwear in general.

Special clothing and suits with fire-retardant treatment are also made from linen and cotton fabrics of high density and thickness of the material.

They are used by gas and electric welders, blacksmiths, boiler house workers, hot shop workers of other industries.

ThermoBarrier - Protective equipment during welding work

Our store offers you a wide selection of insulating materials. In our store you can choose the necessary material to achieve the necessary goals. In the assortment of the ThermoBarrier store you will find such materials as:

Protective equipment for welding work brand WELDTEX (Russia)

This section presents products designed to protect the welder and surrounding objects from sparks, splashes of hot metal, ultraviolet radiation, etc. This category is represented by the following products: welding blankets, welding curtains, welding mats. Standard sizes are always available. However, rapid production according to customer sizes is possible.

Fire retardant material MBOR and fire retardant composition PLAZAS. Manufactured by TIZOL JSC (Russia)

This section presents products intended for fire protection of air ducts, metal structures, and chimneys. This category is represented by the following products: fire-retardant basalt material foiled MBOR, fire-retardant composition PLAZA. The non-protective material MBOR is excellently used for thermal insulation of baths and saunas.

Fire resistant fabrics

This section presents fire-resistant non-flammable fabrics that are produced on the basis of silica fibers and glass fibers of grade E. The fabrics have different coatings (silicone, polyurethane, aluminum foil). These fire-resistant fabrics are used in various fields: metallurgy, construction, automotive industry, as well as in everyday life. Using these materials you will provide yourself with reliable fire protection and thermal insulation.

Construction membranes

In this section you will find building membranes designed for moisture protection, wind protection, and vapor barrier. These products are used to protect the insulation layer from the effects of wind, moisture and steam. Construction membranes significantly increase the service life of insulation.

Soundproofing SoundGuard

Soundproofing materials SoundGuard are presented in the form of soundproofing panels, soundproofing membranes, soundproofing boards. Also in our store you can buy sound-waterproofing and damping substrates, damper tapes, vibration suspensions. Please note that you can buy not only structural elements, but also ready-made sound insulation systems. Soundproofing materials SoundGuard are distinguished by high quality, reliability, and long service life.

welding equipment

Our store's assortment includes welding equipment from the world's leading manufacturers - EWM, Blueweld, FUBAG and many others. A wide range and high quality of supplied welding equipment will allow you to solve all your tasks. In our store you will find both equipment for home use and for industrial use.

Go to the store

termobaryer.ru

Application area

Fire-resistant fabrics/mats are made from fiberglass and asbestos fabrics, which are an effective means of extinguishing small-area fires in fire-hazardous industries during hot work.

Silica, basalt fabric, non-woven materials are used:

- For thermal insulation of heat-generating units, pipelines, including those transporting flammable liquids. For example, for a pipe for supplying heating oil to a boiler in a thermal power plant.

- For flow filtration, as a filler for fire arresters when transporting flammable liquids.

- As fire-resistant heat shields in metallurgical shops and gas-electric welding production areas.

- In the production of roller fire curtains, screens, curtains.

- In construction, as non-flammable breathable membranes, floor insulation coatings; wind protection, vapor barrier of roofs, building facades.

Aramid, hydrocarbon fabrics, being less resistant to fire, more expensive compared to silica, basalt fiberglass materials, are less common, but are also used as inserts, elements in the production of workwear, and for technical production purposes.

Texture of fire-resistant fabrics for curtains

Trade marks

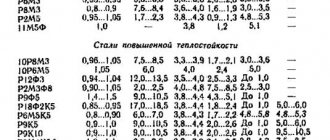

There are many types and brands of both completely non-flammable and fire-resistant fabrics on the market:

- Tend building fabric is a non-flammable material that corresponds to group NG, hazard class KM0. It is used as a steam-, wind-, and heat-insulating material for ventilated facades, roofs, and floors of buildings. The material is resistant to moisture, aggressive environments, sudden temperature changes, and exposure to ultraviolet rays.

- Thermally resistant silica fabric KT-11 . SiO2 content – up to 99%. The main qualities are fire resistance up to 1200℃ (long-term), strength, dielectric, environmental properties, which makes it a multifunctional material.

- Basalt fabric TBK-100 coated with metal foil. The operating temperature range is from – 200 to + 650℃, melts at 1100℃. Used in the production of rolled roofing materials as thermal insulation.

- Izoltex fabric is made from fiberglass. Operating temperature – up to 560℃, maximum short-term – 700℃. It has excellent thermal insulation properties, is chemically inert to strong organic and mineral acids, concentrated solutions of alkalis. An excellent substitute for asbestos fabrics, used in construction and various industries.

- Kevlar, Arcelon, Terlon, Kermel, Nomex are various trademarks, names of types of aramid fabrics that are thermally resistant in the range from 250 to 400℃.

For fire-retardant treatment of natural fabrics, the following impregnations are used: “Negorin-fabric”, “OGNEZA-PO”, “Nortex”, “ANTAL TM”, which do not change their appearance, do not reduce strength, and do not have an unpleasant odor.

Important: for each batch of such products, regardless of the volume of the batch, the customer or buyer has the right to demand a fire safety certificate of conformity, which specifies all the necessary characteristics.

Insulation

Types of Silica Fabric

Silica fabrics of any type are used as high-temperature insulation (working temperature from -70 C to +1100 C).

Silica fabrics are produced single-layer and multi-layer (MKT), with polyurethane, silicone impregnation (PU), different densities from 300 g/m to 1000 g/m and higher, heat-treated (HT) and conventional.

Heat-resistant silica fabric is produced by weaving silica threads. It is an environmentally friendly, multifunctional, thermal protective fabric based on silica fibers, containing 97-99% SiO².

Silica fabrics KT-11 are characterized by low thermal conductivity, high resistance to thermal shock, are an excellent electrical insulator at elevated temperatures, can be used for a long time without changing their properties at temperatures of 1000-1200°C and for a short time at temperatures up to 1700°C.

Heat-resistant silica fabrics are inert to most chemical reagents, resistant to the influence of organic and mineral acids of any concentration (the exceptions are hydrochloric, hydrofluoric, phosphoric) and weak alkalis of molten metals (the exceptions are Mg, Na, Si) and alloys. They are characterized by increased chemical resistance to water and high-pressure steam, stability in a vacuum, and absorb moisture.

termoizol24.ru