Ultrasonic welding operating principle and classification

From a physical point of view, ultrasonic welding takes place in three stages:

- heating of products, activation of diffusion in the contact zone;

- formation of molecular bonds between viscous-flowing surface layers

- hardening (crystallization) and formation of a strong seam.

There are several classifications of ultrasonic welding ultrasonic welding.

According to the degree of automation there are:

- Manual. The operator controls the installation parameters and guides the welding gun along the seam line.

- Mechanized. The parameters are set by the operator and supported by the installation; the parts are fed under the emitter.

- Automated. Used in mass production. Human participation is excluded.

Schemes of oscillatory systems for ultrasonic welding

According to the method of supplying energy to the working area, the following are distinguished:

- one-sided;

- bilateral.

According to the method of waveguide movement they are classified:

- Pulse. Operation with short pulses per waveguide movement.

- Continuous. Constant exposure to the emitter, the waveguide moves at a constant speed relative to the material.

According to the method of determining the amount of energy spent on a connection, there are:

- by exposure time;

- by the amount of precipitation;

- by the size of the gap;

- according to the kinetic component.

In the latter case, the amount of energy is determined by the maximum displacement amplitude of the support.

According to the method of supplying energy to the working area, the following ultrasonic welding modes are distinguished:

- Contact. The energy is distributed evenly over the entire cross-section of the part. Allows you to weld parts up to 1.5 thick. Used for overlap welding of soft plastics and films.

- Transmission. In the case of high values of the elastic modulus, oscillations are excited at several points. The wave propagates inside the product and releases its energy in the joint area. Used for T-welds and butt joints in rigid plastics.

Ultrasonic spot welding diagram

Installation diagram for ultrasonic roller welding

The method of supplying vibration energy to the contact zone of the workpieces is determined by the elastic modulus of the material and the damping coefficient of mechanical vibrations at ultrasonic frequencies.

Ultrasonic welding of metals and its varieties

When ultrasonic welding, a permanent joint of metals is formed by the combined action of high-frequency mechanical vibrations and relatively small compressive forces on the parts. This method ensures the production of highly reliable connections, eliminates general heating of the product, allows you to connect combinations of materials that are difficult to weld using conventional methods, etc.

To obtain high-frequency mechanical vibrations, the magnetostrictive effect is usually used, which consists of changing the dimensions of certain metals and alloys under the influence of an alternating magnetic field. For ultrasonic transducers, pure nickel or iron-cobalt alloys are usually used. To increase the displacement amplitude and concentration of vibration energy, waveguides or concentrators are used, which in most cases they have the shape of a truncated cone. For welding metals, it is enough to have waveguides with a gain of about 5, while the amplitude of vibrations at the end of the waveguide at idle speed should be 20. . .30 µm.

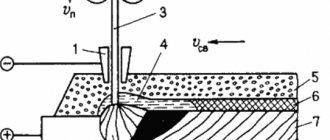

Several types of ultrasonic welding are used. The main component of the machine for making point connections using ultrasound is a magnetostrictive transducer (Fig. 1). Its winding is powered by high-frequency current from an ultrasonic generator. Water-cooled magnetostrictive transducer 1 is made of permendur (K49F2), it serves to convert high-frequency current energy into mechanical vibrations, which are transmitted to the waveguide 7. At the end of the waveguide there is a working protrusion 5. When welding, product 4 clamped between the working projection 5 and the pressing mechanism 3, to which the force necessary to create pressure during the welding process is applied.

High-frequency elastic vibrations are transmitted through the waveguide 7 to the working protrusion 5 in the form of horizontal mechanical movements of high frequency. The duration of the welding process depends on the metal being welded and its thickness; for small thicknesses it is calculated in fractions of a second.

Rice. 1. Installation diagram for ultrasonic spot welding: 1 - magnetostrictive transducer; 2 - diaphragm; 3 — pressing mechanism; 4 - product; 5 - protrusion; 6 — pendulum support; 7 - waveguide; 8 — water cooling casing

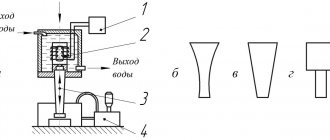

The main components of the machine for making suture joints using ultrasound (Fig. 2): a rotating magnetostrictive transducer 1 and a waveguide 3. The end of the waveguide has the shape of a roller 4. The parts 6 to be connected are clamped between the rotating roller 4 of the waveguide and the idle roller 5. High-frequency elastic vibrations are transmitted through the waveguide to the roller, which rotates along with the waveguide. The product, sandwiched between the rollers, moves between them, at the same time creating a hermetic connection.

Rice. 2. Installation diagram for ultrasonic roller welding: 1 - magnetostrictive transducer; 2 — current supply from an ultrasonic generator; 3 - waveguide; 4 - welding roller; 5 - pressure roller; 6 - product; 7 — converter casing; 8 - drive

Welding along the contour ensures a hermetic seam of the most complex contours. Its simplest form is ring welding.

Rice. 3. Installation diagram for ultrasonic contour welding: 1 - waveguide; 2 - replaceable hollow pin; 3 - product to be welded; 4 - replaceable clamping pin; 5 - clamping support

In this case, a conical pin shaped like a tube is inserted into the waveguide (Fig. 3). When the parts are evenly pressed against the welding pin, a tight connection is obtained along the entire contour

This is interesting: How to use a hair dryer to weld plastic - brief instructions

The essence of obtaining seams with ultrasound

The ultrasonic welding process for plastics and metals has common physical principles, but differs significantly in parameters.

Ultrasonic welding of metals requires heating to high temperatures and the application of high compression forces. For plastics, you can get by with much lower values of these parameters. The installation diagram for ultrasonic plastic welding is also much simpler.

The sequence of actions is as follows

- Connect the ultrasound generator.

- Ultrasound, passing through the converter, is converted into longitudinal mechanical vibrations of the waveguide.

- The waveguide is connected perpendicular to the plane of the seam and transmits vibrational energy to the workpieces.

- Mechanical energy is converted into wave energy, which causes intense heating of the area of contact between the waveguide and the workpiece.

- In the heated surface layer, fluidity increases.

- The dynamic force applied by the emitter contributes to the heating of the contact zone.

- A static force applied in the same direction, perpendicular to the contact surface, forces the formation of strong bonds.

Weld seam after ultrasonic welding

This method makes it possible to combine materials with different structures, such as metal alloys and plastics, using ultrasound.

In this case, the difference in melting temperatures can be multiple.

Advantages

Analyzing the features of ultrasonic welding production, one cannot help but note the following advantages:

- no protective gas environment required;

- there is no need for thorough mechanical cleaning of the welding area;

- there are no restrictions on the shape of parts;

- environmental friendliness and an insignificant amount of released harmful substances;

- low heating temperatures compared to other methods;

- no welding materials required;

- high productivity, comparable only to resistance welding - a fraction of a second.

- low energy costs.

The resulting seam has an aesthetic appearance and rarely requires additional processing.

Comparison of ultrasonic and laser welding

Lithium-ion batteries come in different shapes and sizes.

There are many options for connecting elements, both with each other and with the vehicle’s electronics. In the automotive industry, it is very important to use reliable connections that are suitable for mass production and are also cost-effective. Welding equipment companies provide a wide range of battery solutions. Most often, 2 main joining methods are used in electric vehicles: Ultrasonic and laser welding.

The effect of ultrasound on the material of parts

Atoms of solids, both crystalline and amorphous, are arranged in a certain order, more or less strong bonds are established between them, allowing the bodies to maintain their shape. Atoms and molecules are capable of vibrating around their initial position. The higher the amplitude of these vibrations, the higher the internal energy of the body. If the amplitude exceeds a certain limit, established connections may be broken. If a force is applied to the body, preventing it from losing its integrity, new connections appear instead of broken ones, this process is called recombination.

High-intensity ultrasonic waves, imparting a large amount of energy to the atoms of the body in a short time, increase the amplitude of vibrations of atoms and molecules in the affected area. The bonds between them break, and under the applied pressure new ones arise, with particles from the surface layers of the second workpiece. This creates an extremely strong connection that turns the parts into a single whole.

Application of ultrasonic welding

This method of creating permanent connections is used in the production of:

- Electronics parts and circuits. They form semiconductor pn junctions, connect the pins of microcircuits, etc.

- Toys.

- Packaging.

- Consumer goods with thin-walled elements. For example, glasses frames are made using ultrasound.

- Rechargeable batteries, batteries.

- Freon pipes in refrigeration chambers.

- Medical products.

- Automotive units.

This method is also used for making electrical and thermal connections.

Possibilities of ultrasonic waves

The method allows you to connect workpieces from the following materials:

- metals;

- plastics;

- glass;

- fabrics;

- skin;

- ceramics;

- composites.

The method allows you to connect plastic.

The minimum thickness of the product is 1 micron. For example, in microelectronics, foil is welded to a wire using USS methods.

Ultrasound makes it possible to join dissimilar materials, such as metal and glass. Propagating throughout the product, the waves penetrate into any place, incl. the most difficult to reach.

Established restrictions

Connect blanks with the following parameters:

- Up to 1.5-2 mm thick.

- Dimensions no more than 25-30 cm.

The limitations are due to the attenuation of sound vibrations in the material. The use of the method for joining large-sized workpieces is not economically feasible due to the disproportionate increase in equipment power.

Strength of the resulting seams

The tensile strength in the joint zone reaches 70% of the value characteristic of the base material. To do this, it is necessary to select the optimal process parameters.

It takes about a quarter of a second to form a connection.

Working with metal parts

The use of ultrasonic welding for small parts is highly effective. The method is especially successfully used in microelectronics and instrument making.

The joining of metals takes place at significantly lower temperatures than when using “hot” welding technologies, such as electric arc or gas welding. This opens up a wide range of possibilities for quickly and reliably connecting components that are sensitive to overheating.

In addition, the method is capable of welding pairs of metals that are difficult to join by other methods: Cu+Al, Al+Ni, etc.

The strength characteristics of the weld reach 70% of the values for the original alloy.

The method also allows you to weld metal, plastic, ceramics, composites, glass in any combination. It can also be applied to refractory alloys.

Adjustable Parameters

The use of ultrasonic welding for various materials is possible with proper configuration of the equipment and regulation of the power load. The setting is done experimentally. The laboratories have developed setting tables; they are used to guide the selection of settings and determination of the technological mode. The main adjustable parameters of ultrasonic welding equipment:

- the amplitude of pulse emission by the waveguide (welding tip), the degree of interdiffusion of the materials being connected depends on it;

- pulse duration affects the speed of seam creation;

- static load, in automatic machines the mechanical pressure of the press is regulated, in manual machines the degree of pressure is determined experimentally;

- frequency of electrical oscillations; the pressure force of the waveguide depends on it.

Additional settings that affect the welding mode include:

- temperature of additional heating of parts (depending on material, shape, texture);

- tip height;

- degree of clamping of connected elements.

When choosing an operating mode, welders rely on personal experience. Beginners will have to go through trial and error before tackling critical connections, such as assembling a polypropylene water conduit.

Advantages and disadvantages when working with plastics

When working with plastics, the following advantages of the method exist:

- high performance;

- low cost of surgery;

- tightness of seams on thick-walled workpieces;

- no need for surface preparation;

- no overheating;

- absence of electrical interference and electromagnetic radiation;

- compatibility of the operation with other operations of the technological process, spraying, cutting in other planes, etc.;

- versatility across types of plastics;

- lack of consumables and chemicals.

- aesthetics and invisibility of the seam.

Ultrasonic welding of plastics

There are also disadvantages:

- The low power of the emitter forces energy to be supplied from two sides.

- Difficulty in controlling seam quality.

The quality of the connection depends on the accuracy of the selection and stability of the installation parameters during operation.

Briefly about settings

Ultrasonic welding equipment consists of the following components:

- electrical oscillation generator;

- acoustic unit with waveguide;

- press mechanism;

- process control equipment.

There is no need to make the device yourself, and there are a number of reasons for this. The first and main thing is that creating a machine will require a lot of mathematical and physical calculations. A minimal deviation will lead to resonance at the point of contact of the parts, which will reduce the quality of the welded joint.

Types of ultrasonic systems

Ultrasonic welding is classified according to a number of criteria. The first is the method of energy transfer. So they distinguish:

- contact;

- transfer welding.

The first is usually used for joining soft plastics, films, and synthetics up to 5 mm thick. The most common welding method is lap welding.

The second is applicable when processing hard plastics (polystyrene, nylon, etc.). The connection is butt.

Other criteria for the classification of ultrasonic systems are:

- method of moving the waveguide (press - for one short movement of the element; continuous - for prolonged exposure to the welding area);

- method of dosing the introduced mechanical energy (with fixation of the time of exposure to the ultrasonic pulse, settlement or gap). Features of welding equipment

Unlike manual or semi-automatic work, where you can use different types of electrodes or wires, as well as change other process parameters, in ultrasonic welding equipment everything is calculated to the smallest detail. The process proceeds as follows:

- the generator creates an electrical impulse;

- vibrations are converted into a high-frequency sound wave;

- the wave is transmitted through the waveguide to the junction of the parts;

- here it creates resonance;

- the displacement of materials towards each other leads to their instantaneous connection.

Depending on the physical characteristics of the materials being connected, the vibration frequency is selected. Below are some examples of settings.

Equipment used

Considering the high cost of an ultrasonic welding machine, many home craftsmen are thinking about making the installation themselves. Unfortunately, this is not a welding transformer or even a rectifier, and designing and creating the device will require serious knowledge and skills in the field of acoustics and electronics. In addition, the manufacture of parts for the emitter and waveguide requires high-precision machines that are not available at home.

Ultrasonic Welding Press

Ultrasonic welding equipment is divided into three categories:

- chiseled;

- suture;

- suture-stepping.

Power range - 50 watts to 2 kilowatts, operating frequency around 20-22 kilohertz

The main unit of an ultrasonic welding installation is a vibration generator and a converter of electrical vibrations into mechanical vibrations of the same frequency.

Mechanical vibrations of the ultrasonic generator are converted by a magnetostrictive transducer. A water cooling system is used to remove excess heat

The wave transformer matches the parameters of the interaction between the converter and the waveguide. It increases the oscillation frequency at the output of the waveguide.

The waveguide transports the energy flow to the welding site. A replaceable welding head is mounted at its working end. Its geometric parameters are selected based on the material of the workpiece, its thickness and type of seam. So, to weld the pins of microcircuits, take a head ending with a thin tip.

Waveguide

The supporting frame serves to accommodate all components and parts. A mechanism for moving the workpiece or waveguide head is also mounted on it.

Application of ultrasonic welding in industry

This type of ultrasonic welding is used for welding foil, wire, thin sheets and other elements. It is distinguished from other types of welding by the ability to weld dissimilar and heat-sensitive materials, because the process can occur without heating, or with minimal heating.

Ultrasonic welding is widely used in such industries as the production of microcircuits, semiconductors, microdevices, microelements for electronics, chips, capacitors, transformers, mobile phones, for the manufacture of many elements in various types of home appliances. Also, this type of welding has found application in optical instruments and precision mechanics devices, in the manufacture of reactors, vacuum drying plants, joining the ends of rolls of thin-sheet materials, in the automotive industry and many other areas of science and technology.

Additional

Welding equipment parameters

To obtain a strong and durable seam, it is necessary to accurately calculate and carefully observe the operating parameters of the device. They depend on the type of workpiece material, its thickness, and requirements for seam strength. Fine-tuning of parameters for each new product is carried out in laboratory conditions, with repeated tests to ensure the destruction of the connection. The best combination of parameters is recorded and used in the production process.

The main parameters include:

- Amplitude of oscillations. Determines energy flow and operation time.

- Clamping force. The strength of the seam depends on it.

- Generator operating frequency.

- Static pressure. Determined by the amplitude of mechanical vibrations.

- Duration and duty cycle of pulses. Also determines the duration of the operation.

Auxiliary parameters include the initial heating temperature for workpieces of large thickness, the elevation of the welding head above the workpiece, and some others.

Ultrasonic spot welding machine

Ultrasound capabilities

The use of ultrasound makes it possible to firmly and durablely connect various, even very different materials with thicknesses ranging from several microns to several millimeters. When using ultrasound, distortion of the shape of the workpieces being welded is reduced to a minimum.

The use of spot welds makes it possible to connect large areas at high speed. The pitch of the points is selected based on the thickness of the workpieces and the requirements for the strength of the seam. In areas of the product subject to high stress, the pitch is reduced. The use of roller attachments on the emitter allows you to make continuous sealed seams of any configuration. Such connections are used in packaging products and inflatable structures.

Sheet and film blanks are overlapped. For rod-shaped workpieces, T-welds are used.

The method's capabilities for working with ultra-thin materials are limited. Due to the high speed of work, environmental safety and provision of normal working conditions for personnel, the popularity of ultrasound continues to grow.

Areas of use of ultrasonic welding

The areas of application of ultrasound for creating welded joints are determined based on the characteristic features of the technology:

- the materials to be joined must be ductile;

- their dimensions are limited, primarily thickness;

- the heating temperature is much lower than when using “hot” welding technologies.

Application of ultrasonic welding in the production of building materials

Using an Ultrasonic Sewing Machine

The technology has become widespread in the following areas:

- instrument making;

- electronics;

- production of plastic casings;

- production of plastic products.

The method is also used in other industries for attaching small-sized parts to large ones.

Technological capabilities of ultrasonic welding

Using ultrasonic welding, you can weld various parts of products with a thickness of 0.005-3.0 mm and a diameter of 0.01-0.5 mm. Moreover, if it is necessary to weld a thin sheet or foil to a part, then the thickness of the latter is practically unlimited. The difference in the thickness of the welded parts can reach a hundred times! The figure below shows the most typical connections for ultrasonic welding:

Table of weldability of materials during ultrasonic welding

Using ultrasonic welding, you can weld both homogeneous metals and their alloys, as well as dissimilar ones and even with some non-metallic materials. The weldability of a particular material depends on its hardness and crystal lattice. The higher the hardness, the worse the weldability of the steel. The figure below shows a table of the weldability of some materials during ultrasonic welding: