Wood is a popular material that is often used in construction. To make cuts at home, band saws are used - homemade or factory-made. The article will provide information, after which the reader will understand that a self-made band saw performs the necessary functions no worse than factory equipment. In addition, it is quite simple to assemble.

Homemade band saw

Areas of application for homemade products

Band saws are valued for sawing very large materials at home.

A significant advantage of a band saw jigsaw over a circular saw is the thickness of the blade (1.5-2.5 mm). Thanks to this feature, the tool is very economical when it comes to cutting thick trees.

Because they take a very precise approach to work, homemade bandsaws are often used in sawmills.

For reference! This unit is also used in the production of furniture, where high accuracy and calculation, as well as evenness of cutting wooden blanks, are required.

Types and structure of band saws

- The unit has many advantages, including:

- high degree of productivity;

- low heat transfer to the atmosphere;

- low cost;

- good speed and sufficient accuracy.

All varieties have the same base - there are countertops or a work surface where the log will lie. It is sawed using cutting parts - rotating blades. They can be of various configurations. It is also necessary to take into account all the fasteners and the engine that will drive the entire machine.

The types depend on what material needs to be cut, it can be wood, metal, stone or synthetics, different types of plastics. In the case of strong workpieces, the structure should be strengthened and reinforced with super-strong alloys. Otherwise, the cutting tape will break. If you refer only to a wood sawing machine, which you can make yourself, then the units should be classified as follows:

- Toothless. The name is not entirely accurate, since there are still small teeth, but the main action occurs due to intense heat and friction.

- Serrated. The canvases, that is, the tapes, are closed, so there is a constant continuous process. This is the simplest and most inexpensive type, which we will mainly turn to.

- Electrical search. They have increased strength and wear resistance. They are installed mainly in production, when it is necessary to support the serial production of wood, as well as to cut large logs of large diameter, which are difficult to handle at home.

Technical capabilities

Before making a homemade band saw, it is necessary to study the technical features and possible areas of application. Units are usually divided into categories:

- Data on cutting for a certain period of time.

- Width of the tape web.

- The angle at which the mechanism can be rotated.

- Number of speeds for running-in.

If the thickness of the tape is approximately 14 mm, then it is advisable to use such a unit for domestic needs with a small volume of processed products. If the volume is needed more, and the products are supplied on an industrial scale, then the thickness of the tape should be 20 mm.

Saw band

The location of the tape can be horizontal or vertical. Vertical units are equipped with a special panel with which you can control the work process. The operator must have full control of this console, closely observing the process of cutting wood or other material.

If the unit is small, special attention must be paid to fixing the saw surface. Horizontal placement in this case is used for sawing hard wood.

How to sharpen band saws

In the process of cutting wood or metal, the teeth of a band saw lose their initial sharpness. Therefore, it is necessary to sharpen the band saw. Any sharpening of a saw blade consists of the following stages: • initial sharpening • cleaning • setting • final sharpening.

To restore the cutting qualities of saw blade teeth, special sharpening machines are used. The result of the initial sharpening is the elimination of cracks in the sinus of the tooth, as well as the restoration of the tooth profile while maintaining symmetry in relation to the others. At the cleaning stage, the metal filings remaining after sharpening are removed. At the routing stage, the front and rear angles are changed.

And finally, final sharpening corrects any distortions in the symmetry of the rake angle and sharpens the working edge of the tooth. Sharpening band saws with your own hands requires certain skills and techniques. Professionally performed sharpening restores the perpendicularity of the cutting edges. To return the teeth to normal thickness, you have to grind the saw edge quite deep.

This video will show you how to sharpen band saws.

Homemade band saw design

There are many plans online for making a band saw at home. For homemade products, it is advisable to choose sawmills that have a vertical blade arrangement.

Device components:

- main frame;

- table where sawing is done;

- pulleys;

- drive;

- saws.

For homemade products, an electric motor running on 220V is used. If you plan to cut very massive workpieces, then it is advisable to look for a more powerful machine.

Important! If there is no possibility or desire to use an electric engine as a basis, then you can replace it with a gasoline analogue.

The cutting blade must be securely fastened to the pulleys. The movement of the canvas occurs along a closed path (circular or oval shape).

The size of the future installation must be chosen depending on the goals that need to be achieved. If the owner lives in an apartment and wants to install a belt unit on the balcony, then a mini-machine can be made by converting a jigsaw.

Jigsaw band saw

Purpose of the canvas

Depending on the type of machine and the type of workpiece that will be processed, all tape blades can be divided into three groups:

- Blades for log sawing machines.

Designed for cutting round timber into edged material in sawmills. - Blades for belt dividing machines.

Designed for dissolving (dividing) timber or boards into small molded products for the production of lining, joinery, furniture panels, parquet boards and for processing slabs on sawmills. - Blades for carpentry machines.

Intended for use in furniture and carpentry production in the manufacture of final products, including figured cutting.

Band Saw Parameters

Depending on the type of manufacture, a band saw can be used to process the following materials:

- tree;

- synthetics;

- metal.

The metal has high strength, and therefore it is necessary to use reinforced steel for cutting. When using standard saw blades, the teeth will become deformed very quickly. Therefore, you need to prepare for work in advance, taking into account the type of material.

Blade tooth size and pitch

To select a cutter, you need to start from the dimensions of the created machine. There are also useful recommendations that you should follow:

- For longitudinal cuts, wide blades are used, resulting in a high-quality and even cut.

- If you have to process a thin workpiece, you need to use a very narrow blade.

- If contour and figured cutting is necessary, cutting elements are selected in the width range from 14 to 88 mm. The preferred size is 35-40 mm.

The final processing result will also be influenced by the pitch of the teeth:

- Large setting is suitable for processing thin sheet materials.

- The “thicker” the setting of the teeth, the larger the blade should be.

- The middle option can be used when processing synthetic materials so as not to clog the cutter with waste.

But this is not enough to select the correct blade. It is important to pay attention to the sharpening and location of the teeth.

Tooth placement and sharpening

The tooth pitch affects the final machining. The choice must be made depending on the hardness of the wood:

- WM blades are suitable for hard and soft wood.

- AV - for working with hard wood or frozen wood.

- NV - for figured cutting.

- NU - for soft breeds.

It is also necessary to pay attention to the sharpening of the teeth. The cutting edge must be very sharp and smooth.

Attention! When buying consumables, it is advisable to ask the seller about the possibility of sharpening yourself.

Teeth pattern

Dimensions of Band Saw Blades for Wood

The service life of a wood band saw directly depends on the quality of its sharpening. It can be done either independently or using the services of specialized companies. First, you need to study the technology and a number of features in detail.

The band saw belongs to the level of cutting tools and is an integral part of special equipment for processing wood. It is essentially a closed belt, on the outer edge of which there are teeth.

For production, special grades of steel are used - 9ХФ, Б2Ф or С75. During production, teeth are treated with high-frequency currents. This increases their hardness. This particular fact has an impact on the spread of cutting edges and maintainability. Often several types of steel are used at the production stage. The main belt is made of spring, and the cutting part is made of steel with a high content of tungsten, or cobalt.

Features of the introduction of band saws for wood:

- requirements for wood species. The harder it is, the faster the blade will become dull;

- installation conditions. The tension indicator must be observed. If it is less than required, sagging will occur. With strong tension, the possibility of fabric breakage will increase;

- repeated sharpening. For this purpose you will need a special machine.

Completing the last step will increase the service life of the strip structure. But sharpening without the help of others is problematic - you need to choose the right layout and maintain the angle of the blades.

When purchasing a used saw, you need to pay attention to the presence of repair welds on the blade. They indicate frequent tool failures.

First, the type of band saw is determined. The main indicator is the shape of the teeth. Based on this parameter, they are divided into dividing, carpentry, as it is also called, created for sawing logs. The initial geometry and routing angle are determined by the manufacturer. It is recommended to find out this data at the stage of purchasing devices. They are necessary to determine the characteristics of the machine.

READ Video Review of Table Saw Tc 820

For hard types of wood, the frontal angle will be the smallest. This ensures better contact of the processing material with the metal. In this case, it is planned to process soft species - in order to increase the processing speed, models with a huge frontal angle are used.

The determining parameters for self-updating the cutting edge are:

- tooth pitch. This is the distance between the cutting elements of the structure. Common values are 19, 22 and 25 mm;

- tooth height. The size from its base to the top;

- corner. The main value you should know to form the cutting plane. For carpentry models it is 35°. In dividing saws, the angle is from 18° to 22°. In structures for processing timber – 10°-15°;

- divorce. Determines the deviation of the tooth from the general plane of the blade.

After performing work on the machine in the correct way, these properties must remain constant. For each model, the manufacturer determines the largest difference value. If this is achieved during operation, you need to get the latest model.

How to choose a band saw

In order to eliminate resonance in some types of cutting tools, a variable pitch of the teeth is made. This does not affect manual sharpening, but requires careful setting of the characteristics at the time of automatic sharpening.

Before forming the cutting edge, the teeth must be set correctly. Throughout the entire period of operation, due to constant loads, their placement may change. Therefore, first the geometry is adjusted, and then sharpening occurs.

READ Dimensions of the front adapter for a do-it-yourself walk-behind tractor

Setting is the bending of the teeth relative to the plane of the main blade. This procedure is performed only on a special machine. For which the design is designed for huge discrepancies along the entire length of the belt, you will experience early damage or breakage of the web. Therefore, you should first decide on the type of wiring.

The angle of inclination must correspond to the original one. The type of wiring is also taken into account, which and possibly subsequent:

- traditional. Consecutive bending of the teeth relative to the blade to the right and left;

- cleaning The 1st and 2nd teeth deviate to the right and to the left, and the 3rd remains constant. This technique is used for saws intended for processing hard rocks;

- wavy. The setting angle for each tooth is individual. They eventually form a wave-like cutting edge. A very difficult type of wiring.

During the bending process, not the entire tooth is subject to deformation, but only part of it. Often the deviation occurs along 4/3 of the total height.

The average divorce value is limited to values from 0.3 to 0.7 mm. This applies to standard wood band saw models.

The correct choice of grinding wheel type is of fundamental importance. It must match the grade of steel from which the band saw is made. For structures made of tool steel, corundum wheels are used. If you want to improve the cutting characteristics of bimetallic models, you should use CBN or diamond wheels.

bandsaw blades. where did you buy it?

Based on technical abilities, full-profile processing is performed on each cutting part separately. In the beginning, a CBN circle will be useful, the end of which has the same shape as that of the saw. For the second option, each tooth is processed.

READ Almonte Automatic basic saw

The machine will come in handy in advance. It must have the functions of regulating the speed of rotation of the disk and changing its location relative to the tool. After securing the canvas in a special frame, the following steps should be performed according to the subsequent annotation.

- The emery is directed downwards. At that time, the front face with the cutting edge is processed.

- Forming a cut in the depression. This is done without leaving the canvas. This step allows you to remove microcracks and bulges. The fundamental point is the reduction of surface tension, which is the main prerequisite for the deformation of the web.

- The circle rises up. The back of the tooth is ground and its cutting edge is sharpened.

The same method is used to update all other teeth. It is important that the values of the entry and exit angles be similar everywhere. Otherwise, if there are differences in geometry in one of the parts, the performance properties will deteriorate.

As a result of processing, it is recommended to perform fine-tuning - treat the surface with fine emery. During this process, the geometry of the canvas should not change.

With prolonged contact of the circle with the metal, the temperature of the latter can rise sharply. To eliminate this effect, special cooling waters coming directly from the machine are used. The feed is done constantly to avoid the formation of a hot zone. In this part, the mechanical strength will be deteriorated.

To avoid the occurrence of nicks, before processing wood, it is necessary to check for the presence of iron components. Also, increased attention is paid to fixing and uniform feeding of the workpiece for sawing.

In the video you can learn all about tips for amateur sharpening:

Source

Tools and materials

Homemade wood band saws are made from the following materials and tools:

- Plywood or chipboard sheet for making the frame and pulley.

- Sheet steel for the saw (or a ready-made sample from the store).

- Channel for support frame.

- Metal corners or slats and wooden blocks.

- Bearings.

- Steel pins for making pulley axles.

- Electric motor.

- Bolts, nuts, screws, washers.

- Flexible rubber.

- Bushings.

- Textolite.

- Durable belt.

- Paint or varnish, brush.

- Saw.

- Keys for bolt heads.

- Tape measure and pencil.

It is advisable to use logs 20 mm thick to increase the reliability of the device.

From the history

The band saw has been known for quite a long time, since the beginning of the 19th century (the first patent was in 1808). The very principle of continuous movement of the saw blade (as opposed to the reciprocating motion of a hacksaw) has long been of interest to engineers. It is more technologically advanced for many reasons:

- The hole saw cools naturally - a small part of it is in contact;

- Moving the teeth in one direction causes less damage to the cutting area;

- The tape is easier to sharpen;

- The drive and tension mechanism is simplified as much as possible, as is the lubrication mechanism.

But on the way to implementation, some difficulties arose related to connecting the saw blade into a ring. The tape must be strong, resilient and, at the same time, flexible and sufficiently elastic. Weld such metals that there are no seams left that interfere with its movement in the body of the material and cause overheating (resulting in rupture at the joint).

This is what the first band saws looked like

On wood band machines these difficulties could be minimized, but on metalworking machines everything was different. Only towards the end of the century in France was it possible to establish the production of acceptable saw blades, which were resistance welded and then the seams were carefully ground.

Currently, several types of circular saw blades are produced:

- toothed;

- friction saws;

- electric spark.

A homemade metal band saw, as a rule, is guided by a toothed blade of a bimetallic structure. This is a tape made of durable steel (spring or similar in properties) with teeth made of especially strong tool steel with hardness M42-M71. The sharpening of the teeth is different for different materials.

Largest band saw blade

For example, for cutting pipes and channels you will need a belt with reinforced tooth backs, for stainless steel - with a sharp sharpening of 150 and an increased distance between them. When sawing, stainless steel produces viscous chips that interfere with the movement of the saw, getting stuck between the working edges. If you have to cut large-sized metal, then you need a blade with periodic routing - narrow and wide alternate, to eliminate the threat of the tape getting stuck in the cut.

In order for your DIY band saw to work properly, design it for a factory-made band. It’s quite difficult to do it yourself, even if you manage to find a suitable metal and your workshop has all the necessary welding and sharpening equipment.

Wood band saw - step-by-step production

Once all the tools and materials have been collected, you can proceed directly to manufacturing.

Frame assembly

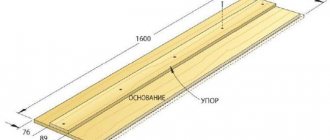

For manufacturing you need to use strong wood. Often boards from old furniture are used. First you need to make a drawing of a wood band saw with your own hands in accordance with specific parameters.

Mounting the rod and pulley support

The simplest machines can be made from plywood or logs. The thickness of the rod should be 8 by 8 cm. Several supports must be attached to it to fix the pulley. It is advisable to use multi-layer hard plywood.

Experts do not recommend using a large gap - with regular use, the machine will wobble due to the gaps created.

Table

The height of the homemade base depends on the height of the individual person. It is important to ensure that the drive and lower pulleys, and the chips created during operation, can fit freely in the created space. You can choose any shape, but usually they use the option of a closed cabinet, like a drum. It will become a container for collecting sawdust.

Important! It is worth considering the possibility of placing a tray - for ease of cleaning the unit.

The tabletop must be mounted on a lower support.

Homemade tabletop

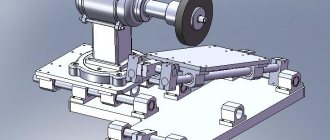

Creation of pulleys and their installation

The tension mechanism needs to be welded. The diameter of the pulleys can be chosen in any order, but the larger it is, the longer the band saw will last without replacing any parts.

Blades should be selected with a ratio of 1 to 1000 (relative to the pulley diameter). If the parts are 40 cm long, then the diameter should be 4 mm.

When choosing parameters, you need to consider some features:

- Calculate the circumference of the pulleys: D=3.14*R.

- The cutting disc should rotate at a speed of no more than 30 m/s.

- Next, calculate the number of revolutions - 0 = 30 m/s.

- Now comes the calculation for engine speed to pulley rotation.

- The tooth set can be selected individually.

In order for the tape to be placed in the center and not go to the sides, you need to make the edge convex with an angle of 5-10 degrees. There should be a small groove on the pulley where the belt fits. The whole thing is covered with rubber on top.

The selected diameter should be smaller than the pulley (about 2 times), then the blade will not slip. The upper part is fixed to the movable block and placed in a horizontal position. This way the edge tension will be sufficient. To do this, it is necessary to use a tension mechanism: a piece of wood under a block to which a spring is connected. When the master presses the lever, the device rises and the saw is tensioned.

It is necessary to attach several pulleys to the lower block: 1 - driving, 2 - driven. At the same time, you need to make sure that they are qualitatively balanced. It is advisable to use a self-aligning bearing to secure the upper pulley.

Blade guides

Now fix the guides at an angle of 90 degrees. Thus, the cut will be as smooth as possible and without distortions. The simplest solution is to screw several bearings to the beam: to fix the flat side, the rest are needed for fastening on the sides. The guides must be aligned with the support fixation point.

Final finishing

You can start working immediately after assembly, but it is advisable to equip the unit with a casing to cover the pulley.

Important! It is advisable to place the belt drive outside the workbench to protect it from sawdust.

In order for the wood to last as long as possible, it must be varnished.

Classification of paintings

The blades are made from materials such as metal, diamonds, steel, etc. Different materials are suitable for processing certain types of products. For example, diamond saw blades are used to work on marble or glass wool.

There are three main methods for classifying this product:

- By function.

- By size.

- According to the location of the teeth.

By function

Saw blades are divided into groups based on the materials they work with.

Such materials include:

- Stone.

- Metal.

- Wood.

- Synthetics.

Expert opinion

Levin Dmitry Konstantinovich

Saw blades, which are designed for working with metal, are divided into subgroups. The classification takes into account the type of material that will be cut by the tool.

Table 1. Types of blades for metal saws

| Blade type | Scope of application |

| Bimetallic M42 | Cutting objects that are made of steel without alloying additives |

| Bimetallic M51 | Cutting materials that consist of alloys or steel with a carbon content higher than 0.6% |

| Bimetallic SP | Cutting alloys with high resistance to metal deformation |

| Carbide type TST | Processing objects made of alloys that have a heterogeneous structure |

By size

In addition to functional features, the nature of the upcoming work is taken into account. The evenness of the final cut depends on the width of the blade. The width range of saw blades for cutting tools is from 14–80 millimeters. For standard saws, typical values are 31–41 millimeters.

If tool instructions are not available, it is recommended to use the widest blades available for general cutting. The main selection criterion is whether the saw blade matches the band saw machine at which the master is working. The wide blade is fed as quickly as possible, which speeds up the processing time of materials.

Contour cuts require narrow tools. The saw is required to clearly cut corners and shapes in the selected material.

Choosing the width of the canvas involves taking into account several details:

- Thin blades are not designed to cut thick workpieces. With prolonged use they are subject to deformation.

- Thick saws are not used for processing thin materials. Under the pressure of the blade, the workpiece bends and may break.

- When cutting along a contour, the width of the saw blade is selected based on turns at the required angle.

Teeth parameters

Teeth or serrations are the projections on the saw blade.

The cutting quality is determined by the following characteristics:

- Size.

- Quantity.

- Step.

- Wiring.

- Sharpening quality.

When selecting a product, the main criterion is quantity:

- A large number of teeth facilitates even cutting of thick-walled materials.

- Low tooth density reduces the load on the material area to be processed.

- The high tooth density distributes stress evenly across the tool surface.

The next parameter that affects the quality of work is the size of the teeth:

- Standard sizes are intended for processing thin materials and shape cutting.

- Large dimensions designed for deep cuts.

- Low-height edges are made for working with thin-walled pipes and other objects.

When choosing a canvas, the master is guided by the following criteria:

- With a large continuous step, thin-walled materials of small size are processed.

- Large objects are cut with frequent, evenly spaced teeth.

- The belt, which has variable teeth, is designed to work with soft materials (such as plastic, non-ferrous metal, wood).

Expert opinion

Levin Dmitry Konstantinovich

The pitch of the teeth is selected based on the parameters of the counter section of the machine tool.

The tooth pattern is presented in three categories. Their characteristics are briefly summarized in the table.

Table 2. Types of tooth set

| Wiring type | Description |

| Wavy | The teeth are arranged in waves throughout the entire blade and have different angles of inclination. Used for processing thin plates and creating compact workpieces |

| Standard | The edge elements are placed alternately in two opposite directions. One tooth is located in the center. The blades are used for working with large sections of metal on horizontal machines |

| Group | The edge is covered with teeth, which are arranged in pairs - on the right and left sides. This design increases the speed of making cuts and improves their quality |

To determine the quality of sharpening, experience with saws is required.

Masters determine quality based on three parameters:

- Sharpness of teeth.

- Uniformity of edge materials.

- Edge evenness.

Before purchasing a blade, it is advisable to ask the sellers whether the material requires sharpening. And if sharpening is possible, then how many update cycles are provided?