The synthesis of the precision of a computer program and the delicate power of a laser beam is a processing technology that allows you to accurately cut sheet metal, cut out the most complex patterns and contours on the surface, but also quickly and without defects perform simple laser cutting of metals according to a given drawing. The resulting result is guaranteed to correspond to the given sketch, regardless of the complexity of the original drawing - computer programming of the movement of the beam when cutting metal is responsible for this.

- Each meter of pattern on the surface is reproduced at an average speed of ~60 mm/sec, depending on the selected material

- When laser cutting, concentrated fiber laser beams are used, the metal cutting error is a maximum of 0.05 mm, including the maximum sheet thickness

- A neat, even cut even with the maximum thickness of metals: the melting boundary in the process of cutting metal goes deep into the sheet material

The resulting result is guaranteed to correspond to the given sketch, regardless of the complexity of the original drawing - computer programming of the movement of the beam when cutting the surface is responsible for this.

Cost of high-precision laser cutting of steel

| Thickness, mm | Contour length up to 100 m, rub. | From 100 to 500 m, rub. | From 500 to 1000 m, rub. | Cost of one plunge, rub. |

| 0.8 | 45 | 28 | 25 | 1 |

| 1 | 45 | 28 | 25 | 1 |

| 1.5 | 47 | 33 | 30 | 1 |

| 2 | 49 | 38 | 34 | 1 |

| 2.5 | 55 | 47 | 42 | 1 |

| 3 | 65 | 54 | 49 | 1 |

| 4 | 75 | 61 | 55 | 2 |

| 5 | 90 | 71 | 65 | 2 |

| 6 | 115 | 82 | 75 | 2 |

| 8 | 160 | 105 | 95 | 2 |

| 10 | 210 | 175 | 132 | 5 |

| 12 | 260 | 200 | 165 | 5 |

| 16 | 450 | 330 | 300 | 10 |

| 20 | 550 | 495 | 450 | 10 |

Lasers

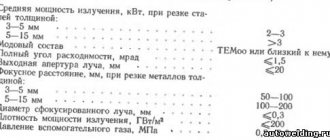

It is clear that the basis of any laser installation is the laser itself. Currently, several types of lasers are used for industrial cutting. Solid-state lasers based on yttrium aluminum garnet. The active element is pumped by high-voltage discharge lamps, continuous or pulsed. The solid-state laser radiation wavelength is 1 micron. The generation mode, accordingly, can be continuous or pulsed, and there is also a mode of the so-called giant pulse Q-switch.

Diode-pumped laser.

This is a new modern version of lasers in which, instead of a high-voltage gas-discharge lamp, pumping is carried out by powerful light-emitting diodes. While they are more expensive, there are no high voltages in the system, the service life of the diode bars is significantly higher than the service life of a gas-discharge lamp, and the lasers are better controlled by electronic systems.

CO2 lasers

— gas lasers based on a mixture of CO2-He-N2 gases. The mixture is excited by different types of electric discharge in gases. The CO2 laser radiation wavelength is 10 microns. Currently, the most compact and efficient are the so-called slab lasers pumped by a high-frequency discharge. Pulsed lasers cut not only steel and titanium, but also aluminum alloys with high quality. It is also possible to cut copper-based alloys, but here the efficiency very much depends on the chemical composition.

CO2 lasers are suitable for cutting both metals and non-metals, and almost any kind; it is not recommended to use laser cutting only for a number of materials with a complex structure - chipboard, bakelite plywood, granites. However, cutting metals requires a fairly high power level (from 500 W), and cutting non-ferrous metals requires 1000 watts or more.

Slit CO2 lasers are especially effective here, providing the so-called superpulse radiation mode, unlike other CO2 systems. This means that the light flux is not continuous, but consists of pulses with a frequency of 10-20 kHz, so that with an average power of, for example, 500 W, the power per pulse is 1000-1500 W. When cutting metals, this is very important, since the width of the cut is reduced, the quality is improved and the threshold for starting cutting is reduced.

Solid-state lasers cut non-metallic materials much worse than gas ones, but they have an advantage when cutting metals - for the reason that a wave with a length of 1 micron is reflected worse than a wave with a length of 10 microns. Copper and aluminum for a wavelength of 10 microns are an almost perfectly reflective medium. But, on the other hand, making a CO2 laser is easier and cheaper than a solid-state one.

Price list for cutting stainless steel sheets

| Thickness, mm | Contour length up to 100 m, rub. | From 100 to 500 m, rub. | From 500 to 1000 m, rub. | Cost of one plunge, rub. |

| 0.8 | 58 | 45 | 38 | 1 |

| 1 | 58 | 45 | 38 | 1 |

| 1.5 | 94 | 65 | 50 | 1 |

| 2 | 120 | 85 | 70 | 1 |

| 3 | 160 | 130 | 90 | 2 |

| 4 | 210 | 160 | 120 | 2 |

| 5 | 300 | 210 | 150 | 5 |

| 6 | 400 | 300 | 225 | 5 |

| 8 | 600 | 450 | 350 | 7 |

| 10 | 750 | 600 | 450 | 7 |

Technology

Currently, machines similar in their basic parameters, set of options and quality cost approximately the same. And since the latest laser cutting systems presented to the Russian market by such well-known global manufacturers as Bystronic (Switzerland), Trumpf (Germany), Mazak (Japan), Prima Industrie (Italy) are very similar, it makes sense to dwell on the general properties and characteristics, inherent in all these systems. In other words, to formulate general trends in the development of laser cutting technology and the main features of a modern laser complex for cutting materials.

Over 20 years of use, laser cutting technology has undergone significant improvements in terms of increasing the thickness of the material being cut and the speed of its cutting. Modern large laser cutting systems are now equipped with CO2 lasers with powers of up to 6 kW. Although typical installations have laser power that does not exceed 4 kW, they nevertheless make it possible to consistently cut steel sheets up to 19 mm thick, and in some cases up to 25 mm. For laser cutting of plates up to 12 mm thick made of corrosion-resistant steel, nitrogen pumped under high pressure is used.

Cutting speeds also gradually increase. If on standard laser installations galvanized sheet low-carbon steel with a thickness of 1.63 mm is cut at a speed of 12.7 m/min, then on the latest laser installations the same steel, but already 2 mm thick, is now cut at a speed of over 20 m/min . In addition, the speed of rapid movement of the working bodies reaches 100 m/min. As a result, the productivity of such installations when laser drilling sheets 2 mm thick can reach 3-4 holes per second.

Another trend in the development of laser systems is their automation. Automation in one form or another is used in most laser installations. Here we can note devices for loading large-sized sheets, loading and unloading systems, as well as tower storage systems into which workpieces are sorted by thickness and type of material. Traditionally, installations are controlled by CNC, including those based on personal computers.

The accuracy of laser cutting reaches 0.1 mm with a repeatability of +0.05 mm, and the quality of the cut is consistently high, since it depends only on the constancy of the speed of movement of the laser beam, the parameters of which remain unchanged.

A laser cutting installation is usually configured as follows: a table on which sheet workpieces are installed, a movable portal with a cutting head and a CNC to control the movement of this head along the workpiece, and some installations are equipped with two heads. However, this arrangement is only suitable for cutting small parts. When cutting large parts or those where the main requirement is the accuracy of the shape of the parts being cut, this arrangement is ineffective.

Most of the laser systems currently produced are made with “flying” optics or a moving laser beam. The material being cut remains stationary, and the laser beam moves along it, carrying out programmable cuts. The laser itself is placed directly on the installation frame or next to it (in this case, the beam delivery system directs it along the X and Y axes). Installations with “flying” optics are designed for processing workpieces with dimensions from 1.2x2.4 to 3x7.8 m and are equipped with two satellites, each of them located on its own work table. After cutting one workpiece, the satellites, together with the tables, change places, and the cut workpiece is removed from the satellite. This design allows for maximum use of the laser beam, and, consequently, maximum productivity of the installation. They continue to produce combined-type installations, in which the workpiece is placed on a table with movement along the X-axis, and the laser head moves along the Y-axis. Although they are simpler in design, they are less productive than installations with “flying” optics. Thus, the positioning speed of the latter is 3-10 times higher, the load capacity is doubled, and if you add a second table, then the shift productivity becomes 50-100% higher.

An important factor for cutting is the piercing of the initial hole to start it. Some laser systems have the ability to produce up to 4 holes per second using the so-called flying piercing process in cold-rolled steel 2 mm thick. The production of one hole in thicker (up to 19.1 mm) sheets of hot-rolled steel during laser cutting is carried out using power piercing in approximately 2 s. Using both of these methods allows you to increase laser cutting productivity to the level achieved with CNC punching presses.

Brief characteristics of the cut: there is usually no scale, the taper is less than 1w, the resulting holes are round and clean, it is possible to obtain very small parts, the cutting width is 0.2-0.375 mm, burns are invisible, the thermal effect is very small, it is possible to cut non-metallic materials.

Price list for laser cutting Dural/Aluminium (AMC, AMG)

| Thickness, mm | Contour length up to 100 m, rub. | From 100 to 500 m, rub. | From 500 to 1000 m, rub. | Cost of one plunge, rub. |

| 1 | 56 | 46 | 37 | 1 |

| 1,5 | 91 | 63 | 49 | 1 |

| 2 | 116 | 82 | 68 | 1 |

| 3 | 155 | 126 | 87 | 2 |

| 4 | 204 | 155 | 116 | 2 |

| 5 | 291 | 204 | 146 | 5 |

| 6 | 388 | 291 | 218 | 5 |

| 8 | 582 | 437 | 340 | 7 |

| 10 | 728 | 582 | 437 | 7 |

Equipment

All of the above is, to one degree or another, characteristic of all the best foreign models. A characteristic feature of the TRUMATIC L 3030-L 4030-L 6030 complexes from Trumpf, PLATINO 1530-2040 from Prima Industrie, BYSPRINT from Bystronic is the combination of precision engineering with the most modern laser and control technology.

So, highly productive, accurate, automated, and fairly easy to maintain - these are wonderful examples of modern machines. Everything seems to be fine. Buy and work. There is only one “but”. These almost works of art are expensive. The average cost of basic models exceeds half a million dollars. The price of even our installations, produced by ZAO Laser Complexes (Shatura), is close to two hundred thousand. Therefore, a quick refund is possible only with the rational use of such equipment. Here it is necessary to return to an issue that we have already touched upon several times - the choice of equipment for the task at hand. If it is necessary to cut thousands of the same part, then the use of such large complexes is justified. And if you have 10 of some, 20 of others, 50 of others, then due to readjustments and reinstallations, the share of direct cutting becomes significantly smaller, and, as a result, the use of such complexes becomes unprofitable. Is there a way out? In any case, the following proposal from domestic manufacturers can be considered as a possible alternative.

Price list for laser cutting of brass metal

| Thickness, mm | Contour length up to 100 m, rub. | From 100 to 500 m, rub. | From 500 to 1000 m, rub. | Cost of one plunge, rub. |

| 1 | 54 | 42 | 36 | 1 |

| 1,5 | 90 | 70 | 60 | 1 |

| 2 | 112 | 87 | 74 | 1 |

| 3 | 135 | 105 | 90 | 2 |

| 4 | 162 | 126 | 108 | 2 |

| 5 | 198 | 154 | 132 | 5 |

| 6 | 270 | 210 | 180 | 5 |

Laser processing of printed circuit boards

Despite the relative simplicity and high technical parameters of a combined laser-mechanical system, the ideal solution would still be to develop a relatively inexpensive all-laser device that allows, using a single laser source, both to process the conductive coating on the surface and to drill holes in the board material. In the process of studying the interaction of laser radiation with various materials used in the electronics industry, it became clear that it is not possible to produce one universal device for all occasions. Therefore, further developments were divided into several separate directions.

Applications and benefits of metal laser cutting

Any metal products are currently the basis and an integral part of human activity, and the need for extremely precise cutting extends to almost all areas:

- radio, electronics, engineering

- mechanical engineering, military industry, industry

- food industry

- medicine

- construction and agriculture

- advertising and design

The advantages of laser processing are a priority if you need to produce a batch or a single finished product according to non-standard dimensions, with the highest requirements for dimensional and shape accuracy.

The Proflazermet enterprise offers its own experience, qualified specialists and equipment capacity if you need to produce parts for electronic equipment, blanks of metal structures, various types of fastening elements, spare parts for equipment and individual parts for them. Separately, we draw your attention to the possibility of producing any volumes of advertising products and design elements for interiors, landscapes, and buildings.

Cutting materials

In industry, in addition to mechanical cutting, cutting is used, based on electrochemical, electrophysical and physico-chemical influences. These are oxy-acetylene cutting and plasma cutting, which provide higher productivity compared to mechanical methods. However, they do not provide the necessary accuracy and cleanliness of the cut surface and in most cases require subsequent machining. Electroerosive cutting allows you to obtain a cut of small width with high quality, but is characterized by low productivity.

Focused laser radiation makes it possible to cut almost any metals and alloys, regardless of their thermophysical properties. With laser cutting, there is no mechanical impact on the material being processed, and minor deformations occur. As a result, it is possible to carry out laser cutting with high precision, including easily deformable and non-rigid parts. Thanks to the high power of laser radiation, high productivity of the cutting process is ensured. In this case, such a high quality of cut is achieved that threads can be cut in the resulting holes.

Additional features of Proflazermet

The standard deadline for completing work is 5 working days. Of course, laser processing often requires extremely fast order execution, and in this case we are ready to consider the possibility of carrying out urgent work on an individual basis.

We send each client the finished volume in our own branded Proflasermet packaging - so you can be sure that you receive the products without damage during transportation.

Call!,

Discount offers, as well as all the detailed information about the features of the cutting technological process, cutting efficiency, timing and delivery, as well as any questions in related areas, can be obtained from our experienced consultants.

Features of laser metal processing

From the name it immediately becomes clear that laser metal processing is performed using a laser beam, which is supplied from a special installation. Due to its properties, the beam focuses high-density energy on a small area of the surface being treated. As a result, the material being processed begins to actively degrade (melt, burn, evaporate, etc.).

Equipment for laser metalworking is capable of concentrating energy with a density of 108 watts per square centimeter on the surface being processed. It is impossible to understand how such an effect is achieved without first understanding the properties of the laser beam. It is characterized by:

- Constancy of wavelength and frequency (monochromaticity). This is its main difference from light waves. Thanks to this property, it is not difficult to focus the beam on any surface using conventional optical lenses.

- High directivity and low tilt angle. This makes it possible to obtain a focused beam.

- Coherence, meaning the consistency and resonance of a large number of wave processes occurring in a laser beam. Thanks to this, the total radiation power increases significantly.

In a nutshell, laser metal processing can be described as follows. The beam, acting on the surface being treated, quickly heats and melts it. And since it continues to act on the metal being processed, the temperature at the point of contact reaches the boiling point, causing the material to evaporate.

Modern laser systems

The global machine tool industry keeps up with the times and offers its consumers a wide variety of equipment for laser cutting of metal.

Multi-axis machines are designed to replace noisy and low-performance mechanical cutters. The laser power depends on the specifics of production and the economic justification of the selected unit. The new generation of precision CNC machining machines allows materials to be processed with an accuracy of up to 0.005 mm. The processing area of some models of laser systems reaches several square meters. A great advantage is the minimization of the human factor, which consists in the high automation of the production process.

The geometry of the part is specified in a software unit that controls the laser and the work table with the workpiece. Focus adjustment systems automatically select the optimal distance for efficient cutting. Special heat exchangers regulate the temperature of the laser unit, providing the operator with control data of the current state of the tool.

The laser machine is equipped with valve mechanisms for connecting gas equipment to ensure the supply of auxiliary gases to the working area. The smoke collection system is designed to optimize the costs of exhaust ventilation, turning it on directly at the time of processing. The processing area is completely shielded by a protective casing for the safety of operating personnel.

Laser cutting of sheet metal on modern equipment turns into an easy process of setting numerical parameters and obtaining a finished part as an output. Equipment performance directly depends on the parameters of the machine complex and the qualifications of the operator creating the program code. The technology of laser cutting of metals harmoniously fits into the concept of robotic production, designed to completely free people from hard work.

Manufacturers offer different types of laser machines: universal and specialized. The cost of the former is an order of magnitude higher, but they allow several operations to be performed and parts of more complex shapes to be produced. A large number of market offers provides a choice for interested consumers.

We invite you to cooperate!

Our company uses high-precision equipment for high-quality laser processing of metal sheets and workpieces.

We provide high-quality cutting of structural steel up to 14 mm, stainless steel and aluminum up to 6 mm, brass up to 4 mm, copper up to 2 mm. To calculate the cost, you must send an application to [email protected] with scans in dxf format, indicating the number of products, type and thickness of the metal being processed.

The minimum cost of laser cutting services without the cost of materials is 3,000 rubles, including VAT. The turnaround time is from 1 working day if ready-made scans in dxf format are available.

If it is necessary to prepare files, we can make them according to your sketches and technical specifications. The cost of these services is determined in each specific case depending on the scope of work.

Application of devices

Industrial enterprises most often resort to the use of solid-state laser processing of metal. Cutting with such a device, or rather, radiation from the laser in this mode of operation can pass both in pulses and continuously. The main working fluid in such devices is ruby, glass with an admixture of neodymium or an element such as CaF2, that is, calcium fluorite. The greatest advantage of this installation is that it is capable of creating a very powerful laser pulse in a fraction of a second.

As for the use of gas lasers, they are most often used not at industrial facilities, but for scientific or technical purposes. When processing metal with laser machines of this type, a mixture of gaseous substances is used as a working fluid. Nitrogen, carbon dioxide and helium are used here. The atoms of these substances are excited under the influence of an electrical discharge. This provides such positive qualities as monochromaticity, as well as directionality. These properties are the main advantages of a gas laser.

The greatest power lies in gas-dynamic lasers. The main working substance is carbon dioxide. The process proceeds as follows. First, the gas is heated to a certain temperature. After this, it is fed into a narrow channel, in which the structure is expanded and the gas is cooled. During this procedure, the necessary energy is generated, which is used to carry out the laser cutting procedure.