offers high-quality equipment for the production of furniture from scratch. In our catalog you can choose a complete set of equipment to perform any production operation efficiently and quickly, including edge processing. Our edge banding machines are reliable lines and machining centers that can work reliably and for a long time for you.

The modern consumer will not be surprised by cheap furniture, and the choice today is varied, so buyers are looking not only for affordable furniture, but also for quality. Furniture production of various sizes has to switch to new technologies and purchase high-tech equipment, otherwise production will become unprofitable.

Purpose:

The machines cover straight and curved edges of furniture panels and blanks with natural strip or synthetic roll material. Edgebanding machines are divided into simple positional ones with manual feeding of workpieces, single-sided edgebanding machines and double-sided edgebanding lines. The equipment options for each type of machine are also different - the configuration of edge banding equipment depends on the complexity of the furniture elements, the volume of its production, the customer’s wishes for the quality of the veneer and other nuances.

How the device works

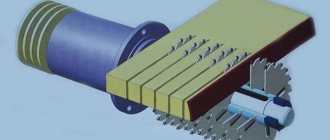

For gluing, a tape is used, the width of which is 2-5 mm greater than the height of the element. This is done to accurately close the edge. As a rule, after gluing, so-called overhangs remain, which are indicated on both edges. In order to remove them, a milling module is used, which cuts off the lining that extends beyond the boundaries of the part.

Usually the mechanism is equipped with a high-speed drive with 12 thousand revolutions per minute, so as not to damage the plane. The module also includes limited rollers for correct installation of the workpiece. The unit is equipped with 2 cutters with drives; it is adjusted to the required height of the part. In order to delicately adjust the module and secure it, a moving system with a screw-nut transmission is used.

After cutting with a knife, the tape is glued to the edge. In order to eliminate it, you should use a trimming module, the system of which can be different. The simplest type involves a circular saw, which has vertical movement and is equipped with a drive with low power.

Upon a special command, this electric saw enters the working area of the edger and saws off the excess section of the cladding. This principle can only function in machines with manual feed. If delivery is mechanized, the end module is the most complex. A power saw with a drive is inserted according to the instructions for the machine on a carriage, which has 2 short directions: the first for feeding the saw to eliminate the tape allowance, and the 2nd for an even speed of feeding the workpiece. The power edge banding machine can be supplemented with a large number of multifunctional elements.

Hand-fed edging devices are used not only at home or in workshops. Even large furniture companies have this device for rapid repairs and finishing of exclusive blanks and small batches of parts.

Thanks to the presence of processors and controllers, devices with manual part feeding are considered very convenient and easy to operate. The main processes during operation are the feed rate, automated temperature control, and, in addition, the length of the glued material.

Read also: Cold welding Ermak reviews

The manual feed unit operates with material up to 3 mm, consumes about 2 kW of electricity, and covers an area of up to 2-3 square meters. meters, is serviced by one user and maintains a workpiece feed rate of 6 meters per minute. In order for the machine systems to be able to operate, a system under a pressure of 0.6 MPa of compressed air is connected.

Typically, the machine is first tested, and the safety of the adhesive seam and the degree of adhesion of the adhesive are monitored. To perform the test, it is possible to use colorless PVC film, which makes it possible to observe the distribution of the adhesive composition after compression and polymerization. If the work shift changes, it is also recommended to carry out tests to prevent the appearance of a hidden disorder.

The entire cutting mechanism is well sharpened. This applies to knives and cutters. Be sure to clean the glue tray regularly.

The edge banding unit may have fencing and markings for heated surfaces. The device frame must be grounded. The device should be connected to a suction system, since heated superglue can release toxic substances that pose a health hazard.

Such a device does not require any complex setup. You should adjust the heating temperature, correctly set the rotation speed of the rollers that apply superglue, and the feed speed

It is very important that during application the volume of adhesive optimally matches the required conditions. If it is not enough, the strength of the relationship between the material used and the workpiece may be lost.

Excess glue will result in excess amount being applied to the surface and causing dirt.

Positional edge banding machines.

Designed for lining straight and curved edges of furniture panels and blanks with natural strip or synthetic roll material.

Principle of operation:

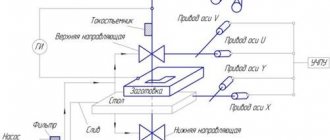

- Fig.1

Edge gluing on positional edge banding machines is done using granular hot melt adhesive. The glue is poured into a bath, where it melts due to heating elements at a certain temperature set by an electronic device. The hot melt adhesive from the bath is fed onto a glue spreading roller with a dosing device. The dosing device is used to regulate the consumption of applied glue. Typically, hot melt adhesive in these machines is applied to the edge, but there can also be a combined application of glue to the edge and the workpiece.

So, the edge material is driven by a drive mechanism using a foot pedal at a certain feed speed (usually adjusted and adjusted to the workpiece). Next, hot glue is applied to the edge and by moving the workpiece manually along the table, the machine operator grabs the edge with the applied glue and moves the workpiece at the feed speed of the edge. rolling it by pressing the workpiece against stationary or driven rollers. By releasing the foot pedal, the edging material is cut automatically by the guillotine and its feeding stops, thereby making the machine ready for applying an edge to the next workpiece.

Now all that remains is to remove the overhangs of the edge material from the workpieces using hand or electric tools or special equipment.

Photos of machines:

- Fig.2

- Fig.3

The operation of a positional edge banding machine can be viewed at the link or

Positional edgebanding machines are produced in Russia, the CIS and many countries in Europe and Asia with various characteristics.

Hot melt adhesive for positional edge banding machines

We recommend using hot melt adhesive for low feed speeds and low melting temperatures. The adhesive produced by Kleiberit brand 788.3, a medium-filled hot melt adhesive for edges made of veneer, PVC, ABS and impregnated paper for manual machines, is well suited for these purposes. Technical parameters of the glue can be found here.

Single Side Automatic Edge Banding Machines

Purpose: Automatic edge banding machine, pass-through type, designed for lining the edges of the straight sides of panels in automatic mode with various edge materials.

Principle of operation:

- Fig.4

- Fig.5

- Fig.6

Let's consider the principle of operation on a machine with the maximum configuration of units and devices included in the machine. Machines are available with and without CNC. CNC machines are controlled by an electronic device capable of changing machine settings automatically; on non-CNC machines, equipment adjustment is done manually. During processing, workpieces are moved by means of a drive conveyor with an adjustable feed speed or without adjustment.

The first unit in the machines (Fig. 4 on the left) is the unit for preliminary milling of the end of the workpiece. Allows you to eliminate defects on workpieces that arise as a result of cutting (chips, steps from a scoring saw), as well as defects associated with the low quality of chipboard, MDF board materials (thickening at the ends). Next: IR - lamp for preheating the workpiece Allows preheating of the end of the workpiece before the glue-applying unit to improve adhesion and uniform distribution of the glue-melt. Next: Edge material feed magazine Includes a driven feed roller and a special holder for feeding strip material. Next: Glue application unit This unit is used to apply and adjust the amount of glue. The glue temperature is regulated by an electronic control unit, which ensures that the desired temperature is maintained and prevents overheating of the glue.

The following units installed on the machine are used to process the removal of edge material overhangs. The first unit (Fig. 14 on the left) is the overhang trimming unit. Finish trimming of edge overhangs is carried out automatically using two saws. Next: Overhang milling unit. The milling unit is equipped with two R2 radius cutters and floating tracers that allow you to monitor the thickness of the workpiece, which ensures excellent quality of the machined surface. Next: Unit for automatic rounding of the end corners of the glued edge material Allows you to automatically round the end corners of the edge material without stopping the workpiece. Next: The scraping unit carries out finishing processing of material (pvc/abs) with a thickness of 1 to 3 mm and completely eliminates such a defect as a “kinematic wave” that occurs when milling overhangs of edge material at high feed speeds.

The following units serve to impart a high-quality appearance to the resulting furniture piece. Industrial hair dryers (Fig. 15 on the left). Designed to restore the natural color of the edge material after processing at the scraping unit. Next: Polishing unit. Designed to polish the processed part of the edge, remove excess hot melt adhesive, and give it a natural color and shine.

Photos of machines:

- Fig.7

- Fig.8

The operation of an automatic edge banding machine can be viewed at the link or.

Positional edgebanding machines are produced in Russia, the CIS and many countries in Europe and Asia with various characteristics.

Hot melt adhesive for automatic edge banding machines

The choice of hot melt adhesive is made depending on the equipment used and the tasks facing production. For medium-speed machines, the most suitable is the hot melt adhesive produced by Kleiberit 788.7, a medium-filled hot melt adhesive for edges made of veneer, PVC, ABS and impregnated paper for feed speeds up to 15 m/min, its technical characteristics can be viewed here. For high feed speeds, you can use hot melt adhesive 744.4, a medium-fill hot melt adhesive for veneer, PVC, ABS and impregnated paper edges for feed speeds from 20 to 40 m/min, its technical characteristics can be found here. There are machines manufactured by Holz-her that do not use granular hot melt adhesive, but cartridge adhesive. For these machines, Kleiberit has glue brand 782/.0, its technical characteristics can be found here.

Why do you need an edging machine?

As soon as the material is cut, all the necessary parts are cut out, their edges are covered with tape made of various materials. These are mainly materials based on PVC, paper, and treated fabrics. This procedure is designed to solve several problems at once.

Decorative design. Edgebanding tapes come in a variety of textures and colors. The most commonly used material is one that imitates the texture of wood or stone.

Slab protection. The tape used to cover the edges is made from polymer-based materials. It is characterized by high strength and wear resistance. This coating protects the slab from possible physical damage, moisture penetration, and structural destruction due to swelling.

Protecting people from harmful fumes. A modern wood-based board is created using high-quality materials and binders, however, chipboard can release toxins during the first months of operation. The laminated chipboard edger is designed to protect the owner from the harmful influence of his own furniture.

Devices of this type are highly specialized, however, such a machine must certainly be in the household of a craftsman who makes furniture.

Double-sided edge banding lines

Purpose: allows you to veneer two parallel, opposite edges of a rectangular panel blank in one pass at once, called. Features of double-sided machines: When particle board began to replace wood slabs and other panel parts in furniture production, it turned out that it looked quite unsightly when cut. In addition, formaldehyde is released through its unlined edges, gradually poisoning the entire volume of the room. Therefore, lining the edges of the panel parts from chipboard has become mandatory on all four sides. At the same time, the productivity of a double-sided machine is exactly two times greater than that of a single-sided machine. A double-sided edge banding machine (Fig. 9, 10) is actually two single-sided edgebanders facing each other. They are placed on a single bed so that one of them can move along the guides of this bed to adjust to the width of the workpiece being processed. The units for gluing the edge material and processing the edges are similar to those used in double-sided ones, practically the same as in single-sided ones. Their composition is also selected depending on the type of adhesives and edge material.

Photos of machines:

- Fig.9

- Fig.10

An example of an integrated full-cycle automatic line with two machines:

- Fig.11

1. Automatic loader 2. 1st double-sided machine 3. Turning station 4.2nd double-sided machine 5. Turning station 6. Unloader

Do-it-yourself edging machine

Factory-made devices are highly expensive, so for a small home workshop it is advisable to make the machine yourself. A home-made edge gluing machine will be noticeably inferior to purchased analogues in terms of power and performance, but it can easily cope with the amount of work in the home workshop of a novice furniture maker.

When planning to make such an edging unit yourself, you should soberly assess your strengths. An edge banding machine is a high-risk device, and the safety of the operator depends on the quality of its assembly. It is important to understand that the working parts of the machine are heated to very high temperatures. When using it, you must be careful and follow safety regulations.

Design elements

Devices of this type are used in various industries and have different designs. In general, a homemade machine should include:

- stable bed and comfortable table;

- tape feeding and centering unit;

- heater with temperature control system;

- heat-resistant guides;

- excess edge trimming system;

- polishing module.

The combination of all these components is a rather complex device, so for home use you can limit yourself to a simpler design. In a homemade edging machine, you can do without unnecessary automation, leaving only a device that feeds the tape and a device for heating it. In this case, you will have to use a tape with a pre-applied adhesive composition, which is somewhat more expensive, but at the same time you will be able to save on the complex components of the machine.

Properly manufactured, this device can be used as a machine for edging boards, plywood, wood boards and other similar materials. The machine will have a simple design; its consciousness will not require expensive components and assemblies.

Assembly order

First of all, you need a tabletop made of textolite or plywood covered with plastic. A horizontal stop, a metal square, is attached to it, against which the workpiece will be pressed.

It is rational to use a heated metal roller from a hair dryer as a heating element and at the same time a clamp. There is a cutout in the guide square where the roller exits. The part of the square behind the roller can be covered with soft material, felt or cloth, which will serve for polishing.

Actually, the machine is ready. You just need to screw the pin into the tabletop, which will become the axis of the roll, bring the end of the tape into the work area, turn on the hairdryer and wait until it heats up the roller. Next, the end of the workpiece is brought to a horizontal stop and the beginning of the tape can be glued. The workpiece is moved along the guide, while trying not to overheat the tape, but also to ensure maximum joint strength.

Care of the edger

It doesn’t matter whether you use factory equipment or a simple homemade machine, you must follow safety precautions when working with it and ensure timely maintenance. There are several important rules that, if ignored, may result in device failure or operator injury.

- Before starting work, be sure to study the structure and principle of operation of the edging machine, and the location of the controls.

- Before turning on the device, you must ensure the integrity of the power cables and protective mechanisms.

- Do not allow oil, water or other liquids to enter the work area.

- Keep your work area clean.

- The moving parts of the device must be lubricated using recommended materials.

- During operation, it is necessary to control the temperature of the pressure roller, to prevent overheating and burning of the adhesive composition.

- If difficulties arise during the operation of factory equipment, you should not try to fix them yourself; you should seek help from specialists.

Times are changing, technology is making life much easier for the home craftsman. Nowadays, making furniture yourself is easier than ever, you only need a few tools and equipment. Those who have a desire to try themselves as a furniture maker are unlikely to be able to do without this useful device. To begin with, you should make a simple device, try yourself in a new capacity, and then think about buying full-fledged factory equipment.

Read also: How much does it cost to wiretap an apartment?

Edge banding machines (Fig. 1) are designed for final processing of the end surfaces of panels made of various wood materials. Edge processing involves gluing cladding material of various shapes and structures to the end surface of wooden panels. This operation not only gives the finished product an aesthetic appearance, but also protects the edge surfaces from the effects of destructive factors.

Figure 1. Edge banding machine.

Today, as a rule, not a single furniture production can do without an edge banding machine. Even small companies and individual production today require this equipment. This is due to modern trends in the field of furniture manufacturing, where untreated end surfaces are considered to be of low culture and production level.

Recommendations for choosing hot melt adhesive.

If you have purchased an edge banding machine or an automatic line and you have a question about selecting a hot melt adhesive, contact our specialists and they will always help you choose a hot melt adhesive for your needs. In this case, you need to inform the parameters of the equipment, indicate the list of materials for use on this equipment and the desired result after processing. Our specialists will take part in commissioning work on the commissioning of new or used equipment and will certainly achieve positive results.