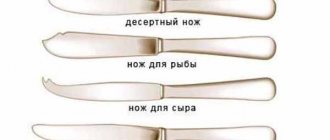

How to sharpen a ceramic knife Sharpening auger knives Sharpening a shoe knife Sharpening mora knives Sharpening cutter knives Sharpening a jamb knife

Even a novice hunter knows that choosing a special knife for hunting is far from easy. In this case, we are talking not so much about the uniqueness of the shape, the cost of the tool, the popularity of the model or the time of existence of the manufacturing company in the world or domestic market, but first of all, the choice of knife for hunting is based on the individual preferences of the future owner, the stated technical characteristics of the product and those chosen for manufacturing materials.

Knife Blade Parts

The word "blade" means the cutting, usually metal, working part of a cutting tool. To properly understand when it comes to sharpening a knife to perfect sharpness, you need to know four terms that refer to parts of the blade:

- butt - wide base of the blade;

- descents are planes that narrow the thickness of the butt towards the chamfers of the blade. The narrowing is carried out along straight lines or, which is more difficult but effective, along a curved or concave (for straight razors) arc;

- chamfers are planes along the narrowing line of the blade from the slopes to the cutting edge. The angle between the chamfers is called the sharpening angle;

- edge - the cutting edge of the blade.

The shapes of the blades are different. Blades can be asymmetrical in the shape of the butt and in the sharpening cut. For example, with a one-sided chamfer, like a chisel.

The dagger is distinguished by a chamfer with a cutting edge along the entire perimeter of the blade, and household knives are single-sided. The correct design has a handle in the form of plastic or wooden plates attached to an all-metal blade.

The more unusual the shape, the narrower the scope of application. Usually, even when hunting, two universal blades are enough - for cutting trophies and for cooking.

Defining features of edged weapons

A blade is recognized as a bladed weapon based on all its characteristics. The decisive factor is the design purpose for delivering damaging piercing blows without causing damage to the striker. In particular, this is facilitated by a safety handle with a limiter).

If at least one of the signs is missing, the blade does not fall under the definition of “edged weapon”!

| Defining Features | Are not melee weapons | Recognized as a bladed weapon if all the signs are present |

| Length and thickness of the blade (the length is determined from the tip to the stop, or the front end of the blade sleeve, the thickness is greatest in the butt area). | Blade length up to 90 mm inclusive, Thickness up to 2.6 mm or over 6 mm. Handle length less than 70 mm | Blade length over 90 mm, Thickness from 2.6 to 6 mm Handle length over 70 mm |

| The presence of a limiter (one or two) or finger grooves on the handle and their linear parameters | Any deviations from the standards prescribed in GOST for edged weapons (see right column) | The limiter (or two in total) protrudes at least 5 mm from the handle of the knife, the width of the limiter is at least 3.5 mm. The depth of one sub-finger groove on top of the handle is at least 5 mm, each of the grooves on the bottom is at least 4 mm |

| Blade material hardness | Brittle or plastic material – less than 42 units. according to Rockwell | Hardness from 42 HRC (clause 5.2 of GOSTs 2 and 3 from the list) |

| General flimsiness of the structure | The shank is too thin or secured with wax or sealing wax; there is a deep groove sawn along the blade near the handle, causing a break when stabbed | The ability to pierce repeatedly without damaging both the owner’s hand and the integrity of the blade |

| Blade sharpness | - lack of an edge as such, - rounding where the tip should have been, - a sharpened edge for a chisel or screwdriver with an area of at least 3 mm, - large, at least 70 degrees, vanishing angle of the blade and butt, — blade thickness more than 6 mm, - no signs of any sharpening. | According to GOST, a sharpened knife should cut a birch branch with a thickness of 10-12 mm with a humidity of about 12% 5-6 times, leaving a smooth, burr-free cut. Law enforcement agencies tend to define sharpening of a knife as simply removing the cutting edge. |

Let us mention one of the common myths “presented” by police officers to owners of knives. The concept of “blood” (officially – dol, a groove along the edge of the blade) is unacceptable for use, see clause 6.1.1.5.1 of GOST R 51215-98. “The weapon is cold. Terms and Definitions". Dole is in no way a defining feature of a bladed weapon.

Knives - can everything be sharpened at home?

As already mentioned, all knives without exception become dull; the service life of high-quality alloys is longer. Buying such knives for home use often does not make sense, since they are quite expensive. The best option in this case is to buy a sharpener for regular knives.

When sharpening ceramic knives, you should not use whetstones; the best option in this case is to turn to professional specialists. The same applies to Damascus steel and damask steel. Knives with a wave-shaped blade are also not suitable for turning at home with your own hands. The workshop will also not be able to bring them into proper shape.

Features of knife sharpening

Before carrying out the procedure, it is recommended to familiarize yourself with the nuances. The angle at which the tool is sharpened plays an important role. At an angle of 15 degrees, you should sharpen products for fish, meat products and bread - such knives are most often used in the kitchen. When processing sport hunting models, the angle is different.

Choosing a sharpening angle

Before you start sharpening at home, you need to know all the rules. Depending on the purpose of the cutting tool, its sharpening angle will be different - this is the position of the blade in relation to the working surface. You also need to take into account the hardness and type of metal: the harder the alloy, the smaller the sharpening angle will be. Depending on the hardness of the alloy, the method of sharpening the blade is selected.

There is a special table developed by the global company CATRA. It indicates the blade angle for each individual type. The following angles are recommended:

- Thinning and filleting - 5−10°.

- For fruits - 10−15°.

- Cutting - 15−20°.

- For meat and large fish - 20−25°.

- Cleavers, hatchets and vegetable knives - 30−35°.

- Axes for cutting - 40−45°.

- Table knives - 55−60°.

- Hairdressing scissors - 45−55°.

- Metal scissors - 75−85°.

- Scalpel and razor blades - 10−15°.

- The sharpening angle of a hunting knife is 25−30°.

The table lists other rare tools that can be used at home.

If we talk specifically about dining room cleavers, the degree of angle for sharpening is determined by the fact that the tool is used exclusively for cutting pieces of prepared food. Ready-made dishes usually have a soft consistency, so cutting them with a table knife will be easy and simple.

Another important fact because of which this particular angle was chosen: in the process of absorbing food, it is important not to spoil expensive porcelain tableware with this cutlery. If you use the device for cutting pieces of prepared food, then when it comes into contact with a porcelain plate, it should not leave a mark in the form of chipped lines

The smaller the angle for sharpening the knife and the harder the material from which it is made, the greater the likelihood of damaging expensive dishes during a meal. To make table knives, relatively soft stainless steel is used, which is sharpened at an angle of 55-60°.

Description of Japanese knives

In large supermarkets you can find Japanese and magnetic versions. Japanese blades can rightly be called self-sharpening, and their magnetic version does not require sharpening at all. For their manufacture, a special type of steel is used, which is capable of restoring its structure thanks to the flexible bonds of the crystal lattice.

These knives are very convenient to use not only in the home kitchen. Chefs in cafes and restaurants love to work with them. After using it, after some time, the blade will be well sharpened again.

Japanese kitchen knives are characterized by sharpening the cutting edge on only one side, just like samurai swords.

Magnetic models do not require sharpening at all. The whole point is that a special magnetic layer is applied to the cutting edge, with the help of which the sharpness of the metal is maintained. If such a blade is sharpened, the magnetic layer will be damaged and lose its integrity. And along with this layer, all the “magic” will disappear.

Deciding which of these two tools is better is very difficult. The only argument in favor of the magnetic model: such a blade can be used in her home by a woman who does not know how to sharpen knives and does not even try to learn.

Advantages of sharpening with us

We have been sharpening knives for several years and have mastered this technique to perfection. The sharpening process is carried out on modern equipment and is controlled by our quality service. By giving us your hunting knife for sharpening, you can be confident in the quality of our work and the professionalism of our employees. The advantages of knife sharpening in our company include:

1) High skill of employees

2) High-quality sharpening equipment for any type of sharpening

3) Quality guarantee

4) Acceptable pricing policy

| In addition to classic sharpening, we offer additional services for caring for your instrument: rust removal, lubrication, polishing, blade alignment, etc. |

Among other things, you can master the technique of sharpening hunting knives by taking special courses at. We also provide a service that will sharpen your hunting knife in Moscow at any time convenient for you. Our company is a professional team of employees who know their business! It is also worth noting that our specialists can sharpen axes in a short time.

| Sharpening a knife saves money and time. We sharpen Japanese knives only on water stones Sharpening of hunting knives must be done with the knife fixed to maintain an angle of 30-40º We sharpen knives on Swedish Tormek machines Sharpening ceramic knives requires special equipment. Ceramic knives are very fragile Sharpening folding knives and hunting knives. Video |

| An improperly sharpened knife, in addition to rapid dulling, may cause the blade to chip. Contacting a sharpening workshop will save your time and effort. The price for the service is 200-400 rubles. |

| Sharpening chainsaw chains. Sharpening features Examples of work on sharpening circular saws Sharpening hairdressing scissors. Why do scissors bite? Sharpening knives for meat grinders. Why does a meat grinder produce less minced meat? How to sharpen a checker, a sword more than 1.2 meters long? Sharpening blades of blenders and other household tools |

We work seven days a week

8

Sharpening tools

To sharpen a blade, different tools can be used:

- Mechanical sharpener. Used for fast edge turning. However, the quality of work is low. Used to restore the sharpness of kitchen knives. Not suitable for hunting blades.

- Sharpening stone. They have different grain sizes. Therefore, they are suitable for repairing serious metal damage. Suitable for sharpening different types of knives.

- Musat is a ceramic rod that is used to correct simple burrs and nicks on kitchen blades. Not suitable for complex sharpening or correction of serious defects.

- Electric sharpener. Automatically calculates the optimal angle and performs edge turning. Used to correct various defects.

- Professional machines. Grinding discs of different grain sizes are used for turning. The equipment is installed in professional workshops and enterprises.

- Lansky sharpener. A device with which it is convenient to set the optimal angle. The kit includes bars of different grain sizes and oil for lubrication.

Professionals agree that it is best to sharpen hunting knives with sharpening stones. They are finished using GOI paste.

How can I sharpen the edge?

You can sharpen a hunting knife using the following devices:

- Sharpening stone. It is also called donkey. These products can have different grain sizes, with which home craftsmen carry out both rough sharpening and finishing grinding. To avoid confusion about grain sizes, read the marking code. It is noteworthy that foreign manufacturers apply it to whetstones. If you use a domestic device, then select the degree of grain at random.

- Mechanical sharpener. With this device you can quickly sharpen your blade, but judging by numerous consumer reviews, the quality of such sharpening leaves much to be desired. The use of a mechanical sharpener for hunting and sports blades, according to experts, is unjustified. The fact is that, unlike kitchen knives, the requirements for these knives are much higher.

- Electric sharpener. The advantage of this device is that with its help you can automatically calculate the angle of the blade. Unlike the previous model, not only household knives, but also hunting knives are sharpened with an electric sharpener.

- Musat. This device is presented in the form of a file with a handle. Musat, according to professionals, will not be the best solution for a very dull cutting edge. This tool is suitable when you only need to maintain your sharpness. Serious sharpening is better done with other devices.

- Professional sharpener. This is a special set. Thanks to the design of this device, you can choose the angle you need. The product consists of a removable sharpening stone and two interconnected corners. They serve as a vice and a scale, based on which you can set the sharpening angle. The sharpener is equipped with several bars of different grain sizes.

Features of care

After performing the necessary operations, the knife should be thoroughly washed and wiped dry. If a long time passes between hunting trips, then in order to resist corrosion, you need to lubricate the blade with wax or gun oil. A handle made of natural materials is wiped with a rag dipped in linseed oil.

You cannot use a hunting knife for other purposes: stick it into the ground, open cans, put it in boiling water. Because of this, a sharp tool will quickly turn into a blunt instrument, unsuitable for cutting or sanding.

A knife is not only a hunter’s assistant, but also a source of pride. It is always pleasant for a man to receive it as a gift, because with such a gift he will either add to his collection, which he will proudly show off to friends, or will acquire another irreplaceable element for hunting.

Dependence of the sharpening method on the steel grade

Not all sharpening methods are equally suitable for different grades of steel. For example, very popular knives made of Damascus steel cannot be sharpened on electric machines, since it has a non-uniform structure. It consists of alternating soft and hard layers, so the blade must be sharpened with extreme care, otherwise the edge of the blade will become ribbed and will crumble in the future. Knives made of this steel should be sharpened by hand, gradually changing the grain size of the stones towards a smaller size.

Bulat steel is characterized by increased hardness. Knives made from it need to be sharpened for a long time. In this case, electrical and mechanical machines are often used. You need to start with coarse-grained stones moistened with water, gradually moving towards fine-grained ones.

It should be noted that with the automated sharpening method it is not possible to achieve the sharpness and accuracy that is provided by manual work. The main advantage is the speed of this process.

Handmade hunting knives require a special approach when sharpening the blade, as they can be made from non-standard grades of steel. Therefore, it is recommended to sharpen them manually.

Read also: Lubricant for drills composition

We conclude: proper sharpening of hunting knives is a very important process for maintaining appearance and durability. This hunting prop should be used only for its intended purpose and remember to keep it clean, periodically lubricating it with oil (both blades and wooden handles) to prevent loss of shine and drying out.

When going out into nature, and even more so before hunting, you always need to make sure that the knife is not dull. You won't get far with a blunt weapon, but you still need to know how to sharpen a knife properly. This process takes some time, and you also need to take into account the type of steel from which the weapon is made in order to effectively sharpen it.

Permit, license or certificate?

All permits are issued by the Licensing and Permitting Department (LPR) of the Ministry of Internal Affairs at the place of registration of the applicant. You can find out the location of the OLRR when choosing a weapon in a hunting store. The seller is obliged to issue a certificate for the selected blade model for review. Not every knife requires a license or permit, but having a certificate holder is highly desirable in case of law enforcement interest. Any knife belongs to a “piercing-cutting” instrument, but does not fall under the definition of “prohibited to be carried” if you have the appropriate confirming certificate on hand.

- The license (see Article 9, Federal Law-150 “On Weapons”) for the acquisition of collectible edged weapons is valid for 6 months, giving the right to collect and exhibit – indefinitely.

The acquisition of sporting and hunting bladed weapons is not licensed.

Required documents:

- Application in the approved form.

- Identity card of a citizen of the Russian Federation (passport).

- Two photos 3x4 cm.

- Data on the conditions for storing weapons (a report with a conclusion is drawn up by the district police officer).

There are no monetary fees when issuing a license.

- A license (at the same time a permit) for wearing with a national and Cossack uniform (Article 13 of the Federal Law-150) - for a period of 5 years, available to citizens of the Russian Federation who have reached the age of 18 years. Up to 5 units of the specified weapons are purchased under one license; within two weeks they must be registered with the federal executive body.

- Permit for hunting bladed weapons – Article 13. FZ-150, for citizens who have a permit for hunting firearms (hunting license).

In both cases, the following are added to the previously specified list of documents:

- medical certificate confirming the absence of contraindications to owning a weapon

- confirmation of payment of the state duty (from October 2021 it is 500 rubles).

The easiest way to obtain permits is in your personal account on the State Services website; to do this, you need to find it in the Ministry of Internal Affairs (Security and Law and Order) section.

Obtaining a permit for edged weapons through State Services

To obtain a license or permit, however, you will have to contact the licensing and permitting department (the address to which you intend to apply is indicated when registering the application on the State Services website). All electronic copies of documents attached to the application must be clear and easily readable.

When submitting an application through the State Services service, a permit document is issued within 2 weeks from the date of application.

- For all other types of blades, a certificate is required confirming that the blade worn by the owner is not a bladed weapon and is not prohibited for circulation on the territory of the Russian Federation (for some types of knives, the bases are shown in the table; a certificate for any legally produced brand of knife can be found on the Internet on the forums " knife makers").

| Blade type | The reason why knives are not edged weapons | Note |

| Cutting and skinning | An injury-proof handle is acceptable for a blade thickness with a butt thickness of up to 2.4 mm inclusive | A variant of an acceptable barrel-shaped safety handle without a limiter with a difference in minimum and maximum diameters of over 8 mm |

| Folding knives with blade length up to 150 mm | If in the folded position the blade does not exceed the length of the handle | excluding knives with dagger or stiletto blades |

| Nepalese kukri knives, karambits | upward deflection (see figure) more than 15 mm | |

| Serrated (wavy or sawtooth cutting edge) | Not mentioned in prohibiting articles of the law |

Blades for use outside the kitchen

When the kitchen was still limited to a fire, knives were already used. Until now, they are used as hunting and military weapons or production tools. An example would be a hunting knife and machete. In the recent past, straight razors were popular. In modern life, penknives are common.

The rule for blades is that each case has its own sharpening angle. Determining the purpose of non-kitchen cutting tools can be done in the same way as kitchen ones - through the sharpness of sharpening.

Sharpening table for non-kitchen cutting tools.

| Tool or knife | Sharpening in degrees |

| Scalpel, razor | from 10 to 15 |

| Shoe cutting machine, penknife | from 20 to 25 |

| Spicy for tourists, hunters, fishermen | from 30 to 35 |

| Carpentry | from 35 to 45 |

| Wear-resistant for tourists, hunters, fishermen | from 40 to 45 |

| Chopping blades, machetes | from 45 to 60 |

| Splitting ax | from 60 to 75 |

Turning tools and hunting tools are slightly different from their kitchen counterparts, since the steel used for these tools must withstand much greater loads and an aggressive environment. The requirements for the sharpness and durability of edges and chamfers are also higher, since the productivity and sometimes the life of the owner depend on them.

Blade for hunting

One of the main differences from kitchen cutters is their high penetrating ability and strength. To do this, the cutting edge, like a dagger, is made not only along the bottom, but also on part of the upper edge of the tapering butt. The overhead handle is attached to the blade with rivets and has hand movement limiters at both ends. In the back of the blade there is a hole for a belt to be worn on the hand. A typical hunting knife looks quite simple, but it needs to be sharpened differently than others.

Sharpening hunting knives

To understand how to properly sharpen a hunting knife, you need to take into account its features. The most influential feature of a hunting blade on the sharpening process is the steep, sometimes repeated bend of the cutting edge.

For blades, carbon alloys with the addition of other metals, forged Damascus steel, titanium and damask steel are used. For hunting knives, for which strength is more important than flexibility, forging, casting, and high-carbon steels are used.

The first difficulties will be with changing the direction of the whetstone when processing the places where the blade bends. But sharpening for hunting can be improved. Based on the fact that the piercing action is characteristic of the front part of the blade, the wear resistance of the blade is needed here. The part of the blade from the handle is used for cutting; sharpness is needed in this place. The second difficulty in sharpening will be creating bevel planes with different angles along the length of the blade.

To do this, it is optimal to use a device with fixation, placing small sections of the blade perpendicular to the stone, gradually changing the plane of the stone when rearranging the blade.

What you need to know about knives

For good owners, any knife used in everyday life should be sharp and sharpened, like a razor. It has always been this way, since ancient times. In this regard, for many men, observing such traditions is a mandatory aspect. Of course, regular sharpening takes a lot of time, but thanks to this, unprecedented sharpness of the kitchen appliance is achieved.

But you shouldn’t consider sharpening only under the prism of some abstract traditions. Any chef can confirm that a sharp knife significantly speeds up the preparation of any dish. It is easy and comfortable to work with such devices; your hands do not get tired at all when chopping meat or vegetable preparations.

Moreover, it is safer to work with a knife sharpened like a razor. Yes it's true! When working with a dull blade, there is a possibility of the blade slipping and moving to the side. Fright is the least dangerous thing that can happen. The risk of causing a serious cut not only to yourself, but also to those around you cannot be ruled out.

Even though the knife does not have razor sharpness, it still remains a dangerous and traumatic device.

In order to sharpen a knife sharply, it is necessary to take into account the hardness of the steel from which the blade is made. However, for each knife these values will be different. It is extremely important to know them, since it is the hardness of the steel that determines the angle of sharpening. These parameters are measured in special units, and you can find out the real hardness indicators using special equipment, which is located in the relevant laboratories. The standard in most cases for knives is the range from 45 to 60 hardness units (HRC), measured according to the Rockwell method. It has been proven that soft and hard types of steel require constant sharpening, since blades from the first wear out quickly, and from the second they crumble.

Ways to find out the sharpening angle

There is a well-established practice for the most common utility kitchen knives used for a variety of purposes. The optimal angle will be between 30 and 35 degrees. If the angle is smaller, the knife will do an excellent job of cutting fillets, but it will be “dull” even when chopping chicken ribs.

Angle measurement

Now is the time to quickly find out which knife in your kitchen set does what. There are several ways to determine the sharpening angle of a knife, but at home the most common is using scissors. The accuracy is low, but sufficient to determine the purpose. It is necessary to insert the blade of the knife until it stops between the cutting ends of the scissors, then with light pressure bring them together until they stop, measure the resulting angle with a protractor or determine visually. Hint: a watch dial can become a goniometer; if you compare the position of the scissors with it, you can determine the inclination by multiplying the number of minutes shown by the scissors by 6 degrees.

The accuracy with which the measurement occurs is sufficient for a correct conclusion.

We find in the table of knife sharpening angles the range in which the measured value falls, and look at the purpose of the home blade.

The sharpening angle of the knife depends on the purpose.

| Sharpening angle in degrees | Purpose of a home kitchen knife |

| from 10 to 15 | fillet cutting |

| from 22 to 25 | for working with root crops |

| 25 | fish cutting |

| from 25 to 30 | separating bones from meat |

| 30 | meat cutting |

| from 30 to 35 | universal kitchen knife |

| 35 | for vegetables |

| from 35 to 45 | cutting frozen meat and fish |

| from 55 to 60 | serving knife |

Specifics of professional tools

There is a slight difference between professional and home products. The angle on professional ones is 5 degrees less for the same purpose. There are two reasons for this:

- Professional knives are usually made from expensive, very durable steel. In order to dull the edge of the blade, it will take prolonged intensive use.

- Significant physical stress on the wrist joint of professional chefs is created when cleaning and cutting food. Sharper knives reduce stress.

How to sharpen a blade

Sharpening a dull blade means ensuring that the chamfers are brought together so that the edge line becomes smooth throughout the entire length of the blade, and the edges of the slopes are parallel to it. The steeper the angle formed by the chamfers, the longer the cutting edge will maintain linearity.

We will immediately upset housewives who use a tabletop disc sharpener, since it only processes bevel planes. Wherein:

- does not give the desired angle;

- the effect is short-term;

- You can break the blade if it is not made of iron.

The use of the whetstone supplied with the knife set will ensure the integrity and required surface roughness characteristics of the blade. In addition, you save time; your hand will not get tired of moving the stone until the required edge is sharp.

This work will be done much more accurately with devices that allow you to simultaneously fix the blade, set and fix the desired inclination of the stone. As a rule, these are structures in which the stone moves in a plane on an axis. Not critical, but still a drawback, can be considered a limitation on the length of the processed section of the blade. To process the entire length of the blade, you need to remove and rearrange the blade several times in a vice. In addition, by applying force to the stone, you can bend the structure, which changes the angle of the stone, which will change the sharpening.

7-step instructions for sharpening and finishing a kitchen knife

So, in sharpening a knife, one goal is to remove enough metal from the blade so that the cutting edge becomes sharp again. You need to start work with a coarse-grained abrasive and finish with a fine-grained one.

It is important to remember the following principles of sharpening knives:

- The most important thing is to choose the optimal sharpening angle and maintain it along the entire cutting edge while sliding along the block.

- Movements should be smooth, without pressure.

- All bars must be moistened with water, or better yet, with a soap solution: before sharpening (so that the blade glides better and metal dust does not clog the pores), during the process (to remove the resulting suspension) and at the end, to clean the bar.

And one more important tip - the first time it’s better to practice on a knife that you don’t mind ruining. Especially if your main knife is too good and expensive. Well, let's start practicing.

Step 1. Rinse the stone with water, and then run over it, say, with a sponge with a drop of dishwashing liquid.

Step 2. Next, sit down at the table and place the stone on a wooden board, for example, a cutting board. You can place a towel under the stone. For some it is more convenient to place the block perpendicular to themselves, and for others at an angle of approximately 45 degrees. Over time, you will understand how it is more convenient for you to work.

Step 3. Now you need to decide on the sharpening angle and fix the position of the knife. What should the angle be? The general principle is that the smaller it is, the sharper the blade, and the larger it is, the longer the blade retains its sharpness.

- Regular kitchen knives are sharpened to an angle of 40-45 degrees. If you are sharpening a fillet knife (designed for cutting thin pieces of fish, poultry and meat), then you should sharpen it sharper - at an angle of 30-40 degrees. The selected value must be divided by 2, and then we will get the angle that should be between the blade and the surface of the block. That is, to sharpen a blade at 45 degrees, you need to sharpen each side at 22.5 degrees to the sharpening surface.

A simple technique shown in the photo below will help you fix the knife at an angle of 22.5 degrees.

- Remember, you should try to stick to the chosen angle throughout the entire work.

Step 4. Place the knife across the block so that the upper edge of the handle is above the lower edge of the stone. Holding the handle with one hand and the blade with the other, we begin to slide along the block away from ourselves along the trajectory shown in the picture below.

Watch a short and clear video:

- The point is that the cutting edge sliding along the stone should always be perpendicular to the direction of movement.

- At the bend of the blade, the knife handle needs to be slightly raised to maintain the selected angle.

- Remember also that you can’t put pressure on the blade, but you shouldn’t give it any slack either.

Thus, you need to pass the blade along the stone about 40-50 times, namely until a “burr” (burr, microsaw) appears along the entire length of the cutting edge. Its appearance will tell you that the excess metal has worn out and there is no point in grinding further. Then you need to turn the blade over and repeat the same steps. Clearly in the video:

Read also: Device for finding hidden wiring

- A burr is a small roughness that is difficult to see, but can be felt by carefully running your finger along the edge of the blade (but not along the edge, so as not to cut yourself).

During operation, a suspension will appear on the blade - metal dust, which must be periodically washed off with water.

Step 5. So, the burrs have appeared, now we proceed to finishing. To do this, we repeat the same manipulations on a stone with half the grain size. An alternative finishing method is using musat.

- Musat is a steel rod of oval or round cross-section with longitudinal notches. It is only suitable for editing and maintaining sharpness, but not for sharpening a knife. It is recommended to edit the knife with musat every time before and after work.

How to sharpen a kitchen knife with musat can be seen in the following video master class from the respected knifemaker Gennady Prokopenkov, who, by the way, specializes in making kitchen knives.

Step 6. If desired, you can bring your knife to a razor sharpness. To do this, take any leather or leather belt, treat it with GOI, Dialux or any other abrasive paste, and then do the same steps, but only in the direction from the cutting edge.

Step 7. Finally, we check the quality of sharpening. This is done very simply. It is enough to cut a tomato or cut paper. If you wanted to achieve razor sharpness, then you should try to shave the hair on your arm. The sharpest knives can even cut hair, as shown in the photo below, but in the kitchen such sharpness is not required for the most ordinary knife.

Sharpening a knife with musat

Musat is a file with a round or cut-off cross-section on both sides, which has a handle. It is made from very hard steel or diamond-coated ceramics. Musat usually only corrects blades that are not too dull. In this case, the cutting edge is not damaged even with repeated use. If a knife has completely lost its cutting properties, then you cannot sharpen it this way.

The process is carried out as follows:

- one hand holds the musat in a vertical position (on a non-slip surface);

- in the other hand we take the blade at an angle of 15-20 degrees, stretch it from top to bottom (from ourselves and to ourselves) along the entire length of the blade (first from one side, then from the other). Such repetitions should be done from 4 to 6. When using ceramic or diamond musat, once is enough.

Why do knives become dull?

This is a fairly serious and common problem even if the steel has the required hardness parameters. Why then does its razor sharpness lose so quickly after sharpening?

The reasons are completely different. It is worth noting the first and main one, that regardless of the hardness of the blade material, when using it, it is one way or another subject to third-party influence. The frictional force acts on the blade in such a way that it leads to the separation of microscopic particles from the base, which causes its gradual destruction. In particular, it is impossible to constantly maintain the “ideal position” (contact of the cutting edge with the plane at optimal angles) when using a knife. The occurrence of loads has a destructive effect on the metal product, which entails a loss of razor sharpness.

But due to the microscopic nature of the process, it is quite difficult to check the sharpness of the product. The first signal of its dullness is the increasing effort that a person makes in the process of cutting an object using such a knife. You can find out whether the device has lost its sharpness even by eye: the dull part of the blade has a polished appearance and signs of a characteristic shine. In the presence of such defects, we can talk about the need that it is time to sharpen the blade like a razor. To make the process as efficient as possible, care must be taken to select the right tools.

Do-it-yourself blade sharpening

Many sharpening devices have been developed. You need to follow some simple rules.

Sharpening with a whetstone

To sharpen, it is important to follow the recommendations:

- The coarse-grained whetstone is secured in a vice.

- The blade should be held at an angle of 20–25 degrees relative to the surface of the whetstone. The movement begins with the blade along the block with the cutting edge.

- The weapon is moved so that the blade is in contact with the entire surface of the block.

- Check the tilt angle regularly.

- After 2-3 passes, change the side of the knife and repeat the steps.

- Use a fine-grained stone to polish the uneven surfaces.

- To check the quality, cut a rope or a sheet of paper.

Sharpening a knife with improvised means

When traveling, you don’t always have sharpeners with you. You should familiarize yourself in advance with items that will help maintain the sharpness of the blade:

- stone;

- second knife;

- splinter;

- belt made of natural dense koi.

Peculiarities of sharpening some types of steel

Damascus steel has become popular among hunters. Hunting knives made of Damascus steel are sharpened by hand. In this case, fine-grained bars are recommended. When you achieve sharpness, the result must be secured with “velvet” sandpaper. Movements are performed strictly along the blade.

What should you consider?

Due to the fact that hunting knives are made of hard steel, you will most likely have difficulty sharpening them. Moreover, you will not be able to give the blade a perfect sharpness if you do not know the sharpening angle of the hunting knife. It is very important that after processing the blade is free of broken bevels and cutting edges.

You should know that the knife is equipped with bevels on both sides - two decreasing planes that stretch from the blade to the butt. They are also called chamfers. As with any other knives, the edge that needs to be sharpened in hunting knives is represented as a sharp edge on the cutting area. The sharpness will depend on the angle you give it. In general, it varies from 15 to 30 degrees. The angle, in turn, depends on the intended purpose of the blade. For example, it will be more convenient to perform rough cutting and deboning of carcasses with a product whose sharpening angle is 30 degrees. Products with a 20-degree sharpening are considered universal, since such knives are good for performing all types of work. If you need a blade to make neat, thin cuts for fumigating carcasses or cut off cartilage and small bones, then sharpen the knife to 15 degrees. It is very important that the sharpening is the same on both sides. The cutting edge angle is common to both sides. In order not to make a mistake when determining the degree, divide its value in half. This way, you will know how you will need to place the sharpening device - above the blade or directly the knife above the abrasive.

Classification of hunting knives

The main elements that make up the product are the handle and blade

When choosing, you need to pay maximum attention to the blade. The service life and performance characteristics of the weapon will depend on its strength and sharpness.

Determining the reliability of a knife is very simple - the higher the carbon component in the steel, the stronger the product

To find out its value, you need to pay attention to the HRC number (Rockwell hardness) - the higher it is, the better, but, accordingly, the more expensive. A knife from 55 HRC is suitable for hunting

A sharp blade can become dull over time due to corrosion. To prevent this phenomenon, the blade is coated with chrome.

The types of hunting knives are varied. First of all, they are divided by purpose:

- For specific purposes (single-functional) - dismembering prey, separating bones from meat.

- For general operations (universal) - finishing off a wounded animal or bird. The blade of this type is always smooth, without jagged edges, the handle is separated by a stopper.

The shapes of life-size hunting knives differ. Their blade can be shaped to allow both cutting and piercing. The most common are six types of blades:

- Rectangular shape.

- The upper part of the edge is lowered (drop - point). This configuration reduces the weight of bladed weapons. On the butt there is either another blade or a “false blade”.

- With an elevated line of the blunt part (trailing - point). This type has the longest blades.

- Bowie blade (clip - point). The edge is beveled in such a way that the tip is as close as possible to the place where the force is applied when piercing. It has some similarities with the drop-point type, but the Bowie point is thinner, awl-shaped.

- With curved blade and straight spine. Designed mainly for piercing.

- A dagger-like blade. Its sides are sharp on both sides.

Classification of knife types based on their configuration:

- Classic. They have a weight of 120-180 g, blade length - from 100 to 130 mm. Any blade shape, except for double-sided sharpening. Used for cutting up animal carcasses.

- Big size. The weight of the gun is from 180 to 300 g, the blade is 130-170 mm. The form can be varied. Necessary for heavy blows and not suitable for precise, delicate cuts.

- Foldable. The most secure. They can have one or two blades, different weights and sizes. Ideal for carrying out small, short, scrupulous work on cutting up prey. When purchasing, be sure to check the quality of the mechanism. To do this, you need to try to slightly shake the blade - if this is successful, you should not purchase such a product.

Selecting a sharpening tool

To bring the blade to the required sharpness, you need to choose the right materials and tools for sharpening it. Among them are:

- sharpening stones;

- musats;

- electric sharpening machines;

- abrasive machines;

- grinding machines;

- mechanical sharpeners;

- electric sharpeners.

To understand the features of each of them, you should consider them in turn. Sharpening stones are ancient tools that can truly make a knife razor sharp. Experienced craftsmen know that there are different types of whetstones, which have different grain sizes (the smallest abrasive particles that make up such whetstones), different hardness and density.

If you need to sharpen the knife as efficiently as possible and grind the blade, you will need to use at least two sharpening stones. The first should have large grains, the second - small. You can find out by looking at their markings or less accurately determining the difference by eye.

Musats, as well as mechanical sharpeners, belong to kitchen life. They are used not so much to sharpen knives as to sharpen them, to remove microchips and impart minimal razor sharpness for a short period of time. It is enough to operate the device a couple of times and the blade will begin to become dull again, since grinders and sharpeners do not have the desired effect on the steel surface of the product.

Electric sharpeners save a person from using significant physical effort when sharpening blades, but they also do not provide full sharpness . Special sharpening and grinding machines will help give knives their cutting properties in the shortest possible time, but the disadvantage of such equipment is the overhead and unsafeness of storing and using them at home. Such machines generate dust, are quite noisy and energy-consuming. But thanks to them, any knife can be provided with the necessary sharpness quickly, efficiently and with minimal effort.

Experts recommend not to engage in such work on your own using machine tool sharpening equipment if you do not have the proper experience in the field of sharpening tools. There is a possibility of not only permanent damage to the blade on the knife due to overheating or failure to maintain the correct sharpening angles, but also the risk of dangerous injury due to inept handling of the equipment.

Foreign knife steels

420 is a cheap knife steel used for mass production knives. It contains a small amount of carbon, therefore it has low hardness, quickly dulls, and wears out quickly. Serious manufacturers do not use this steel in their hunting knives.

420HC is the stainless blade steel used by most knife manufacturers to produce mass-market knives. It has a higher carbon content compared to 420 steel: 0.45-0.54%. It has good cutting properties and good wear resistance. With high-quality heat treatment, the hardness of 420HC steel can reach 57HRC.

440C is the most common foreign knife steel. It is a high-quality tool stainless steel. Contains: 1.1% carbon, 17% chromium and 0.75% molybdenum. The blade of a hunting knife made of 440C steel does not rust, has good flexibility, is easy to sharpen and holds an edge for a long time. Hardness of steel 440C: 58-60 HRC. For many years, this steel has been considered the most suitable in its properties for the manufacture of hunting knives. The most expensive steel from the group of 440 steels. Similar to Russian steel 95X18.

D2 - American alloy tool steel. D2 steel was originally used to make high-speed cutters. Steel is not highly resistant to corrosion. It has a fairly high hardness: 57-61 HRC, so it retains the sharpness of the cutting edge for a long time. The closest analogues of D2 are German steels X155CrVMo12-1 and X155CrVMgl21, among Russian steels X12MF.

S30V is a powdered martensitic (high carbon) American stainless steel. The composition of S30V includes: carbon - 1.45%, chromium - 14%, vanadium - 4%, molybdenum - 2%. It is the presence of a large amount of vanadium carbides in the steel that explains the high cutting qualities and strength of the blades of knives that are made from it.

The cutting edge of the blades is made of S30V steel and has excellent resistance to chipping and chipping. Blades made from S30V steel are four times more durable and hold an edge 45% better than blades made from 440C steel. Blades of hunting knives made of S30V steel have excellent cutting properties, good corrosion resistance, good impact toughness, and hold an edge well.

Most of the world's leading knife manufacturers use this steel to produce mid- and high-end knives.

S35VN is a powdered martensitic (high-carbon) American stainless steel. It is an improved version of S30V steel in terms of impact strength. To increase impact toughness, niobium carbides are included in the steel, due to which the impact strength of the blade increases by 15-20% compared to S30V steel. S35VN steel is resistant to chipping of the working edge and holds an edge well compared to other types of steel. The hardness of blades made from this steel is 58-61 HRC.

VG-10 is a Japanese high-carbon and corrosion-resistant steel. Contains a fairly high amount of cobalt, which is an expensive and rather rare alloying additive. Cobalt gives steel more hardness and toughness. The toughness of this steel makes it possible to harden knives to a hardness of 60-63 HRC. VG-10 steel is used in production by many global knife manufacturers. Some of them locate their entire production in Japan. Knives made of VG-10 steel practically do not rust, allow you to sharpen them to razor-like condition, and hold an edge well.

AUS-8 is a Japanese stainless steel used to make knives. It is an improved version of AUS-6 steel. AUS-8 steel is used by knife manufacturers all over the world. The hardness of steel is 56-59 HRC. AUS-8 steel has excellent cutting properties, high corrosion resistance, and does not require frequent sharpening.

Sandvik is a Swedish stainless steel often used for hunting knives. Steel is quite difficult to harden, so it is not cheap. The hardness of Sandvik steel is 59-59 HRC. A hunting knife blade made from this steel is very flexible and elastic and holds an edge well.

Materials used for kitchen knives

The most common, frequently used and indispensable types of knives in the household are kitchen knives. In the home kitchen, various types of knives are used, it all depends on the hobbies and wishes of the owners. In professional kitchens in restaurants and cafes, the use of professional kitchen tools is practiced. Such sets are a whole range of blades that differ in design and functionality. They also differ depending on the material from which they are made.

Among the most common materials are the use of:

- Carbon steel. It is an iron and carbon alloy containing the addition of vanadium or manganese. Over time, the surface of such blades rusts and becomes stained.

- Of stainless steel. An alloy with iron, carbon and chromium, to which inclusions of molybdenum or nickel are added. Such blades must be constantly sharpened; after the metal becomes tarnished, the knife begins to become unusable.

- High carbon stainless steel. It is a combination of carbon and stainless steels, which contain vanadium additives, molybdenum, and cobalt. They have increased strength, the period of blade sharpness is increased.

- Damascus steel. It is a blacksmith forging, for which different types of metal are used, with a series of hard and soft alloys. The use of such material is expensive and is often in demand among professionals. Damascus is used to produce hunting knives, collectible blades and razors. Sharpening of such blades is carried out exclusively by hand along the blade.

- Titanium alloy. To produce this alloy, a titanium powder matrix and carbide inserts are sintered. For the longest possible period of time, it does not require sharpening, but such knives require careful use, which requires special skills in work and the availability of professional sharpening equipment.

- Zirconium alloy. It is a product made of hard mineral ceramics, which was subjected to dry pressing and firing. subjected to dry pressing and firing. They are sharp blades that do not dull for quite a long time, but their disadvantage is increased fragility and the need for special care and storage. Used for cutting soft products only. Sharpening is carried out using specialized tools.

To properly sharpen a knife, it is important to know what material was used to make it. The sharpening angle depends on these criteria

The harder the alloy, the smaller the angle should be. In addition, the hardness of the alloy is also affected by the method of sharpening the blade.

Alternative sharpening methods

If your kitchen knife is a simple and inexpensive “hard worker” and/or you just don’t want to delve into the “knife culture”, then we recommend using an electric sharpener, a roller knife or a sharpening system for sharpening at home. What are their pros and cons?

- An electric sharpener sharpens knives perfectly and quickly, but even the highest quality models remove too much material from the blades, thereby shortening their service life. Another disadvantage of an electric sharpener is that a good device costs more than $200.

- A roller knife is an inexpensive and easy-to-use option. With its help, you can quickly sharpen a kitchen knife, but, unfortunately, the sharpness of the blade will not last long and the knife will deteriorate over time. The most trusted tool among roller scissors is the one from Fiskaris (pictured). Do not confuse a roller blade with a V-shaped blade. The latter is an option for the most frugal.

- Sharpening systems are good because they allow you to more accurately set and maintain an angle. There are different types of such sharpeners - with blade fixation (manufacturers DMT and Lanski) and with fixation of the stones themselves at a certain angle (Spyderco Triangle Sharpmaker). Separately, we can highlight a sharpening system in which you can select the desired angle and control the position of the knife - this is the Edge Pro Apex Knife Sharpening System. Each system has its own pros and cons. For example, on sharpeners with a fixed blade it is inconvenient to sharpen wide chef knives, but on a triangle from Spyderco the knives are straightened rather than sharpened, and you can only choose an angle of 30 or 40 degrees. However, for kitchen knives these are the angles that are needed, and using a triangle is very simple. A detailed review and operating instructions for the Spyderco sharpener can be seen in the following video.

What are the disadvantages of Apex Edge Pro? Perhaps this is just a high price - $245. However, to sharpen kitchen knives, you can buy a Chinese copy of this sharpener (for example, on Aliexpress).

There is another clever way to sharpen a knife at home - using a rough mark on the bottom of a ceramic mug or plate. The principle of operation is still the same - maintaining the angle, smooth movements, maintaining the cutting edge (cutting edge) perpendicular to the direction.

It is very important to choose the right hunting knife. It is necessary to take into account many factors: length, width, shape, material of the handle and blade, sharpening angle. Much depends on the purpose of using the knife.

How to sharpen a knife at home?

The most affordable and fairly effective way is to sharpen a knife at home using abrasive stones. Such bars are presented in a wide range in almost any hardware store, however, in the case of a hunting knife, options with a wide and perfectly flat surface, up to 25 centimeters long and a dense fine- and medium-grained structure can be used.

Sharpening a cutting edge with your own hands must be done in the following way:

- a device with medium-sized abrasive grains is placed and preferably secured on a completely flat surface;

- on a block moistened with any vegetable oil, a knife blade is placed at the calculated desired angle and held with both hands;

- under pressure, the blade is pulled across the surface with intersecting movements, several times towards itself on one side, then the same on the other;

- the process is repeated until a new smooth shiny strip with the same width on both sides is obtained in place of the cutting edge;

- it is necessary to replace the timber with its fine-grained analogue; it is used to fine-tune the sharpness of the blade using several sliding movements without pressure;

- to achieve the ideal condition of the cutting edge, the blade is edited on the back side of the belt, ten times on each side;

- checking the quality of sharpening involves lightly cutting a vertically placed newspaper sheet in one motion.

Expensive tools are best sharpened using special equipment. Specialized service centers and workshops can help with this.

How to sharpen correctly

To do everything according to technology, you need to understand how the blade sharpening process should take place. So, we come to the most important question: how to sharpen correctly so that the blade reaches razor sharpness?

You can get razor sharpness if you are patient in this matter. The process of processing metal products requires a certain amount of time: to get the best result you will have to spend more time. To make the knife sharp, like a razor, you need to spend about 30 minutes on intensive sharpening.

We will use the classic method of sharpening, using sharpening stones. Abrasives should be placed on a flat surface (table or workbench), and there should also be a rough cloth or fleecy material underneath them. This will make the main task easier, since the block will not fidget and you will not need to hold it with your hand.

The knife is sharpened in such a way that it cuts through the entire abrasive. At the same time, it is necessary to ensure that the cutting edge of the blade is always perpendicular to the longitudinal axes on the block. In reality, it looks like this: the blade has a curved surface, and thus, during movement, the knife must be turned so that its sections are at right angles to the axes of the abrasive materials.

During the entire working process, the metal blade must be held at the same angle to the surface of the sharpener.

The value of this angle should be from 20 to 25 degrees; it is optimal for the cutting edges of knives. Knives that are designed to chop and slice meat should have a sharper cutting edge. By maintaining a constant angle while processing metal blades, you can sharpen absolutely any type of steel to the maximum level of sharpness.

The blades must run their entire length on the bars, and for this there is absolutely no need to apply much effort. If too much pressure is applied, the material may collapse and its integral surface may be damaged, which will lead to difficulty and delay in the sharpening process.

After a thin, uneven edge appears on the knife blade, you can perform the next step and change the coarse bar to one with less abrasive. Having completed uniform sharpening, it is necessary to consolidate the obtained result by grinding.

Available means

Sometimes cases arise when you need to quickly sharpen knives in the absence of conventional tools. In such situations, the procedure can be carried out using other objects.

Main methods:

- Stone, cobblestone - this method is suitable if it is necessary to sharpen blades while traveling. The blade must be drawn along its surface; ideal sharpness cannot be achieved, but the knife is suitable for normal cutting.

- Second knife - you can also sharpen the blade on another without tools. You need to take the blades and drive for 5-10 minutes. them against each other.

- Glass objects - the knife can also be sharpened by holding the blade against glass/ceramic products (glass, tile). The main condition is a rough surface of the product.

- Leather belt - suitable for final sharpening in extreme cases. To do this, you should carefully move the blade along the tensioned belt, due to this you will be able to achieve a polishing effect.