Chainsaw malfunctions and how to repair the tire yourself

A chainsaw is a necessary thing in the home and garden, helping to quickly and efficiently carry out various work with wood. Like any electrical device, it periodically fails and requires diagnostics. The result of the last event is often the conclusion that it is necessary to repair the chainsaw tire - the mechanism that experiences most of the load during operation.

When is chainsaw chain repair necessary?

Not only the convenience and quality of cutting, but also the consumption of fuel and lubricants depends on the condition of the saw chain. In addition, the operation of a faulty chain can lead to both complete failure of the tool components and injury. Therefore, before starting work, you must check the condition of the chainsaw, the presence of oil and combustible mixture, as well as the integrity of the body and the functionality of the controls.

The service life of a chain depends on many factors - the materials from which it is made, operating conditions, operator's work style, etc. During normal operation, a professional chainsaw is serviced every day. As for home tools, they are not used so intensively. But you should still prepare for cutting by drying and cleaning the material from dirt and foreign objects.

The chain of a household chainsaw must be repaired immediately if signs such as:

- slowdown and difficulty cutting;

- beating or increased vibration of the saw bar;

- chip heterogeneity;

- deposits on the cutting line and chips;

- characteristic smell of burnt wood or overheated metal;

- dust emission when cutting, etc.

If you have the necessary tools, knowledge and skills, it is not at all necessary to contact a service center if these symptoms occur - you can do tensioning, sharpening, etc. yourself. Direct visual inspection of the saw chain allows you to verify the presence of faults, as well as identify their extent and determine the appropriate remedy.

The chainsaw loves to work, so it should not be left idle for long periods of time. If you are not going to use the tool in the near future, you need to properly prepare it for storage.

How to choose a tire

Choosing a tire is a responsible event, the result of which depends on the operation of the entire device. Installing an unsuitable element not only leads to failure of other parts, but is also unsafe for the operator. In order to correctly select a component, you will need data on the length, size, shape and parameters of the shank.

The size is determined by the types of work you plan to do with the saw. Small dimensions are suitable for simple manipulations and cutting thin boards. The most powerful installations are useful for harvesting firewood from thick tree trunks.

Electrical equipment, light, lighting

Even if you want to, a chainsaw cannot be classified as a complex device. Moreover, the simplicity of the design is its distinguishing feature. But repairing a chainsaw can still be time-consuming. The difficulty lies not directly in repairing a chainsaw with your own hands, but in accurately diagnosing the malfunction. One symptom of inoperability can be caused by many reasons. Therefore, before disassembling the engine or carburetor, it is necessary to carefully analyze the symptoms of the malfunction. No instructions for repairing a chainsaw on your own can replace simple logic.

Table of contents:

Types of chainsaws

A chainsaw is a tool that cuts wood with a closed chain and is equipped with a two-stroke gasoline internal combustion engine. The ability of a chainsaw to work continuously for a certain time is the main distinguishing ability that you should pay attention to.

The main structural units of a chainsaw are: a chainsaw bar, a chain and a gasoline engine, which drives the chain and bar. Based on their scope of application and functionality, chainsaws are divided into the following categories: professional, semi-professional and amateur household.

Amateur chainsaws are used mainly in everyday life, for gardening in the countryside or at a summer cottage. Such saws are very light in weight (3-4 kilograms without chain and bar), compared to their older brothers, their vibration is very low, which makes working with this device quite comfortable. Household chainsaws are primarily designed for a short period of use (about 5 hours a week), the motor power is low, but these shortcomings are compensated by ease of operation. With the help of household chainsaws, summer residents most often do small work - harvesting firewood, cutting garden trees and pruning branches.

With a semi-professional chainsaw, you can easily perform a wider range of work - from repairs on your site to felling. The continuous operation time of such a saw is 2-3 hours per day. The power of the gasoline engine in semi-professional devices has been increased. You can achieve maximum productivity and fell trees with medium and small trunk diameters. Semi-professional chainsaws are often used for cutting knots. The only difference between such devices and professional ones is that they cannot be used continuously throughout the entire working day.

Professional chainsaws are mainly used in logging and industry. The engine power of professional chainsaws is designed to cut trees of any size and diameter. Such chain saws are made of wear-resistant material and have a particularly strong chain, which allows you to work continuously for 8-16 hours.

Chainsaw malfunctions

All chainsaw breakdowns are conventionally divided into two groups: malfunctions of the engine with all its systems and components (fuel supply system, ignition, exhaust system, cylinder-piston group) and malfunctions of other components (lubrication system, clutch, tire, chain brake).

Malfunctions in the functioning of chainsaw engines occur quite often, and it is their correction and detection that takes users the most time. They mainly boil down to the following manifestations: the engine does not start, the engine starts, but stalls or is completely unstable, the engine does not develop power, that is, it runs normally at idle, but stalls under load.

When repairing a Stihl chainsaw with your own hands, you must use the method of elimination - check all possible causes of failure one by one, starting with those that will take you less time to diagnose and eliminate.

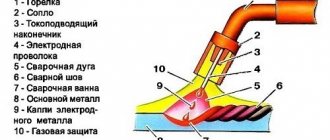

Ignition system

Almost all types of engine problems that were listed above can be caused by failures of the ignition system. If they occur, it is recommended to start troubleshooting with a spark plug. This is also justified by the fact that its condition will also provide useful information about the functioning of the fuel system. If problems occur, remove the spark plug and inspect it.

When the spark plug is dry, then most likely the problem is not in the ignition system, but in the fuel mixture not getting into the cylinder. You can wrap the spark plug back and take on the fuel system. When the spark plug is splashed with fuel mixture, there is an excess of it. This may be caused by a carburetor misalignment or a violation of the starting rules. The spark plug must be wiped and dried, draining the cylinder, then turn off the fuel supply and operate the starter to remove excess fuel. After this, replace the spark plug and restart.

Perhaps in your case the ratio between gasoline and oil in the mixture is incorrect, the carburetor is not adjusted, or low-quality oil is used. Rinse the spark plug in gasoline, remove carbon deposits with a needle or awl, clean the electrodes with fine sandpaper and install them in place. Even when repairing a Goodluck chainsaw with your own hands, which consists of checking the spark plug, there is good reason to believe that the faults are in the fuel system; you need to check the spark plug for the presence of a spark.

If there is no spark, you simply need to replace the spark plug. The reasons for the lack of a spark may also be hidden in a failed ignition module or a violation of the gap between the flywheel magnetic circuit and it. The distance should be 0.2 millimeters. Violation of the gap becomes especially likely if you have previously disassembled the saw and removed the ignition module and flywheel. The gap must be set using a gasket, which has a thickness of 0.2 millimeters, placed between the ignition module and the flywheel boss. A faulty ignition module must be replaced.

DIY chainsaw carburetor repair

In order for the carburetor to serve for a long time and properly, it is enough to carry out the following actions:

- Gasoline and oil must be mixed in accordance with the numbers noted by the manufacturer.

- There is no need to prepare the fuel composition in advance, since the properties of the substances in the mixed state change. The exception applies to fuel for intensively used tools, however, even here it is better not to store the composition for more than 7 days.

- Use oil designed for your chainsaw motor. Fuel composition with non-standard composition will lead to breakdowns.

- When preparing a fuel composition, it is necessary to take into account the impact of natural factors on its components.

Replacing the chainsaw bar and its fastening elements

To replace fastening elements, tires and chain fittings, it is necessary to disassemble the entire fastening mechanism. It doesn’t hurt to prepare in advance a rectangular piece of fabric or cardboard, as well as free space on the table for disassembling the tool and temporarily placing the removed parts.

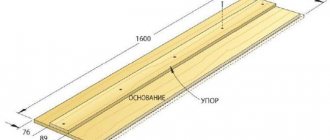

Chainsaw bar mounting diagram

Replacing fastening elements and the chainsaw tire is necessary when:

- Critical wear of the landing groove or shank elements.

- Damage to the casing.

- Failure to secure the fastening bolts.

- Damage or deformation of the tire body.

- Abrasion or breakage of the teeth of the drive and driven sprocket.

- Damage to the grooves for supplying lubricant to the chain.

- Worn chain tensioner.

- Worn seat groove and tire retainer.

Chainsaw bar mount

The tire and its fastening elements belong to consumable parts. Wear of this unit occurs both under work loads and as a result of improper operating conditions. You can immediately identify any faults in this area. The tire will not be able to provide normal tension, lubrication and smooth running of the chain, and its fastening will not be able to secure the cutting axis relative to the tool body.

Fastening the saw bar

It is unsafe to operate a saw with a faulty guide bar. Therefore, at the first sign of a unit failure, you need to turn off the engine and find out what’s wrong. Knowledge of the design features of the tire and its mounting on your chainsaw will help you successfully eliminate the cause of the malfunction.

The bar determines the axis and length of the cut, guiding the chain. But the basis of the mechanism is still the fastening. It is installed in the groove between the inner plate on the motor housing and the outer plate located on the chain set casing. The tire and casing are fixed using a bolted connection. This part of the mount is called the “engine assembly”, and its shape and design depend on the chainsaw model. The tire mount and drive sprocket are covered with a separate cover.

Chainsaw bar mounting studs

The drive links of the saw chain are installed in a guide groove on the edge of the bar and are driven into engagement with a drive sprocket connected to the power take-off shaft. If the fixing bolts are loosened, the tire may move. The chain tension can be adjusted manually or, as on professional chainsaws, automatically. Finally, there is a stop at the front of the tire mount. It serves to securely fix the cutting axis when the moving chain comes into contact with the wood.

Design of the chainsaw drive sprocket: with replaceable and stationary ring

A working tire should provide normal chain tension. To check it, you need to release the chain brake and pull the chain by hand in the direction of its movement. If the chain does not move, the fastener is too tight. You need to loosen it slightly, and then check the free movement of the chain again.

Adjusting chain tension using a wrench

Reasons why it takes away from a straight cut

Sometimes situations arise when it is almost impossible to make a straight cut with a chainsaw; the tire moves to the left or right. The reason for this behavior of the tool may be the following:

- Incorrect chain sharpening. The teeth of the chain are sharpened on one side more than on the other. The problem can be resolved by sharpening the chain correctly.

- Uneven wear of the chain links, the support pads of the chain links on one side have a large wear-out, due to which the chain tilts slightly and obtaining a straight cut is no longer possible. The problem can only be solved by replacing the chain.

- And lastly, uneven wear. As in the previous case, for this reason the chain will change its slope and will no longer cut smoothly. The only way to solve the problem is to replace the tire.

The inability to make a straight cut with a tool is a sign of increased wear of the bar and chain, which in turn should be sought for its cause. Eliminating the effects of wear by replacing consumable parts will not bring the desired result, because... If the lubrication system malfunctions are not eliminated, after a while everything will repeat itself.

Post-repair restrictions

The problem is that the hastily repaired part contains one or more “weak links”. In this state, the operating time of the headset under heavy loads is significantly limited, and increased demands are placed on the full operation of the lubrication system.

It is possible to use the restored chain in operating mode, provided that the repair was performed by an experienced riveter who has a riveting machine and other special equipment at his disposal.

What you need to know when choosing a chain

If you have determined that it is time to change the saw set, you need to decide how to choose it correctly. The easiest way to do this is to refer to the instruction manual, which contains recommendations on this matter. At fdfmoto we have a large selection of chainsaw chains from various brands.

Another way is that you can match the markings on the old chain to the same one.

To avoid making mistakes when purchasing, you need to know the following information:

All chains are divided by size based on pitch, which is measured in inches. There are sizes 0.325 for household saws, 3/8 or 0.375 for semi-professional and professional saws, and 0.404 for professional tools.

Drive link thickness. This size is determined by the width of the chain groove in the tool bar. Their difference also depends on the class of the chainsaw; the more professional the tool, the higher this figure is.

This knowledge is enough to navigate the range offered by the market.

Source www.ssa.ru

Not everyone, of course, has the opportunity to buy a brand new one, although it is still in question what is better, whether new or tried and tested old. Well, how can you not get a “cat”. With a chain everything is clear, it’s based on the longitudinal length of the tooth, the longer, the newer. Look in the tire and measure the depth of the groove where the chain runs. If the chain goes along the “bottom” it is junk. If it is 3-4 mm longer than the guide tooth, it will still work. Well, and the width of the groove.

Source www.remotvet.ru

The chainsaw bar is the guiding and fixing element of the saw set. The blade itself, the drive sprocket and fasteners are consumables.

Working with a broken tire is very dangerous, since at high speeds it can fall off the body and injure the operator, or due to poor fixation on such a tire, the chain can jump off and cause injury.

Most often, wear of this element of the chainsaw occurs naturally, due to long-term use. Since it bears the main load when cutting. But there are situations when the tire breaks due to improper use of the tool. Excessive load beyond the specifications of the tool.

Or lack of proper chainsaw care. In addition, it also happens that a professional or semi-professional tire is installed on a low-power unit, or vice versa, tires intended for household saws are installed on a pro-class and universal tool.

First of all, tires differ in length. Thus, tires of 11 and 13 inches are suitable for household saws, and 14 - 16 inches for universal and professional saws. The elements also differ in design features. There are blades that are flat and narrow, some that consist of two parts, connected by polyamide, and finally, with a removable head.

The last two types are used on semi-professional and professional saws. The FDFmoto online store has a large selection of tires, fasteners and other accessories for gasoline tools - https://fdfmoto.com/ru/catalog/shinyi-dlya-benzopil

How to Disassemble a Chainsaw Tire

DIY chainsaw repair

All malfunctions of chainsaws can be divided into two main groups: engine problems with all its components and systems (ignition, fuel supply system, cylinder-piston group, exhaust system) and malfunctions of other components (chain brake, lubrication system, clutch, tire , etc. .).

Engine malfunctions

- the engine does not start;

- starts but stalls;

- works unstably;

- does not develop power, i.e. It runs fine at idle, but stalls under load.

When repairing a chainsaw with your own hands, you must use the method of elimination. inspect alternately all the probable causes of a malfunction, starting with those that take the least time to check and eliminate (see here about the structure and operation of a two-stroke engine).

Ignition system

. Almost all types of engine problems listed above can be caused by ignition system failures. Therefore, when they occur, it makes sense to start troubleshooting with a spark plug. This is all the more justified since the state of the latter can provide useful information about the operation of the fuel system. So, if a problem occurs, you need to unscrew the spark plug and inspect it.

The wire is disconnected and the spark plug is unscrewed with a special wrench.

If the spark plug is dry, this means that the problem is most likely not in the ignition system, but in the fuel mixture . You can wrap the spark plug back and get to work on the fuel system. If the spark plug is heavily splashed with fuel mixture, it means there is an excess of it. This may occur due to carburetor misadjustment or violation of starting rules. The spark plug is wiped and dried, the cylinder is dried by turning off the fuel supply and operating the starter. to ventilate the combustion chamber and remove excess fuel. Then install the spark plug in place and repeat the start.

The presence of a large amount of black carbon also indicates a malfunction in the fuel system.

The ratio between oil and gasoline in the mixture may be incorrect, the carburetor may not be adjusted, or low-quality oil may be used. The spark plug is washed in gasoline, cleaned of carbon deposits with a needle or awl, the electrodes are cleaned with fine sandpaper and replaced.

In all these cases, it would be a good idea to check the gap between the spark plug electrodes. Depending on its brand, it should be in the range of 0.5-0.65 mm. You also need to check the spark plug seal. If it is worn out or damaged, the tightness of the combustion chamber may not be ensured, which leads to a decrease in compression in the cylinder and problems in engine operation.

Even if, when checking the spark plug, there is good reason to believe that the fault is in the fuel system, you need to check the spark plug for the presence of a spark. At least to be sure that everything is in order. For this:

- put the ignition cable on the spark plug;

- using pliers with insulated handles, apply the thread or nut of the spark plug to the cylinder;

- pull the starter handle and watch. whether there is a spark or not.

If there is no spark, you just need to replace the spark plug. If the new spark plug does not have a spark, you need to check the condition of the high-voltage wire for a break and contact with the spark plug.

The reason for the lack of a spark may also be a faulty ignition module or a violation of the gap between it and the flywheel magnetic circuit. It should be 0.2 mm. Violation of the gap becomes especially likely if the saw was previously disassembled and the flywheel and ignition module were removed. The gap is set using a 0.2 mm thick gasket placed between the flywheel boss and the ignition module. A faulty ignition module must be replaced.

Having checked the ignition system in this way and not finding a malfunction, you can move on to the fuel mixture .

Fuel supply system

. If by inspection of the spark plug it is determined that fuel is not entering the cylinder, all possible reasons for this need to be considered. It could be:

- failure of fuel to flow from the tank due to a clogged hole in its lid (breather), while a vacuum is created in the tank, preventing fuel from leaking out;

- contamination of the fuel filter installed in the tank;

- no or insufficient supply of fuel mixture from the carburetor to the cylinder.

To diagnose the first two reasons, it is enough to disconnect the fuel hose from the carburetor and see whether fuel flows out of it or not. If it flows in full stream, the breather and filter do not need to be checked; if it does not flow or flows weakly, we can assume that the cause of the malfunction has been found. The breather is cleaned with a needle. The fuel filter is removed through the filler hole of the empty fuel tank using a wire hook, along with a suction hose, from which the filter is disconnected and cleaned or replaced with a new one. Chainsaw manufacturers recommend changing the fuel filter every 3 months.

A simple knife made from a chainsaw tire part #1

In the video I will show you how to make a homemade knife from a tire

from

a chainsaw

and an aluminum alloy, I’ll show you the simplest one.

How to select a tire for a chainsaw - tips for proper operation.

4 / 5 ( 2 voices)

The tire, or as it is also called the saw blade, is an integral attribute of the chainsaw. Together with the chain, it is part of the cutting set. The tire serves as a stationary guide plate along which the chain moves. The saw set bears the main direct load during the sawing process, and the speed and quality of the cut depends on its condition. All headsets are consumables and the tire is no exception. Depending on the intensity of use, replacement with a new one will be required in any case.

In this article we will tell you how to choose a guide bar for your saw and other nuances with its installation and use.

Chainsaw tire compatibility |

When you buy a chainsaw, in most cases it comes with a factory saw set. As a rule, it is the optimal size for a particular mechanism. Therefore, when replacing with a new tire, you need to rely on the option that was supplied as standard. The bar must be exactly compatible with the other elements of the saw set and the chain saw mechanism as a whole.

The easiest way to select a tire is to bring a sample to the store. An experienced seller will easily determine the desired option even by looking at a standard chain or the name of the saw. In addition, the manufacturer indicates the tire dimensions directly on the body or in the tool instructions.

If for some reason none of these options work, then we offer you two options. First, delve into the basic parameters and dimensions that a chainsaw tire has and read this publication further. Second, follow the link to another article and select a tire based on the name of your saw.

| ¦¦ THIS IS INTERESTING ¦¦ |

|

The main parameters of a chainsaw tire |

Let us highlight four main parameters of the saw bar:

- bar length (L)

- tire thickness (T)

- groove and sprocket pitch

- shank type

Tire length (L).

This is the length of the cutting working part of the tire, not the full one, from the front body of the tire to the very tip. This distance is rounded to the nearest side and measured in inches or centimeters.

If you install a longer bar, you will have to select the appropriate chain for it. Please note that this will increase the load on the engine, since the contact area with the wood will increase. In this case, you need to be careful and correlate the length with the power so as not to ruin the mechanism of the tool. There is an increasing tendency among users to shorten the size of the bar and chain. This is especially true for Chinese chainsaws. The length of the cut, of course, will become shorter, but the load on the engine will decrease, which means its service life will increase.

| step | TIRE LENGTH IN INCHES IN CENTIMETERS | Number of links | thickness | |

| 3/8. | 10″ | 25 cm | 40-43 stars | 1,1/1,3 |

| 12″ | 30 cm | 44-46 stars | 1,1/1,3 | |

| 14″ | 35 cm | 50-53 stars | 1,1/1,3 | |

| 16″ | 40 cm | 54-60 stars | 1,3/1,6 | |

| 18″ | 38 cm | 62-68 stars | 1,3/1,6 | |

| 0,325 | 15″ | 38 cm | 64 stars | 1,3/1,5 |

| 18″ | 45 cm | 72 stars | 1,5 | |

| 20″ | 50 cm | 76 stars | 1,5 | |

Chainsaw bar thickness (T)

or more precisely, the thickness of the guide groove is another key parameter. The thickness of the groove of the bar and the drive link must match perfectly. Due to this, a stable state of the structure is achieved and, with proper tension, jumping is prevented even at high speeds of the operating saw.

It is worth noting that the leading link running along the groove plays the role of an oil distributor along the entire edge of the chain and bar. The international classification is based on 5 standard dimensions for the groove thickness of the guide rail:

1.1 mm (0.043 in) - not as common on low-power saws or single-handed saws.

1.3 mm (0.050 in) and 1.5 mm (0.0578 in) are the most common sizes. Installed on household and semi-professional models of chainsaws.

1.6 mm (0.063) and 2.0 mm (0.080 inch) - headset with thick drive link. Found on professional high-power chainsaws.

Step of the groove and driven chainsaw sprocket

The tire must also match the pitch of the chain and drive sprocket. Otherwise, the chain simply will not fit into the groove and will not move along it. It can be more or less, depending on the 5 standard groups. Groove pitch chain pitch) measured in inches: "1/4", "0.325", "3/8", "0.404" and "3/4" (chronology in order of increasing length).

“0.325” and “3/8” - the majority of saws are equipped with these chain pitch sizes, and all well-known manufacturers of chainsaws and electric saws install these popular groups. It is highly likely that you will need one of these options.

Chainsaw bar shank

It has a certain shape and holes with a groove for attaching the bar to the studs of the saw body, due to which it is rigidly fixed to it. Any tire has mirrored sides, i.e. turning it over you can see an absolutely identical picture. This was done to ensure uniform wear of the drive tire due to its regular rotation.

Also on the shank you can see technological holes - channels. They serve to dose oil into the tire groove and then distribute it along the entire edge. The channel on the bar must match the channel on the saw, otherwise there will be no oil supply. Therefore, do not underestimate the shape of the grooves and holes, which play a role in securing and lubricating the tire.

The first three parameters have worldwide standardization, which cannot be said about the last one. Some brands make a customized shape for the shank and lubrication channels. For replacement, you can only use original equipment, which is not very convenient and cheap. Therefore, most manufacturers have unified these parameters.

The length of the bar, the thickness of the groove and the pitch of the driven sprocket, together with the parameters of the chain of the driving sprocket of the saw, must be mutually applicable and form a single “composition”. Knowing all the standard sizes, you can easily select the right tire and chain.

Which chainsaw tire is better? |

As a rule, chain saw manufacturers are engaged in parallel production of guide bars, both for their models and other standard sizes for units from other manufacturers. Of course, there are companies that are exclusively engaged in the production of saw sets, but there are few of them.

Each chainsaw manufacturer recommends installing its own fitting, but this is not mandatory. Conventionally, the guide bar for a chainsaw is divided into 3 quality classes:

- Hobby class

- Semi-pro

- Professional

The main difference between classes is the dimension. The hobby class will be the shortest, the professional class will be the longest, and accordingly the tire thickness will be greater. But, it is worth repeating that this is a conditional division and not always a long tire is of high quality, but a short one is the opposite.

It is much wiser to choose a tire based on the manufacturer. There are not so many famous manufacturers of saw sets; remembering them will not be difficult.

- STIHL, HUSQVARNA and OREGON are the most common companies producing not only tires, but also chains and other components for gasoline tools. Of course, their cost is higher, but they will last many times longer than others. Less popular brands for the production of saw sets - MAKITA, ECHO - have similar excellent quality. But you can’t find them at all on the market.

- The category of Chinese manufacturers is only growing every year; in it you can find both good and bad products. The following companies can be noted: CHAMPION, RedVERG, REZER, ZUBR. They have been on the market for a long time and, along with an affordable price, have proven themselves to be of good quality.

In other cases, you should be careful about your choice. After all, a high-quality tire for a chainsaw and a headset in general is not only the key to successful work, but also safety. Do not buy tires from unknown manufacturers and beware of counterfeit ones. Original products almost always come in packaging and are well painted. In some cases, the tire has laser engraved parameters on the side.

Installing a saw set on a chainsaw |

- Remove the side protective cover with chain brake

- Install the tire, placing the groove in the studs for fastening

- Place the chain on the drive sprocket and then, starting at the top edge of the bar, on the driven sprocket.

- Insert the side cover until the tension groove in the tire fits into the tension bolt. Tighten the nuts and check that they are installed correctly; the chain should move in the groove without jamming.

- You can tighten the chain until the chain is completely adjacent to the bottom edge of the tire.

- Finally check the tension by lifting the chain from the top edge with your hand. One chain link should be completely above the tire, and the two adjacent ones should barely touch. Tighten the side cover nuts firmly.

When installing a new headset, you need to take into account that the new chain stretches faster and needs to be broken in. It is necessary to check the tension more often, especially after the first cuts. A correctly installed bar and chain will ensure high quality sawing and will last longer.

Operation and reasons for rapid tire wear |

Here are a number of reasons leading to rapid wear of the guide bars:

- Excessive chain tension.

- Excessive user effort, especially when cutting hard wood.

- Sawing with the end of a bar.

- Overheating due to lack of chain lubrication. Also, the reason may be the use of low-quality oil (waste oil).

- Contamination of the groove and oil channels with sawdust, earth, sand, etc.

- Pinching of the tire by the barrel or material due to improper cutting.

Any of these reasons can lead to rapid tire wear. The malfunction can be determined visually, or you will simply notice a deterioration in the quality of sawing. The chain will begin to jump along the groove in the tire or even fly off it. In this case, the tire will be pulled to the side and the cut will be crooked.

To avoid premature wear and increase the service life of the guide bar, it requires maintenance. Here are a number of rules for proper operation:

First of all, before each use of the saw, you need to ensure that the saw set is properly tensioned and installed. Fill in high-quality oil to lubricate the saw set and be sure to ensure that it is supplied regularly.

Checking the oil supply to the chain:

- Find a light surface

- Start the saw and, at full throttle, point the lowered end of the saw at this surface.

- After a few seconds, an oil trail should appear

It is not recommended to saw with the end of the bar. This will not only increase the load on the engine, but can also lead to breakage of the drive sprocket.

The drive sprocket can be maintenance-free when the resource is designed for the entire service life of the blade. The serviceable sprocket has holes for periodic oil injection.

Rotating your tire regularly will balance out tire wear. By the way, using several sharpened chains in turn will also extend the life of the guide bar. There is no need to put much pressure on the saw when working; the weight of the tool and a little effort from the user are enough for this.

Conclusion |

A correctly selected and high-quality guide bar is the key to stable operation and straight cuts. Our experience shows that the buyer does not always choose tires from premium manufacturers such as STIHL or HUSQVARNA. This is due to the high cost. Since for saw chains the difference between a premium manufacturer and a high-quality Chinese analogue is 15-30%, the majority is inclined to the first, higher-quality option. A similar difference in the cost of tires by 2-3 times makes you think, and usually in favor of a cheap analogue. Of course, premium ones will last longer, but high-quality Chinese CHAMPION or REZER tires also have a decent service life.

Everyone relies on the possibility of their own pocket, so it’s up to you to decide whether it’s worth overpaying or not, and how much you need this resource reserve. In conclusion, we will once again provide a brief reminder on choosing a guide bar for a chain saw.

Have a good job!

5 7 votes

Article rating

What do you need to know to repair a chainsaw yourself, and what tools are required?

First of all, you need to understand the kinematics of the device. Superficial knowledge like: “gas tank, motor, starting cord, shaft, chain” is not enough. Study the technical description of your instrument, read relevant literature.

When carrying out warranty service (during this period it is better to entrust repairs to the service), do not hesitate to ask questions to the craftsmen, try to understand the structure of the chainsaw. Moreover, it is better to do this preventively, without waiting for the first breakdown.

Standard tool for work:

- Set of socket and open-end wrenches;

- Spark plug spanner;

- High quality screwdrivers;

- Pliers, tweezers, side cutters;

- Retaining ring pullers;

- Soldering iron, tester.

A welding machine is not required, since housing failures require replacement of elements. Even repairing a chainsaw tire with mechanical damage is undesirable.

Conclusion

A correctly selected saw guide for a chainsaw will ensure high-quality operation of the tool and relieve the engine from excessive loads. The coincidence of the lubrication hole of the guide and the oil pump guarantees regular lubrication of the chain edges and, as a result, will prolong their cutting properties. To maintain even wear on the chain groove, it is recommended to rotate the bar from time to time. By following the selection criteria and operating rules described above, you can significantly extend the operating life of the unit.