Repairing a gas generator begins with identifying the cause of the breakdown and eliminating it. The main cause of failures in the operation of gasoline generators is the failure of the gasoline engine or electric generator. To carry out repair work, you should independently study the design and operating principle of the equipment.

Gasoline generators are needed to power the network or various devices.

Design and principle of operation of the generator

Most gasoline generators consist of a tubular frame that houses an internal combustion engine and an electrical converter. They are connected to each other by a special coupling. The generator converts the mechanical energy of the engine into electrical current. This element can be single-phase or three-phase. Its operation is controlled by an electronic control unit, which protects against overloads and short circuits.

Depending on the model, engines have one or more cylinders. It can be two-stroke or four-stroke. Four-stroke engines are most commonly used due to their efficiency. A manual or electric starter is used for starting. More expensive models are equipped with an autostart system.

Is it possible to repair a gas generator yourself?

Repairing a gas generator begins with identifying the cause of the breakdown and eliminating it. The main cause of failures in the operation of gasoline generators is the failure of the gasoline engine or electric generator. To carry out repair work, you should independently study the design and operating principle of the equipment.

Gasoline generators are needed to power the network or various devices.

The device of a portable gasoline electric generator

A portable gas generator is an indispensable device for generating electricity in conditions where there is no possibility of connecting to centralized power supply lines.

The industry offers consumers a choice of gasoline and diesel generators. Regular motor gasoline is used as fuel in gasoline installations.

Gasoline generators are small in size, which is their advantage if the device needs to be transported.

A gasoline generator is an installation for generating alternating current. The generation of electric current is carried out on the basis of synchronous rotation of the installation elements. Depending on the design and purpose of the device, the generated current can be either single-phase or three-phase.

Depending on the purpose of the installation, they may differ from each other not only in the parameters of the electric current, but also in the power of the installation itself. Devices that generate single-phase current with a voltage of 220 V are designed to power a household consumer network.

Generators that produce three-phase current with a voltage of 380 V are most often used to power various devices, such as welding machines.

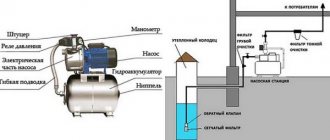

Gasoline generator circuit diagram.

The design of the gasoline generator consists of two blocks. One of the blocks is a generator that produces electricity, and the second block of the installation is a gasoline engine that supplies the electric generator with energy.

The structural blocks are connected to each other using an elastic coupling.

An electric generator in its design has a block that has devices designed to turn on the generator, instruments for monitoring the operating parameters of the device and automatic machines that protect the installation from accidental short circuits.

A gasoline-powered engine system can include from one to eight cylinders. The number of cylinders in a gasoline engine depends on the engine power. These engines can be either two-stroke or four-stroke. Four-stroke engines are more economical units and have greater efficiency compared to two-stroke engines.

The principle of operation of a gasoline generator

The task of the installation is to convert mechanical energy generated by an internal combustion engine into electrical energy, which is produced by an electric generator. Gasoline generator repair involves replacing engine and generator elements that fail during operation.

The propulsion system is equipped with a whole complex of systems that ensure its operation. Such systems are:

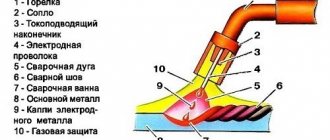

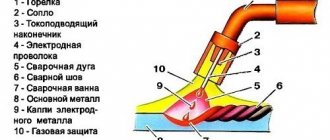

Operating principle of a portable gas generator.

- starting system;

- engine shaft speed stabilization system;

- propulsion system cooling system;

- exhaust gas removal system;

- air purification and supply system to create a combustible mixture.

The propulsion system is started using a manual start or an electric starter.

Modern installations use autostart systems. You can carry out repairs yourself only on those units that are equipped with a mechanical starting system. If it is necessary to repair propulsion systems equipped with automation, it is impossible to do without the use of specialized equipment.

Power from the internal combustion engine is transmitted to the shaft of the electric generator through a flexible coupling. This flexible connection, in addition to transmitting power, provides vibration damping.

The most common breakdowns and causes of their occurrence

Connection diagram for a portable gas generator.

The main breakdowns when operating a portable gasoline generator set occur in the engine or generator of the installation.

The most common systems that can fail in a propulsion system are:

- fuel supply system;

- fuel mixture preparation system;

- gas distribution system;

- gas distribution mechanism drive;

- engine starting system.

To identify the specific cause of a malfunction, it is necessary to check all components that may cause the installation to fail.

The main breakdown and malfunction of the fuel supply system is a clogged fuel line from the gas tank to the carburetor. The system can become clogged as a result of using low-quality fuel during operation of the installation.

To repair a gas generator with your own hands, you need to dismantle the fuel supply system and clean the tap and supply pipe. During operation, the fuel level sensor in the fuel tank may fail.

If a sensor is damaged, it should be removed and replaced with a new one.

Engine stopping may be caused by carburetor failure due to clogging and sticking of moving structural elements. To clear the blockage of the needle channel responsible for fuel injection, you need to blow out the channel with compressed air.

As a result of using low-quality fuel, the float mechanism that supplies fuel may become stuck.

To eliminate sticking, it is necessary, using a special liquid for cleaning carburetors, to moisten the float and its needle and move the float manually.

http:

If you suspect a malfunction in the engine gas distribution system, remove the cover from the valve block and try to move the rocker arms. If during movement the valves of the gas distribution mechanism do not open, then sticking or burning of the valves has occurred.

Such phenomena are observed when low quality fuel is used during operation of the installation. To clean the valve, moisten it with a special fluid for cleaning carburetors, then turn the rocker arm and hammer the valve completely in with a hammer. After this, by turning the shaft, push the valve back.

This procedure should be repeated several times until the valve moves freely in its seat.

Checking the oil level of the gas generator.

If a belt is used to drive the engine timing mechanism, it can stretch and tear during operation. In case of failure, it must be replaced with a new one.

If there is an electric starter, the gas generator may not start as a result of the battery being dead or uncharged.

If there is a malfunction in the generator unit, it is better to invite a specialist to carry out repairs, since this requires special knowledge.

The main signs of a breakdown of an electric generator are the lack of voltage in the network during operation and voltage instability.

The most common cause of generator failure and breakdown is damage to the stator or rotor windings. The first sign of a malfunction during operation is the appearance of burning and smoke from the generator unit. The appearance of these signs may indicate the occurrence of an interturn short circuit or short circuit of the output ends of the windings.

http:

Repairing a breakdown of this type is an expensive operation, since the procedure for rewinding the windings is quite expensive and is carried out using special equipment.

If there are voltage drops generated by the generator of the installation, and there is no smell of burning or smoke, you should check the stability of the voltage regulator, which prevents the occurrence of drops. If a malfunction is detected, this structural element should be repaired and the condition of the brushes of the generator device should be checked.

Signs of generator problems

It is necessary to diagnose and possibly repair inverter generators in the following situations:

Indication of the “battery” on the parting panel - if it flashes, it means that there are interruptions in the operation of the generator, if it is constantly on, no current is generated, and the power comes from the battery:

- Rapid boiling of the electrolyte in the battery.

- Less bright headlights.

- When you press the accelerator pedal, the brightness of the headlights increases.

- The presence of constant sounds in the generator.

- Generator overheating.

- Frequent spontaneous engine shutdowns.

Malfunctions associated with the operation of the electric generator

Most often, a gasoline generator in the budget and mid-price segment is equipped with a brush synchronous alternator, which copes well with the imposed loads and is relatively cheap. However, it has some disadvantages:

- The need to periodically replace brushes

- Sensitivity to dust and high humidity

Untimely replacement of brushes can damage the entire alternator, which will entail additional costs. Alternator failure can also result from operating the device in polluted conditions.

The cause of a malfunction of a gasoline generator may be wires that are subjected to mechanical and temperature influences during operation - loss of contact, short circuit, chafing, rupture. Diagnostics and repair of electrical wiring must be carried out by qualified specialists.

Most common faults

If you arrange the possible malfunctions of a gas generator in a kind of rating, you will get the following list:

- Failure or contamination of the spark plug: difficult or impossible starting, unstable operation.

- Carburetor clogged: difficult starting, excessive fuel consumption, unstable operation under constant load.

- Ignition coil failure: no spark, unable to start.

- Starter breakdowns: breakage, cable snagging, ratchet destruction.

- Violation of valve clearances: difficult starting, increased noise during operation.

- Brush wear (on synchronous generators) – lack of output voltage.

- Faulty speed controller: floating engine speed, dips when the load changes.

- Wear of the crankshaft bearings and generator rotor - increased operating noise and oil leakage.

- Wear of the cylinder, piston rings - difficulty starting a cold engine, excessive oil consumption.

This does not take into account breakdowns that result from a gross violation of the operating rules of the generator: for example, scuffing on the crankshaft journal due to insufficient oil level, burnout of the windings of the generator or voltage converter (on inverter gas generators) due to frequent overloads.

In fact, gasoline generator faults can be divided into three groups: mechanical, electrical and fuel/ignition system faults .

Malfunctions in the operation of power and ignition systems and their maintenance

Difficulty starting the generator, which appears suddenly and is not accompanied by an increase in engine noise, is a clear sign of either abnormalities in the carburetor (too lean or rich mixture) or a faulty ignition system (weak or intermittent spark formation). Since the diagnostics of the state of these systems is interconnected, it is combined into one section.

Remove the spark plug and inspect the carbon deposits on its electrodes.

- Dense and dry black carbon deposits are a sign of a rich mixture (the carburetor is faulty, the air filter is clogged);

- Oily black soot is a sign of severe wear of the piston rings; oil enters the combustion chamber;

- White carbon deposits are a sign of running on a lean mixture; you need to check the carburetor.

- Brick-brown soot is normal for carburetor engines.

- Red, green-red soot is a consequence of working on low-quality fuel.

It is easy to check the functionality of the ignition system itself because of its extreme simplicity: turn on the ignition, insert a known good spark plug into the spark plug cap and, placing its skirt on the nearest metal part of the engine, sharply turn the recoil starter. If there is no spark, disconnect the ignition switch and oil level sensor in turn from the ignition coil: if, after disconnecting both elements, there is still no spark, replace the ignition coil.

If the spark is present and has sufficient strength (white or white-blue color), remove the spark plug after several starting attempts. A spark plug filled with gasoline is a sign of over-enrichment of the mixture; a dry spark plug is a sign of a lack of fuel.

Sometimes, after long-term storage, the carburetor needle and float stick and prevent gasoline from flowing inside. Hit the float chamber cover sharply, but not very hard, several times and repeat the start.

The most common malfunction of the carburetor is its contamination. Dirt getting into the air channels leads to over-enrichment of the mixture, and into the fuel jets - to depletion. Dirt on the float shut-off needle leads to loss of tightness and overfilling of the float chamber, which will be immediately noticeable by fuel leaking from the carburetor.

Let's look at servicing a carburetor using the example of one installed on Honda GX engines - its design is typical for a gasoline generator.

- Remove the float chamber cover (4). Wash it in gasoline or aerosol carburetor cleaner - dirt and deposits accumulate at the bottom.

- Do the same with the gas tap sump (22).

- Check whether the gas valve is ventilated in the “open” position.

- Remove the float shaft (3), remove the float and locking needle (2). Blow out the channel with air.

- Blow out the fuel nozzle (25), emulsion tube (11) and all carburetor channels with an aerosol cleaner or compressed air.

- Turn out the adjusting screw (5) and blow out its channel. Then screw it all the way and loosen it by 2 (foam rubber, paper filters) - 2.5 turns (cyclone filters), depending on the type of air filter.

- Assemble the carburetor.

Electrical faults

The electrical system of gas generators is quite reliable. Most often, you may encounter two problems: lack of battery charging on generators with electric start or lack of voltage at the generator output .

- Lack of battery charging is a consequence of a failure of the rectifier or low-voltage winding. It’s easy to check this system with your own hands: connect a 12-volt light bulb in parallel with the low-voltage winding of the generator and start it. A burning light means that the generator itself is working properly and the rectifier needs to be replaced.

- The lack of voltage at the generator output is most often a consequence of brush wear. Remove them and assess the degree of wear, replace if necessary. If your generator is of the inverter type, check whether voltage is coming to the input of the converter by connecting a low-power 220 V lamp in parallel with it.

Mechanical faults and adjustments

One of the routine works provided for in the operating instructions for gasoline generators is monitoring and adjusting, if necessary, the clearances of the valve mechanism. Increasing the gaps beyond the norm will lead to a decrease in engine power and increased noise during operation. Reducing the gap is the most dangerous, since it is not audible during operation, but pinched valves, especially exhaust valves, begin to quickly burn out. As a result, the engine begins to operate unstably and when the plate burns out, it stops starting.

The procedure for adjusting the valves is quite simple:

- Remove all components that interfere with removing the engine valve cover.

- Remove the spark plug.

- Remove the valve cover.

- Align the crankshaft to the top dead center of the compression stroke using the mark on the flywheel (if there is one) or by monitoring the movement of the piston through the spark plug hole. Do not confuse compression TDC ( both valves are closed ) with exhaust TDC ( exhaust valve closes, intake valve opens ).

- Loosen the locknuts of the adjusting screws and use a flat feeler gauge inserted between the rocker arm and the end of the valve to set the gaps by rotating the screw. Typically, a gap of 0.2 mm is accepted for the exhaust valve, and 0.15 for the intake valve (check the operating instructions).

- Tighten the locknuts and rotate the crankshaft twice, bringing it to TDC. If everything is done correctly, at the next dead center both gaps will go away, and after another turn they will take the set value. The gaps that have increased after the first revolution are a sign that they were adjusted at TDC of the exhaust stroke.

- Assemble the generator.

Emergency generator start

Sometimes it happens that the generator urgently needs to be started, but the manual starter fails at that very moment. If necessary, there are several methods for emergency starting.

The methods listed below

are not safe !

Remove the starter housing. Below it is a flywheel with a cooling impeller, pulled to the crankshaft by a nut. To set it in rotation, you can:

- Wrap a rope around the flywheel and use it in the same way as a recoil starter cable. Please note that if it gets caught on the fan blades, when the engine starts, this rope will turn into a whip whipping in all directions, so be careful. Stand so that the rope cannot hit your hands or head.

- Low-power engines can also be started manually: with the ignition off, turn the crankshaft several times, rotating the pulley by hand in the desired direction. In this case, the gas tap must be open and the starter flap must be closed. After this, turning on the ignition, bring the crankshaft to compression TDC (you will feel an increase in force on the flywheel), and then turn the pulley with a sharp jerk so that the spark energy is enough to ignite the mixture.

- A powerful cordless drill and a head with an extension from the tool kit are a good quick replacement for an electric starter. Clamp the extension in the chuck, put a socket of a suitable size on it and unscrew the crankshaft by the flywheel mounting nut. True, in this way it will only be possible to start a low-power generator - for a large-volume engine, the torque of the drill is not enough to turn it on the compression stroke.

Diagnostics of breakdowns

Diagnostics is a mandatory process that should be carried out regularly, and especially if there are doubts about the serviceability of the unit. The diagnostic procedure allows you to identify mechanical and electrical faults. Of course, for a full diagnosis you need special equipment and a specialist, but some part of the procedure can be identified on your own.

- If the control lamp does not light up when the ignition is turned on, then you should pay attention to the following details:

- It is possible that the lamp simply burned out

- Short circuit of the generator windings to ground

- Broken wiring, problem with fuse or charge lamp relay

- In a situation where the lamp is constantly on, it is worth checking the following:

- First of all, you need to check the belt; it is possible that its tension is not sufficient for normal operation. This is especially true if a belt whistle is heard at high speeds.

- Pay attention to the deterioration or possible destruction of current collection points.

- Oxidation of contacts or broken wiring

- Damage to the voltage regulator or malfunction

- Extraneous noise during generator operation can be caused by premature wear of the bearings; other less significant problems can lead to this:

- Oxidation of the positive terminals of the battery, which increases the load on the unit

- Mechanical impacts and contamination, in particular the ingress of moisture, dirt, sand, etc.

- If the car owner has noticed that the battery is insufficiently charged by the generator, then you need to check the following:

- The simplest and most common reason is insufficient belt tension.

- The problem could also be in the battery itself.

- Oxidation of battery terminals and terminals

- Damage to the wiring, in particular the line going from the generator to the battery

- Break in one of the windings

- Diode bridge breakdown

- There are times when the battery does not charge at all, then the following must be checked:

- Current collecting brushes, due to increased load they can simply “stick”

- Broken wires

- The rotor may touch the stator during operation

MALFUNCTIONS WITH THE ELECTRICAL PART OF THE PETROL GENERATOR

The gas generator does not produce current.

The engine starts normally, but there is no current. The reasons are trivial: the AVR burned out (the generator does not excite), faulty diodes, problems with electrical wiring, problems in the stator or rotor, and also individual modules fail (on some generators). On inverter generators, the main fault is the inverter board.

The gas generator produces current, but it is too strong or weak

The connected devices do not work or are burning. There are two reasons: the engine does not operate at 3000 rpm (3000 rpm ~ 50 hertz ~ 220 volts), electronic components are faulty (automatic transfer switch, inverter board, capacitors, diodes)

When connecting devices, the engine stalls or does not turn on

– again a problem with the engine. Something is clogged or not adjusted.

Troubleshooting methods

Now let's talk about how to repair the device in question yourself if the most common problems occur.

Dirty air cooling fins

One of the fairly common problems that can arise when working with a gasoline generator is dirty air cooling fins. The reason for this could be two things. In the first case, we are talking about the fact that the device has not been used for a long time; dust has settled on it and got inside. Naturally, when the device is actively operating, the system will overheat, which will sooner or later simply burn out.

The solution to this problem can be found in any instruction manual for any model of gasoline generator.

It can also appear for another reason - the use of low-quality fuel can cause carbon deposits to appear on various types of filters and on the cooling mechanism of the device as well. It can be eliminated very simply - the air cooling fins should be very carefully wiped with a cloth to remove dust and dirt. If you wish, you can do this without disassembling the device, but it would still be better to disassemble it, remove the necessary part and thoroughly clean it, and then install it in its original place.

How to repair a gasoline generator?

Today it is difficult to imagine our life without electricity. It is the “fuel” for technology and makes any human activity simpler and easier. And very often in places where there is no electricity for some reason, we understand how important its presence is.

Recently, a device such as a gasoline generator is used to generate electricity. But it, like any other equipment, can break. Let's try to understand the problems with gasoline generators and how to repair them yourself.

DIY generator repair

Most of the malfunctions that occur in the generator are solved by simply replacing one or another component. Actually, let’s take a closer look at how you can repair a car generator with your own hands and start with disassembly:

- Before starting to disassemble the generator, you will need to mark the position of the housing covers in order to subsequently facilitate reassembly.

- Next, the pulley is removed

- The brush holder is carefully dismantled to avoid damaging the current collection brushes.

- All possible wires are disconnected, and the contact bolt located, as a rule, on the back cover is unscrewed

- After this, the case bolts are unscrewed, which prevent the rear cover from being removed. It is worth noting that the case elements fit quite tightly and it will be necessary to apply some effort.

- At the end of disassembling the case, the front cover and rotor are dismantled. Quite often the cover cannot be removed by hand, so it would be wise to use the following method. The cover is installed on two wooden blocks and the rotor is knocked out not with strong blows, you need to be extremely careful in order to avoid damage.

- Finally, the windings are disconnected from the diode block and the elements are dismantled.

Recoil starter spring fault

The tight starter spring with hook is the main design element of the manual starter. In addition to the spring, the starter also includes the following components:

- Ratchet;

- Cord with reel;

- Screw for fixation;

- Return spring;

- Plastic ratchet fuselage.

Repairing a spring, the main component of a manual starter, comes down to replacing the element.

Here's how the replacement is done:

- Use a screwdriver to unscrew the pulley screw;

- Then the spring itself is removed.

On chainsaws, for example, it is an element in the form of a circle, inside of which a flexible spring is wound.

Springs are sold in this form in hardware stores. All that remains is to buy the part and replace it.

When should you contact the workshop?

A number of malfunctions, alas, are quite difficult to fix with your own hands without sufficient qualifications: for example, a faulty inverter converter or voltage regulator can be repaired only with a good understanding of the operating principle and circuitry of such devices. Not every owner of a gas generator will undertake to overhaul the engine, although this is not as difficult as it might seem.

In this case, you should contact a specialized repair shop. You can find out the coordinates of workshops in your city on the Internet or in stores selling gas-powered tools.

What kind of work can you do yourself?

Almost all typical gas generator malfunctions and methods for eliminating them are prescribed in the instructions for use. Manipulations that the user can carry out independently:

- Cleaning filters

- Filling oil

- Fuel replacement

- Replacing and cleaning the spark plug

All other actions involve penetration into the internal structure of the gas generator. Such work can only be performed by certified specialists. Even if you have certain skills, you should know that repairing a gas generator with your own hands entails loss of warranty from the manufacturer and, as a result, unnecessary costs.

Preventive measures

The device should be cleaned from time to time. We are talking about cleaning the fuel tank, as well as the elements of the cooling system from carbon deposits and dust. This will keep the device clean, and blockages will not cause it to overheat and subsequently fail.

In addition, it would not be superfluous to disassemble it from time to time and check the functionality of various mechanisms.

You will need to check the ATS and the functionality of the control unit especially carefully. If possible, it would be a good idea to also clean the internal elements from dirt and dust. Considering the design features of this device, there are no large-scale preventive measures for it.

To this you can also add monitoring the fuel and oil levels, checking the strength of fastening of various elements with bolts, as well as periodically cleaning the air filter from dirt and dust.

Detonation

Causes and solutions:

Ignition system malfunction

- Poor condition of contacts (put contacts in order)

- Faulty or clogged spark plug (cleaning or replacing the spark plug)

Fuel system malfunction

- Unsatisfactory quality of the fuel mixture (cleaning, adjusting, or replacing carburetor components)

- Poor carburetor performance (disassembling and cleaning the carburetor)

- Fuel hose is damaged or clogged (clean or replace)

- The intake manifold sucks in air (tightening the manifold pipe or replacing the gasket)

Cylinder head failure

- The walls of the combustion chamber are covered with carbon deposits (cleaning the combustion chamber)

- Leaky cylinder head gasket, which leads to blow-by (gasket replacement)

Valve failure

- The valve clearance is different from the clearance set for this model (adjusting the clearance)

- Worn valves due to overheating (replacement of valves)

- Worn valve springs (replace springs)

- Incorrect valve timing (valve timing adjustment)

Some recommendations for proper operation

It is necessary to regularly check the voltage in the car network. Performed with a multimeter with the car turned on. The terminals of the device are connected to the battery terminals. The voltage should be between 13.8 and 14.2 V.

Indicators outside the specified values will indicate the presence of problems:

- The problems will be related to either the battery or the regulator.

- Checking the brightness of the headlights. When the brightness decreases, it makes sense to check the regulator and/or diode bridge.

- Checking the drive belt tension. It should not be pulled too tight.

Listen to the generator regularly. If noises appear, the alternator belt must be diagnosed and repaired.

You can better understand the sequence of actions by watching a video of repairing generators with your own hands.

Spare parts and accessories for DDE electric generators

In our service center you can order spare parts and accessories for DDE electric generators. We work on pre-ordering spare parts. The most common items are always in our warehouse! We order unique spare parts and accessories directly from manufacturers without extra charges, their delivery time varies from 5 to 30 working days.

The availability, completeness and cost of the necessary spare parts can be easily clarified by calling us by phone or leaving a request for spare parts on the website.

Generator disassembly procedure

If you want to repair the generator yourself, you should learn how to properly disassemble the generator.

Naturally, each generator model can be disassembled differently, especially generators from foreign cars, but still the algorithm of actions in all cases is almost the same.

The first step is to clean the generator from dust, and if necessary, even blow it with compressed air.

Next, the generator brushes are removed simultaneously with the brush holder; to do this, you only need to tighten one screw.

Immediately check the condition of the brushes and brush holder. If the brushes protrude less than 0.5 cm from the brush holder, they must be replaced immediately.

Also, when removing the brush holder, pay attention to the condition of the socket where it is attached. Usually, the nest contains a lot of coal dust, which is mixed with oil; remove all this with a cloth.

If necessary, if you want to completely disassemble the generator, remove its pulley. To do this you will need a special device 67.7823.9504

but before removing, do not forget to unscrew the nut that secures this pulley.

The device 67.7823.9504 has a special gripper, which is made in the form of 2 metal half-rings, and it must be used to remove the generator pulley.

But it is better to give this work to a specialist, since it requires a certain skill, and device 67.7823.9504 is something unimaginable and incomprehensible for many who want to repair the generator with their own hands.

Next, we disconnect the rear cover, which is located on the side of the slip rings from the cover on the generator drive side, and at the same time remove the stator, rectifier unit and rotor, the shaft of which is located in the bearing of the cover on the generator drive side.

Next, there is nothing complicated in disassembling the car generator; we disconnect the wires from the stator and from the rectifier unit, and remove this unit.

Removing and disassembling the generator

- Remove the generator from the engine compartment;

- After unscrewing the fasteners, remove the brush holder and voltage regulator;

- Remove the tension bolts;

- Having disconnected the phase windings from the wires on the rectifier, you need to remove the stator cover;

- Lastly, the shaft pulley and the front cover of the generator are removed. To do this you need to use a special puller.

When dismantling the generator, you should avoid excessive force when unscrewing soured bolts. Thread failure entails a very unpleasant procedure for cutting new threads and turning new bolts. It is better to fill the problem screws with Vedashka and leave for a couple of hours.

When disconnecting phase windings, it is important not to tear out the soldering points by the roots, otherwise the soldering procedure can easily result in a cycle of complete rewinding of the stator.

Replacing brushes and generator relays

If you have to replace the alternator bearings, it's time to replace the brushes as well. It is unknown when they were last changed or if they were changed at all. To ease your conscience, you can remove the brushes from the generator for a visual inspection, but it is better to change them immediately, because you are unlikely to want to climb into the generator again. When replacing a relay, the main thing when choosing is to find one that is recommended by the manual for your car. It is best to remove the old one and pick up the same one.