Aluminum is considered one of the most common metals at the moment. This metal is used in various industries due to its characteristics. However, it is not always possible to join aluminum parts by welding. A bolted connection will be unreliable for this metal. Because of this, cold welding for aluminum has become very popular.

High-tech joining of aluminum with “Cold Welding” glue

Cold welding of aluminum is the joining of parts using a special adhesive mixture. Thanks to it, a reliable connection is obtained without heating the metal.

An epoxy compound acts as a binding mixture. It is a thick mass, the consistency of which resembles mastic. Cold welding for aluminum consists of epoxy resin saturated with metal powder. Due to its content in the resin, the strength of the hardened composition increases. The glued area can be stronger than the material itself.

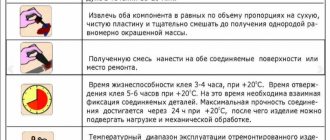

In addition to the main component (epoxy resin), the package contains a second component. This is a special hardener that, when mixed with epoxy, reacts and the composition begins to harden. In a period of time from 10 to 30 minutes, the master must have time to apply resin to the parts and connect them. Next, you need to press the individual parts together for 15-20 minutes (in some adhesives, the fixation time for hardening reaches 40 minutes).

Advice! It is advisable to begin further work 2-3 hours after applying the adhesive mixture. As a rule, you need to wait at least a day for the epoxy resin to completely harden.

It is important to remember that both high-temperature and cold welding are harmful processes that require individual protection of the human body. When interacting with adhesives, the room must be well ventilated and there is no open fire nearby. To protect your respiratory system, you should wear a respirator. To avoid irritation of the mucous membrane of the eye, it is advisable to wear safety glasses. If epoxy resin is swallowed, you should go to the hospital immediately.

Adhesive mixtures have a number of serious advantages:

- There is no need to buy additional equipment or look for network connection points.

- Anyone can work with epoxy resin without any skills. The packages contain step-by-step instructions. The same cannot be said about welding using electrical equipment.

- The hardened glue forms a strong seam, which is slightly inferior to welded joints.

- Hardened compounds are resistant to corrosion processes, moisture, oils and fuel.

- After 20-60 minutes, a strong connection is obtained.

- Cold welding is considered an economical option for repairing a variety of equipment.

When using automatic welding machines, the metal being joined is exposed to high temperatures and severe deformation. Cold welding does not have these disadvantages. However, glue cannot be used when repairing high-pressure vessels and containers that are often subject to changes in the environment (humidity, temperature).

How to brew silumin

So, for welding silumin, argon arc technology is required. The equipment includes an inverter, a gas cylinder, an oscillator and a special burner. A non-consumable tungsten electrode is installed in the burner. Silumin wire should act as an additive here.

Before starting the welding process, silumin blanks must be prepared. The basic rule is to remove the oxide film.

- First, you need to clean the edges of the parts to be welded using sandpaper, a wire brush, a sandblaster or any other method.

- Next, chemical treatment is carried out. This can be any solvent, gasoline or caustic soda solution. If the latter material is used, then after processing it is recommended to rinse the metal workpieces with water pressure.

Welding is done with reverse polarity and a short arc. This can only be explained by the fact that with a short arc the metal melts better. The filler wire is fed into the welding zone, where it is also melted and combined with the base metal, ultimately forming a single, homogeneous liquid substance. When it cools, it turns into a monolith.

It is impossible to quickly feed the additive into the weld pool. This will lead to metal spattering, which will reduce the quality of the weld. The wire must be fed in front of the burner and held at an angle. The movement and feed must be uniform exactly along the seam. Do not deflect the filler rod or move it across. An even and narrow seam is a high quality connection.

Everything else, in principle, is exactly the same as when welding aluminum. Namely:

- When igniting the electrode, do not touch the metal workpieces being welded.

- Gas supply must begin 15 seconds after ignition of the tungsten electrode. This will ensure heating of the space in the burner nozzle.

- When finishing welding, do not stop the gas supply. Shutdown can be carried out after 10 seconds, when the power supply to the electrode is turned off. This will ensure uniform cooling of the metal in the gap between the workpieces.

At home, you can weld silumin with a consumable electrode. For example, consumables from the well-known Swedish company ESAB brand OK 96.50. But here too there is some specificity.

- The blanks are prepared in the same way.

- Pre-welded parts are heated to 250-300C.

- The electrodes are also preheated to 150C.

ASTROhim cold welding for aluminum, Total Bond series

ASTROhim – cold welding for aluminum. Used for various types of repair work. In addition to aluminum, this composition effectively joins wood, steel and ceramic parts in various combinations.

Stages of performing work using ASTROhim cold welding:

- Clean work surfaces from dirt and dust. Remove rust using sandpaper, degrease and dry.

- Next, you need to wet your hands under running water, cut off part of the epoxy rod, mix it with the hardener and knead it in your palms.

- Apply the prepared composition to the surfaces to be bonded. Press them for 15 minutes.

If you need to restore the thread, you need to spread the prepared mixture on the old part of the thread and screw in the bolt. After 20 minutes you need to unscrew the bolt. You can use the finished thread after 90 minutes.

Characteristics:

- The pot life of the mixture after mixing the components is 7 minutes. The room temperature should be about +20° C.

- Setting time: 20 minutes.

- Other work can be carried out after 1.5 hours.

- Retains its properties at temperatures from -60 to +150° C.

The glue hardens faster when heated and slower when the temperature drops.

This series produces “ASTROhim heat-resistant cold welding” - high-temperature cold welding for aluminum and silumin. Reliably repairs parts made of other non-ferrous and ferrous metals, as well as ceramics, operating temperature from -60° C to +250° C.

Alloy groups

Silumin alloys are divided into several groups. This distinction is made according to the purpose of the materials:

- AK 12 is a eutectic silumin containing 12% silicon. During heat treatment, the casting is not strengthened and does not become hard during shrinkage. Parts made of such material are structurally designed for sealed low-load devices.

- Highly alloyed hypereutectic silumin is labeled, for example, AK4M5. Belongs to the piston group and is used when performing work under high-temperature conditions. It has high resistance to high temperatures and wear resistance. The use of this alloy for particularly important products operating under high load conditions. These are large-sized and critical parts.

Sealant (cold welding) Anles Uniplast-universal 20g aluminum

Epoxy plasticine, supercompound. Anles Uniplast-universal is a cold welding based on aluminum. Used for fastening workpieces made of various metals (non-ferrous and ferrous), restoring threads, repairing plumbing pipes and fuel storage tanks. This is a two-component composition, which consists of a hardener and epoxy resin. The base is further strengthened with aluminum or bronze dust.

Stages of working with Anles Uniplast-universal:

- The working surface is cleaned of dirt and rust. Processed with sandpaper. Then the surface is degreased and dried.

- The hardener and base must be cut in equal parts, mixed until a homogeneous mass is obtained and applied to the parts to be glued.

- Secure the gluing area with a rope or place it under a weight.

It is recommended to continue work after 24 hours. Has high electrical insulating properties.

Characteristics:

- The viability of the finished composition is about 25 minutes. Temperature +20° C.

- The maximum strength of the connection occurs after a day.

- Cold welding is resistant to prolonged exposure to water, gasoline and oils.

- Withstands temperatures from -40 to +120° C.

You need to work with this glue in a well-ventilated area and away from sources of fire.

Weicon Repair Stick ST Aluminum. Repair rod

Weicon Repair Stick ST Aluminum is a repair stick that is used to repair plumbing pipes, repair visual damage to the trim of ships, boats, cars and window frames. The rod consists of epoxy resin with copper filler. Refers to repair sticks.

Weicon Repair Stick ST Aluminum Cold Welding Steps:

- The surface of the parts to be joined is cleaned of dirt, treated with sandpaper, and degreased.

- Using a stationery knife, you need to cut off the required part from the rod, wet your hands and knead the glue in your fingers.

- Apply to the broken part and press for 20 minutes.

It is advisable to continue working with the glued product after a day.

Characteristics:

- At 20 degrees, the pot life of the composition is 4 minutes.

- Resistant to temperatures from -50 to +120° C.

- Total curing time is 24 hours.

You can work with the adhesive from +10 to +35° C.

How to use the mixtures?

Those who do not know how to glue aluminum at home should follow the following sequence of actions:

- Rust and dirt are removed from the surface of the joined areas using fine-grained sandpaper or a brush.

- Next, the surfaces are treated with acetone.

- After this, you need to wait a while for the area to dry.

- Mix glue and hardener in a separate container. You should get a homogeneous viscous mass.

- The adhesive mixture must be applied to the surface in the form of dots or thin strips. Then the parts are pressed tightly against each other. They need to be fixed in this position and left for 15-20 minutes.

If you have any excess, you can remove it with a rag previously soaked in solvent.

Cold welding “Fast steel” METALFIX LAVR 60g

“Fast steel” METALFIX LAVR is a two-component mixture that is used to join ferrous and non-ferrous metals, concrete, wood, plastic, granite and various polymer materials. This cold welding is also used to repair plumbing pipes, repair cars and industrial equipment.

Application:

- The surfaces of the parts to be glued are cleaned of dust and rust. Next, it is processed using coarse sandpaper.

- Surfaces need to be degreased and dried.

- Cut off a piece of epoxy resin and knead it thoroughly in your palms.

- Apply the mixture to the surfaces to be glued, rub it to the desired shape with any flat object.

To continue work, you only need to wait 1.5 hours. Not inferior in strength to a welded seam. Eliminates leaks in gas tanks, radiators, engine crankcases and gearboxes.

Characteristics:

- The glue partially sets in 15 minutes.

- Resistant to prolonged exposure to moisture and oils.

- Complete hardening is achieved after a day.

- Withstands temperatures from -60 to +150° C.

- It is advisable to have time to apply cold welding within 10 minutes.

Useful tips

Craftsmen advise following some useful tips when buying glue and carrying out work:

- Two-component compounds cope with the connection of aluminum elements, but if it is necessary to glue aluminum alloys, then it is better to use products containing methyl acrylate.

- Bonding of aluminum occurs due to the splitting of the coating by the components contained in a special product.

- If the design provides for use for storing food and water, then you cannot use products containing epoxy resins.

Gas welding can cause metal oxidation, which does not occur when using adhesives.

We recommend videos on the topic:

Aluminum Putty F (Devcon F), metal polymer filled with aluminum

Aluminum Putty F (Devcon F) is a two-component composition that is saturated with aluminum powder. Used for joining non-ferrous metals, as well as plastic and concrete. With this cold welding it is possible to create aluminum surfaces that are resistant to corrosive processes.

Application:

- Initially, the surfaces of the parts to be glued are cleaned of paint, dirt and rust. Remaining oil and grease must be removed using a solvent. When working with aluminum products, you need to clean it before applying cold welding.

- If work is carried out at a temperature less than +10° C, the surfaces are heated to +40° C.

- On a flat board, mix the base and hardener using a spatula. They also apply the finished glue to the parts.

- Treat the finished product with wet sandpaper.

When applying glue, you need to press it into the voids and cracks of the material. This type of cold welding can be used to repair containers that will contain gasoline or oil.

Characteristics:

- Start mechanical work on the glued product after curing no earlier than 4 hours later. After 16 hours at room temperature, it reaches 75% readiness for use.

- Resistant to corrosive processes. Protects metal.

- When fully prepared, it retains its properties at temperatures up to +120° C.

- The glue can be applied within 60 minutes.

Devcon F compounds are chemically resistant to water, salt solutions, gasoline, petroleum products, oil and propylene glycol. Not suitable for prolonged contact with concentrated acids and organic solvents.

What else can you combine aluminum with?

An adhesive mixture with two components has high adhesive properties.

It can be used to bond aluminum to materials of other thermal expansion. For example, plastic, glass, wood or stone. However, due to differences in thermal expansion, strength may not be ideal. To mitigate this drawback, it is recommended to use elastic adhesive tape or resort to mechanical connection. Despite the fact that not everyone recognizes the high efficiency of using adhesive mixtures for aluminum, if the work is done correctly, you can ensure a reliable and durable connection of parts. This approach also has one advantage. Adhesive mixtures can also be combined with mechanical fasteners. Motorka.org » Repair » Repair of light alloy bodies

Cold welding - epoxy multi-purpose compound Permatex GOLD WELD

“Permatex GOLD WELD” is a multi-purpose compound, an epoxy-based mixture. Used for joining various metals, plastics, ceramics, glass, wood, rubber and various polymers. Apply using a tube. The application process is similar to applying instant glue. Recommended for rigid connections and pouring forms.

Characteristic:

- The hardened composition is resistant to the destructive effects of alkalis and acids.

- Resistant to corrosive processes.

- Hardens in 4 minutes. Partial curing time is 10 minutes.

- The finished product can withstand temperatures up to +177° C for a short time.

This cold welding is resistant to physical impact and vibration. Because of this, it is used to repair industrial equipment. Main applications: aluminum, steel, brass, bronze and copper. The product is resistant to most automotive, industrial and cleaning fluids.

Deformation welding technology features

When aluminum pieces are joined at room temperature, this method is called “cold welding.” In addition to the use of adhesive compositions, which were described above, there is the principle of deformation. This technology consists of several key stages:

- Aluminum surfaces are initially degreased.

- Next, the workpieces are brought as close as possible and compressed under pressure.

During the compression process, the outer oxidized layer is destroyed. Intermolecular bonds are formed between the crystal lattices of the metal. This ensures a reliable connection.

Hydraulic Cold Welding Machine for Aluminum and Copper

This technology can be used to bond other non-ferrous metals. Pressure can be applied uniformly or vibration can be added. Based on deformation technology, three connection methods can be distinguished, which will be described in more detail below.

How to upgrade a regular TIG welding machine?

Welding oscillator circuit.

As a rule, argon welding at home is carried out using a modernized machine.

To do this, you will need additional devices that will ensure high quality welding process.

An oscillator is a unit necessary for non-contact ignition of an electric arc, maintaining a stable arc even with alternating current.

It generates a discharge with a power of up to 8 kW, breaking through the arc gap.

A ballast rheostat will be needed to regulate the current.

Butt method

This technique is one of the most reliable in terms of cold welding of aluminum. Suitable for connecting parts through their ends. This way you can combine the plates into one large shield. The process of metal bonding occurs in several stages:

- First of all, the ends of the parts are cleaned. Paint, rust and dirt are removed from them. Next they are degreased.

- After cleaning, the parts are clamped in a special vice located opposite each other. Only the ends and 1 cm of metal should stick out.

- When the workpieces are securely fastened in a vice, end pressure is transmitted through them to the ends. With its help, a reliable connection is obtained.

Technologically, this is a simple and low-cost process that is accessible to any craftsman working with metal. However, it has significant drawbacks.

Firstly, the size of the holding vice does not allow the use of large parts for joining. Secondly, part of the metal clamped in a vice is also subject to deformation. Thirdly, after cold butt welding is completed, it is difficult to remove the finished part from the clamps.

Point technology

With this cold welding method, aluminum sheets can be overlapped. It is considered the most popular technology of the three presented. Bonding process:

- The parts are placed on top of each other and pressed on both sides with special clamps.

- The punches are located at a certain interval, to which the precision pressure will be transferred.

- A force is transmitted to the punches, which presses them into the metal.

The strength of the connection will depend on how hard the punch is pressed into the metal and what material these point elements are made of. Also important is the number of points in the connecting line.

The main advantage of spot cold welding is low deformation of the part. It occurs only at the points of contact of the elements through which pressure is transmitted to the aluminum.

Advantages and disadvantages of argon arc

Argon arc welding is the only method today to obtain a joint of silumin parts that is not inferior in strength to the base metal.

Its other advantages include:

- speed;

- possibility of adjustment and adjustment to any type of alloy;

- reliability and ease of preventing the formation of aluminum oxide.

There are two serious disadvantages:

- the price of devices with the help of which successful silumin welding is achieved starts from 40-45 thousand rubles;

- high qualification requirements for the welder.

In addition, the process itself is not cheap, so it makes sense to use it to repair unique products.

Suture method

An effective cold welding technique that involves creating a continuous seam using special equipment.

It consists of two rollers, between which parts are secured. The rollers are located parallel to each other. Punches or a special ring are attached to their working part. These elements form the joining seam. Seam welding can be divided into two types:

- One-sided - one roller rotates, the other is firmly fixed in one position.

- Double-sided - two rollers are driven by electric motors.

The process of fastening metal sheets:

- The area that will be fastened is initially degreased and cleaned of dirt and rust.

- The parts are pressed between the rollers.

- After the engine starts, they begin to rotate and drive parts through the working part. This results in a smooth, uniform seam.

Metallurgists often join large sheets of aluminum and other non-ferrous metals in this way. However, it must be remembered that continuous seams reduce the strength of the overall part. Because of this, the suture technique has been modernized over time. In the process of technology development, the point-suture connection method appeared. It involves installing punches on rollers, which make the seam divided into many points. This way it turns out much stronger.