Characteristics of zinc coating

The most popular way to protect metal fasteners from corrosion is galvanizing - applying a zinc layer.

When exposed to air, zinc oxidizes and forms a film that prevents oxygen from reaching the bolts. This coating performs its protective function at temperatures up to +70 °C in light operating conditions without the aggressive influence of various environments. The anti-corrosion properties of zinc weaken with increasing temperature, and the product remains protected only mechanically.

The method of applying the zinc layer and its thickness depend on the conditions in which the bolts will function.

A coating thickness of 5 to 8 microns will be sufficient for light operating conditions in a dry and warm place.

To function in conditions of condensation formation, you will need to apply a denser layer - 8-12 microns.

In temperate climates, the coating thickness increases to 25 microns.

An even thicker layer of 25 microns is applied to the bolts when operating in a marine climate and under the influence of aggressive substances.

The zinc coating was tested in salt spray according to the DIN EN ISO 9227 standard. It showed a result of 120 hours of corrosion protection.

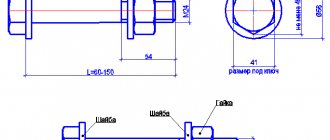

Rice. 1. Galvanized bolts

Foundation bolts M56, M48, M30 hot-dip galvanized

03.11.16

Hot-dip galvanized foundation bolts have been shipped to the Customer. The bolts are made of alloy steel 09G2S-6 in accordance with the requirements of the design documentation of Maire Tecnimont, the general contractor for the construction of the ammonia plant in Kingisepp.

The package included:

- Bolt 4.1 M56x1700.09G2S-6 hot-dip galvanized - 44 sets

- Bolt 4.1 M48x1450.09G2S-6 hot-dip galvanized - 80 sets

- Bolt 2.1 M30x760.09G2S-6 hot-dip galvanized - 36 sets

- Bolt 2.1 M30x790.09G2S-6 hot-dip galvanized - 164 sets

The total quantity for this shipment is 324 sets, for the order as a whole - more than 2,500 sets.

Working drawings of bolt parts were developed by the engineering service of the Spetsmashmetiz plant in accordance with the requirements of the procedures of Maire Tecnimont Group (Italy), which is a leading player in the international market of engineering, general contracting and licensing in the hydrocarbon sector.

All foundation bolts passed the quality control department of Spetsmashmetiz, multi-stage incoming inspection of the Serbian Subcontractor Velesstroy and the Italian general contractor Maire Tecnimont, the Russian Customer EuroChem Group AG, which confirms the compliance of the Spetsmashmetiz plant’s products with Russian and global quality requirements.

The choice of hot-dip galvanized anchor bolts as anti-corrosion protection is associated with high international requirements for the protection of metal structures for the chemical industry. In particular, the general contractor of the project, Maire Tecnimont Group, rejected proposals from suppliers to replace hot-dip galvanizing of bolts with thermal diffusion galvanizing (actively used in the Russian Federation for about 10-15 years, in the world for 20-25 years). After which the number of suppliers was sharply reduced, to almost two or three competitors. Based on tender procedures, the Spetsmashmetiz plant was chosen as the supplier. Taking into account the specifics of ammonia production (high temperatures and pressures of up to 1000 atm), its potential danger in case of accidents, strict requirements for building materials are applied. The Spetsmashmetiz plant ensured compliance with these requirements.

Hot-dip galvanizing provides the most long-term protection of metal structures from corrosion. But for threaded products, the use of such anti-corrosion protection has a number of technological limitations. The production of hot-dip galvanized anchors requires special approaches to thread manufacturing technology. A feature of hot-dip galvanized threaded products is the need to ensure screwability of bolts and nuts.

Standard thread clearances are not sufficient for hot dip galvanizing. Threads for hot-dip galvanizing are made with an increased gap; the use of standard gauges is not permissible. In addition, after hot-dip galvanizing, the threads require calibration by machining, which is also an additional problem due to the brittleness of zinc.

The Spetsmashmetiz plant has developed a technology for manufacturing anchor threads from M20 to M72 for subsequent hot-dip galvanizing.

A feature of the Spetsmashmetiz technology is the preservation of a zinc layer of more than 100 microns on the threaded areas of bolts after the operation of mechanical removal of excess coating. Incoming inspection of the Customer, General Contractor and Subcontractor confirmed the compliance of our bolts with the design solutions. See more See other news...

Methods for applying zinc coating to bolts. Advantages and disadvantages of galvanizing

Sherardization (diffuse galvanizing)

– processing in zinc vapor at very high temperatures up to +900 °C or in zinc powder when heated to +300-450 °C.

The thickness of the created layer can be from 6 to 110 micrometers. This method of coating bolts is the most effective for giving them corrosion resistance. The protective layer comes out uniform and exactly follows the shape of the product.

However, this procedure is not cheap, so I resort to it extremely rarely.

Galvanic (cold) galvanizing

– application of zinc composition to bolts by painting.

This method allows you to process products of any size. However, the thickness of the coating (from 5 to 30 microns) is not enough to provide effective anti-corrosion protection.

Hot galvanizing

– immersion of pre-prepared bolts in zinc heated to +450 °C.

This method makes it possible to form an effective anti-corrosion protective layer on the fastener with a thickness of 40 microns, but not uniform. Therefore, hot-dip galvanizing is not used in cases where the final size and shape of the product are of significant importance.

Advantages of galvanizing:

- Low cost

- Mechanical and anti-corrosion protection of products

Minuses:

- As a result of the penetration of hydrogen into its structure, a metal product loses its mechanical strength, becomes porous and cracks (diffuse galvanizing is an exception)

- Harm to the environment

- Only a thick and durable film can provide good protection to the product, but it significantly changes the final size of the fastener

- Every year the coating is destroyed by several micrometers

- Complex application procedure

Choosing a coating for fasteners

Selecting Protective Coatings for High Strength Fasteners

High-strength fasteners (bolt sets: bolt, nut and washers) used for the manufacture of metal building structures have a number of specific features arising from the conditions of use of this fastener. The main ones are increased requirements for reliability and the ability to create a calculated pre-tension during installation.

According to the established practice of constructing bridge structures, the installation of their mounting connections is carried out due to the frictional forces that arise when the mounting surfaces are compressed to the design force with high-strength bolt kits. Calculation of friction connections is carried out in accordance with the requirements of SNiP 2.05.03 “Bridges and pipes”.

The calculated tension forces of bolt sets are achieved by monitoring the tightening torque of the bolted connection, calculated by the value of the torque coefficient.

Until now, high-strength bolts and nuts have been supplied to construction sites without protective coatings. Therefore, the only way to protect hardware from corrosion for the period before installation is a conservation lubricant, the further use of which when tightening fasteners during the assembly process is unacceptable due to a decrease in the tightening force of lubricated bolts and spreading of the lubricant over the surface of the mounting connections, which will lead to loss of adhesion of the standard paint and varnish coverings. In accordance with STP 006-97, to remove conservation grease and contaminants, fasteners are washed in hot alkaline solutions before installation, followed by lubrication in a 10-20% solution of oil in gasoline. The shelf life of bolt kits prepared in this way does not exceed 10 days. The noted auxiliary technological operations are costly and labor-intensive to carry out on a construction site, especially in winter.

To eliminate these operations for pre-installation preparation of fasteners, it is advisable to apply protective coatings to them at the factory stage of manufacturing hardware, which are subject to the following requirements: ● the coating must retain protective ability at least for the period before their installation, including transportation and storage; ● the thickness of the coating should ensure free screwing of the nut onto the bolt without preliminary lowering of the thread in order to maintain the strength of the threaded connection; ● the coating must provide the standard value of the twist coefficient in the Kclose range. = 0.11-0.20; ● the technology for applying coating to fasteners should not cause hydrogenation of the steel substrate of the fastener, which contributes to its subsequent unpredictable embrittlement and destruction.

Special attention should be paid to protective coatings for long-term anti-corrosion protection of fasteners, for which the following requirements can be presented: ● the coating must maintain protective ability for a long service life when exposed to various aggressive environments; ● ensure the standard value of the twist coefficient in the Kclose range. = 0.11-0.20; ● coating technology should not require thread reduction; ● the technology for applying coating to fasteners should not cause hydrogenation of the steel substrate of the fastener, which contributes to its subsequent unpredictable embrittlement and destruction.

The practice of using protective coatings for fasteners has shown that the best means for their anti-corrosion protection is galvanizing. However, when using this type of coating, the operation of preparing the steel surface by acid etching should be excluded from the galvanizing process, since it promotes the process of hydrogenation of steel. For this reason, electroplating cannot be used to protect high-strength fasteners. Hot zinc coating can be applied subject to the use of technology that eliminates the risk of hydrogenation.

It should also be noted that the use of high-strength hot-dip galvanized fasteners is hampered by the significant thickness of the coating, which does not allow its application to bolt sets with threaded connection tolerances of 6g/6H. In this regard, when using hot-dip galvanized fasteners, it is necessary to loosen the tolerance on the outer diameter of the thread. GOST 32484.1÷32484.6-2013 “High-strength structural bolt sets for pre-tensioning”, which come into force in July 2015, provides a 6az thread tolerance zone for nuts for their use in bolt sets with hot-dip galvanized coating. In this case, the thread on the nut is cut when the hot-dip galvanizing coating has already been applied to the workpiece. Only under such conditions is the use of hot-dip galvanizing justified for long-term anti-corrosion protection of high-strength fasteners.

The only competitor to hot zinc coating can be a thermal diffusion zinc (TDZ) coating of appropriate thickness. It should be noted, however, that fasteners with hot-dip galvanizing and TDC coating are characterized by unacceptably high values of the torque coefficient, as a result of which the standard level of tension force is not achieved when tightening the bolts. This problem is solved by the use of anti-friction coatings, known as “duplex systems”.

At the same time, we emphasize that, unlike bridge construction, high-strength fasteners with hot-dip galvanized coating are widely used in construction, mechanical engineering and shipbuilding within the limits of rights and responsibilities determined by the design documentation and the law.

Of the available types of galvanizing for anti-corrosion protection of high-strength bolt sets, the most appropriate is the use of thermal diffusion galvanizing of classes 2 or 3 and zinc-filled lamella-type paint and varnish coatings (Fig. 1). Both methods involve the use of light abrasive-jet blasting when preparing the surface of hardware for coating to remove corrosion products and oxide films that arose during their manufacture, which eliminates the need for acid etching.

| Rice. 1. High-strength bolts with different coatings: a) bolt with TDC coating; b) bolt with lamellar coating |

TDC coating, which has existed for more than 100 years, is traditionally performed using the following technology: galvanized parts are placed in a retort with a powder mixture consisting of powdered zinc, alumina and an activator (ammonium chloride or activated carbon). By means of radiation heating, the retort is heated to the melting temperature of zinc (420 oC), and due to temperature diffusion, zinc atoms from the solid and vapor phases are introduced into the iron crystal lattice. In turn, active iron atoms move towards zinc. As a result of this process, an intermetallic Zn-Fe coating is formed, consisting of several phase layers. The first, actual diffusion α-layer with a thickness of 10-12 microns, is a solid solution of zinc in iron, containing up to 4.5% Zn. Due to it, subsequent layers are firmly fixed to the steel base. The next G-layer precisely ensures the diffusion of zinc and iron in opposite directions. The G-layer with a thickness of 4-5 microns contains up to 28% iron and is very fragile. On top of these layers, an intermetallic δ-layer is also formed, which has a columnar structure and contains, in addition to zinc, from 11.5 to 7% iron. It is this that, due to the higher zinc content, that begins to provide protective properties for steel. Since it is an intermetallic compound, it has high microhardness (up to 4800 MPa) compared to pure zinc, which has a microhardness of no more than 900 MPa. The thickness of the δ-layer is 30-40 µm. Then, with longer heating (more than 3 hours), a ζ-layer is formed, which is an almost pure zinc coating that has a microhardness comparable to zinc and provides the highest protective properties. The thickness of the ζ-layer, depending on the exposure in the oven, can reach 40 microns or more. Thus, a TDC coating on fasteners can have good protective ability with a total thickness of at least 30-40 microns. The specified thickness of the TDC coating fits into the value of the total inter-threaded gap between the threaded surfaces of the bolt and nut with a tolerance of 6g/6H, which for the most common standard size of high-strength bridge hardware M22 is 113 microns, which does not interfere with the screwability of the specified threaded connection, provided that the zinc coating is sufficiently ductile.

| Fig.2. Installation for applying TDC coating: a) loading a retort containing 1.2 tons of fasteners into the oven; b) cooling the retort after galvanizing. |

Among the advantages of the TDC method, the following should be mentioned: ● parts are galvanized in hermetically sealed retorts, therefore the diffusion galvanizing process is environmentally friendly and does not require the creation of treatment facilities; ● the resulting coating has no pores and, due to the diffusion layer in the form of a solid solution of zinc in iron, has a strong adhesive bond with the steel substrate; ● the protective ability of the coating is 2-4 times higher than that of galvanic coatings and slightly higher than that of hot-dip galvanized coatings; ● diffusion zinc coats parts with a uniform layer without sag, accurately repeating the profile of the galvanized surface, including blind holes, elements of complex configuration, cracks, cavities, threads, etc.; ● production waste does not require burial.

At the same time, the traditional TDC method using radiation heating has the following disadvantages: ● the impossibility of obtaining a high-quality coating with coating thicknesses less than 30 microns due to the high content of zinc-iron intermetallic in the upper layers, which causes high microhardness of the coating, and, therefore, high twist coefficient; ● relatively low productivity of the TDC method, limited by the volume of retorts for galvanizing and the duration of heating of the retort with powder mixtures and galvanized parts; ● significant consumption of electricity and zinc powder, zinc burnout during radiation heating; ● the need for a massive metal-intensive heat-insulated furnace body. Based on these disadvantages, it is more rational to use a new TDC method for galvanizing high-strength fasteners - with induction heating, which allows: ● to obtain a uniform homogenized protective coating of the required thickness with high corrosion resistance over the entire area of the galvanized surface, containing up to 98% zinc; ● reduce galvanizing time from 2.5 hours to 5-20 minutes, i.e. 12-48 times faster; ● reduce by 2 times the consumption of zinc powder for coating the surface of metal products by reducing the degree of zinc burnout; ● reduce energy consumption by 4 times by reducing the duration of the galvanizing production cycle; ● maintain the geometry, profile and diameter of the thread when galvanizing threaded connections; ● restore the zinc coating if it is damaged by re-galvanizing; ● significantly reduce capital investments for the creation of an industrial installation using the proposed TDC method, compared to an installation made using the traditional method.

Currently, there is a pilot plant for galvanizing parts using the TDC method with induction heating, which has a working chamber with a diameter of 300 mm and a length of 4 m. The productivity of such an installation is up to 30 kg of hardware per hour.

An alternative to the above methods of protecting fasteners can be a zinc-aluminum lamellar coating such as Dacromet or Delta. These are actually paint and varnish coatings filled with scaly particles of zinc and aluminum no more than 10-15 microns thick, having excellent decorative properties (silver color) and durability of at least two years - for the entire period of transportation and storage of hardware until installation operations are performed. The lamellar coating technology eliminates the possibility of hydrogenation, because when using it there is no contact with acids. The coating base suspension is applied to the products in three layers by dipping them into centrifuges filled with the suspension and subsequent drying for 5-10 minutes in continuous ovens at temperatures of 200 and 300 °C. There is no diffusion of zinc into the steel substrate.

As our research has shown, both TDC and Dacromet coatings require the use of special polymer-based lubricants to ensure the required value of the twist coefficient (in the range Kzakr. = 0.11 – 0.15) under the assembly conditions of the mounting surfaces of bridge structures. In this case, the problem arises of the compatibility of these lubricants with standard paint and varnish coatings for bridge structures. In this case, suppliers of paints and varnishes do not guarantee the durability of standard coatings in bolted joints.

It would be promising to form a coating on high-strength bolts that simultaneously provides the required torque coefficient (0.11 - 0.15), anti-corrosion protection and compatibility with coating coatings. A universal coating would solve several problems in different directions at once: eliminating the pre-installation preparation of fasteners, ensuring the necessary durability of anti-corrosion protection, ensuring the required compression forces of fasteners, which would arouse mutual interest among manufacturers of high-strength hardware and in bridge construction organizations. A zinc-filled lamellar coating with polymer-based lubricants is seen as such a universal coating.

Other ways to protect bolts

An alternative method of protecting fasteners is MODENGY anti-friction solid lubricant coatings. Teflon-based materials MODENGY 1011 and MODENGY 1014 are applied to the bolts.

Rice.

2. Bolts coated with MODENGY 1014 Advantages of MODENGY 1014 coating:

- More impressive salt spray test results according to DIN EN ISO 9227 – from 672 hours of corrosion protection

- Operates in a wide temperature range from -75 to +255 °C

- Stabilizes twist ratio

- Gives products a decorative appearance

- Reduces thread friction

- Helps avoid jamming, sticking and scuffing

- High chemical resistance

- The ability to repeatedly assemble and disassemble threaded connections (zinc coating allows for one-time tightening)

Galvanizing of fasteners

Home \ Galvanizing of fasteners

The issue of increasing the service life of hardware and fasteners is very pressing these days. In this regard, some enterprises began to think about applying a protective coating of zinc to the metal.

You can choose which technology you will choose for galvanizing your products yourself, or you can contact our specialists who will help you choose. The fact is that there are large parts that cannot be placed in the same galvanic bath. With small hardware everything is much simpler, but it is more difficult to coat them with cold galvanizing.

What hardware and fasteners can be coated with zinc:

- Slate nails

- Self-tapping screws for sandwich panels

- Rivets

- Dowels

- Anchors

- Nuts

- Washers

- Bolts

- Screws

Our company can offer the following types of zinc coating of products:

- Galvanic

- Cold

- Hot

- Thermal diffusion

How galvanic galvanizing of hardware is carried out

This type of coating is one of the most interesting, since everything happens in galvanic baths. Parts of certain types and sizes, hardware, fasteners and other things are loaded there. After this, the plates must be connected to direct current sources, which is why the coating literally begins to stick to the parts.

How cold coating of hardware with zinc occurs

This method can be considered one of the simplest, and it was also one of the very first. A zinc coating is applied to a clean part under high pressure. All this must take place in a special room and using professional equipment. Only in this case can you achieve a truly high galvanizing result.

Hot galvanizing of parts or dipping

Experts call this method the most reliable, because the parts are immersed in molten zinc, the temperature of which is over 400 degrees Celsius. Thanks to this, the coating is evenly distributed over the entire part. The only thing is that sometimes these parts have thickenings, and not in all cases zinc can get into all hard-to-reach places, as is the case with cold galvanizing.

Powder based thermal diffusion galvanizing

This process of applying zinc to products is quite complex, because everything happens at high temperatures, and even using powdered alloy particles. Everything happens in a closed space where the parts and powder mixture are located.

The method of mechanical galvanizing of parts is very interesting.

For this method, small glass beads are used, as well as a zinc suspension, which, together with the part, is immersed in an aqueous solution. All this should be in a special drum or bell that can be closed. The rotation speed of the drum should not be high so that all parts are completely coated with zinc.

Many people ask what function glass balls perform in this galvanizing method and why they do not break. The fact is that this method is applicable only for small parts, and the balls act as an element that literally rubs zinc into the base of the product.

The coating for this type of galvanizing can be from 8 to 20 microns. The advantage of this type of galvanizing is that during the process no traces of processing of the parts appear, that is, they look solid. In this regard, in the future they can be used without much difficulty for assembling furniture, as well as for internal repair work. Indoors can also be humid, which is why various parts, fasteners and hardware can begin to rust. To avoid all this, fasteners are coated with zinc or painted, which our company also does without much difficulty.

Contact us! We work for you!

Phone, email