Thermite pencil: composition

The thermite pencil consists of a core, which is made of carbon steel, and thermite, which is a flammable compound applied to the core.

Its combustion temperature is about 250 degrees Celsius, so be careful. Thermite itself consists of aluminum powder (25 percent) and crushed iron scale (75 percent). The ratio of components is determined by weight, not volume. There is another component known as nitrocellulose glue, which is used to give the metal components of the thermite a certain solid shape. When making your own, you can use other glue, but the process will go fastest with nitrocellulose, given the speed of its hardening and drying.

Thermite pencils also differ from each other in the diameter of the steel core. The thicker it is, the greater the mass of parts will be available for welding with a thermite pencil. As a rule, this diameter is two to five millimeters.

Finally, the third, quite important detail of the thermite pencil. A seed is applied to the tip of the pencil, which is prepared from one part of aluminum filings and two parts of Berthollet salt. They are also combined with each other using glue. Already from the name it is clear that with the help of a seed the pencil is set on fire.

How to use a thermite pencil

To activate the thermite pencil, you should set its seed on fire, and after the thermite itself flares up, you should directly weld the necessary parts. This process is similar to ordinary electric welding when an electrode is used. The seam will be almost identical.

When working with termites, you should be very careful; you must wear safety glasses and tarpaulin gloves (the combustion temperature is equal to the temperature of a hot oven). Be sure to weld in dry weather, when there is no possibility of water droplets getting on the welding surface. Otherwise, you risk causing a spontaneous explosion, which will splatter thermite and cause serious burns to you.

One final tip: Store your thermite stick in an airtight container that will protect it from moisture.

Using such a pencil, you can weld absolutely any steel surface that has a small area.

With this compact solution you can easily eliminate the need for electric or gas welding.

Comparison of the main characteristics of welding pencils from different manufacturers

Float switch for a pump: principle of operation, advantages

There are welding pencils with completely different characteristics. Each individual manufacturer brings something special to the product:

Oxal. These products boast high efficiency in the absence of any sources of electricity. To get started, all you need is a lighter or any other open flame. Repairs to restore the functionality of materials can be carried out regardless of the ambient temperature.

Nanopike. The welding pencil of this production is famous for its relatively low cost. It is even suitable for repairing heat-resistant plastic and enamel cookware. One rod can be used many times, since the material consumption is very economical.

Welding pencil Extreme. This version of the pencil is also used to restore metals and enamel. Pencil welding "Extremal" in quality gives more than half the strength of conventional contact welding.

Thanks to this universal tool, you can carry out emergency repairs even when you do not have the most necessary materials at hand. With its help, you can not only solder the resulting crack, but also cut the material. You just need to select the required brand of product with the required properties. Thermal pencil is capable of repairing the following surfaces:

- steel;

- cast iron;

- iron;

- brass;

- copper;

- ceramics;

- slate;

- heat-resistant plastic;

- bronze;

- stainless steel and other similar materials.

Lebedev welding pencil

There are times in life when things crack, rust or break. Urgent repairs are required, but the necessary materials are not at hand. At such moments, only a thermite pencil can save you. This unpretentious material will help carry out urgent repairs in the most emergency cases.

General description of the pencil

A welding pencil is a kind of universal tool for repeated welding. Outwardly, they resemble a cylindrical tube or pin, densely filled with an esothermic mixture mixed with metal oxides.

During combustion, the internal mass generates the necessary amount of heat that can melt the metal border of the surface being repaired. A layer of slag remains on the surface of the weld, protecting the solder joint from the harmful effects of the external environment.

This is extremely important, since pencil welding is usually applicable to materials where the degree of quality of the seam and its reliability should not be compromised

Comparison of the main characteristics of welding pencils from different manufacturers

There are welding pencils with completely different characteristics. Each individual manufacturer brings something special to the product:

Oxal. These products boast high efficiency in the absence of any sources of electricity. To get started, all you need is a lighter or any other open flame. Repairs to restore the functionality of materials can be carried out regardless of the ambient temperature.

Nanopike. The welding pencil of this production is famous for its relatively low cost. It is even suitable for repairing heat-resistant plastic and enamel cookware. One rod can be used many times, since the material consumption is very economical.

Welding pencil Extreme. This version of the pencil is also used to restore metals and enamel. Pencil welding "Extremal" in quality gives more than half the strength of conventional contact welding.

Thanks to this universal tool, you can carry out emergency repairs even when you do not have the most necessary materials at hand. With its help, you can not only solder the resulting crack, but also cut the material. You just need to select the required brand of product with the required properties. The thermal pencil is capable of repairing the following surfaces:

- steel;

- cast iron;

- iron;

- brass;

- copper;

- ceramics;

- slate;

- heat-resistant plastic;

- bronze;

- stainless steel and other similar materials.

How to use the product

An individual feature of the use of this welding material is the possibility of its use in welding even on an unprepared surface. The pencil contains special oxidizing fluxes. which are capable of self-cleaning surfaces. Still, it is worth noting that cleaned and prepared parts are easier to weld and have a more reliable connection.

- The instructions for use are quite simple and consist of the following steps:

- Set fire to a pencil, you will not see a bright flame, it will slowly melt;

- Gently “smear” the softened end over the surface to be welded;

- The thermite welding process begins, the mixture will periodically emit sparks, and active interaction of fluxes with the metal is observed;

- The welding is completed, the hardened and cooled joint can be cleaned with a wire brush or sandpaper.

Attention! As a safety precaution, you should use pliers or other clamps. It is a good idea to wear safety glasses and gloves to avoid burns to your eyes or skin.

DIY making

Physical basis of PES operation. advantages and disadvantages of PES, their impact on the environment. pros and cons of pes. pes advantages and disadvantages

Similar products can be purchased in specialized stores. Their cost is relatively low. But it’s really possible to create a pencil with your own hands. To do this, you will need to find a base - carbon steel wire. A conventional electrode rod with a diameter of 3-5 mm, which should be freed from coating, is suitable. This is done by lightly tapping the hammer along the entire length of the electrode. Next, the steel wire is cut into pieces of 150 mm.

The metal base must be provided with another coating. Your homemade composition should include 24% aluminum filings and 76% iron scale. The connecting link is Moment glue or similar substances. Mixing can be done in clay or glass containers.

The metal rod must be dipped into the coating composition, and the product must be wound onto the base with rotational movements. You should strive to form a coating layer of 5-7 mm on each side of the wire axis. The end can be left free - a homemade pencil will be held by it.

The second end serves as the ignition point. To do this, you need to create a seed. It consists of Berthollet salt and aluminum filings in a ratio of 2 to 1. All this is held together with the same glue. Balls are rolled from the mixture and attached to the end of a pencil. All this should dry within 20-30 minutes, after which you can practice welding.

Welding pencils have their drawbacks: the ability to weld only for 30 seconds, and work with metals whose thickness does not exceed 4 mm. But despite this, such a welding device is indispensable in situations where you need to quickly weld a hole or attach a fallen part. And the ease of use allows even non-specialists to use it.

Welding pencil

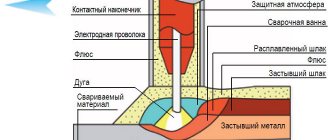

Electric arc welding allows high-quality joining of various metals by fusing their edges and filler material.

But if using a welding machine is impossible due to field conditions, lack of electricity, or an emergency situation, then a welding pencil can help.

This is not a 100% replacement for electric arc welding, but only a means to quickly resolve the situation. Over time, the connection should be redone using more reliable welding methods.

What it is?

A welding pencil is a thin cylinder, about 170 mm long.

It consists of a base - a metal rod that serves as solder, and a part covering it, designed to create a melting temperature and form a protective cloud that prevents the interaction of the molten metal with the external environment. Because it works with temperatures up to 2900 degrees, it is also called a thermal pencil. The invention is intended for welding work on metal, as well as for soldering aluminum and copper.

To use a pencil, just light one of its ends and apply it to the parts to be welded. Next, the seam is made evenly along the connection line. Thermal pencil can also be used for cutting metal plates or rods. To do this, instead of drawing above the surface, they should warm up the desired place and try to push it with the pencil itself.

Thermal welding pencil has a number of advantages that make it indispensable in some situations:

- ease of adaptation;

- autonomy (no electricity or fuel required);

- compactness (fits into any pocket of clothing or backpack);

- allows you to carry out welding work in hard-to-reach places (under the car, between battery registers);

- a temperature of 2900 degrees ensures the melting of most metals;

- stable combustion, which is difficult to stop, which makes it suitable for welding even on a wet surface;

- versatility of the product, applicable to work on different materials;

- ease of use as described on the packaging.

Where is a welding pencil used?

The soldering or welding pencil has been successfully used in a variety of field conditions. For example, when hiking and fishing, you need to quickly build a simple canopy, a tripod for a fire, or fix a leak in an iron boat. If the muffler or bumper mount comes off while driving a car, you can also use welding pencils.

This product is also irreplaceable in the countryside. With its help, you can straighten a fence, repair a torn canopy on a gate, or weld a gap in a metal door. It is convenient for them to repair batteries when they leak in the middle of the heating season.

If a milk can has leaked, there are universal pencils that are also suitable for soldering aluminum. They work on the same principle, only they do not need to make a seam, but only point the solder to the right place.

The aluminum composition continues to burn on the product itself, allowing it to fuse deeper into the base metal.

Technology of use

It is easy to work with a welding pencil, which is convenient in the household if you have to solve some everyday issues yourself. To perform welding, you must adhere to the following order:

- Prepare the surface to be welded by clearing it of debris and placing the product in the desired position.

- Print out the packaging and take out a pencil.

- The metal cover moves to the rear end, where it acts as a handle.

- Wear gloves made of thick fabric.

- A lighter is used to ignite the exposed end.

- The welding pencil burns like a sparkler - this is its natural behavior in working condition. To protect your eyes, you must wear dark glasses or use a mask.

- The end of the welding device is brought to the starting point of the connection and pressed tightly against the surface. It takes about 3 seconds to hold the pencil in one place to sufficiently warm up the sides to be welded.

- The seam is carried out without hesitation, from right to left. If you do it too quickly, the joint will be filled with slag, but there will be no bond between the metals. If done slowly, burns may occur.

- When the seam is laid, the pencil stub should be thrown onto a non-burning base (concrete, earth or water). There it will burn out safely and go out.

DIY making

Similar products can be purchased in specialized stores. Their cost is relatively low. But it’s really possible to create a pencil with your own hands. To do this, you will need to find a base - carbon steel wire. A conventional electrode rod with a diameter of 3-5 mm, which should be freed from coating, is suitable. This is done by lightly tapping the hammer along the entire length of the electrode. Next, the steel wire is cut into pieces of 150 mm.

The metal base must be provided with another coating. Your homemade composition should include 24% aluminum filings and 76% iron scale. The connecting link is Moment glue or similar substances. Mixing can be done in clay or glass containers.

The metal rod must be dipped into the coating composition, and the product must be wound onto the base with rotational movements. You should strive to form a coating layer of 5-7 mm on each side of the wire axis. The end can be left free - a homemade pencil will be held by it.

The second end serves as the ignition point. To do this, you need to create a seed. It consists of Berthollet salt and aluminum filings in a ratio of 2 to 1. All this is held together with the same glue. Balls are rolled from the mixture and attached to the end of a pencil. All this should dry within 20-30 minutes, after which you can practice welding.

Welding pencils have their drawbacks: the ability to weld only for 30 seconds, and work with metals whose thickness does not exceed 4 mm. But despite this, such a welding device is indispensable in situations where you need to quickly weld a hole or attach a fallen part. And the ease of use allows even non-specialists to use it.

Share with your friends

Technology of use

Hydrogen engine: features, advantages and disadvantages

Working with a welding pencil is easy, which is convenient for housewives who have to solve some household issues themselves. To perform welding, you must adhere to the following order:

- Prepare the surface to be welded by clearing it of debris and placing the product in the desired position.

- Print out the packaging and take out a pencil.

- The metal cover moves to the rear end, where it acts as a handle.

- Wear gloves made of thick fabric.

- A lighter is used to ignite the exposed end.

- The welding pencil burns like a sparkler - this is its natural behavior in working condition. To protect your eyes, you must wear dark glasses or use a mask.

- The end of the welding device is brought to the starting point of the connection and pressed tightly against the surface. It takes about 3 seconds to hold the pencil in one place to sufficiently warm up the sides to be welded.

- The seam is carried out without hesitation, from right to left. If you do it too quickly, the joint will be filled with slag, but there will be no bond between the metals. If done slowly, burns may occur.

- When the seam is laid, the pencil stub should be thrown onto a non-burning base (concrete, earth or water). There it will burn out safely and go out.

Welding pencil: characteristics and application of a universal tool - Welding

There are times in life when things crack, rust or break. Urgent repairs are required, but the necessary materials are not at hand. At such moments, only a thermite pencil can save you. This unpretentious material will help carry out urgent repairs in the most emergency cases.

Description of the welding pencil, its operating principle, advantages and disadvantages

Every person in life may have a situation when it is urgently necessary to solder a radiator, zinc bucket, enameled basin or other product.

But not everyone has a welding machine or soldering iron at home or in the garage; to work with them you need to have certain skills. Therefore, an easy-to-use welding pencil can be an alternative for home craftsmen.

It is used for thermal welding, surfacing and cutting of alloys and metals both in domestic conditions and during emergency rescue operations.

A welding stick, or thermal solder, is a thin-walled tube or rod of flammable material. On one side the tube is filled with a dry flammable substance, and on the other it is closed with a plug. The substance is an exothermic mixture that consists of flux and solder.

The diameter of the product can be from 4 to 16 mm, and the length of the tube can be from 7 to 20 mm. Pencil device:

- incendiary mixture;

- exothermic process mixture;

- cardboard sleeve;

- hole for pen holder;

- shell from instruction label;

- outer protective waterproof shell.

The average burning time of the rod is at least 30 seconds, the maximum combustion temperature is from 2200 to 2900 degrees Celsius, the weight is no more than 80 g. Depending on the thickness and type of material, the length of the seam can be from 8 to 15 cm.

Principle of operation

Thermal solder is easy to use and does not require special skills. To work, it is enough to study the manufacturer’s instructions and strictly follow the technology outlined in it. To weld, you must:

- Clean the workpiece from dirt and rust and fix it in the desired position.

- Remove the thermal solder from the package.

- Remove the metal cover and secure it to the plug side. She will act as a holder.

- To protect your hands from burns, wear gloves made of thick fabric, and to protect your eyes, wear dark glasses or a welding shield.

- Use matches or a lighter to ignite the exposed end.

- Bring a welding pencil, which burns according to the principle of a sparkler, to the welding site and hold tightly for three seconds at an angle of 45-60º. During this period, the surface to be welded warms up well.

- The seam must be carried out confidently, from right to left. The joining of metals will not take place if it is done quickly, the seam will simply be filled with slag. And if you drive too slowly, you can burn the surface.

- After the seam is laid, throw the burning cinder onto any surface made of non-combustible materials so that it goes out.

- Clean the cooled seam from scale.

When working with the device, you should remember that in welding, seams are processed using different methods. The following types of seams exist:

- Horizontal. In this way, the material is most often joined with an overlap. The workpiece is placed on a surface made of non-combustible materials.

- Vertical. For this method, a special shelf is used, which is placed under the soldering area so that the molten metal does not spread.

- Metal cut. With this method, the seam must be made slowly to burn through the metal.

Description of the welding pencil, its operating principle, advantages and disadvantages

Every person in life may have a situation when it is urgently necessary to solder a radiator, zinc bucket, enameled basin or other product.

But not everyone has a welding machine or soldering iron at home or in the garage; to work with them you need to have certain skills. Therefore, an easy-to-use welding pencil can be an alternative for home craftsmen.

It is used for thermal welding, surfacing and cutting of alloys and metals both in domestic conditions and during emergency rescue operations.

A welding stick, or thermal solder, is a thin-walled tube or rod of flammable material. On one side the tube is filled with a dry flammable substance, and on the other it is closed with a plug. The substance is an exothermic mixture that consists of flux and solder.

The diameter of the product can be from 4 to 16 mm , and the length of the tube can be from 7 to 20 mm. Pencil device:

- incendiary mixture;

- exothermic process mixture;

- cardboard sleeve;

- hole for pen holder;

- shell from instruction label;

- outer protective waterproof shell.

The average burning time of the rod is at least 30 seconds, the maximum combustion temperature is from 2200 to 2900 degrees Celsius, the weight is no more than 80 g. Depending on the thickness and type of material, the length of the seam can be from 8 to 15 cm.

Principle of operation

Thermal solder is easy to use and does not require special skills. To work, it is enough to study the manufacturer’s instructions and strictly follow the technology outlined in it. To weld, you must:

- Clean the workpiece from dirt and rust and fix it in the desired position.

- Remove the thermal solder from the package.

- Remove the metal cover and secure it to the plug side. She will act as a holder.

- To protect your hands from burns, wear gloves made of thick fabric, and to protect your eyes, wear dark glasses or a welding shield.

- Use matches or a lighter to ignite the exposed end.

- Bring a welding pencil, which burns according to the principle of a sparkler, to the welding site and hold tightly for three seconds at an angle of 45-60º. During this period, the surface to be welded warms up well.

- The seam must be carried out confidently, from right to left. The joining of metals will not take place if it is done quickly, the seam will simply be filled with slag. And if you drive too slowly, you can burn the surface.

- After the seam is laid, throw the burning cinder onto any surface made of non-combustible materials so that it goes out.

- Clean the cooled seam from scale.

When working with the device, you should remember that in welding, seams are processed using different methods. The following types of seams exist:

- Horizontal. In this way, the material is most often joined with an overlap. The workpiece is placed on a surface made of non-combustible materials.

- Vertical. For this method, a special shelf is used, which is placed under the soldering area so that the molten metal does not spread.

- Metal cut. With this method, the seam must be made slowly to burn through the metal.

Advantages and disadvantages of thermal solder

Based on the opinions of welding pencil users, it is possible to systematize its advantages and disadvantages identified during the work process.

Advantages of thermal solder:

- budget cost;

- small dimensions, which allows you to move the device without problems;

- ignition from a lighter, matches;

- high-quality sealing;

- temperature resistance;

- quick repair of damaged products;

- there is no need for a specially equipped place for such work;

- no need for electrical power;

- high productivity and efficiency;

- no need for special skills;

- versatility in working with various materials.

Disadvantages of the device:

- radiation of sufficiently strong fire;

- unpleasant odor after use;

- unacceptable for large volumes of welding work.

Almost all users are unanimous on only one thing: repairs using a welding pencil should be partial or temporary.

Welding Pencil Manufacturers

There is a wide variety of welding pencils on the welding products market, but you need to buy only from trusted suppliers who produce certified products, which is documented. Such products include the following brands.

- Extra ration. This soldering pen is reusable and has an unlimited service life. It is made using special technology and ensures adhesion to any surface made of plastic, ceramics, metal, in different planes. The manufacturer promises the consumer up to 30 rations with one pencil.

- Nanopike. This is a reliable tool for repairing holes and cracks in cars, plumbing, and household appliances. The manufacturer recommends that before sealing, wipe the damaged area with a rag and clean it with a knife or sandpaper. Light the welding pencil and transfer the molten mass to the soldering site. After burning the molten mass for 15-20 seconds, distribute it over the damaged surface. The renovation is complete. The soldering hardens in 15 minutes, and its complete hardening will occur in 1.5 hours. The manufacturer provides a one-year warranty on soldering. Recommended for working not only with various types of metals, but also with non-metallic surfaces.

- Extreme. This model is a universal thermal solder. Strong soldering is guaranteed due to the use by the manufacturer of tin, lead, as well as aluminum powder and magnesium in the composition of the combustible substance. In addition to metals, the substance contains flux and soldering acid. The scope of application of the pencil is varied. Soldering can be carried out in different planes.

About using the product

Before starting repair work, the parts to be connected are prepared. The work area is cleared of flammable substances, dirt and grease. The parts are pressed tightly against each other and secured with a clamp or vice.

When using the product, observe the following rules:

- Carefully prepare the work area. Remove all flammable materials and substances.

- Parts are never welded by weight.

- Be sure to use protective equipment. A special mask will prevent facial skin burns. Thick gloves will protect your hands from exposure to hot melt. The work suit should not leave any exposed areas of the body.

- When igniting and applying, the product is held tightly with a special device. It is guided along the seam smoothly, without sudden movements. You cannot walk around the room with a burning rod.

- The metal should not splash to the sides or get into the hands of the master.

- Leftover pencils should not be thrown on the floor. They leave the workplace only after burning out.

Horizontal seam connection

When welding parts using this technology, a plate of refractory material - brick, concrete, thick metal - is placed under the seam.

After installing the parts to be welded, perform the following steps:

- Bend down the edge of the heat sealing pencil package. The lower part is secured with a holder.

- Light the thermite mixture, which should become loose. The end of the rod is placed on the connection, and the molten mass is applied in a circular motion.

- After 3-4 seconds, straighten the seam, giving it the desired shape.

- The remaining product is placed in cold water or snow. They will burn to the place where the holder is installed.

Metal cutting

Thermal pencil is used not only for joining, but also for cutting metal sheets and rods. The rod is guided along the line at a speed lower than during welding. There is no need to place a substrate; the melt should not remain in the cut.

Welding pencil technology

In order to carry out welding or soldering work using a welding pencil, you must follow the instructions, which do not require special professional skills and are extremely simple:

- the control tape on the packaging wrapper breaks; when the tape is torn off, the extreme edge of the pencil is exposed;

- remove the metal cover and place it on the back end of the pencil as a handle when lighting it;

- you need to bring a pencil to the cutting site and light the fuse wick; you can use a lighter to ignite;

- The already burning welder's pencil must be pressed tightly to the place where welding or cutting of the metal surface should begin. It is necessary to wait 3-4 seconds for the metal to warm up, and then, moving the pencil, cut or weld;

- After this, the pencil can be thrown onto a layer of non-flammable material (concrete) or into water. The pencil will burn to the metal handle-cover.

It is also necessary to remember that a pencil for welding metal at a high combustion temperature can burn the surface that needed to be welded.

For each surface there are pencils of various diameters with additives that slightly reduce the burning temperature and prevent burning.

The welding stick contains metal oxides, which when burned create a layer of slag over the weld (only in large diameter sticks that are used for welding).

This innovation is used to then protect the melt layer from the surrounding air from the atmosphere.

This is due to the fact that pencil welding can be performed on surfaces where the quality of the seam and its strength are important

The entry of air is unacceptable, as this can destructively change the structure of the metal in the melt.

Metal welding pencil

In a situation where there is no welding machine and repair of metal surfaces is necessary, a welding pencil will help out. It is applicable in any conditions and does not require any skills to operate. Compact, you can take it with you on hikes, long car trips, hunting or fishing.

A thermite pencil can be used when repairing a radiator, muffler, or utensils when there is no access to power. In extreme situations, emergency services use metal cutting rods. The rods are named after the creator, Professor Lebedev. Currently, 18 trains of different capacities have already been developed.

What it is

Externally, Lebedev's welding pencil looks like a steel rod with a pointed end. This is a combustible pencil case filled with compacted powder. For safety, the design is equipped with a holder; it can be put on either side of the rod. Main structural elements:

- waterproof protection (marking is done on it);

- a sleeve made of cardboard or thick paper;

- thermite mixture;

- exothermic reaction components (solder and flux);

- mount for holder (cover).

The thermite mixture contains flammable components that provide the temperature necessary for melting the solder and flux. When it is lit with matches, an oxidation reaction occurs. At the tip, reduced liquid metal appears under a layer of slag. When these hot components are transferred to the damaged area, a weld is formed.

On average, the rod can be used for about 20 seconds. Safety must be observed: the temperature in the heating zone reaches 3000 degrees. The composition of the thermal mixture may include manganese steels alloyed with: tin, copper, chromium, nickel, silicon.

The operating principle is the same as welding. The difference is that the area of processing with a pencil is insignificant, the delamination of the alloy into metal and slag is difficult, so a fragile seam is formed, something between welding and soldering. The rod is suitable for emergency situations and is used in hard-to-reach places. It cannot be considered as an equivalent replacement for electrodes.

Where is it used?

A universal welding pencil is used for repairing metal surfaces outdoors at any time of the year. Combustible components can be ignited in the rain or wind. With the right choice of mixture, you can make a seam or cut of any geometry in the vertical, horizontal and inclined plane. Several standard sizes of rods of different power are available.

A pencil for welding metal can be used when restoring heat-resistant materials:

- cast iron;

- carbon alloys of any chemical composition, including stainless steel;

- copper and its alloys (brass, bronze, cupronickel);

- aluminum and its alloys (duralumin);

- metal ceramics;

- refractory plastic;

- roofing multicomponent heat-resistant coatings;

- slate.

Using a thermal rod, without welding skills, you can:

- eliminate defects in parts and body of the machine;

- restore non-ferrous metal products;

- remove chips on cast iron;

- install metal structures in extreme conditions;

- repair the pipeline and heating system;

- connect the wires;

- carry out cutting of metal and other non-flammable surfaces.

Advantages and disadvantages of using a thermite pencil

The exceptional properties of a welding pencil are explained by its composition: The mixture is simply ignited, in a matter of seconds it heats up to high temperatures, and forms joints comparable in strength to a weld.

Pros of using a pencil:

- there is no need for power supply;

- no need to prepare the work area;

- short duration of work;

- easy start of the chemical process, just ignite the mixture with matches or a lighter.

- the ability to carry out work in extreme conditions and hard-to-reach places;

- safety during transportation;

- high performance;

- does not require special skills or professional training;

- no need to use eye protection - the material practically does not spark;

- versatility: suitable for metals and other refractory materials.

The thermal rod was created for extreme situations, this explains its disadvantages:

- short duration of action;

- there is no way to control the quality of the seam;

- harmful components are released during the heating of the mixture;

- too expensive to use for large volumes of welding work;

- If the protective packaging is damaged, the mixture can absorb moisture, after which it can be difficult to ignite.

Common types

The main characteristics of the welding pencil are indicated on the packaging. The minimum width of the rod is 4 mm, the maximum is 16. The length varies, the maximum is 20 cm. The smallest 7 cm are designed for spot restoration work. Weight ranges from 70-100 grams.

, the largest manufacturer of welding products, differentiates by color: cold-colored labels are made for welding mixtures. If you need mixtures for cutting, look for packages in warm colors. Each diameter has its own distinctive color. There is a table that determines the type of rod corresponding to the thickness of the parts being repaired.

Types of welding pencils:

- oxal - has high efficiency, is easy to ignite, works in any conditions;

- extra solder - designed for tinning, suitable for aluminum, plastic, restores enameled surfaces well;

- nanosolder - contains magnesium as part of the thermite mixture, suitable for refractory steels and plastics, fire-resistant metal-ceramics;

- extreme - sales leader; The strength of the seam is comparable to welding, suitable for many types of materials.

Advantages and disadvantages of using thermite pencil

The significant advantages of this emergency repair method include the following:

- the welding pencil fits even into the most difficult to reach places;

- it does not require an electrical connection;

- due to its minimal size, it can be carried even in a jacket pocket;

- working with the rod is so simple that it does not require any specialized skills;

- solder allows welding both at home and in the field;

- the created weld is resistant to heat treatment up to 180 degrees;

- The cost of the pencil itself is extremely low.

We recommend! Types and classification of electrodes for welding

The product creates the appearance of a lifesaver for all occasions, but it still has disadvantages:

- if the volume of necessary repairs is too large, then several pencils may be required at once, which simply may not be at hand;

- high consumption of material, as with conventional resistance welding, only instead of electrodes the pencil itself is consumed.

Universal thermal solder-sealant “Extremal”

Solder sealant extreme is a unique repair and restoration product that saves in a wide variety of situations.

A leaky galvanized bucket, garden watering can or enamel basin no longer has to be thrown away. Now it’s easy to solder the radiator right on the track. Welding pencil (solder-sealant) “Extremal”: - designed for mobile elimination at home and in the field of damage to products made from almost any material, both metals and non-metals; — does not require pre-treatment of the soldered metal with rosin or acid (including no need to strip enameled products to steel); — does not require additional flux (flux included); - does not require the use of electricity; — does not require special storage conditions; - can be reused; - shelf-life Unlimited. - one pencil is enough for about 40 - 50 rations.

Considering that the welding pencil (solder-sealant) “Extremal” can be used repeatedly and its shelf life is not limited, it makes sense to purchase it even just in case, so that it is always at hand. It is especially recommended to purchase it for people who have a garden plot (at their dacha there are always watering cans, buckets, tanks and iron barrels) and motorists.

You can use a welding pencil (solder-sealant) “EXTREMAL” without pre-treating with rosin or acid the damaged surface (rusted hole, cracks, etc.) of products made from materials such as: - cast iron; - steel; - iron; — aluminum and duralumin; - copper; - bronze; - brass; - slate; - plastic; - stainless steel; — galvanizing; - and others.

Method of application: — wipe the damaged surface dry (rust does not need to be removed); — set fire to the pencil from either end, for example, from a lighter; - place the burning molten mass on the damaged surface directly from the pencil; — the entire mass from the pencil instantly sticks to the surface, and the pencil no longer burns; — the product continues to spark and burn on the surface being repaired, give it 15-20 seconds to work; - after completion of the reaction, tamp with the same preparation (pencil) or glass (run the pencil over the soldering area); - wait 15-20 minutes until restoration after soldering is completed.

Tinning: - on heated metal up to 110°C (it is not necessary to remove rust), apply the preparation in a circular motion to the damaged surface, while thickness and quality do not matter.

Invention of the pencil

Ultimately, these technologies led to the birth of the idea of a compact welding tool in the shape of a pencil rod.

However, when bringing the idea to life, the “pioneers” faced failure. The fact is that when the mixture cools quickly in the weld pool after the pencil stops burning, the slag and metal mix and the material becomes brittle.

As a result, mixtures based on aluminum thermite did not give a positive result both in the professional environment and in the literature, the “pencil” model was recognized as “not feasible” and for a long time no one dealt with this issue until a professor, Doctor of Technical Sciences appeared, Academician Lebedev Vladimir Georgievich.

Having accidentally become acquainted with the idea, he first calculated a mathematical model, and then implemented a chemical one, based on copper thermite, in which the metal-slag pair is separated in the process of forming a solder-alloy.

Open publications by V.G. Lebedev in Russian publications became the basis for the creation of several welding tools present on the Russian market.

Welding pencils Shkval and Oksal are produced in St. Petersburg and are used for welding, soldering and cutting without the use of any special gas welding or electric welding equipment.

Autonomous mobile welding – pencil SK-1, Moscow

Varieties

The market is constantly updated with new products for fast welding. Some of the products, unfortunately, do not have accurate information about the composition, manufacturers, or product certification.

Sometimes it seems that such products are produced using artisanal methods. You need to choose welding pencils carefully. You should buy products only from trusted brands that have proven themselves well among users. The list of well-known quality products includes:

- The extra solder welding pencil is good at welding holes in parts made of ferrous metal, aluminum, alloys with enameled coatings, and polymers. They can restore the enamel layer and tinning surfaces. The thermal cylinder has an unlimited shelf life. Manufacturers recommend purchasing it with a reserve in order to avoid difficulties in extreme situations;

- nanosolder is a welding stick containing magnesium as part of the thermite mixture. It also reduces iron from scale, releasing large amounts of heat. Recommended for working with any metallic and non-metallic materials;

- The extreme welding pencil has a good reputation. It is suitable for repairing metal products without coatings and with an enameled outer layer. It is inexpensive, the strength of the resulting seam reaches up to 70% of the strength of the joint obtained by electric arc welding.

Operating principle

Thermite mixtures consist of aluminum and iron oxide, which is often called scale. When this mixture is ignited, an intense exothermic process begins.

Let us recall that exothermic reactions include those that release energy. The reduction of iron from oxide by aluminum occurs with the release of a large amount of heat.

The reaction temperature is so high that the resulting iron melts. It is this melt that is used to fill holes, gaps, and cracks in repaired products.

The aluminum oxide formed in parallel acts as welding slag. In a metal welding pencil, in modern terms, “everything is included”: flux, metal to form the weld, an energy source for melting.

There are several types of pencils. Instead of aluminum, magnesium can be added to the thermite mixture. The effect will be exactly the same. Depending on the material that is recommended to be welded, welding pencils are made using different technologies.

Sometimes, in addition to the thermite mixture, a metal rod is placed in the center. It melts at high temperatures and serves as the basis for the seam. In other modifications, they are limited to only the thermal mixture. Fusion occurs due to the resulting iron.

Varieties

Thermal pencils are a ubiquitous and relatively cheap product. Therefore, many fake pencils or models are produced that are made without the appropriate conditions and materials.

At the moment, about 18 types of different mixtures for thermal pencils have been developed. However, there are only a few types of thermal pencils that are guaranteed to be of good quality.

- Extra ration. Designed for welding enameled objects, plastic and aluminum products.

- Nanopike. It is a thermite pencil. It got its name because of the mixture with which it is filled. The latter includes magnesium. Designed for refractory materials.

- Oxal. It is distinguished by easy ignition, as well as the possibility of universal use.

- Extreme. The seam that this pencil can make will be practically no different from a welding one. Designed for all materials.

Some manufacturers give their products different colors depending on the purpose of use (cutting or melting).

Special craftsmen are able to make a welding rod using a graphite pencil at home.

Welding pencil: features and application

Over time, any, even the strongest weld can fail, and the product will lose not only its aesthetic appeal, but also its practical properties. It is not always possible to carry out repairs using a full set of welding equipment, and in such situations a welding pencil, also called a soldering-welding rod, comes to the rescue. With its help, you can perform quick and relatively durable repairs even in extreme conditions.

In this article we will describe in detail what a metal welding pencil is, how to use it in your work, and what nuances should be taken into account.

General description of welding pencil

Solder welding rods are cylindrical pencil-like products consisting of a combustible shell and an esothermic mixture, which in turn includes solder and welding flux. To work with welding rods, they must be set on fire using matches or a lighter, after which the shell burns and the release of solder and flux begins. Therefore, a welding pencil is also called a thermal pencil.

Using a thermal pencil, you can not only solder, but also cut metal. Its properties may vary depending on the manufacturer. We talk about this in detail in the “Popular Manufacturers” section.

How to use a welding pencil

The use of a thermal pencil requires preliminary preparation. Clean the future soldering or cutting area from rust, dirt, paint and stains. Then you need to set the pencil on fire using matches or a lighter. Hold the pencil over the flame until solder and flux begin to release from it; they need to be applied to the damaged areas of the part.

Note! Once solder and flux are applied to a part, they may spark. Follow safety precautions, use protective gloves, glasses and clothing

It is recommended to keep the thermal pencil in a clamp or pliers at a distance to avoid getting burned.

Then wait 15-20 seconds and press the pencil onto the area where you previously applied the solder and flux. This is necessary for final welding of the part. Ready! For a better result, you can use a clamp, tightly fixing the parts to be welded, if necessary.

Advantages of working with a welding pencil

Welding rods have the following advantages:

- To carry out welding work, you only need an open flame, unlike a welding machine, which requires electricity.

- It does not take up much space and is resistant to temperature changes, so it is a frequent companion on hikes.

- You can carry out repairs anywhere: from your own apartment to completely field conditions.

- The repair does not take much time and after a couple of minutes the product can be used again, moreover, the connection is sealed and relatively durable.

- Affordable price (on average from 50 to 200 rubles per package).

Popular manufacturers

There are many manufacturers of welding rods, but we will focus on three popular ones. Each manufacturer makes its own adjustments to the composition and characteristics of pencils, so they may differ.

Welding pencil Oksal. This is the most popular brand of pencil; it can be used to make repairs in a wide range of temperatures, so that even in hot summers or cold winters, the Oksal welding pencil retains its characteristics. The Oxal welding pencil is very popular among beginners because it is the easiest to work with. It is universal and can be used for any repair since the welding temperature is around 3000 degrees Celsius.

The Extreme welding pencil is also popular. It is similar to Nanopayk, but costs half as much. However, it has one significant drawback: the resulting connection is not very reliable and durable, so it is better to use it for temporary repairs.

Instead of a conclusion

Welding pencils allow you to quickly perform minor repairs; this does not require special skills or high qualifications. They can be quite effective when repairing small items, but we recommend using pencil welding only in special cases when it is not possible to use a welding machine. Subsequently, it is better to have the part “overhauled,” especially for automotive repairs. Do not consider thermal pencils as a complete replacement for welding equipment.

[Total: 0 Average: 0/5]

What is a welding pencil

When repairing metal products, it is very difficult, almost impossible, to do without welding.

In situations where there is no welding machine nearby, and the problem is acute, you can use an extra solder welding pencil. The invention is based on the known reaction of the thermite mixture. For this reason, the pencil is sometimes called thermite. The successful introduction of chemical transformation into practice allows many metal parts to be repaired in the field.

Operating principle

Thermite mixtures consist of aluminum and iron oxide, which is often called scale. When this mixture is ignited, an intense exothermic process begins.

Let us recall that exothermic reactions include those that release energy. The reduction of iron from oxide by aluminum occurs with the release of a large amount of heat.

The reaction temperature is so high that the resulting iron melts. It is this melt that is used to fill holes, gaps, and cracks in repaired products.

The aluminum oxide formed in parallel acts as welding slag. In a metal welding pencil, in modern terms, “everything is included”: flux, metal to form the weld, an energy source for melting.

There are several types of pencils. Instead of aluminum, magnesium can be added to the thermite mixture. The effect will be exactly the same. Depending on the material that is recommended to be welded, welding pencils are made using different technologies.

Sometimes, in addition to the thermite mixture, a metal rod is placed in the center. It melts at high temperatures and serves as the basis for the seam. In other modifications, they are limited to only the thermal mixture. Fusion occurs due to the resulting iron.

Varieties

The market is constantly updated with new products for fast welding. Some of the products, unfortunately, do not have accurate information about the composition, manufacturers, or product certification.

Sometimes it seems that such products are produced using artisanal methods. You need to choose welding pencils carefully. You should buy products only from trusted brands that have proven themselves well among users. The list of well-known quality products includes:

- The extra solder welding pencil is good at welding holes in parts made of ferrous metal, aluminum, alloys with enameled coatings, and polymers. They can restore the enamel layer and tinning surfaces. The thermal cylinder has an unlimited shelf life. Manufacturers recommend purchasing it with a reserve in order to avoid difficulties in extreme situations;

- nanosolder is a welding stick containing magnesium as part of the thermite mixture. It also reduces iron from scale, releasing large amounts of heat. Recommended for working with any metallic and non-metallic materials;

- The extreme welding pencil has a good reputation. It is suitable for repairing metal products without coatings and with an enameled outer layer. It is inexpensive, the strength of the resulting seam reaches up to 70% of the strength of the joint obtained by electric arc welding.

There are several other types of well-known pencils under different names with similar capabilities. Using the services of trusted suppliers, the buyer purchases thermite pencils of excellent quality.

Rules for safe use

Welding pencils are easy to use and do not require special skills. The main condition for safe, effective use is careful reading of the instructions and strict adherence to them:

- Before welding, clean the surface of debris and place it in a convenient position;

- Put on protective gloves on your hands and goggles on your eyes. Many craftsmen work without them, but it’s better to play it safe and protect yourself from sparks flying around;

- print out the packaging, pick up a pencil;

- there is a metal cap on the working end, remove it and put it on the rear end part;

- Set the exposed working end on fire with a lighter or matches;

- bring the burning end of the pencil to the area being brewed, press and hold for a few seconds. Then calmly, slowly, move along the hole in the part, applying the molten paste.

After application, the paste may spark and the pencil will stop burning. This is fine. Having distributed the melt evenly throughout the problem area, you need to wait for the result . After the mass has cooled, it can be cleaned with sandpaper.

The pencil is indispensable in case of unforeseen situations, convenient for use in the country, on a trip, fishing, in the garage and at home. The price of the product is affordable for everyone. It must be stored in a dry place.

Advantages and disadvantages of use

The thermal pencil has no analogues due to the following advantages:

- ease of use;

- complete independence from electricity or fuel;

- compact dimensions compared to a traditional welding machine;

- the ability to manufacture welded structures of any complexity;

- ability to work with different metals;

- stable combustion, allowing welding of wet surfaces.

Disadvantages include the inability to control the quality of the seam and the release of toxic substances during the welding process. Due to the high consumption and high cost, repairs become expensive, so the pencil is not used for large-scale work. If the integrity of the packaging is damaged, the mixture draws in moisture, so it can be difficult to ignite the mixture.

How to make a thermite pencil with your own hands

The design of a thermite pencil is quite simple, and for its manufacture you will need the following materials:

- Carbon steel wire. The diameter of the wire should be from 2 to 3 mm, here everything largely depends on the thickness of the metal that will need to be welded with a thermite pencil. Therefore, the thicker the metal needs to be welded, the thicker the steel wire should be;

- Glue;

- Aluminum sawdust (fine fraction, no more than 0.5 mm);

- Iron oxide.

Sawdust of scale and aluminum is used to make thermite pencil coating. These components are mixed with glue. To seed the thermite pencil, which will help ignite it, you will need berthollet salt and aluminum filings.

Let's take a closer look at how you can make a thermite pencil for welding with your own hands:

- First you need to cut the steel wire into pieces 30-35 cm long;

- Next, you need to mix aluminum filings with iron scale into the glue. The proportions are as follows: 24% aluminum filings and 76% iron scale;

- Then the resulting mixture of sawdust, scale and aluminum should be applied to the wire;

- Give the coating time to dry sufficiently.

The seed at the end of the thermite stick looks like a match head. To make it, you need to mix bertholite salt (1 part) with aluminum filings (0.5 parts) into glue. After this, you need to dip the tip of the pencil into the mixture and let it dry for a while. The seed at the end of the thermite stick is needed to initiate the combustion process.

It goes without saying that even though a thermite stick is not an electric welder, when it burns, it still emits ultraviolet radiation that is harmful to the eyes, dangerous gases and high temperatures. Therefore, we must not forget about our own safety measures when working with this kind of thing.

Be sure to use a reliable holder during welding work, thick leggings, as well as an eye and face mask that would protect against ultraviolet radiation. If you pick up “bunnies” from welding with a thermite pencil, you can seriously harm your eyes.

TEC Torch Promotion

Tech Torch - a laser sword from "Star Wars" - as it was dubbed in the USA

There is also a foreign analogue (startup in the USA) TEC Torch Promotion - a thermite cutting device with a replaceable cartridge (the device costs $300; the cartridge costs $50).

In America, TEC Torch is used as a compact tool that can be used by American law enforcement agencies, military personnel, and emergency services in their work. TEC Torch can open any door in a matter of seconds, which can save the lives of people caught in force majeure circumstances.

Thermite cutter in action

The combustion time of the cartridge is only a few seconds - the optimal time for surgical intervention

The Rod Cutter cartridge can burn through a rod up to 2cm in diameter (whether it's hardened, mild steel or stainless steel), and the Plate Penetrator cartridge can cut a hole up to 1cm in a metal plate up to 1.3cm thick. Complex tasks may require multiple cartridges or a combination of cartridges

Areas of application

Thermite pencil is commonly used to join both vertical, inclined and horizontal surfaces in various parts. Work can be carried out at any ambient temperature, in any weather conditions. It can be used in the following situations:

- repair and installation work in emergency situations;

- prompt correction of breakdowns in cars, water, railway and other

- vehicles;

- soldering of copper wires;

- repair of radiators and pipelines in heating systems;

- sealing cracks and chips of cast iron and bronze products;

- correction of shortcomings in the operation of agricultural machinery in the field;

- cutting materials in hard-to-reach places.

Pencil welding is widely used in welding railway rails - thermite compacted in certain portions is used for welding. The work is performed by a team of two to three people. Thermite welding of rails has proven itself well compared to resistance welding: it does not require sophisticated expensive equipment, a large number of workers and long interruptions in train traffic. In addition, it can be used when welding on turnouts. The process of welding one joint in a rail track takes about an hour, and thanks to the ability of several teams to work simultaneously, greater productivity can be achieved.

As can be seen from the above comparison, the product has significantly high efficiency, however, it is still not recommended for permanent connection of materials. It is recommended to use a pencil for temporary connections only. Subsequently, it is still necessary to carry out repairs in its classical sense.

Metal welding pencil

There are times in life when things crack, rust or break. Urgent repairs are required, but the necessary materials are not at hand. At such moments, only a thermite pencil can save you. This unpretentious material will help carry out urgent repairs in the most emergency cases.

General description of the pencil

A welding pencil is a kind of universal tool for repeated welding. Outwardly, they resemble a cylindrical tube or pin, densely filled with an esothermic mixture mixed with metal oxides. During combustion, the internal mass generates the necessary amount of heat that can melt the metal border of the surface being repaired. A layer of slag remains on the surface of the weld, protecting the solder joint from the harmful effects of the external environment. This is extremely important, since pencil welding is usually applicable to materials where the quality of the weld and its reliability should not be compromised.

Comparison of the main characteristics of welding pencils from different manufacturers

There are welding pencils with completely different characteristics. Each individual manufacturer brings something special to the product:

Oxal. These products boast high efficiency in the absence of any sources of electricity. To get started, all you need is a lighter or any other open flame. Repairs to restore the functionality of materials can be carried out regardless of the ambient temperature.

Nanopike. The welding pencil of this production is famous for its relatively low cost. It is even suitable for repairing heat-resistant plastic and enamel cookware. One rod can be used many times, since the material consumption is very economical.

Welding pencil Extreme. This version of the pencil is also used to restore metals and enamel. Pencil welding "Extremal" in quality gives more than half the strength of conventional contact welding.

Thanks to this universal tool, you can carry out emergency repairs even when you do not have the most necessary materials at hand. With its help, you can not only solder the resulting crack, but also cut the material. You just need to select the required brand of product with the required properties. Thermal pencil is capable of repairing the following surfaces:

- steel;

- cast iron;

- iron;

- brass;

- copper;

- ceramics;

- slate;

- heat-resistant plastic;

- bronze;

- stainless steel and other similar materials.