A furniture stapler is a device that drives staples into material. You simply cannot do without this device when building or renovating a room. A stapler will help when driving canvases or posters to the wall, assembling furniture or upholstering it.

A damaged tool can harm the entire work, so you need to choose a stapler carefully! In this article, we will look at the ranking of the best furniture staplers for 2021. We will analyze separately network, battery and mechanical devices. Let's start with the simplest model and thus reach the best devices!

Attention! It is very important to choose a high-quality mechanism, since furniture upholstery or repairs directly depend on this.

TOP 13 best staplers

| Photo | Name | Rating | Price | |||

| Mechanical staplers | ||||||

| #1 | Rapid R153 WORKLINE RUS 5000061 | ⭐ 100 / 100 2 — votes | Find out the price | |||

| #2 | STANLEY Light Duty 6-TR150L | ⭐ 99 / 100 3 — votes | Find out the price | |||

| #3 | BOSCH HT 14 0.603.038.001 | ⭐ 98 / 100 3 — votes | Find out the price | |||

| #4 | COBALT 240-683 | ⭐ 97 / 100 1 — vote | Find out the price | |||

| #5 | GROSS 41002 | ⭐ 96 / 100 2 — votes | Find out the price | |||

| #6 | Center tool 1609 | ⭐ 95 / 100 | Find out the price | |||

| #7 | Inforce 06-09-42 | ⭐ 94 / 100 2 — votes | Find out the price | |||

| Cordless staplers | ||||||

| #1 | BOSCH PTK 3.6 Li 0.603.968.120 | ⭐ 100 / 100 | Find out the price | |||

| #2 | MILWAUKEE M12 | ⭐ 99 / 100 1 — vote | Find out the price | |||

| Network staplers | ||||||

| #1 | BOSCH PTK 14 EDT 0.603.265.520 | ⭐ 100 / 100 5 — votes | Find out the price | |||

| #2 | BISON ZSP-2000 | ⭐ 99 / 100 1 — vote | Find out the price | |||

| #3 | Hammer HPE2000C | ⭐ 98 / 100 2 — votes | Find out the price | |||

| #4 | Kolner KES 650 | ⭐ 97 / 100 2 — votes | Find out the price | |||

Which stapler would you choose or recommend?

Take the survey

Charging the mechanical stapler

Working with a mechanical tool is easy. However, let’s take a closer look at the process of charging a mechanical tool.

- The stapler is put on safety.

- We fold back the flap on the back of the stapler, behind which there is a groove for staples.

- A rod with a spring is pulled out of it.

- The block of staples is turned “backwards” to the handle and inserted into the groove.

- The rod returns to its place - it clamps the staples inside the tool.

- The sash slams shut until you hear a characteristic click and you can start working.

Cordless furniture staplers

These models are battery operated. The battery in the device transfers energy to the engine.

MILWAUKEE M12

The device is manufactured by an American company. The battery is connected to the handle. The handle has a non-slip coating, which makes use comfortable. The impact force is easily controlled with your thumb using a wheel. The charge can be seen on the side of the case. There are 4 diodes that display the amount of charge. The device has a very high productivity (140 rounds per minute).

Price: 13,000-15,000 rubles.

MILWAUKEE M12

pros

- comfortable handle;

- excellent store capacity;

- Convenient spout for placing the device in the right place.

Minuses

- heavy weight, bulkiness;

- considerable cost.

Stapler MILWAUKEE M12

BOSCH PTK 3.6 Li 0.603.968.120

The tool is shaped like the letter C. The device has an extended spout, which makes it more convenient to use. The battery has a capacity of 1.3 A/h. The LED charging indicator will show how much energy is left in the device. The handle is made of rubber and is shaped to hold the hand for ease of use. The tool cannot be accidentally triggered due to the tight fit function (in order for the staple to come out, you must simultaneously press the stapler firmly against the surface and hold the trigger). The productivity of the mechanism is 30 staples per minute.

Price: 4000-4500 rubles.

BOSCH PTK 3.6 Li 0.603.968.120

pros

- high battery capacity;

- Excellent value for money and quality;

- 1000 staples from the manufacturer as a gift;

- comfortable handle.

Minuses

- power is not adjustable;

- bulkiness of the device.

Stapler BOSCH PTK 3.6 Li 0.603.968.120

What kind of instrument is this?

A construction stapler or automatic staple gun is a special device used in repairs, furniture production, decoration and other work. Its task is to attach materials to the base. Its closest relative is the office stapler. But unlike its smaller counterpart, a construction tool is large in size, powerful, and various energy sources can be used for its operation.

Using the device, you can pierce both thin materials, such as films, and more dense ones - lining, chipboard, MDF and others.

Comparison of stapler models

We have also placed all the models discussed above in a comparison table to make it easier for you to make your choice:

| Model | Maximum number of beats per minute | Magazine capacity (staples) | Cost (rubles) | Device type |

| Kolner KES 650 | 30 | 50 | 1200-1700 | Network |

| Hammer HPE2000C | 30 | 50 | 3000-4000 | Network |

| BISON ZSP-2000 | 20 | 50 | 3500-4500 | Network |

| BOSCH PTK 14 EDT 0.603.265.520 | 30 | 100 | 6000-6500 | Network |

| MILWAUKEE M12 | 140 | 89 | 13000-15000 | Rechargeable |

| BOSCH PTK 3.6 Li 0.603.968.120 | 30 | 105 | 4000-4500 | Rechargeable |

| Inforce 06-09-42 | — | 100 | 600-800 | Mechanical |

| Center tool 1609 | — | 120 | 800-1100 | Mechanical |

| GROSS 41002 | — | 105 | 1200-1400 | Mechanical |

| Cobalt 240-863 | — | 150 | 1500-1900 | Mechanical |

| BOSCH HT 14 0.603.038.001 | — | 110 | 1000-1200 | Mechanical |

| STANLEY Light Duty 6-TR150L | — | 105 | 1400-1800 | Mechanical |

| Rapid R153 WORKLINE RUS 5000061 | — | 120 | 2500-3200 | Mechanical |

A few words about safety

Considering the specific area of application of the stapler, when choosing it, it is advisable to take into account safety criteria. (Read about safety features when working with an angle grinder here)

So, for example, in expensive models of instruments the following types of locks can be used:

- A safety mechanism that blocks the operation of the tool (for example during transportation);

- The device operates only in standby mode (with such protection, it will be impossible to shoot the staple into the air);

- Control of complete recession of the bracket into the fixed material.

Electric stapler

It is an improved analogue of its mechanical counterpart, and their only difference is that the operation of the impact mechanism does not require the application of muscular force, and all the work will be done by an electric drive. Taking into account the design features, the use of electric staplers is justified when a large volume of work is required. Plus, such tools allow you to work with denser materials, due to the increased impact force.

We advise you to study - What the thickness of a parquet board can be in layers and in total and what it affects

If we talk about the limitations of electric staplers, then in addition to the increased cost, we should highlight their large weight (compared to mechanical options) and the presence of a power cord. Because of this, autonomous (battery) tool models have become increasingly popular lately. (The battery recovery method can be found here).

If we talk about power characteristics, then for modern electric staplers this figure can reach 1.5 kW. This allows you to drive fastening brackets of impressive size (up to 50mm deep) with specified accuracy.

Considering the presence of an electrical component, when choosing a stapler of this type, it is advisable to pay attention to the following factors:

- The body of the device must be made of non-conductive material (usually plastic), and the handle must have a rubberized coating.

- The length of the cord should allow work to be done at a distance from an electrical outlet (the best option is a length of 5 meters or more).

- Availability of additional options (smooth change in impact force and pulse frequency, depth gauges, automatic multiple impacts (for finishing off the staple), etc.

By the way, special attention should be paid to the pulse frequency of the electric stapler. So for high-quality models, this indicator should vary between 20 – 30 beats per minute. . If we talk about the features of cordless staplers, then it is advisable to purchase models equipped with two batteries (one is in operation, the second is charging)

Moreover, the performance of the tool should guarantee driving up to 1000 staples (nails) in one charge cycle.

If we talk about the features of cordless staple guns, then it is advisable to purchase models equipped with two batteries (one in operation, the second being charged). Moreover, the performance of the tool should guarantee driving up to 1000 staples (nails) in one charge cycle.

Pneumatic stapler

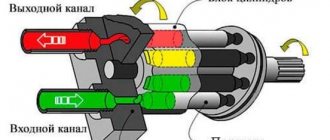

It belongs to the category of a professional tool and in most cases is used in the industrial sector. Unlike the above-mentioned analogues, pneumatic staplers do not have a spring impact mechanism in their design, and the kinetic energy required for driving the staple is created by a pneumatic cylinder, the air to which is directed using a controlled pneumatic distributor (mechanically connected to the trigger).

If we talk about the advantages of a pneumatic stapler, we should note its high productivity (up to 60 staples per minute), significant power and relatively low weight.

Whereas the disadvantages of this tool include the need to connect it to pneumatic communications (usually a pneumatic stapler requires a working pressure in the range of 4 - 6 Bar).

Specialized types of staplers:

- Cable staplers. They are used for laying low-current electrical communications (telephone lines, information networks, etc.).

- Packaging staplers. Used for quick assembly of packaging containers. They usually have a counter anvil for bending staples.

- Stapling hammers. They function like conventional mechanical staplers, with the difference that the impact energy is transferred to the staple by the hammer handle (during the swing process). They are characterized by high speed of work, but have low hit accuracy.

The best construction staplers

If a person wants to choose a stapler for repair or construction, then it is better to purchase mains or battery options. A mechanical one will not be convenient when driving into hard wood. In our opinion, the best mechanism is the MILWAUKEE M12 stapler. It has an excellent rate of fire, a powerful battery and a convenient charge indicator.

Important! It is definitely not suitable for a budget buyer, as it has a considerable cost!

Network stapler for attaching vapor barriers

How to use a stapler

Refueling

In order to load the stapler with staples (i.e. load the staple gun), you must first move away the spring intended for pressing them.

The staples themselves are placed in a special groove, in which, in fact, they need to be placed. After this, the spring is put in place. The tool is completely ready for use. Video: how to thread a stapler with staples

Now you know how to insert staples into a stapler, we can proceed directly to work.

Shot

In order to fix the necessary element, you should firmly attach the device to the place where you plan to hammer the bracket. After this, without lifting the device from the surface, you must press the trigger button (lever). If these manipulations are successful, you will hear a characteristic sound and see a staple inserted into the material.

Tips and tricks

In order to protect yourself when working with a construction stapler, you should follow some rules:

- If you use a mechanical model of the device, it is necessary to adjust the screw regulator. This operation should be performed on a piece of rough material by rotating the screw from minimum to maximum. If the staple goes in all the way from the first shot, you can start working on the “finishing” part. Otherwise, re-adjustment is required;

- In order to drive the staples at the same distance, you should first mark the necessary places with a pencil or ballpoint pen;

- Hold the material with your free hand so that when firing it does not move from the pre-designated place;

- Keep track of the number of staples in the “store” so as not to be left without a single fastening element at the most inopportune moment;

- After finishing work, secure the handle with the safety catch to prevent spontaneous or accidental firing.

In addition to all the above tips, you may also need help repairing this construction tool, since the stapler, like any other equipment, tends to break.

Repair

The most common cause of stapler failure is a breakdown of the impact mechanism. However, in order to get to it, you must first disassemble the tool. This can be done by performing a number of simple operations:

- Remove the adjusting screw;

- Remove the spring;

- Remove the protection cover;

- Remove the pins;

- Remove the lock washers.

If the list of actions does not make it clear to you how to disassemble the stapler, then you can see this in the video below.

After performing all the above manipulations, you will be able to see the drummer, which, for the most part, fails due to the exhaustion of its resource.

In order to repair this element, you should remove it, place it in a vice and, using an ordinary file, give the striker its original shape.

That's it, the repair is completed, and the instrument is again in full combat readiness.

Tips on why the stapler does not work and how to fix it:

- If your tool does not finish (does not finish) the staples, then try tightening the spring, it may have weakened;

- If a construction stapler bends the staples, try adjusting the spring tension bolt (relax or tighten, experiment). Another probable cause of malfunction is a mismatch between the type of staples and the structure of the material - for chipboard and plywood it is recommended to buy staples made of hardened steel;

- If the staples do not come out of the stapler, but bend and get stuck inside, perhaps the striker (tongue) that pushes them has become rounded and needs to be sharpened;

- If the mechanism itself works, but the staple does not fire, it is possible that the staple does not grip, or the firing pin has worn out. Try filing the firing pin and turning the damper with the other side.

Watch the video to see how to repair a staple gun with your own hands.

Video: do-it-yourself stapler repair

How to disassemble a furniture stapler, what to do if it jams. What could be the reason, what to do if the construction stapler does not fire staples:

The real-time video shows step by step how to disassemble the stapler, what could be the cause of the breakdown and how to fix it yourself, as well as how to assemble the stapler.

The best furniture staplers

Need to know! Mechanical staplers are used for repairing and upholstering furniture. They do a great job!

If you want to purchase a high-quality model for furniture repair, then the STANLEY Light Duty 6-TR150L and Rapid R153 WORKLINE RUS 5000061 will be excellent tools in this matter!

Choosing the best stapler for furniture repair

No. 1. Operating principle and advantages

The first staplers date back to the 18th century. They appeared in France, at first the design was intended for fastening sheets of paper, then a mechanism for connecting thin, but already brass sheets was patented. Years have passed, new solutions have appeared, and today we are fortunate to use a tool that allows us to perform many operations. When the first construction staplers were in the hands of domestic craftsmen, they used them to fasten literally everything, even drywall to a wooden frame and cork wallpaper to the wall.

The construction stapler has many names, both professional and popular: tacker, nailer, stapler, stapler, stapler. Surely, there are some other names, and all of them in one way or another hint to us about the principle of operation of this tool.

The design of a construction stapler is simple. The main element is a spring, coiled or flat spring. The spring first compresses and then expands, giving force to the staple and driving it into the material. How is the spring compressed? Thanks to muscular force in mechanical staplers, or thanks to the motor - in electric ones. There are also pneumatic staplers, they work somewhat differently, but in everyday life and even when performing repair work, such models are rarely used.

The stapler can work not only with staples, but also with nails, pins and some other fasteners. Some models, like their stationery counterparts, can bend the paperclip tabs from the reverse side.

We advise you to study - Fusion style in the interior - feel the freedom

The main advantages of a construction stapler include:

the fastening process takes less time and effort compared to using a hammer, and you won’t be able to hit your fingers; one hand always remains free, and when performing work, for example, on a stepladder, this is very important; the ability to mount in hard-to-reach places; precise transfer of impact energy, so you can work with very complex surfaces without fear of damaging them; durability and reliability of the tool, because there are a minimum of parts in it - there is nothing special to break; multifunctionality.

Note that not every fastener can be hammered using a tacker, although the tool has long gone beyond just a staple driver. Each type of stapler (mechanical, electric and pneumatic) has its own disadvantages, which we will discuss below.

Which stapler is better to choose?

There is no definite answer to this question. The choice may depend on many factors:

- purpose of the stapler;

- buyer's budget;

- required performance;

- duration of work.

The best solution is to take your time! Look again at all the models on our website and decide which one suits you best.

We also invite you to watch a video that will help you choose a tool!

Video - How to choose a stapler

Materials required to operate the stapler

A pneumatic stapler operates using a compressed air compressor.

Usually when the term “type of staple” is used, they mean its thickness. Available in different sizes and widths of staples. In European countries, staples are most often used:

- thickness - 0.75 mm;

- width - 11.4 mm.

Basically, there are many types of staples with different dimensions. The choice of consumables depends entirely on the task at hand. For example, long staples are best suited to create high loads. To fasten not very durable material, for example, polyethylene film, it is better to use thick staples. When fixing a cable, the choice of bracket depends on its diameter.

If you work with a branded stapler, you must definitely purchase branded staples. They differ in many ways from their regular counterparts. They have many positive qualities and lack corrosion.

These brackets are made of stainless material and have a galvanized surface. Besides:

- superbly sharpened;

- they correspond to all drawing data;

- the slipway is characterized by absolute accuracy;

- have a warranty period.

The presence of a guarantee indicates the originality and quality of such material.

It is always a pleasure to use such a device. I installed the staples in the magazine, pressed the stapler, pressed the lever, and that’s it - the material was securely fastened. But there are times when the staples do not fly out due to the charger. All that remains is the trace of the striker. There is only one conclusion - it needs to be repaired. To do this, you need to disassemble the stapler in a certain sequence:

- remove the adjusting screw;

- remove the spring;

- remove the protective cover.

- remove the pins;

- remove the lock washers.

To carry out repair work you will need:

- pliers;

- screwdriver;

- hammer;

- vice;

- file.

After this work, it will be possible to examine the striker. The main failure of the tool is the wearing out of the thrust pad of the striker body. With its help, the joint operation of the trigger lever and the impact mechanism is ensured.

The drummer is the main executive part of the stapler. It is pressed by a powerful spring, the force of which can be adjusted with a special screw.

The charging carabiner is fixed at an angle of 90° relative to the impact device. It contains brackets that constantly perceive the influence of the spring. When not in use, the brackets are closed by a special plate attached to the body.

The trigger system is responsible for the joint operation of the firing pin combined with the charging device. It contains:

- cocking lever;

- powerful spring;

- rocker.

To hammer in the staple, you need to press the lever. The rocker arm bracket will lift the hammer. The spring will stop compressing when the staple enters the firing pin mechanism. With great force, the striker hits the bracket, it hits the base.

In fact, the main criterion for the normal operation of a construction stapler is the compliance of several operations:

- drummer platoon;

- supply of staples.

https://www.youtube.com/watch?v=mSQ9Oqg45vA

The work of the drummer must be synchronous with the rocker arm. If this does not happen, it means that the shot was fired “dry”. In other words, the trigger device was cocked and triggered, but the striker at this time was unable to capture the bracket. This is exactly what happens when the thrust pad of the firing pin protrusion wears out greatly.

The repair will take a little time. You need to clamp the drummer in a vice. Use a regular file to sharpen the protrusion and give it its original shape.

Similar actions can significantly extend the life of the stapler. You just need to do this repair operation immediately after the gun starts working “idle”. During repairs, the striker plate will be shortened, since it will need to be sharpened all the time.

These convenient and ergonomic devices have won well-deserved appreciation from both professional furniture makers and home craftsmen. There are even models of staplers on sale that can work with small studs. Using a hammer, with almost inevitable injuries, is gradually becoming a thing of the past. In addition, the speed of work increases significantly. However, this design sometimes becomes unusable. Frankly speaking, I don’t want to throw away my old stapler. Let's talk about how to repair a furniture stapler yourself.

Voting for the best stapler

Which stapler would you choose or recommend?

Rapid R153 WORKLINE RUS 5000061

8.33 % ( 2 )

STANLEY Light Duty 6-TR150L

12.50 % ( 3 )

BOSCH HT 14 0.603.038.001

12.50 % ( 3 )

COBALT 240-683

4.17 % ( 1 )

GROSS 41002

8.33 % ( 2 )

Center tool 1609

0.00 % ( 0 )

Inforce 06-09-42

8.33 % ( 2 )

BOSCH PTK 3.6 Li 0.603.968.120

0.00 % ( 0 )

MILWAUKEE M12

4.17 % ( 1 )

BOSCH PTK 14 EDT 0.603.265.520

20.83 % ( 5 )

BISON ZSP-2000

4.17 % ( 1 )

Hammer HPE2000C

8.33 % ( 2 )

What is a stapler player

The stapler is similar to the office stapler, but with one exception. Instead of having an upper lever that is engaged to create the fastening functions, a lower handle is used instead. That's why the design is called "pliers". Essentially, it is a hand-held tool that can be used to easily stitch together sheets of paper, fabric and cardboard.

Throat depth is not an indicator of sheet capacity and this is where most people run into trouble when shopping in this particular category. A stapler with a throat depth of less than 5 cm can have a sheet capacity of up to 45, while a standard throat depth of 5 cm, 12 cm, 20 cm may not even hold up to 20 sheets of paper.

The stapler is similar to the office stapler, but with one exception

Throat depth is not an indicator of sheet capacity

The type of materials you plan to fasten also plays a role.

Think about your needs when choosing a tool

Staplers are heavy duty pliers, have pneumatic or electrical components

With such a wide range of stapler functions available today, it is important not to go wrong when choosing a specific tool.