DIY float for a water tank

The toilet is truly considered a truly indispensable fixture in every home.

When any malfunctions occur in such plumbing mechanisms, everyone tries to determine the cause and carry out repairs as quickly as possible.

To adjust the optimal filling level and timely stop the water supply, a special float valve for the toilet is used.

However, such devices can quickly break down. Therefore, it is advisable to familiarize yourself with information on how to avoid the occurrence of various difficulties and prevent their development.

Operation of the filling mechanism in the tank

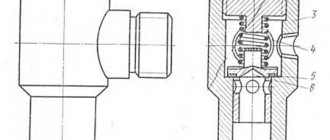

Float valve for toilet

To begin with, you will need the most detailed familiarization with the design features and operating principle of such tanks.

This makes it possible to carry out sufficient repair work at a professional level with your own hands without outside help.

This ensures significant savings in the family budget.

As one of the main structural elements of the flush tank, a special button is used, interaction with which allows you to direct the flow of water into the container of the plumbing fixture, so that everything is flushed under pressure into the drainage system.

Filling is carried out in various ways:

Upon superficial inspection, the mechanism of the tank seems quite simple. Visually, only the float device and part of the drain mechanism are determined.

In reality, the design of all components cannot be called so simple. The float valve circuit includes the following components:

A screw device is installed on the float, with the help of which the filling process is regulated. When such a screw is turned, the height of the float changes in accordance with the direction of rotation.

In this way, the most convenient volume of water for the drainage device is selected. This function is quite useful in situations where there is a need for more thorough flushing or saving utility costs.

The drainage device in most models consists of several main components:

The operating principle here is extremely simple. The body, which in most models is made of plastic, contains a valve with a system of levers that connects it to a device for flushing liquid.

The mechanism also includes an overflow device that prevents water from spreading across the floor. When the tank is empty, the overflow system ensures that water re-enters.

Design and application of a float water level sensor

Float liquid level sensors are considered the most reliable and cheapest devices for determining the amount of substance in a container . Due to the simplicity of their design, float-type sensors are widely used in almost all areas of industry. They remain indispensable assistants in everyday use.

Based on their location in the tank, float switches can be divided into vertical and horizontal .

The use of float sensors with a vertical rod arrangement is much more common than horizontal indicators. Reed switches are located inside the vertical rod. The float is always located on the surface of the liquid; there is a magnetic ball inside it. Approaching the reed switch, the magnetic field causes the contacts to activate, which serves as a signal that the container is full. This signal triggers the relay contacts on the pump.

If installing a vertical rod in a tank is difficult, then the sensor is mounted on the wall in a horizontal position.

Float switch for electric pumps

Such a device is designed to automate the operation of electric pumps in various water supply and sanitation systems. The principle of operation of the switch is very simple - turn on or off the electric pump when the required liquid level is reached . Switches come with two contacts or three contacts . A two-prong switch simply connects an electrical circuit when it is in the “off” position or disconnects it when it is in the “on” position.

Three-wire switches are a universal device where there is one common contact, and switching is carried out between the other two. In one position, the electrical pump control circuit is connected by one wire, and in the other by a second. Therefore, such switches can operate both when the container is filled and when it is completely empty.

The plastic housing of the switch can have different shapes (rectangular, round, oval) and is waterproof and sealed. The presence of air inside the housing allows the switch to be constantly floating. The metal ball, which is located inside the housing, rolls and switches the electrical circuit of the pump relay. To ensure high-quality contact when closing, there are magnets in the switch body. Thanks to them, the ball is securely fixed in extreme positions. The strength of the magnet is designed to firmly hold the ball at an incline of up to 70°.

Float Valve for Water Tanks

The float valve provides control of the water level in any open tank . Its work is carried out without human intervention. Therefore, the system using such a valve is fully automatic.

The float valve consists of:

A valve is installed inside a specific container intended for storage and, if necessary, for autonomous water supply if there is no central water supply.

The operating principle of the valve is very simple. If the water level has dropped, the float lowers, opening the valve and access to the water supply. When completely filled, the float rises, closing the valve.

As can be seen from the article, in many cases, the installation and maintenance of control systems for monitoring the liquid level in a tank does not present any difficulties. Therefore, it’s easy to set it up yourself. And also, having at least a little knowledge of electrics, it is not difficult to connect the pump yourself.

Homemade water level sensor in a summer shower

After installing a new barrel with a larger volume on the outdoor shower, the need arose to install some kind of “sensor” for the water level, so as not to constantly climb onto the roof of the shower, and besides, the new barrel is equipped with a lid that is fixed with a clamp, and you have to constantly remove it and I don’t really want to see how much water is left.

So I installed this easy-to-make device. Necessary materials:

– polystyrene foam (I found a piece like the one in the photo in a box from a gas stove; they are used to cover camphors during transportation.); – small nut; – large nut; – long screw; – two pieces of plastic strip; - fishing line.

Operating principle of a float valve

In tanks made using old technologies, a toilet float valve with a bottom supply is installed. The main purpose of such a device is to ensure the optimal filling level of the tank.

The main disadvantage of such devices is the increased likelihood of failure. In addition, splashes are formed, as well as some other undesirable phenomena.

As the float is filled, it changes position. This ensures that the water supply process stops if its level reaches a certain level.

Design highlights of the mechanism

Let's look at what a valve with a float for a toilet is, and what specific elements are included in its design:

To regulate the amount of water on the float there is a special screw. While you rotate it, it becomes possible to change the position of the element to the required height. This achieves an ergonomic water level for the toilet to operate. There are also models where the iron lever is replaced by a plastic hinge with a screw in the middle.

Tip: by adjusting the level, you can achieve a more thorough flush of the toilet bowl or save water consumption.

How the device works

In sanitary facilities of dilapidated models, the principle of operation of the toilet float was a simple and reliable design. Its main purpose was to ensure the required water level in the drain tank.

The main disadvantage of the design was its periodic failure. As a result, water began to flow into the toilet bowl in a continuous stream.

The mechanism of its operation is as follows:

After pressing the drain button or lifting the bulb up, the reverse process begins to occur. Due to the decrease in water in the tank, the float lowers, as a result of which the lever releases the piston and water begins to flow into the tank.

Selecting a float valve

We should immediately state that if a mistake is made when choosing a device, there will be no point in repairing it. In addition, while you fix everything, after a couple of days the water from the container will start leaking again.

The right choice depends on knowing the pressure in the water supply.

There are 4 types of devices, which are classified by water pressure, for:

and stabilizing. We recommend the latter to owners of apartments and houses located in areas where the pressure in the water supply is unstable.

If you don’t want to repair mechanisms with your own hands quite often or change them, then you need to carry out their preventive maintenance. Periodically inspect for possible damage. In this way, you will protect yourself and your neighbors below from unplanned expenses.

Device malfunctions and circumstances of their occurrence

Knowing the structure and mechanism of operation of the drain tank and float, it is possible to carry out repairs without much difficulty in the event of incorrect operation. Let's look at an example:

| Flaw | Deficiency indicator | Repair methods |

| Gasket No. 5 is worn out | Water from the water supply invariably flows into the storage tank and is not shut off | Replace gasket |

| Saddle No. 4 has rust | It is not possible to shut off the flow of water into the tank | Replace the entire valve or perhaps install a soft rubber gasket |

| The float takes in water | The float does not float up and the piston does not move lever No. 2 | Replace the float or turn it upside down if it is small |

| Lever axis No. 2 is worn out | The piston does not press well and the lever gets stuck, it is not possible to turn off the water | Replace the axle. It is also possible to use a stainless steel nail of suitable diameter. But, if the wear is enormous, install a new lever No. 2 |

| Damage to thrust cap No. 7 | In this case, water can flow through the entire valve | To replace the part, you can use any suitable bottle cap |

Tip: remember that the float mechanism may vary between different toilet models. For example, there are options that are hollow in and sealed on all sides, but there are also configurations that in appearance resemble an inverted glass.

In the second case, the device may fail due to very heavy contamination. If this happens, it will be closed and the float will begin to function again.

Closing valve does not work

It is possible to cope with the problem on your own. In most cases, the cause of the breakdown is the membrane or holes through which water enters the tank. The latter can become clogged due to debris that enters the water supply system.

Don’t forget, such membranes often fail, so when choosing a replacement, give preference to higher quality products, the price of which cannot be very low. Then it will take a long time before the next repair.

If you cannot purchase it, it is temporarily possible to make it yourself. Take the old membrane, which will act as a template, and apply it to hard rubber up to 2 mm thick. Cut out the part of the desired shape and size using this template.

Replacing and adjusting the device

When the float cannot be repaired, it must be replaced.

Do the following:

Drewpatch68 › Blog › Living intricately or DOING YOUR OWN HANDS PLUMBING!

I found such an interesting idea from one comrade Radomir Mirolyubov. He installed good plumbing in his house. I'm sure it will be useful to someone.

Enjoy if anyone is interested!

The simplest, fastest and most inexpensive option is to install a pumping station underground. However, the big disadvantage here is that if there is a power outage, there will be no water in the house either. Therefore, I chose a more expensive option: a pump in the well + a 200-liter barrel in the attic. Then, even without electricity, there will be enough water for two to three days if used sparingly.

1. Drainage pump Gilex 220/14 for clean water (pumps 220 liters per minute horizontally, maximum water lift height is 14 meters). The cost starts from 3600 rubles, but it works silently. Before this, we used a cheap vibration pump of the “Baby” or “Rucheyok” type. They transmit strong vibrations through the water, well rings and pipes into the ground, and this is bad for the water and for the moles and for the well itself.

2. A 32mm HDPE pipe (from the well to the barrel in the attic) is laid at a depth of about 1.5 m with a slope towards the well. As soon as the pump stops pumping water up, it immediately drains from the entire pipe back through the pump into the well, so the pipe is always “dry” and there is nothing to freeze there. My neighbor had such a pipe even going through the air from the well to the 2nd floor of the house (about 20 m), and the water in it did not have time to freeze even in the most severe frost (up to 30 degrees).

3. A 200-liter plastic barrel sits IN A COLD UNHEATED ATTIC! It's only a few degrees warmer there than outside. To prevent the water in it from freezing, I made a cap out of hard foam, 5cm thick (10cm on top). Just in case, I installed a 1.5 kW heating element in the barrel, and a 40 cm section of pipe from the barrel to the bathroom (which constantly contains water) was well insulated and equipped with a heating cable. All this will turn on only in case of freezing for 1-2 hours (reinsurance is shorter). This year there were 3-4 days minus 15 degrees, nothing froze, I’ll write what happens next later.

4. The pump is controlled by a “frog” switch installed in a barrel (sold separately in stores that sell pumps). This is an ordinary sealed float with two pairs of contacts and a ball that opens and closes them. As soon as the water raises the float above the desired level, the ball rolls back and turns off the pump.

5. In case of overflow, provision was made for emergency drainage and forced shutdown of the pump using an ordinary switch. That is, if the level has already been exceeded, and the pump continues to pump water, it will loudly drain through the emergency pipe into the shower stall, and then you can come up and forcefully turn off the pump. Through this empty pipe, warm air from the bathroom goes directly into the barrel of water and also prevents the water from freezing in winter.

6. In summer, the attic is hot from the roof, so condensation will form on the barrel of cold water (well water is +4 degrees in both winter and summer). In summer, a foam cap works to reduce temperature differences and condensation. In addition, the barrel stands in a metal tray, where you can look in the summer and remove excess condensate.

7. There was a problem with the water pressure for the automatic washing machine. 3 meters of water column is 0.3 atmospheres, and all instructions for washing machines indicate a minimum pressure of 0.5-1 atmospheres or even more. While clarifying this issue, I pestered all the managers and sellers of washing machines that I came across. It turned out that almost any model works with this pressure without problems, it just takes a little longer to fill the water. And only some, the most “smart” and expensive washing machines, detect the time of pouring water into the drum, but nothing may work with them, they will give an error and refuse to work. Another possible consequence of low pressure is a high probability of refusal of warranty repairs or replacement of a faulty washing machine.

8. Should I install a pump that increases pressure or not? With it, water flows from the shower at normal pressure, but the water consumption with it is higher and there is an additional connection to electricity. I have nothing against it, but I decided to do without it. I had to lower a 32mm HDPE pipe from the attic and do all the wiring with a 25mm PP pipe. As a result, there is enough pressure, although I would like more for the shower, because it is raised 2 m from the floor and the level difference remains a little more than 1 meter of water column. There is an option to install a booster pump and use it only when you take a shower, and turn it off the rest of the time, then the wiring can be made from a thinner and cheaper pipe. For myself, I have decided for now that I will leave everything as is, I will not cut into the pump.

Difficulties that arise and tips for eliminating them

Being aware of the peculiarities of the functioning of the tanks and, of course, the float itself, you can make adjustments without any difficulties. Most often, the float breaks in several cases.

Sometimes the water supply to the tank completely stops. In other situations, water continues to rise after reaching the optimal level.

Such troubles can be caused by individual design components, for example, a float or a special shut-off valve.

The design of the floats, depending on the type of toilet model, may differ significantly. Some floats are hollow and hermetically sealed.

Often designs are designed that resemble an ordinary inverted glass. If the structure is hollow, when liquid enters the device completely loses its functional features.

The second float option most often fails when too much dirt accumulates in it. In this case, you can simply perform the cleaning procedure and the float valve of the side-facing toilet mechanism will work normally.

Select and buy a float valve for a container or tank

Using modern solutions and the necessary equipment, you can automate various processes of dacha life. Turning the well pump on and off for water supply, energy saving, heating - all these are important elements of country life.

An important factor is watering the garden, and heated water in the reservoir is the key to the health of your plants. To maintain automatic control of the water level in the tank, you will need a float valve for the tank as well as several fittings for its installation.

Let's look at the different types of these devices.

Before you buy a mechanical or electric type float valve for a tank, think about the implementation of your goals. It is necessary to take into account the productivity with which water will be drawn from the tank, as well as the volume of the irrigation tank itself.

At the same time, your tank will quickly fill and warm up, which means the time between watering cycles will be significantly reduced.

This float valve for a tank has a waterproof body and a wire of 3 or 6 meters. It can also be used to turn the automatic pump on and off during dry running by setting the float to the lowest point of the water level.

In this case, you do not have to constantly turn on the pump by hand when the automatic operation is activated during dry running. This solution is very convenient if you rarely visit the site, and the water in the village water supply runs rather slowly. The energy dependence of the system on a constant power source is perhaps the only negative.

If this is not available, you should consider a 1” mechanical type float valve.

Upon supplying the top-up pipe, a hole of 1” or 25 mm is made in the tank. The valve itself with a crimp nut and a rubber gasket is inserted into it. At the output we will get a threaded pipe for connecting the topping pipe using a fitting.

We adjust the plastic float of the valve to the maximum water level by loosening or tightening the nut on the movable float arm.

All is ready! We open the main valve to supply water to the tank; as it fills, the float will move to the upper adjusted level mark, and the valve mechanism will block the access of water to the tank.

Thus, the main control of the water level in the tank is provided by an electric float valve for the tank, and auxiliary control is provided by a mechanical float valve for the tank. In the event of a malfunction of the top-up electromagnetic valve (membrane clogged, old age, leakage, etc.)

) the mechanical valve will stop adding water to the tank when it reaches its maximum level. This method will protect the container from overflowing and unforeseen consequences for its owner.

Advantages

Among all the advantages that a float switch has for controlling water level, the first thing that should be highlighted is that it is capable of performing the function of a conventional sensor for determining the water level in tanks.

Moreover, it successfully performs this task, even regardless of the purpose for which the container is used and what its volume is. At the same time, this water level control device can help make the operation of pumping equipment more convenient. With the help of such a device, monitoring the functions of industrial and domestic water supply systems is simplified. In some cases, it can be used to successfully drain fluid. Also, a float switch for controlling the water level can be part of the equipment when constructing sewer lines. The simplicity of operation and the high efficiency of its use have ensured that the float switch is widely used in a wide variety of systems where the task of water control arises.

It is worth noting that the ability to provide reliable protection for pumping systems during dry-running operation is not the only positive quality of such devices. At the same time, with their help you can avoid situations where water overflows into containers.

Difficulty with the shut-off valve

If malfunctions of the shut-off valve occur, everyone can cope with them without much difficulty on their own. The most common cause of such malfunctions may be the membrane, as well as special water-conducting devices that can become clogged from time to time.

Most often, the cause of such malfunctions may be the membrane, as well as water-conducting mechanisms, which tend to become clogged periodically.

To resolve such problems, simply disassemble the float device. A removable cap is provided for this.

After this, the membrane is removed, cleaned and installed in its proper place. The cap must be screwed back on.

In most examples, membranes often fail, so when replacing it, you need to select sufficiently high-quality products that are guaranteed to last as long as possible. If it is difficult to purchase such a device, there is always the possibility of making a new element with your own hands in accordance with the specifications of the instructions.

An old faulty part can be used as a suitable template. It needs to be leaned as tightly as possible against thin, hard rubber. After which the required shape is cut out in accordance with the design features of the existing sample.

Design and application of a float water level sensor

Float liquid level sensors are considered the most reliable and cheapest devices for determining the amount of substance in a container . Due to the simplicity of their design, float-type sensors are widely used in almost all areas of industry. They remain indispensable assistants in everyday use.

Based on their location in the tank, float switches can be divided into vertical and horizontal .

The use of float sensors with a vertical rod arrangement is much more common than horizontal indicators. Reed switches are located inside the vertical rod. The float is always located on the surface of the liquid; there is a magnetic ball inside it. Approaching the reed switch, the magnetic field causes the contacts to activate, which serves as a signal that the container is full. This signal triggers the relay contacts on the pump.

If installing a vertical rod in a tank is difficult, then the sensor is mounted on the wall in a horizontal position.

Float switch for electric pumps

Such a device is designed to automate the operation of electric pumps in various water supply and sanitation systems. The principle of operation of the switch is very simple - turn on or off the electric pump when the required liquid level is reached . Switches come with two contacts or three contacts . A two-prong switch simply connects an electrical circuit when it is in the “off” position or disconnects it when it is in the “on” position.

Three-wire switches are a universal device where there is one common contact, and switching is carried out between the other two. In one position, the electrical pump control circuit is connected by one wire, and in the other by a second. Therefore, such switches can operate both when the container is filled and when it is completely empty.

The plastic housing of the switch can have different shapes (rectangular, round, oval) and is waterproof and sealed. The presence of air inside the housing allows the switch to be constantly floating. The metal ball, which is located inside the housing, rolls and switches the electrical circuit of the pump relay. To ensure high-quality contact when closing, there are magnets in the switch body. Thanks to them, the ball is securely fixed in extreme positions. The strength of the magnet is designed to firmly hold the ball at an incline of up to 70°.

Operation, maintenance and repair

Long-term operation of pump floats can only be ensured if the rules for their use are not violated. In a situation where the float switch is part of the water supply and sewerage system, you do not have to waste time and effort on its maintenance. If this device controls the operation of fecal or sewer pits, then it is recommended that at least once a month the float and pump be cleaned of dirt using a jet of water supplied under pressure.

This procedure will prevent the float from sticking or sticking to the pump or discharge pipe. A float switch, which due to certain circumstances is not able to perform its main task, is not repairable, so in such situations it is replaced. This work should be performed by service center specialists.

How does the drain tank work from the inside?

Absolutely any toilet tank, regardless of its design features, fills the drainage container with water , normalizes the volume of liquid and directly flushes the toilet. In this case, a standard ceramic container has the following structural elements:

The water supply valve is a structural element of the tank , responsible for the flow of liquid from the plumbing system. In addition, such a mechanism controls the volume of water in the tank. To control the liquid level in the drain tank, it is equipped with a float. The principle of operation of a float valve is based on the floating of a float, which raises a lever that activates a plug that blocks the flow of water into the container when it reaches a certain level.

In turn, the overflow device is responsible for redirecting excess water directly into the toilet. This is necessary to prevent the tank from overfilling. Structurally, the mechanism is a small plastic tube, which is located in the central part of the tank. At the same time, in order to adjust the water level in the tank, this mechanism is lowered down or raised up, respectively reducing or increasing the volume of liquid.

Drain fittings are installed in the flush tank to ensure that water exits the tank directly into the toilet. When you press the drain button, it uses a special lever to trigger the mechanism for draining water from the tank, which flushes human waste into the sewer.

Source

Homemade float switch

If you have the time and desire, then you can make a simple float water level sensor with your own hands, and the costs for it will be minimal.

Mechanical system

In order to simplify the design as much as possible, we will use a ball valve (faucet) as a locking device. The smallest valves (half-inch or smaller) work well. This type of faucet has a handle that closes it. To convert it into a sensor, you need to extend this handle with a strip of metal. The strip is attached to the handle through holes drilled in it with the appropriate screws. The cross-section of this lever should be minimal, but it should not bend under the influence of the float. Its length is about 50 cm. The float is attached to the end of this lever.

You can use a two-liter plastic soda bottle as a float. The bottle is half filled with water.

You can check the operation of the system without installing it in the tank. To do this, install the faucet vertically and place the lever with the float in a horizontal position. If everything is done correctly, then under the influence of the mass of water in the bottles, the lever will begin to move down and take a vertical position, and the valve handle will turn with it. Now submerge the device in water. The bottle should float up and turn the valve handle.

Since valves vary in size and the amount of force required to switch them, the system may need to be adjusted. If the float cannot turn the valve, you can increase the length of the lever or take a larger bottle.

We mount the sensor in the container at the required level in a horizontal position, while in the vertical position of the float the valve should be open, and in the horizontal position it should be closed.

Purpose and principle of operation

When water, oil or fuel mixture is consumed, the float lowers , with a downward thrust, and the lever stops pressing on the piston.

This in turn leads to the stop cap. Under water pressure, the piston moves back and liquid flows into the reservoir until the pressure is restored. Using the device, the following goals are achieved:

The modern models produced are high-quality and silent, regardless of the scope of application - at home or for professional needs .

Valve modifications are different:

The latter type is necessary when working with increased hygiene conditions or in aggressive environments. At the same time, it is undemanding to control, operates stably, is easy to clean and has a well-thought-out design with different connection methods.

There are two main types of products:

A mechanical water valve is often used in everyday life, for example, it is a float in a toilet flush tank.

The second type performs the functions of a signaling device and is used to turn on or off electric pumps when the level of the liquid medium changes. It is optimal to use it for frequent consumption in a small container. A float valve for water tanks can be used in conjunction with a solenoid valve to keep running automatically and prevent it from idling without water.

Features of choosing a device

The design of the float provides for different installation methods:

In this case, the valves can close or open when or other liquid medium in the container decreases

The choice of valve is determined by three parameters:

Possible mechanism malfunctions

Despite the simplicity of the device, breakdowns of individual components of the mechanism are possible. Evidence of a malfunction is that:

All these signals indicate that the membrane has failed or the water inlet valve is clogged.

It is also possible that the seal of the amendment itself is broken, and water is poured inside, preventing it from floating to the surface. In this case, repairing the mechanism does not make sense and the entire structure must be replaced.

Difference between different types of sensors

The design of water level detectors differs depending on the area of use and the conditions for measurement accuracy.

The following types of sensors have become most widespread:

- float;

- electronic;

- reed switch

Each of these options has established advantages and can be recommended for installation. The choice of a specific modification depends only on the conditions imposed on the device, including measurement reliability, safety, service life and stability to external conditions.

Thus, float detectors are considered a more economical type, providing acceptable measurement reliability, and are often used in everyday life. And innovative electronic level gauges are used in complex mechanical systems to monitor accurate values.

It is worth noting that electronic systems can be used for ordinary tasks, however, such a step is unjustified from a financial point of view.

The main component of a float type level meter is the sensor head. The cable entry is most often made with a hermetic lining. All seals in the devices are used of both plastic and silicone types. The release flange of the models contains special holes. The connecting wire is located at the bottom of the device. There is a small insulating plate under the sensor head. The loading capacity of the device depends on the type of output contact.

Electronic

Electronic sensors are produced on the basis of different types of meters. The only option is capacitive detectors, which allow you to detect level changes in real time . One of the positive aspects of similar devices is the absence of moving components, which has a beneficial effect on the reliability of operation and its service life.

The operating principle of such a level gauge is based on changing the capacitance of the capacitor depending on its composition and the distribution of dielectric material between the plates. In this case, there is a change in the level of the capacitor, inscribed in the electrical circuit, changing its own capacity, which is secured by special equipment.

To ensure the accuracy of the readings, the sensor is calibrated directly in front of the structure, taking into account the properties of the measured water. Capacitive sensors are used not only to control the degree of water, but also other liquid and bulk materials.

With absolutely all the advantages of the meter , it is necessary to take into account the interdependence of the characteristics on temperature, therefore, to accurately measure the level with variable temperature, you should in addition install a temperature sensor to correct the obtained values.

Optic

The second type of electronic water level sensor needed is optical. This device is used as an alternative to float sensors when there is a significant likelihood of water vibration (which in automatic systems leads to distortion of the obtained indicators). Optical detectors are used to monitor the maximum water level. The operating rule is based on a change in the reflectivity of the optical system when water reaches a specific level.

The positive aspects of similar meters include the absence of moving elements and independence from external conditions. Optical level gauges are used in transport to control the level of coolants and in household appliances (coffee machines). Often installed to measure the maximum level in tanks that are transported by road or rail (vibration resistance).

In general, all electronic sensors are free from the key shortcomings of automatic analogues, and make it possible to carry out measurements with significant accuracy. The only limitation is the higher cost and the need for professional installation and configuration.

Reed water level meter

One of the most famous types of meter, representing an improved type of float devices with an automatic switch. Reed level meters are distinguished by their low price, simple and reliable system, and, in addition, the ability to monitor level changes over a wide range.

There are a number of types of reed switch meters:

- Dry.

- Mercury.

In its simplest form, the mechanical switch of the float meter is changed to a contact, which somewhat increases the safety of the device (thus, reed level meters of a side design are organized). But more often a model with several installed reed switches and a float with special magnets is used.

As a sample, we can analyze one of the most well-known systems. The device is made in the form of a tube through which the float can easily move. Reed switches are formed from inside the tube, the number of which can vary depending on the conditions for the discreteness of the measurement. That is, the more water levels need to be monitored, the greater the number of reed switches that need to be determined.

When water indicators change, the indicator rises or falls, triggering the built-in magnet to turn on the reed switch, which is included in the control circuit. In its simplest form, one reed switch is used to signal the maximum level.

The housing of reed switch meters can be made from different materials; plastic is used in an economical form; more expensive and durable modifications are made from stainless alloys. The selection of the material used mainly depends on the location in which the device will be installed (requirements for mechanical strength and strength).

Reed detectors are one of the most well-known devices and are often used in home independent water supply systems. The elementary system makes it possible to make the device yourself, while its safety and measurement reliability will be at a high level. Reed level sensors can be used for different liquids.

In particular, these devices are widely used to control the level of fuel in vehicles and are used in the chemical and oil and gas industries.

Use in everyday life

A float valve for the water level in a tank for irrigation or an outdoor shower in the country has become widespread.

The simplest design is connected to a barrel for collecting rainwater and is connected with a hose that drains the excess into a drainage ditch. When filling the barrel, in order to avoid overflow, the float blocks access to the barrel, and excess water is removed from the house. In fecal and sludge pumps, the presence of a float allows owners to free themselves from constant monitoring of the level of wastewater in septic tanks and drainage wells. When a certain waste limit is reached, the float turns on the pump and the liquid is removed for further purification naturally in the filtration field.

In this case, special attention must be paid to the correct installation of the pump. Since the float is located outside the device, when immersed in a drainage well or septic tank, you need to carefully check that the lever does not catch on the walls of the container and can move freely. Otherwise, the float valve in the container or tank will not be able to regulate the level of wastewater, which will lead to rapid failure of pump parts or to burnout.

Instruments with float valves should not be used in sub-zero temperatures as frozen liquid will cause damage. To avoid this, you need to either install heating in the room where the container is located, or drain the tank and the float valve itself so as not to damage the plastic parts and the membrane.

Source

Equipment classification

Float sensors can independently monitor the liquid level or send a signal to the control circuit. According to this principle, they can be divided into two large groups: mechanical and electrical.

Mechanical devices

Mechanical valves include a wide variety of float valves for the water level in the tank. The principle of their operation is that the float is connected to a lever; when the liquid level changes, the float moves this lever up or down, and it, in turn, acts on the valve, which shuts off (opens) the water supply. Such valves can be seen in toilet flush tanks. They are very convenient to use where you need to constantly add water from the central water supply system.