To cut efficiently and relatively quickly with a chainsaw or chainsaw requires some skills honed over the years, the right tool and sharp equipment (chain). The last point should be given special attention, since without proper and high-quality sharpening of the chain you will not be able to achieve serious results, even if you are a true guru in this matter, and your tool belongs to the class of high-tech innovative “monsters”. In our article we will consider only the best machines for sharpening chainsaw chains.

Sharpening machine for chainsaw chains - what is it?

The equipment is available in 2 versions: stationary and portable.

The main design elements are:

- Support bed.

- Rotary table.

- Chain guides.

- Swivel joints.

- Sharpening head.

Expert opinion

Kuznetsov Vasily Stepanovich

To sharpen chain links, grinding wheels of varying thickness are used. The most popular of them is 3.5 mm. The design of all types of equipment allows you to adjust the sharpening angle of the saw teeth. For ease of adjustment, the design is equipped with a graduated scale.

Types of equipment

Existing machines are divided into manual and automatic, stationary and portable, professional and household. Each type of device has its own characteristics, pros and cons.

Manual machines

Setting the sharpening parameters is done manually for each chain link.

The main advantages of equipment of this type are low price and the possibility of use in places remote from electrical networks. Such devices are popular with loggers who cut down trees in areas remote from populated areas.

Among the advantages of the equipment:

- Safety.

- Autonomy.

- Versatility.

Saw teeth sharpened by manual machines last much longer than chains that have undergone automatic processing. Manufacturers include an instruction manual with the equipment, which contains information about the angles to be set. It is presented in the form of tables.

The disadvantages of the equipment include:

- Low performance.

- Mandatory knowledge of the rules for setting sharpening angles of cutting edges.

Expert opinion

Kuznetsov Vasily Stepanovich

Without professional skills, it is impossible to sharpen chains with high-quality sharpening using this type of equipment.

Automatic machines

Large enterprises use professional machines with a power of more than 0.5 kW.

This type of sharpening machine is equipped with electric motors. The location of their installation is tied to the location of the sockets. The operating voltage range of most models is between 0.2 and 0.5 kW. Such devices find their application in small sawmills and in everyday life.

Principle of operation

Sharpening of the links is carried out with an abrasive wheel one at a time. If the chain is sharpened incorrectly, the uniformity of the load on its surface is disrupted. This leads to rapid wear of the canvas and its destruction. The grinding machine wheel is fixed to the bed with special rotary clamps.

During the sharpening process, it is alternately transferred from one chain link to another. On stationary machines the chain moves automatically. Each time before starting work, the device must be configured. For this purpose, the designs provide various adjustment mechanisms.

With their help, the following are displayed:

- The amount of cutting of the tooth edge.

- Depth of depressions.

- The sharpening angle of the front cutting corner of the tooth.

How to make it yourself

In this paragraph, we’ll look at how to create your own machine for sharpening chainsaw chains with your own hands at home.

Materials:

- Engine.

- Grinding wheel.

- Grinding wheel fasteners.

- Sheet steel.

- Switch.

- Wiring is insulated.

- Construction corner.

- Various small items (bolts, nuts, screws).

- Engine. Motors from old washing machines are actively used in sharpening machines. When searching for a motor, it is important to take into account the power; it must be compared with the diameter of the grinding wheel. The larger the diameter of the circle, the greater the torque the motor shaft must develop, otherwise the circle may stop under load. In purchased versions of the machines, a 250 W motor rotates the circle by 200 mm, these figures should be approximately adhered to. Of course, it is better for the machine to have a power reserve, but do not forget that the grinding wheel will decrease in diameter as it wears out.

- Base and circle. We prepare a reliable base for the sharpener (the simplest frame is made from a corner and sheet steel). We make reliable fasteners for the motor; it needs to be screwed with bolts and nuts. Grovers and nuts with plastic locking rings will not be superfluous. Many people immediately install a grinding wheel on the motor shaft; here they need to select a plus and make bushings depending on the diameter of the wheel. The circle is usually clamped with large washers on both sides; it would be a good idea to place cardboard spacers under the washers.

- Protection. Next, you need to create a special protective frame, the installation of which takes no more than twenty minutes, but during the process of sharpening something you will not be bombarded with various consumables. In this case, the protective shield is welded into the frame where necessary, secured with ordinary metal rods, pipes, and brackets.

- Emphasis. To make it comfortable and safe to work on the machine, we put emphasis on it. The emphasis must be adjusted in at least two positions - vertically and horizontally. It will move towards the grinding wheel as it wears out, and will be used in other equally important stages of work. We assemble the stop from a corner, plates and sheet steel, and we find the drawings on the Internet or invent them ourselves, since the mechanism is simple. You can also weld pipes to the nuts, and insert steel rods into the pipes as the main handles - it will be much more convenient to use the device.

- Shield cover. We are making a cover for the shield; it should be removable so that the circles can be replaced as needed. We cut out the cover itself from sheet steel and drill holes in it. We weld bolts or threaded rods to the shield itself; as a result, the cover will be secured with nuts. It would be a good idea to make a window at the bottom of the shield through which excess debris will pour out.

- Final touches. At the end, you need to make a sleeve with wiring, install a reliable switch and paint the machine in your favorite color (this will make the work process much more interesting). The homemade product looks great and works flawlessly. There is another axis on the back of the motor; you can put a brush or polishing wheel here. This completes the project, I hope you liked the homemade product and found something interesting. Good luck and creative inspiration if you decide to do this again. Also, think about the cost of such a device and find out how much a machine for sharpening chainsaw chains costs directly from the store.

You will be interested in: TOP 7 best rotary hammers: which one to buy, reviews, characteristics, price, pros and cons

How to choose the right one?

What chainsaw sharpening machine do you use?

ManualAutomatic

When purchasing sharpening machines, a number of factors are taken into account:

- Planned place of use of the machine.

- Price.

- Performance.

- Manufacturer's warranty period.

- Availability of a repair base.

The last factor is relevant for individual equipment models. The absence of the necessary part of the device creates great difficulties in work. When buying sharpening machines, you need to understand that there is no point in buying expensive models if there is no need for their constant use.

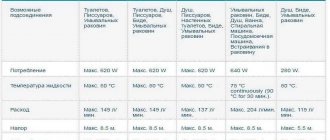

Main technical characteristics

Grinding equipment has various operating parameters.

Among them there are important characteristics and minor ones. The main indicators of equipment performance include:

- Rotation speed of the working element. The quality of processing of the cutting edge of the teeth depends on it. The most common rotation speed range is 3000−7500 rpm.

- Grinding wheel diameter. The most popular abrasive materials have a diameter from 105 to 400 mm. The ability to adjust the angle set for sharpening chains depends on its size.

- Electric motor power. The indicator affects the performance of the equipment. For professional machines it is more than 0.5 kW.

- Functional. Most devices are equipped with additional devices that increase operational safety and expand the range of equipment capabilities.

Manufacturers indicate the technical characteristics of equipment in their passports.

TOP 7 best models

When determining which sharpening machine is better or worse, their performance indicators, reliability, safety, value for money, as well as the popularity of the models with customers are taken into account.

"Oregon 519789"

The chainsaw chain sharpener is manufactured in the USA. This is professional electrical equipment. It is used to sharpen chains for all types of chainsaws with a chain thickness of 1.1-1.3 mm. The Oregon 519789 design has a self-centering mechanism. The work surface is backlit. The start button is built into the control lever. It has a comfortable ergonomic shape.

| Name | Unit change | Index |

| Power consumption | W | 214 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 2800 |

| Weight | kg | 6 |

Advantages of "Oregon 519789" : accelerated grinding, improved sharpening geometry, high productivity, ease of reconfiguration of operating and maintenance modes.

The cost of the machine starts from 31 thousand rubles. Manufacturer's warranty - up to 36 months.

STIHL USG

The machine is manufactured in Germany. Serves for sharpening all types of saw chains of chainsaws. It can be used to sharpen discs, cutters of brush cutters and brush cutters. The model is intended for equipping large wood processing enterprises. It has a large supply of working resources. The design of the device has a rotary support.

| Name | Unit change | Index |

| Power consumption | W | 180 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 2800 |

| Weight | kg | 8 |

Advantages of "STIHL USG" : good sharpening quality, silent operation, high productivity, versatility.

The cost of the model starts from 26 thousand rubles. The manufacturer's warranty period is 1 year.

"REZER EG235"

The machine is produced by Russian-Chinese manufacturers. The model is completely vibration-free during operation. It is intended for industrial and home use. The control handle has a convenient design. It is made of material that prevents it from slipping out of your hands. Operational safety is ensured by a transparent protective screen.

| Name | Unit change | Index |

| Power consumption | W | 235 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 3000 |

| Weight | kg | 7,6 |

- Advantages of the machine : ease of installation and operation, reliability, illumination of the working area.

- Disadvantages : plastic frame, inconvenient form of fastening the casing.

The cost of “REZER EG235” starts from 5,600 rubles. The manufacturer's warranty period is 12 months.

"SADKO SCS 85Pro"

The model is developed and produced by a Slovenian manufacturer. It is a semi-automatic device used for sharpening electric chains and chainsaws. "SADKO SCS 85Pro" has found wide application in everyday life and service centers. It provides high quality chain sharpening. The design has a regulator for quickly adjusting the sharpening depth. The chains are clamped manually. The sharpening angle range is from 0 to 30 degrees.

| Name | Unit change | Index |

| Power consumption | W | 85 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 5000 |

| Weight | kg | 2,5 |

Advantages of the model : sharpening accuracy, ease of use, low price.

The cost of “SADKO SCS 85Pro” starts from 4,200 rubles. The manufacturer's warranty period is 12 months.

"CHAMPION C2000"

The machine produced by a Chinese manufacturer is compact in size and intended for domestic use. It is used to sharpen the main and persistent cutters of chainsaws. The work area is illuminated.

| Name | Unit change | Index |

| Power consumption | W | 230 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 3000 |

| Weight | kg | 5,8 |

Advantages of CHAMPION C2000 : light weight, mobility, safety.

The cost of the machine starts from 6,900 rubles. The manufacturer's warranty period is 12 months.

"Foreman GM4P"

The model is designed for calibrated sharpening of chains. It is intended for household use. A graduated scale is installed on the rotary table of the machine, which helps to set the desired sharpening angle. “Brigadier GM4P” is distinguished by increased strength of fasteners, ensuring reliable fixation of chains. A protective screen is installed on the casing.

| Name | Unit change | Index |

| Power consumption | kW | 0,65 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 6300 |

| Weight | kg | 3,25 |

Advantages of “Foreman GM4P” : mobility, reliability and safety in operation.

The cost of the model starts from 3,300 rubles. The manufacturer's warranty period is 18 months.

"Proton TE-130"

A cheap and reliable sharpening machine. The machine bed is made of aluminum. The chains are secured using convenient fastening mechanisms.

| Name | Unit change | Index |

| Power consumption | W | 400 |

| Operating voltage | W | 220 |

| Revolutions | rpm | 3000 |

Advantages of the Proton TE-130 : low price, mobility, versatility.

The cost of the machine starts from 1,300 rubles. The manufacturer's warranty period is up to 18 months.

Which chain sharpening machine is better to choose?

The Russian market offers a large selection of sharpening instruments from different manufacturers; they differ in price, technical purpose and parameters. However, not every manufacturer offers guaranteed tool quality. Based on expert opinion and numerous user reviews, a rating was compiled that included companies that offer the best chain sharpening machines.

- Rezer – belongs to . Produces a wide range of consumables, spare parts and accessories for garden equipment. Consumables and accessories for chain saws are a priority area of production; they are suitable for different brands of electric chain saws and chainsaws.

- Diold is a Russian manufacturing company that has been supplying the market with a large selection of power tools for over 15 years. Provides stable prices for all products, offers high quality, and uses a competent approach to serving users.

- Whirlwind is a recognized authority in the production of power tools and pumping equipment. Supplies a good selection of hand-held units for DIYers and professionals. All equipment undergoes strict quality control, which makes it possible to provide a long-term guarantee and stable operation under high loads.

- Huter produces a wide range of power tools and garden equipment. The trademark was registered in 2004 and has earned the trust of consumers. All products undergo multi-stage control and meet international quality standards.

- Patriot - occupies a leading position in several categories simultaneously: power tools, garden and power equipment. Offers modern developments, innovative technologies, taking into account the needs of each customer.

- Champion is one of the most popular Russian manufacturers of portable garden and power equipment. Constant growth of capacity, decent quality and a well-coordinated team of professionals. The main advantage is affordable prices for all equipment, including the professional series.

- Caliber - produces a wide selection of tools in the segment from budget to premium class. All equipment and equipment is manufactured using modern equipment and undergoes strict quality control.

- Soyuz – produces a wide selection of electrical equipment, equipment, consumables and accessories. A feature of the brand is the high quality, durability of the devices, and a guarantee. One of the advantages of Soyuz brand equipment is its high maintainability rate.

- Dnipro - M - the best Ukrainian manufacturer produces a wide selection of diverse garden machinery, equipment and power tools. For several years, the brand’s equipment has enjoyed popularity and authority among home and professional craftsmen. Today the company has more than 22 service centers.

- Spets is a well-known Russian company that represents more than a hundred types of products. All machinery, power tools and power equipment meet international quality standards. The quality of components, assembly technology and a stable combination of price and quality make the brand’s products one of the top leaders in the Russian market.

Expert advice

Sharpening chainsaw chains has its own characteristics. In accordance with the technology of work, the teeth should not be allowed to overheat and should not be cooled with water. This leads to the destruction of the metal from which the chain is made. The material must never be cooled with water.

Expert opinion

Kuznetsov Vasily Stepanovich

Chains can be sharpened only with abrasive discs that have a perfectly flat surface. When using wheels with a coarse-grained surface, the cutting edges must be ground.

Which chain sharpening machine is best to buy?

Before you buy a unit, you need to accurately determine the frequency of its load. For infrequent use, it is better to take a compact, low-power model; for large amounts of work, you should pay attention to devices with a powerful engine. When you need to choose which machine is better, you can be guided by several factors:

- Whirlwind SZTs-200 is a good, stable machine with a protected shock-resistant body, according to reviews, a decent combination of price and quality.

- Rezer EG -85 CN – suitable for the home craftsman, the best choice when the saw is not sharpened often.

- Diold MZ-1.13 is a compact desktop unit, a good choice for a garage or home.

- Huter ECS -100 is a compact lightweight machine for sharpening chainsaw chains from the lightweight “loppers” series.

- Patriot MG 220 is the most economical power machine, a budget option for the home, garage, and garden.

- Champion C 2001 is the best model in terms of safety, reliable protective casing.

- Caliber EZS-220 is a machine with the fastest rotation speed of 7500 rpm, inexpensive and powerful.

- Soyuz TSS-60013 is a compact economy class model of good assembly, high-quality equipment, and high operating speed.

- Dnipro – M VSP-560 – Compact Machine with the Most Powerful Motor 550 W.

- SPEC-3244 SZ-150-250 is a good productive model for workshops, fast and accurate sharpening.

The review presented the best chain sharpening machines mainly for the household category. Each nominee has special parameters, pros and cons, and is able to cope with certain tasks.