Chainsaw device

An electric chain saw consists of the following elements:

- Frame. There is a panel with buttons for turning the saw on and off. In modern models, a special handle is installed on the body. It is designed in such a way that the operator can independently change the degree of tension of the electric saw.

- Electric motor. It operates from a mains voltage of 220 V. The electric motor is designed to create and transmit torque.

- Saw set. It consists of a removable bar and chain. Using this element, sawing of wooden blanks is carried out.

- Tensioner. He adjusts the tension of the saw set. The operator can independently specify the degree of tension using a special regulator.

- Drive sprocket. This part is used to transmit torque directly to the chain. It is made of steel.

- Lubrication mechanisms. With their help, lubricants are distributed over the surfaces of the main moving elements: the removable bar and chain.

- Braking system. It includes a safety relay to protect the operator from injury in the event of a kickback.

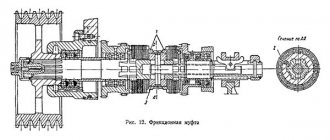

- Clutch. This element is designed to ensure interaction between the electric motor and the drive sprocket.

- Bevel gearbox. This mechanism consists of gears and a gear. It changes the torque and regulates the power of the electric motor. Some models of electric saws have a direct drive instead of a bevel gear.

Electric chain saws are characterized by the following parameters:

- Power of the power unit. This characteristic affects the weight of the electric saw and the cutting speed. Devices with a powerful motor are resistant to voltage surges. The average power of the electric motor is 2.2 kW.

- Tire lengths. This parameter determines the weight of the saw and ease of use during operation of the tool. The length of the bar of modern electric saws is 0.3-0.4 m.

- Chain pitch. This indicator determines the size of the chain mechanisms. The average value of this parameter is 3/8 inch. The higher the pitch, the lower the quality of the cut.

The main advantage of electric chain saws is their environmental safety. During the operation of the instruments, the atmosphere is not polluted by exhaust gases. Electric chain saws also have a long service life. This is due to the presence of lubrication mechanisms.

Specifics of electric saws

Hand saws and hacksaws are a thing of the past. Today, only gasoline and electric models are in demand, differing in the resource on which they operate (an electric engine is tied to the power grid, a gasoline engine operates by burning fuel ). The demand for them is due to high productivity with minimal physical effort on the part of the operator.

Benefits of the tool

The main advantages of electric chain saws include the following parameters:

- environmental Safety . The main advantage of electric saws is that they do not emit combustion products (unlike gasoline analogs), which are potentially hazardous to human health. Therefore, they can be used even indoors;

- light weight . Assuming the same power, an electric saw will always weigh less than a gasoline saw. Due to this, not only men, but also women and older people can work with the tool;

- economy . An electric saw is cheaper to operate because it does not require regular monitoring of the engine condition, filling with gasoline and oil. Its only maintenance comes down to filling the crankcase with oil to automatically lubricate the chain. The technician will not have to clean the air filter or change spark plugs;

- ease of operation . To start the electric chain saw, you only need to plug it into a power outlet. Unlike gasoline, it does not need to be warmed up, which is especially important when working in cold weather;

- affordable price . A good German electric saw is cheaper than a gasoline chain saw. This is due to the simplified design. The manufacture of the engine does not require the use of expensive materials, installation of a combustion chamber, spark plugs and cylinder.

Disadvantages of electric models

As for their weaknesses, the main one is the limited operating radius by the length of the cable. With such a saw, it will not be possible to move an unlimited distance away from power grids, for example, to go into the forest to collect firewood. If absolutely necessary, this parameter can be increased, but it is still tied to the maximum length of the extension cord. Therefore, it is still impossible to achieve complete autonomy.

Electric saws are also sensitive to the quality of the current and any fluctuations in the network can lead to motor burnout.

Purpose of the tool

A handheld power saw is used to perform the following tasks:

- Sawing small logs, boards, slats and other lumber.

- Carpentry and carpentry work.

- Sanitary and forming trimming.

- Dismantling of wooden buildings.

- Forest felling.

Most often, an electric chain saw is used for caring for trees in a summer cottage and preparing firewood. It is used in the production of furniture products and the construction of small houses. In other areas, circular saws or electric hacksaws are used instead of this tool.

Varieties [ edit | edit code ]

- Chainsaws

- Electric chain saws

- Cordless chainsaws

- With another drive (air, steam)

- Crown cutters

- Chain attachments for circular saws

- Hand chain saws

Chainsaw [edit | edit code ]

A chainsaw, or chainsaw, is a hand-held chain saw equipped with an internal combustion engine. The chainsaw is powered by a two-stroke gasoline internal combustion engine connected through a transmission system (clutch and sometimes gearbox) to a saw chain. Starting the engine is a manual recoil starter. Ignition is electronic, the magneto rotor is usually combined with a flywheel and a cooling fan impeller. The carburetor is a membrane type, which, in combination with an appropriate fuel intake system from the tank, allows the engine to operate normally in any position.

The chainsaw has an automatic clutch mechanism that operates on a centrifugal principle, thanks to which the chain is motionless and safe at idle. If the load on the engine when sawing exceeds the permissible limit (for example, if the chain is jammed), the automatic clutch will break (or weaken to an acceptable level) the transmission torque

on the tire, and the engine will not stall. Modern chainsaws also have a brake mechanism that immediately stops the chain when the tire bounces toward the sawyer, the chain breaks, or other emergency situations.

To lubricate the chain and bar on modern chainsaws, there is a separate tank with sufficiently viscous oil and an oil pump with a small flow. Ordinary mineral (petroleum) oil can be used, but recently, especially in everyday life, biodegradable “chain oils” of plant origin, which also do not have an unpleasant petroleum odor, have become widespread. It is necessary to monitor the presence of oil and the operation of the pump so that the chain does not run “dry”, wearing out the bar. The simplest check is to point the bar of a running saw at a clean surface and “turn on the gas” for a while - droplets of oil flying off a normally lubricated chain will leave a mark.

Periodically (including during long-term continuous operation), it is necessary to check the chain tension and tighten it using the appropriate mechanism on the bar (this can be an adjusting screw and fastening nuts of the bar, or a device that does not require additional tools). It is usually required that, under a certain tension force on the chain, its internal drive teeth do not come out of the groove on the bar; The exact requirements are contained in the manufacturer's instructions.

Electric chain saw [ edit | edit code ]

Electric chainsaws differ from chainsaws only in the engine and related features. Electric saws do not have gas tanks and often no clutch [1] . The length of the tire is usually 35-40 cm (14-16″). They are network dependent and therefore, as a rule, are intended for work on small garden plots and small volumes of construction work. All modern models are necessarily equipped with a chain brake. The chain is lubricated in the same way as for chainsaws. Chain tension can be adjusted either without tools or using an adjusting screw and screwdriver.

In the USSR, in the post-war years, the two-handed electric saw VAKOPP (named after the names of the authors: G. A. Wilke, N. V. Aleksandrov, V. V. Kuosman, A. I. Osipov, P. P. Patsiora, A. K. Plyusnin [2]), which received electricity from mobile gas-generating power plants.

The cordless chainsaw combines the characteristics of a chainsaw with independence from gasoline power sources. The 36 V battery allows you to cut about 100 ten-centimeter logs without additional recharging. Ryobi cordless chainsaws, for example, feature batteries that are compatible with other cordless garden tools (lawn mowers, hedge trimmers, hedge trimmers, trimmers, etc.), which significantly reduces their cost.

Crown cutters, or height cutters [edit | edit code ]

They can be gasoline, electric or battery-powered. The cutting organ is a small chain attachment (20 cm). The chain is lubricated according to the same principle as other chain saws. The chain can be adjusted either without tools or with the help of special tools. Gasoline ones can be attachments to brush cutters that have a connector. In this case, they can be expanded using special adapters. Electric and battery-powered ones have telescopic rods and can be extended up to 3 m.

Chain attachments for circular saws [edit | edit code ]

It was first produced by Kress on the Duo-sage model. If necessary, the attachment is installed instead of a disk on a circular saw. Main purpose: allows you to quickly cut 100-150 mm timber, which most circular saws are not able to do in one pass.

Hand chain saw [edit | edit code ]

A hand chain saw (pocket chain saw) is a saw with handles for sawing wood by hand. Can be used both for two people and alone. Compared to wire saws, it has a longer service life. For normal operation, the saw must be bent, lowering (raising) the handle below the level of the sawing surface when operating, so that the saw seems to grasp the tree when sawing. A larger contact area of the working surface provides faster results.

According to unconfirmed information, an order for the development of a hand-held chain saw was sent to the military-industrial complex back in the years of the USSR, to equip “portable emergency supplies” (NAS) for the crews of aircraft, helicopters and spacecraft, as well as for special forces soldiers. The main purpose of the saw is to enable the preparation of firewood in extreme conditions. At the same time, one of the requirements put forward for development was compactness, reliability and light weight.

Types of chain saws

Based on the type of power supply, the following types of electric chain saws for wood are distinguished:

- Network. These saws are powered by an electrical outlet. They can only function in places where there is a source of electricity. The advantage of corded electric saws is their long operating life. The disadvantage of these electric saws is the short length of the wire connecting the motor to the source of electricity. To solve this problem, it is recommended to purchase an additional extension cord. This will improve comfort while using the saw.

- Rechargeable. These electric saws are powered by a built-in battery. The main advantage of these devices is their high autonomy. The operator can carry the cordless saw over long distances and move it freely around the workplace. The disadvantage of cordless electric saws is their low operating time. The built-in battery is discharged within 3 hours if the tool is used continuously. The charge is restored within 1-2 hours.

According to the location of the engine, electric chain saws are divided into:

- Transverse. In these instruments, the electric motor is placed across the body. This design allows you to install a more powerful engine. The drive sprocket and clutch mechanisms are installed on the shaft of the power unit. To attach them, you do not need to equip electric saws with additional components. The disadvantage of transverse devices is low maneuverability. This is due to the fact that the motor casing protrudes from the side of the saw.

- Longitudinal. In these devices, the power unit is located along the body, which reduces the weight and size of the structure, improves maneuverability and ease of use of the tool. For stable operation of longitudinal electric saws, a special unit connecting the engine, drive sprocket and clutch is required. In the absence of this element, it is impossible to connect the sprocket to a removable bar, chain and other metal parts. Due to the presence of an additional unit, it is impossible to equip the electric saw with a powerful motor. In this case, the lightweight structure will not be able to withstand the load from a large electric motor.

The type of electric saw determines its purpose. Network and longitudinal devices are used for caring for trees and preparing firewood. Cordless and cross-cut tools are more commonly used in the construction and woodworking industries.

Main types of electric saw designs

The saw part of an electric saw is similar to a chainsaw. The saw part is:

- drive sprocket;

- tire;

- chain;

- clutch (centrifugal, inertial or friction).

Electric saws are equipped with tires (metal plates with grooves for the movement of the chain and a driven sprocket) up to 45 cm long. The pitch of the chain and sprocket must match.

It is not recommended to install a longer bar on the power saw. This will not lead to an increase in cutting speed, but to overloading the engine or failure of the clutch. It is not recommended to install a headset on the saw with a pitch different from that provided by the design.

The difference between electric saws is the location of the electric motor. If its axis of rotation is perpendicular to the longitudinal axis of the saw, then the layout is transverse. If the axes coincide, then it is longitudinal. Many performance qualities depend on the layout.

Crosscut saws

The engine is positioned in such a way that the drive sprocket is connected to the shaft by direct drive. This eliminates power loss and increases circuit dynamics. The saw instantly picks up speed, which is important when working with a large amount of material of small thickness. The operating efficiency of such a saw is high in almost all cases when the sawing plane is vertical or at a slight angle from the vertical.

If you need to make a horizontal cut, then it is more difficult to work with such a saw - the torque, especially with a sufficiently high engine power, has a noticeable effect on the operator’s hands. But these inconveniences are practically not felt when using an electric saw at home and are fully compensated by high efficiency and long service life.

Electric saws with longitudinal engine arrangement

The force from the engine is transmitted to the drive sprocket through a bevel gearbox. The presence of an additional mechanism of high complexity somewhat reduces the technical reliability of the saw, increases its longitudinal dimensions and imposes certain restrictions on engine power.

Rip saws are much more maneuverable than cross saws. You can work with them in confined spaces at any sawing angle. In addition, better balancing of the saw allows you to work for longer periods of time without rest - although the weight of both types of saws is almost the same, its better distribution in a saw with a longitudinal layout causes less fatigue.

How to choose a chain saw

When choosing a universal electric saw, it is recommended to take into account the technical characteristics of the tool and the following factors:

- The presence of a starting and braking system for the power unit. It limits the starting current, which allows the electric motor to smoothly gain speed. This system facilitates the operation of an electric saw and protects the motor from heavy loads. With an inertia brake, the operator can stop the engine instantly, reducing energy consumption.

- Safety. A power saw is a dangerous piece of equipment that can cause great harm to the operator if safety precautions and correct operating conditions are not followed. To avoid serious injury, it is recommended that you purchase a tool with an automatic brake. This device prevents the motor from starting if the operator grips the tool incorrectly. The automatic brake stops the engine when the saw rebounds from hard material. Also a safety element of the electric saw is a manual locking system. It is activated by pressing a button located on the body. The manual locking system locks the electric motor and prevents it from starting suddenly.

- Availability of lubrication mechanisms. Modern models of electric saws are equipped with an automatic lubrication system. It evenly distributes lubricants over the surface of all moving elements.

- Ease of use. It is recommended to purchase devices equipped with an LED lamp. It acts as a voltage indicator and lights up when the instrument is connected to the mains. The LED lamp informs the operator about the presence of electric current. Ease of use is also ensured by the viewing window installed on the lubricant tank. It allows the operator to determine the amount of lubricant.

When purchasing a power saw, you must consider the manufacturer's brand. Companies use different materials and technologies when assembling tools. Most electric saws are made in Germany, China, Japan, Russia and the USA.

The leading positions in the ranking of electric chain saws are occupied by models from Makita, Husqvarna Interskol, Stihl, Champion and Greenworks. The average cost of saws from these manufacturers is 6-10 thousand rubles. The best electric chain saws cost at least 15 thousand rubles.

Before choosing an electric saw, you need to test it. During the test, it is necessary to check the strength of the structure, the degree of chain tension, the operation of lubrication mechanisms and braking systems. Additionally, you need to inspect the appearance of the instrument. Its parts should not have scratches, dents or other external defects.

The best inexpensive household chain saws

The rating of the best chain saws in the budget segment includes the following devices:

- McCULLOCH CSE 1835 is a small electric saw developed by the Swedish company Husqvarna together with the Taiwanese company Jenn Feng Industrial Co., Ltd. McCULLOCH CSE 1835 is small in size and weighs 3.5 kg. For this reason, this electric saw can be used for long-term work. The length of the removable bar is 0.35 m. The McCULLOCH CSE 1835 saw is used for collecting firewood, felling trees and caring for trees in the garden.

- DDE CSE2418 is a budget saw produced by the American company DDE. It is equipped with an electric motor with a power of 2.41 kW. The motor is equipped with a thermal protection system. The length of the bar is 0.45 m. The advantage of the DDE CSE2418 is the ease of chain adjustment. The disadvantage of this device is the frequent clogging of the valves supplying lubricant.

- PARTNER P820T is a compact electric saw manufactured by the Swedish company Husqvarna Partner. PARTNER P820T is equipped with a 2 kW motor and weighs 3.6 kg. A distinctive feature of this device is its good ergonomics. The reliability of the saw design is determined by the high strength of the tensioners. The gear of the PARTNER P820T gearbox is made of plastic.

Household tools can only be used in dachas and gardens. They can cut small sized lumber.

The best professional electric chain saws

The list of the best professional electric chain saws includes the following models:

- Stihl MSE 250 CQ-16 is one of the most powerful electric saws produced by the German company Stihl. It is equipped with a 2.5-kilowatt power unit with soft start mechanisms and a temperature control system. The length of the tire is 0.4 m. The disadvantage of the Stihl MSE 250 CQ-16 is the inconvenient chain tension adjustment system.

- BOSCH GKE 40 BCE is a power saw developed by the German concern Bosch. It is equipped with a power unit with a power of 2.1 kW and weighs 4.8 kg. BOSCH GKE 40 BCE is not recommended for heavy work. In this case, the gears of the gearbox wear out quickly.

- KARCHER CS 330 BP is an electric saw manufactured by the German company Karcher. It has a power unit with a power of 2.2 kW. The device is powered by a battery. In offline mode, the saw can work for 2 hours.

Professional electric saws are used in construction and large industries: furniture factories and woodworking shops.

The best cordless chainsaws

The rating of the best cordless electric saws includes the following models:

- Stihl MSA 120 C-BQ-AK20-AL101 is a reliable electric chain saw that belongs to the category of professional tools. Her weight is 2.5. The length of the tire is 0.4 m. The Stihl MSA 120 C-BQ-AK20-AL101 is equipped with a lithium-ion battery with a capacity of 3.3 Ah. When using the saw continuously, the battery charge is consumed in 45 minutes.

- Champion CSB360 is an electric saw developed by the American company Champion. It is equipped with a 36-volt battery with a capacity of 2.6 Ah. The length of the bar is 0.3 m. The tension of the Champion CSB360 chain is adjusted using an ergonomic handle. In offline mode, the saw can operate for 20 minutes. The disadvantage of this device is the noisy engine.

- Greenworks G40CS30 is a cordless saw manufactured by the American company Greenworks. It is equipped with a 40-volt battery with a capacity of 2 Ah. The length of the tire is 0.3 m, the weight of the structure is 3.6 kg. The advantages of Greenworks G40CS30 are high autonomy and compact size.

The cordless saw comes with a charger designed to restore the battery's charge.

Choosing a saw by brand

If you focus only on the brand of saw, then it is difficult to make a mistake when choosing any model of companies:

They produce a wide range of household and professional models of the highest quality, but, unfortunately, also in the highest price category. Good premium models are produced by McCulloch, Black&Decker, Intertool. When purchasing electric saws from these brands, it is also difficult to end up with a low-quality tool.

Good models for the home are produced under the brands “Brigadir”, “Interskol”, “Fiolent”, “Energomash”, Foresta. Electric saws of these brands have almost a full range of functions, but are cheaper. There is no better choice for a home workshop.

Photo of an Energomash electric saw

You can buy the cheapest electric saws from unknown or new brands only if you plan to turn them on only when absolutely necessary and work several times a year. Under moderate load they work quite well. But for long-term work on the construction of a summer house, for example, or a wooden fence around the perimeter of a country house site, they are not very suitable. After 10 - 15 minutes of work, it is necessary to make a technical stop for the same amount of time. They are usually made from cheap materials and buying them is reminiscent of playing the lottery.

Photo of Foresta electric saw

Makita and Bosch companies produce interesting models of cordless electric chainsaws. They are equipped with two replaceable 36 V Li-Ion batteries with a capacity of 2.2 Ah each. Charging from a special device included with the saw lasts 1.5 – 2 hours. The saw operates for approximately the same amount of time on one battery at an average load - up to 100 cuts of a log with a diameter of 0.1 m. Close to home, the saw can be used almost continuously.

Photo of Shtil electric saw

Cordless saws are equipped with tires from 20 to 30 mm long. The cutting chain used is a standard 3/8 inch. With chain speeds of up to 8.5 m/s, this provides decent performance comparable to chainsaws of similar power. Cordless saws are convenient when working with low-density materials - plasterboard, plywood, mineral wool, OSB boards. But they also cope with deck boards, clapboards and block houses without any particular difficulties.

Safety precautions when using an electric chain saw

When using a power saw, the following rules must be observed:

- Before starting work, you need to check the serviceability of the tire, chain brake, motor, gearbox, connecting cables and cords. Defects identified during the inspection must be eliminated.

- When working with a power saw, the operator must use protective equipment, glasses, a helmet and specialized shoes.

- You need to work with the tool on a flat surface with a stable base.

- During operation of the saw, it is necessary to control the level of lubricant in the tank and the supply of electricity.

- When sawing wood pieces, you must hold the tool firmly with 2 hands. It is important that no strangers are near the workplace. The operator's hands must be dry. Otherwise, the likelihood of the saw handle slipping increases.

After completing the work, the electric saw must be turned off. Do not leave the device connected unattended.

Which saw is better - gasoline or electric?

Electrically driven saws are equipped with motors with a power of up to 1800 - 2500 W and are designed for work in the garden, in the garden, and on the construction site. They are more convenient than chainsaws if you have to work indoors. There is no exhaust, the noise from their operation is much lower, they are lighter than chainsaws of similar power - they are easier to work with in confined spaces.

Performing complex work, such as felling trees or sawing thick timber with an electric saw, is much more difficult. The distance to their place of work is limited by the length of the cable; if they have to work in the far part of the site, inconvenience arises. It is difficult and unsafe to work with an electric saw in conditions of high humidity - they are connected to a 220 V network, and all safety rules for operating a power tool must be followed.

It is impossible to say unequivocally that a chainsaw is better than an electric one. This depends on the working conditions and tasks that are performed with the chain saw.

For professional work in the forest, gasoline models are better, for home purposes and construction - electric ones.

Video - Which saw to choose, electric or gasoline?

Security measures

When repairing an instrument, we must not forget about safety measures. First of all, you need to disconnect it from the power supply and do not plug it into the network until final assembly.

It is recommended to wear gloves when working with the chain and bar; this will protect your hands from cuts. When disassembling screw connections, if the screw cannot be unscrewed, you need to stop making efforts and use an aerosol lubricant like WD-40; this will relieve the tension and after a few minutes you can simply unscrew the screw.

It is also worth remembering about electrical safety; you can repair parts of electrical equipment by using only the nominal value of the parts that were originally installed.

Disassembling a power saw to repair damage

To begin troubleshooting yourself, it is recommended that you first learn how to disassemble a power saw. Complete disassembly of the unit using the example of a Makita electric saw occurs as follows.

- Unscrew the screw that secures the tire and loosen the fastening slightly. Next, use the chain tension regulator to loosen the saw chain.

- Completely unscrew the tire mounting screw and remove the cover.

- Remove the chain from the sprocket and disconnect the bar from the unit (along with the chain).

- Now you need to unscrew the 2 screws that secure the engine on the sprocket side.

- You should also unscrew a couple of screws on the other side of the unit. For convenience, you can remove the oil tank cap.

- Once all the fasteners have been removed, you can disconnect the gearbox from the engine.

- The next step requires removing the drive sprocket. Since it is secured with a lock washer, it must be removed using a flathead screwdriver.

- After removing the retaining ring, remove the washer located under it and remove the sprocket from the gearbox shaft. Then tighten the 6 screws that secure the gear stops and the handle of the device.

- After tightening the fasteners, disconnect the stops and the handle from the gearbox.

- Next, you should turn the gearbox over and remove the cover.

- After removing the tube from the pump, remove the oil reservoir.

- Press the brake lever in the direction of braking until you hear a click and release it.

- Turn the gearbox over and disconnect the aluminum housing along with the shaft.

- Under the plastic cover, as well as on the gears, you can see an accumulation of dust, sawdust and grease.

- All gearbox parts must be cleaned of dirt.

- Next, you should remove the oil pump plunger.

- Remove the oil pump from the plastic gearbox cover.

- Rotate both parts of the pump in different directions, try to gently pull them one from the other. Once the pump is disconnected, the ball and spring will fall out.

- Next, you need to disassemble the brake mechanism. Put the lever on and turn it until it clicks. The spring tension in this position of the lever will be minimal.

- Pry the spring with a screwdriver and remove it from the aluminum housing.

- Remove the rods together with the spring.

- To remove the brake band, unscrew the screw that holds it.

- Before assembly, the drive gear must be lubricated. This can be done as shown in the following photo. When the unit operates, the lubricant will spread through the gear teeth due to centrifugal force.

- The next step requires disassembling the engine housing. Remove the gear mounted on the motor shaft.

- Remove the electric brushes and unscrew 6 screws on one side of the housing and 1 screw on the other.

- Remove the cover.

- Remove the motor rotor using slight force.

This completes the complete disassembly of the unit. The electric saw is assembled in the reverse order.

Diagnostic and repair algorithm

When starting to repair an electric chain saw, it is necessary to carry out sequential diagnostics of all components of the unit to determine the cause of the breakdown. Repair of the unit is carried out based on the signs of malfunctions that were listed above. Below is a diagram of the electric saw, which shows in detail the internal structure of the unit.

The power saw does not turn on

If, when you press the start button, the unit does not turn on, then diagnostics are carried out in the following order.

- Check the voltage at the outlet. It may not exist due to a general shutdown or a malfunction of the outlet. Try turning on the unit in a different location.

- If there is voltage in the outlet, then you should check the network cable. Remove the engine housing cover and test each wire with a tester, touching one probe to the contact inside the unit, and the other to one of the rods of the electrical plug.

- If the wire is fine, then continue checking further. Check the wires going to the start button with a tester to see if there is a break.

- Next, you should ring the contacts of the button at the input and at its output while the key is pressed.

- After this, check the conductors going to the unit’s motor. If there is a soft start module in their way, then check the circuit at the input and output of it.

If the previous actions did not reveal the cause of the engine failure, then the brushes should be removed and checked. There are times when the engine does not start due to complete wear of one or both brushes, as well as due to broken conductors in them. If the brushes are working properly, then most likely the motor has failed, namely the stator or rotor windings have burned out. In this case, in order to ring the coils, you need to have some skills and knowledge in this area. It is better to take the electric saw motor to a specialist who will find the fault and rewind the coils.

Brushes and commutator burn

The appearance of strong sparking under the brushes can be caused by poor contact between the armature lamellas and the electrodes due to wear of the latter. To check this, you need to remove the parts from the brush holders.

It is believed that normal wear of brushes should be no more than 2/3 of their original length.

If the brushes are worn out, they need to be replaced. Also, brushes can spark due to clogging of the gap between the armature lamellas with graphite dust. Since graphite is a conductor, it causes short circuits and sparks.

To remove dirt, you need to thoroughly clean the slats using alcohol, cotton wool and a toothbrush. It is also recommended to polish them with the finest sandpaper (zero).

No lubrication on chain and bar

Lack of lubrication on the tire or its complete absence can be caused by a clogged hole or tube through which oil is supplied to the tire. Often the chain is not lubricated if the supply of lubricant from the reservoir is interrupted. This can happen if the filter at the end of the hose becomes clogged. The latter is always inside the container. To fix the problem, you need to remove the hose from the oil tank and rinse the filter with gasoline.

Advice! Sometimes the oil cannot reach the tire if it is too thick. It is recommended to use a special lubricant for chains of electric and gasoline saws.

A broken oil pump can also cause oil to not flow to the chain of the saw. After cleaning the filter, hose and lubricant supply hole, turn on the power saw and observe whether lubricant is supplied to the bar, provided that there is enough oil in the tank. If lubricant does not flow, it is necessary to remove and disassemble the oil pump, check the serviceability of the spring or its other parts (depending on the model of the unit) and, if necessary, replace it with a new one.

The engine gets very hot

The cause of engine overheating may be jamming of the gearbox gear, if it is heavily contaminated with small sawdust, or if foreign objects have come into contact with it, for example, fragments of a spring or plastic parts. Try turning the gearbox shaft by hand with the brake off. If rotation is difficult, you will need to disassemble the gearbox and fix the problem.

A break in the motor windings can also cause the motor to overheat. In this case, it will not be possible to repair the motor yourself. You will need to seek help from a specialist.

The engine may also overheat if there is no oil supplied to the saw chain. This leads to poor sliding of the equipment on the tire, and as a result, to increased load on the electric motor. How to diagnose and eliminate this malfunction was described above.

The engine does not develop full power

First of all, you need to check the voltage in the network. It can sometimes decrease and lead to a drop in the power of the unit. Also, a drop in power is caused by gearbox jamming or brush wear. How to fix these problems was discussed above.

A faulty start button also causes similar symptoms. If, when checking this part with a tester, a malfunction is detected, it cannot be repaired. The button must be replaced with a new one. But if checking the above reasons does not produce results, then one can only suspect that the armature windings have burned out or an interturn short circuit has occurred in them.

The unit stops during operation

If the unit stops during operation, one or both brushes may be completely worn out. This is checked quite simply: remove the brushes from the holders and check their length.

Sometimes you come across brushes with a short conductor located inside the pressure spring. In appearance, such a brush will have a sufficient electrode length, but if you look closely at the spring, it will not be fully compressed due to the short conductor.

Also, the unit can stop during operation if there are faults in the gearbox. In this case, you will hear the hum of the engine, which will not be able to rotate. Often the unit stops due to jamming of the end sprocket located at the end of the tire due to its clogging. The sprocket's main job is to move the chain around the top of the bar. As in the case of a gearbox failure, you will hear the engine humming. You can check whether the sprocket is jammed if you try to manually stretch the chain with the unit turned off and the brake released: if it does not move, it means that jamming has occurred in the tire.

Some models of tires have a collapsible design, which allows you to replace the end sprocket on the electric saw tire when it is worn out or replace the bearings. If your unit has a permanent tire, try cleaning the entire space near the sprocket using a thin wire and some penetrating liquid, such as kerosene or WD-40. After cleaning and lubricating this part, try turning it. If the sprocket turns with difficulty or does not turn at all, the bearing is damaged. In this case, the tire must be replaced.

The electric saw does not cut straight

If the electric saw is pulled to the side, in most cases this is due to one-sided tire wear. The chain, passing along such a bar, warps, and the headset produces an uneven cut. If you look at the tire, it will be more worn on one side than the other. The problem is solved by replacing the tire, as well as the chain and sprocket, which have also suffered uneven wear. Even if a new tire is installed on the unit, previously worn parts will quickly render it unusable.

Advice! To avoid uneven wear of the tire, it is recommended to remove it at regular intervals (every 2 hours during intensive work) and turn it over to the other side.