Final result

In the photo you see the finished mask hanging on the wall of my workshop. When one of your customers or friends needs to weld something, they can use this homemade mask to be present during the welding work.

This mask, despite being made of cardboard, does the job well. It will not ignite from sparks, since its users are always located at a distance from the welding site.

Source

Chameleon welding helmet? Easily!

Today, we will talk about the tools of a locksmith workshop

DIY masters.

In particular about electric arc welding

metals The simplest and most reliable method of joining various metals, in demand both in the country, home renovation and in the garage when repairing a car and related work.

The older generation, now fifty to sixty years old, remembers very well the time when welding machines were mainly the fruit of their own creative process and weighed like a one and a half pound weight.

But fortunately

,

those “hard” times when you needed a cart to transport your welder have sunk

into oblivion variety of compact inverter welding machines

that fit into a simple work bag have appeared on sale.

Finally, this summer, technical progress reached me (I put away my old, heavy one, my eyes would not have seen it, my neck was always covered in soap when working), a transformer welder in a distant country corner. And having looked at Aliexpress, I began to look for new items in welding progress

.

My eyes ran in different directions, but after thoroughly searching, and listening to the advice of very intelligent people, I purchased a small, compact one, weighing only 2.5 kg

inverter welding machine

Micro ARC 200

. The soul still sings and dances.

For fans of inverter welding machines, I leave a link

to Micro ARC 200

, use it if you need AliExpress Welding inverter Micro ARC 200

If anyone is more helpful

it is necessary, here is such an option Micro ARC 250

link

AliExpress Welding inverter Micro ARC 250

Video instructions for making a homemade Chameleon mask with your own hands.

Let's start manufacturing. What do we need to make a homemade version

welding helmet? And we need the following.

Tools for making:

1. Hacksaw or electric jigsaw. 2. Scissors. 3. Measuring tool, ruler, caliper. 3. Drawing tool, pencil or felt-tip pen. 4. Educational skin. 5. Inverter welding machine for testing our design link where you can buy it cheap

AliExpress Welding inverter Micro ARC 200 6. Of course, our hands are not for boredom. 7. Drill or drilling machine. 8. Drill.

1. Classic welding helmet, with a fixed darkening filter. Preferably inexpensive. 2. Automatically dimming filter link where you can buy it cheap

AliExpress Self-darkening filter 3. A small piece of plastic, with a thickness of 0.5 millimeters or more, within reasonable limits. 4. Bolt with washer and nut. 5. Plastic corner, small. 6. You can use a little hot glue to make sure that the self-darkening filter is firmly fixed.

Making a welding helmet of the “Chameleon” type:

1. Measure the dimensions of the fixing plate of the classic mask. 2. We mark the prepared piece of plastic to the size of the fixing plate, with a window for an automatically darkening filter. 3. We cut the marked plastic according to the marked dimensions, we get a new fixing plate for our Chameleon mask. 4. We mark another plate to support the darkening filter and close the gap between the filter and the lower part of the welding helmet window. 5. Cut out a plastic corner for additional fixation above the specified pressure plate. 6. Drill a hole in the welding helmet for the fixing angle. 7. We assemble the structure as shown in the video clip. For a more reliable fixation of the light-darkening filter, it can be pinpointed with hot-melt adhesive. I didn’t need it; the filter fixation was sufficient. 8. The Chameleon type welding mask for home use is ready. You can start testing. 9. The tests were successful, everything works.

Principle of operation

The mask is put on before connecting the welding electrodes; it is not intended to be worn for a long time; the battery capacity of the filtration unit is small. When the fan is turned on, air enters the filter, then is forced under the casing into the nose area, blowing on the welder’s face. The exhaled mixture is disposed of through a check valve.

Operating principle of a welding helmet with air supply

Sealed air-supplied protection has a number of advantages:

- provides reliable protection from production factors, allows welding work to be carried out in hazardous conditions,

- has a wide viewing angle,

- Light filters have a large spectral range.

DIY welding mask

Every professional welder or DIYer who has to deal with this type of work knows how important it is to provide personal protection. For example, using a high-quality and comfortable protective mask will greatly simplify the task. It is worth noting that the use of a standard sample is not always possible, because the anthropometric data of each person is individual, so knowing how to make a welding mask with your own hands is worth it for everyone who is engaged in this difficult but important work.

Table of contents

General description and features

To begin with, it is necessary to say a few words regarding general definitions. So, a welding mask is a special device designed to protect the eyesight and skin of the face from the harmful effects of ultraviolet radiation emitted during the welding process. In addition, during work, the surfaces of the elements being welded are heated to high temperatures, which causes melting of part of the metal. This leads to the formation of harmful fumes, which should also be shielded by the mask.

The nuances of using this protective equipment determine some of the features of its manufacture. For example, the material from which the mask is assembled should not transmit ultraviolet radiation. When making this element of equipment yourself, this point must be taken into account, since some materials, for example, linoleum, which can be considered as a material suitable for the task, transmit ultraviolet radiation. Failure to comply with this condition may result in injury, so it must be taken into account.

Distinctive features

A welding helmet with air supply is a multifunctional device. Unlike other analogs that do not have similar functions, it provides a more tight fit to the welder’s body. Thanks to this, everything is isolated from external influences. In this case, the natural supply of air becomes difficult and forced injection is required. The presence of a ventilation unit that provides this injection is the main distinguishing feature of this product. Modern models have a cleaning filter that creates normal breathing conditions, regardless of the conditions outside. The welding helmet headband here has additional fastenings for stability. It is also worth noting the presence of additional batteries that work with filters and ventilation. You should always check that they are working correctly to avoid accidents.

Chameleon mask

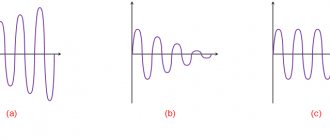

A separate category includes welding helmets with installed chameleon filters. Their main difference from other manufacturing options is the use of special light filters that can automatically change a number of their operational parameters from the degree of darkness to the interval for switching operating modes.

This filter consists of a protective film, LCD glass and a direct protective filter that screens ultraviolet and infrared radiation. An automatic control element is supplied with it, with the help of which all necessary adjustments are made. This also includes an arc detection element and a solar panel needed to power the filter. Such filters are more expensive than conventional ones, but provide good protection, while saving time, which means they have a positive effect on overall labor productivity.

The choice of a specific option for manufacturing a welding mask should be made based on the specifics of the intended tasks. Naturally, it is not advisable to purchase an expensive mask if you are going to use it only from time to time. As for making it yourself, it’s simply not possible to assemble the most complex types of masks with your own hands.

Design

A distinctive design feature of a welder's mask with forced air supply from other protective shields can be considered its sealing. The casing is made of fire-resistant soft materials, designed taking into account the geometric shape of the head. In the neck area there are adjustable seals with locks.

Air supply welding helmet design

The filtration system, which ensures full breathing of the worker during welding, is remote, the unit is located on the back side, and is connected to a sealed protective device by a hose. The design includes a fan powered by an autonomous, fast-charging battery. Often, for these purposes, a solar battery is used, powered by the luminous flux of an electric arc.

Welding mask with air supply

Replacement filter cartridges become unusable as they become dirty. Manufacturers produce these consumables with different performance characteristics and service life.

A light element with a large viewing angle is built into the front part of the helmet; a “chameleon” window is usually used; it darkens under the influence of ultraviolet radiation; the components of such a screen significantly reduce its throughput in a certain part of the spectrum only at the time of welding. The use of a color-changing liquid crystal filter allows you to control the quality of the weld without removing the protective mask.

DIY drawings on a welding helmet

The desire to decorate your working tool is inherent in all professionals. This will not only allow you to realize your creativity, but will also highlight an individual element of protection, which means no one will use it “by mistake.”

For example, you can apply some kind of colorful design to a welding mask. To do this, you just need to find a suitable picture and, after transferring it to paper, make a stencil. Next, the design is applied using a can of paint.

If it is possible to use a spray gun, then the task is greatly simplified. As you gain experience, you can try to apply more and more complex multi-layer designs.

Video

You can watch the video on how to make a design on a welding helmet with your own hands.

In conclusion, it is worth noting that personal protective equipment should never be neglected, and especially when it concerns a risk to vision, as is the case with a welding helmet. It is not always possible to purchase an expensive professional sample, but with the help of simple manipulations, you can significantly improve the simplest manufacturing option, which will allow you to achieve a significant improvement in performance characteristics, and therefore greater health protection. By the way, assembly, modification and external tuning of welding helmets can also be considered as a business idea that can also generate income. How to use this idea is up to you.

Source

Design features and operating principle

A welding helmet with air supply is noticeably different from other, simpler options. When the welder puts on this product, the ability to breathe outside air stops. Now the supply is made through a thin filter that allows air masses to pass through it. The filter is cleaned, after which everything is fed inside the helmet. The cleaning basis of the filter are special cartridges, which may have different characteristics, depending on the model and manufacturer. They should be selected depending on the required degree of protection, since the cost can vary widely, and over time, after a certain period of operation, the cartridge becomes dirty and becomes unusable.

Air Welding Mask

Models are developed taking into account the physiological nuances of the human body. The contours fit perfectly to the oval of the face, which ensures tightness. The design also has an additional seal made of fire-retardant material. In addition, there are all the protection functions against molten metal and sparks, as in standard masks.

Specifications

Forced air welding helmets can have a number of unique characteristics. This can be considered using the Optrel e650 as an example:

Source