If you need to connect pipes, the American one is the ideal option. After all, later, when performing repair work, there is no need to dismantle part of the network.

It is impossible to assemble a pipeline from a single pipe. It is necessary to perform turns and connections of pipeline elements to obtain the desired configuration. Fittings have always been used to make joints.

You can also carry out installation using a coupling, which in the standard version is a threaded part. When connected, it is screwed onto the threaded part.

The next part is twisted into the coupling by rotation, and such an operation (especially if all the elements are large) represents quite a noticeable inconvenience.

We suggest you read the article which describes how to connect a metal pipe with a polypropylene pipe + video instructions.

What is an American

The connecting part in this design consists of three parts:

- threaded fittings - attached to one part of the water supply at the connector;

- counter pipe with collar - installed on the other end;

- union nut - installed on a fitting with a collar before installing it in its location.

Next, when the nut is screwed in with pressure on the shoulder, the fittings are pulled one to one and these two parts are compressed. To ensure the tightness of the joint using a coupling, gaskets are used. And with a conical joint, it is not necessary.

If it is necessary to dismantle a section joined using an American connection, it is enough to unscrew the nut, while the mating elements of the pipeline remain motionless.

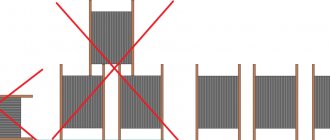

Types of docking points. The number of design solutions for installation corresponds to the number of varieties of molded products.

Advantages and disadvantages

Why are American fittings so good that they are used almost everywhere? There are many advantages:

- The speed and ease of installation and dismantling is very high. No tow planted on paint or sealant. Even after several years, the connection can be easily unscrewed. At any time you can remove, say, radiators for cleaning. Or during repairs - so as not to have to worry about gluing wallpaper behind the radiator. Remove the boiler for cleaning. Well, you get the idea. Any device can be easily disconnected from the pipeline, and then just as easily connected back.

- Any home craftsman can install and remove the fitting - no special skills are required.

- Compact and versatile. The thread on the union nut can be external or internal. In addition, there are straight, angled American (different angle sizes), tees, crosses and other fittings. Almost all plumbing fittings have recently been produced with American fittings. These are taps, thermostats, filters, check valves, etc. That is, any node can be assembled.

Some types of American women

There are also disadvantages of this combination. Since the connection is detachable, it is not recommended to wall it up. It must be serviceable. That is, it should always be possible to tighten it, replace the gasket (if there is one), or even replace the nut. The second disadvantage is the high cost, which is due to the need for precise cutting and polishing of the thread.

By type of materials used

Installation of water supply systems using a coupling requires the use of homogeneous elements, primarily in order to avoid electrolytic corrosion, therefore fittings are produced in various designs:

- Steel - the main disadvantage of the material is its susceptibility to corrosion. The life cycle of such parts is also limited by the tendency for lime deposits to form from water on internal surfaces.

- Copper - less susceptible to corrosion, used only on pipelines made of the same material.

- Brass - the most popular in use, are resistant to oxidation, durability is at least 50 years.

- Polypropylene - in terms of strength characteristics and ease of use, they are increasingly competing with metal products.

- Polymer - have all the advantages of plastic products. For polypropylene pipes, American is the best type of connection.

- Combined - used as adapters when joining metal pipes with plastic pipes when partially replacing a pipeline. To make such fittings, a metal threaded part is pressed into a plastic body.

Fitting purpose

This coupling was developed in the USA, so the name is appropriate - American. Many beginners are interested in how suitable American is for plumbing and what kind of connection it is. It is intended, first of all, for connecting pipes of different materials and cross-sections. Although American thread standards differ from European and Asian ones, American threads are excellent for installing plumbing fixtures and devices of various manufacturers. For this, American developers came up with a technology for universal and high-quality joining of pipes made of copper, steel and even plastic.

The main tasks that are performed using an American coupling:

- installation of pipelines into tees, taps and other devices;

- eliminating damage to the pipe section;

- installation without the use of electric and gas welding.

The American connection has spread greatly in Russia, thanks to its design features and versatility.

Coupling according to American standards Source uspehidelo.ru

By type of assembly method

In addition to differences in materials of manufacture, the threaded connection differs in the design of the docking units.

They are threaded, with different cutting directions, having internal or external threads on the sides. Samples with a conical joint are also used, with the help of which an American connection is made using a thrust ferrule under the nut.

Video

Such a variety of fittings creates certain difficulties when choosing them for an inexperienced person, but gives real pleasure to professional performers.

Advantages of a detachable connection

The American fitting has a collapsible design compared to standard adapters and couplings.

American coupling for PP pipes

It also has other features:

- The connection is tightened exclusively with a nut using a conventional tool without the use of special wrenches for American women.

- The joint is easily opened when it is necessary to clean the system, replace its section, fittings, or insert additional bends.

- Precise alignment of the connected pipe parts is ensured. Therefore, the likelihood of leakage is significantly reduced compared to using conventional connecting elements. As a result, affecting the spatial position of the pipes. This is especially important when parts of water supply systems are connected.

- Simplifies installation in confined spaces. The same cannot be said about squeegees, the conditions of use of which are directly affected by their size.

- The fitting design has its own seal. Therefore, when tightening the connection, there is no need to use additional material or cut out rubber gaskets.

American connections for polypropylene pipes are available in various types. This allows you to select an element for a specific engineering system. The fitting can also be reused by removing it from one pipeline and installing it on another service.

Joining of metal components

Metal pipelines for various purposes are still widely used in plumbing. Therefore, the installation of metal pipes is widely used in a wide variety of options.

For simple joining, you need to cut threads at the ends of the assembled elements using a standard thread-cutting tool. The American thread is screwed onto the prepared ends, and the threads need to be sealed by winding FUM tape or strands of flax fiber.

The final connection is made by tightening the nut and installing the gasket. When reusing the connecting assembly, the gasket must be replaced. The joint turns out to be reliable and repairable. What are the American types for metal components:

- direct connection of metal pipes;

- installation is carried out at right angles, as well as at angles of 30 and 45 degrees;

- installation of cantilever elements of a water supply system with a pipe, such as taps, mixers, air vents;

- threaded connection for changing to another diameter;

Connecting pipes using an American allows you to get a sealed joint in pipelines of any configuration.

Joining plastic components

The connection of components of pipelines made of composite materials has its own characteristics. Polypropylene pipes are joined by welding using special equipment. The process is very simple and is carried out on site during installation.

Video

Widely used are designs where connections are made to a polypropylene pipe on American conical pipes, where devices with a sealing ring are used.

Connecting polypropylene pipes using an American method is the most reliable and perhaps the only method of joining using a detachable coupling, including connecting a heated towel rail.

Several types of connections for polypropylene pipes are used:

- coupling with external thread;

- coupling with internal thread;

- a device with the simultaneous use of internal and external threads;

- angular, produced at angles of 30, 45 and 90 degrees for installation in hard-to-reach places.

Installing a towel dryer

Installation of such a device in the bathroom can serve as an example of using a threaded connection for inserting additional equipment. The heated towel rail is connected either to a heating system or to a hot water supply circuit.

Video

In the second case, you will have to use the services of a remote control service to turn off the hot water riser for several hours; in the first case, you will have to wait until the end of the heating season.

Work can be performed in the following order:

- Install the dryer in its permanent location.

- Make a connection into the hot water supply or heating riser and install threaded fittings for the inlet and outlet flows.

- Install corners with ball valves on them.

- The heated towel rail connection is made through plastic pipes. The critical temperature for them is 95 degrees; this temperature is not used in either system.

- Install a tap on the upper register to bleed air from the system, otherwise an air lock may prevent the coolant from circulating.

- Check for leaks in the dryer by opening the inlet and outlet ball valves. If there are leaks, you need to recheck the joints using additional seals on the threads. Linen tow and fluoroplastic sealing material (FUM) in the form of a tape or cord are suitable for this.

- Installing ball valves will allow you to carry out repair work without disconnecting the riser. It should be noted that connecting a heated towel rail to a polypropylene pipe requires careful handling, since the pressure ring cannot always be reused due to its deformation.

Connecting the heated towel rail to the riser with a polypropylene pipe using American cones allows you to avoid the use of pipe benders. This reduces the labor intensity of work and their adjustment in place.

An example of connecting a heated towel rail through a threaded connection is shown in the figure.

Dimensions of coupling elements

In domestic plumbing standards, American ones are classified as “coupled connections with a union nut.”

Naturally, their size range corresponds to that on the molded elements of water pipelines. What types there are depend on the method of docking to the main line or cantilever element.

So, when installing a tap or mixer as a plumbing element, American ones are used in sizes from 3/8 to ¾ inches with conical threads. This allows for reliable installation in just a few turns of the nut.

For water supply systems they are used within the range of 10 – 50 mm, the maximum value is typical for connection with a heated towel rail.

To connect pipes made of polymers, special couplings are used - American conical couplings, onto which the plastic shell is literally pulled by the force of a screwed nut through a thrust ring, ensuring a joint density that is several times higher than the pressure in the system.

Pipe sizes

For American plumbing, the thread can be selected based on the data given in Table 1.

Tips and tricks

When using plastic pipes, you need to take into account the properties of the material. Polypropylene is a material endowed with a number of specific properties, such as elasticity, plasticity and chemical resistance.

Video

Therefore, for polypropylene products, American is practically the only connection method that ensures high-quality joining. Using them locally, you can assemble a pipeline of any configuration with a high degree of reliability.

For installation using American means, its dimensions must be adequate to the pipes used. For cold and hot water supply networks this is an inch or an inch and a quarter; for heating systems in a private home it is better to use one and a half inch products.

When using plastic products for drip irrigation systems, it is enough to use half-inch sizes.

It should be remembered that the critical temperature for polypropylene pipelines is 95 degrees; this parameter must be controlled when connecting to heaters. The temperature at the outlet of the device may be above permissible limits.

When partially replacing the water supply with a plastic one, the American one is used as an adapter.

Video

When installing with American ones that have a protective coating, you need to use a special tool that does not damage the cladding layer.

When selecting components for a pipeline, you need to take into account their location in terms of accessibility and functionality.