Step-by-step instructions for adjusting the carburetor of a chainsaw Partner (Partner)

Problems with the operation of the chainsaw can arise due to incorrect carburetor adjustment. This procedure must be performed regularly. This will help extend the life of the tool. The Partner can adjust the chainsaw carburetor with his own hands, but it is first recommended to study the device and how to troubleshoot basic faults.

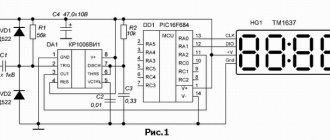

Adjusting the Husqvarna chainsaw carburetor

General view of the Husqvarna chainsaw carburetor and adjusting screws:

A distinctive feature of this saw is the ability to operate at low idle speeds. In the instructions, the manufacturer notes the following: on a correctly adjusted device, the minimum idle speed is 600...700 rpm. If work occurs at a higher crankshaft speed, the chain will not stop in idle mode. This is dangerous for the user.

To correctly adjust the carburetor, place the chainsaw on a horizontal surface.

Before starting the adjustment, you need to allow the internal combustion engine to warm up for 8...10 minutes (in summer) or 12...15 minutes (in winter, at negative air temperatures).

Turn screw L on the carburetor clockwise. Having reached the limit position, they return back approximately a quarter turn counterclockwise.

The idle speed is set with a screw marked T. Turn this screw clockwise and watch the chain begin to move. As soon as the chain starts to move, turn the screw back until the drive sprocket stops rotating. The chain will stop.

Screw H determines the quality of the mixture at maximum speed. If you turn it clockwise all the way, the internal combustion engine will make a lot of noise. The exhaust will be smoky and the mixture will be too rich in the carburetor. Therefore, from the maximum position, reverse rotation is performed approximately half a turn back.

Recommendations for adjusting the carburetor on Husqvarna saws are shown in the video:

How does a carburetor work?

Correct adjustment is only possible if the structure of the chainsaw carburetor has been studied in advance and the quality of this part has been checked. For example, for the Partner p350s tool, the carburetor manufacturer is Walbro. The indicator of quality in this case is the WT-891 marking.

Knowing this information is necessary to order spare parts.

The carburetor of the Partner 371 chainsaw or any other model has a classic structure. The main elements are:

- fuel pump;

- main chamber with membrane;

- throttle and air dampers;

- screws (adjusting quality, quantity and idle speed adjustment).

In addition to these parts, the carburetor has technological channels through which the mixture of gasoline and oil moves.

The principle of operation is as follows. An impulse is supplied from the crankcase to the fuel pump. This is where the work of the carburetor begins. After receiving the impulse, the fuel mixture is directed to the main chamber, entering there through a needle valve, which is controlled by a diaphragm. From the main chamber, the liquid is directed through the technological channels into the cylinder, and the amount of liquid can be independently adjusted using the throttle valve.

Additionally, the throughput of technological channels can be adjusted. For this purpose, it is necessary to use quality and quantity screws, which work on the principle of valves.

Partner 350 chainsaw carburetor structure and operating principle

In order to be able to independently adjust the carburetor on the Partner 350 chainsaw, you need to know how it works.

The Partner 350 is equipped with a carburetor manufactured by Walbro. On the body of the original product there is a WT-891 marking, by which you can determine its quality. The number is also required when ordering spare parts or a complete repair kit.

The WT-891 carburetor is made according to the classical design and has several main elements:

- Fuel pump.

- Main chamber with membrane.

- Throttle valve.

- Air damper.

- Quality adjustment screw.

- Quantity adjustment screw.

- Idle adjustment screw.

The carburetor body has technological channels through which the fuel mixture moves.

Principle of operation

The operation of the carburetor of the Partner 350 chainsaw begins from the moment an impulse is sent from the engine crankcase to the fuel pump, which causes the membrane to work and pump fuel into the pump. Next, through a needle valve, which is controlled by a diaphragm, fuel enters the main chamber. From the main chamber, through special channels and through the nozzle valve, into the cylinder.

By adjusting the throttle position, the operator increases the amount of fuel entering the cylinder. Closing the choke means that even more fuel will enter the cylinder, which will have a positive effect on starting a cold chainsaw.

Quality and quantity adjusting screws operate on the principle of valves, reducing the capacity of the channels through which fuel enters the cylinder.

The injector valve has a fixed capacity and transfers fuel in only one direction. Its second function is to prevent air from entering the main chamber of the carburetor.

Basic faults

The following types of faults are typical for the Partner chainsaw:

- engine malfunctions, such as problems with ignition, fuel supply, or exhaust and piston-cylinder systems;

- failure of carburetor components, such as the clutch assembly, chain brake or lubrication system.

The causes of failures can be different, but most often it is improper operation, insufficient amount of oil or poor-quality fuel mixture.

How to remove and disassemble

Correcting malfunctions of a chainsaw carburetor is possible only after this part has been removed. And to do this you need to disassemble the chainsaw itself. This work will have to be done in the following sequence:

- Remove all components in strict order. First the chain brake cover and saw set, then the top cover, saw handle and starter.

- After these parts are removed, you need to clean the saw using a compressor with an attachment.

- After this, you need to plug the inlet window, since there is a risk of dirt and foreign objects getting inside.

Cleaning

You can clean the carburetor in different ways, most often it is done with air. The sequence of work is as follows:

- Unscrew the top bolt of the part cover.

- Remove the valve gasket. After this, you need to blow the mesh with compressed air. In this case, you should not blow closely, but at a short distance.

- There is no need to remove other parts of the carburetor. You can use a special liquid to clean the surface.

- Now the carburetor needs to be assembled, attaching the parts in the reverse order.

Other renovations

For the Partner chainsaw to operate efficiently, other repairs may be required. It is not difficult to carry out repairs with your own hands.

The most common problem is the lack of:

- sparks in the spark plug (you need to either clean the gap on the spark plug, or replace the coil or flywheel with similar parts);

- fuel supply (the cause may be a clogged hose or fuel filter);

- air supply (air filter needs to be washed).

Chainsaw carburetor repair Partner 351 (main faults and their elimination)

Even a very careful and correct adjustment of the carburetor may not solve some of its malfunctions and the problems they cause in the operation of the Partner 351 chain saw. If the adjustment fails to restore the normal performance of the internal combustion engine power unit, its dismantling, disassembly and repair are necessary.

In some cases, interruptions in the operation of the carburetor are associated with clogging of jets, fuel and air filters and, as a result, “underfilling” of fuel. The main symptoms of this problem are loss of power and unstable engine operation. The cause may be trapped dust, small debris and even water drops, and frozen water in the carburetor completely blocks the fuel supply channels.

If there is a compressor, all carburetor channels are purged with compressed air, and if the procedure does not help, wash it in an ultrasonic bath (suitable for jewelry or for washing optics) using a special carburetor fluid. During the cleaning process, the use of metal needles, wire, fleecy or “loose” cloth is prohibited.

Along with “underfilling” of fuel, its “overfilling” is also considered a malfunction.

There are often cases when a chainsaw begins to operate unstably due to a leak in the seal, which is formed due to a burst spacer between the carburetor and the chainsaw engine (pictured below). The only way to solve the problem is to replace it with a working one.

How to adjust

Setting up the carburetor of a chainsaw Partner with your own hands requires preparing the following tools:

- tachometer (electronic crankshaft speed counter);

- slotted screwdriver;

- a set of filters (their replacement is part of the adjustment process).

You can adjust the carburetor on a Partner 352 or other model chainsaw only if you first clean it of dirt. For this, it is best to use a compressor with an air nozzle. The adjustment itself is performed in several stages:

- To access the adjustment screws, you need to remove the cover. They are also accessible through special holes on the left side of the carburetor. It must be remembered that the left screw is a quality screw (marked H), and the right screw is a quantity screw (marked L).

- After this, you need to tighten the screws completely and then loosen them ⅕ of a turn.

- Then the chainsaw needs to be started, since the carburetor can only be adjusted when the engine is hot.

- After this, the quantity adjustment screw must be tightened clockwise to maximum engine speed. Once this result is achieved, the screw must be unscrewed counterclockwise by ¼ turn. After this, the chainsaw should run at idle. If the revolutions are too low or too high, then use the throttle valve.

- Now, using the quality screw, the maximum speed is set. This parameter is determined by the tachometer. The maximum possible value can be easily viewed in the instructions. For example, for a chain saw Partner 350 this value is 12500 rpm

If there is no tachometer, then you can determine the quality of the adjustment visually. If the tool smokes a lot during operation, then the quantity screw needs to be tightened a little. Another option is also possible. A chainsaw may work well at idle, but poorly at maximum speed. The situation can be corrected by tightening the quality screw, while keeping the gas fully clamped.

Self-adjustment of the carburetor Partner 350

When starting to adjust the Partner 350 chainsaw, you need to clean it as much as possible from dirt and dust in the carburetor area.

The easiest way to clean a chainsaw from small chips is to use a compressor by installing a blow gun or nozzle on it.

First stage of adjustment

The Partner 350 has special holes on the left side of the top cover through which you can access the adjustment screws, but if you are adjusting the chainsaw for the first time, it is better to remove the cover. This will be more convenient, because you will see in what position the heads of the adjusting screws are located.

Next, you need to set the quality and quantity screws to the fully tightened position, and then loosen them 1/5 of a turn.

If you adjust with the cover removed, then you need to remember that the left screw is the quantity screw, and the right screw is the quality screw. To make it easier, the manufacturer puts markings (L) and (H) on the carburetor body, under each of the screws. (L) – quantities. In some manuals it is also called a screw, which is responsible for traction at low and medium speeds. (H) – fuel quality, regulates the number of maximum revolutions.

Also, there is a third adjustment screw on the carburetor, which is designated by the letter (T). It is necessary to adjust the throttle position in idle mode.

Tip: If for some reason the carburetor does not have markings on the adjusting screws, you can identify the screw (T) by the spring installed on it, which is necessary to prevent spontaneous unwinding during operation. It also has a head for a Phillips screwdriver.

Second phase

After the screws are installed in the required position, the Partner 350 chainsaw must be started and allowed to run for several minutes, since the adjustment must be carried out on a hot engine. As soon as the cylinder becomes warm, you can begin to adjust the quantity screw; to do this, you need to tighten it clockwise until the engine produces maximum speed, then immediately unscrew the screw in the opposite direction by one quarter of a turn.

The best information about adjusting carburetors on a chainsaw

Greetings to you dear and most faithful readers of my blog. In today's article, I decided to look at how to adjust the carburetor on a chainsaw. After all, it seems to me that you have more than once encountered the problem that your “darling” let you down when you needed it most. And since you and I are frugal and don’t want to spend money on something we can do ourselves, let’s learn how to adjust the carburetor on our chainsaws with our own hands, without involving professional repairmen. And as you will soon see, this is quite easy to do. You don’t even need to do anything special. I specifically examined the adjustment of carburetors of all well-known brands of saws, each of which has its own tricks and nuances, and in my opinion this is the best information on the network!

So let's get started!

What do you need?

- First, the operating instructions for the device itself.

- Secondly, the tachometer. We’ll look at why exactly we need it a little later.

- Thirdly - a screwdriver.

Oddly enough, this is all we will need.

First, carefully familiarize yourself with the structure of your saw. The first thing you need to do is determine where the carburetor jets are located, and what is even more important than the jets - the adjusting screws. Usually there should be two or three screws. One of them regulates idle speed, and the other two regulate low and high speed.

Step-by-step setup

“Partner 350” is regulated similarly to many models of chainsaws.

In this model we have three regulators:

- Low speed – L

- High – H

- Singles – T.

When released from production, these chainsaws are configured to supply more mixture than necessary. This should only happen during the first hours of operation.

When the engine warms up, it is better to reconfigure it. At idle speed, tighten screw T counterclockwise until the chain stops, then adjust each of them in order: L, H, T.

Screw L should be turned counterclockwise ¼ turn at the moment when the largest turns begin at idle.

Screw H is adjusted as follows: warm up the converter and turn it counterclockwise ¼ turn. To determine if everything is in order you will need a tachometer. The revolutions should be the same as the maximum indicated in the chainsaw's passport.

Your actions should result in the engine immediately accelerating and making noise like fourfold.

The Husqvarna carburetor is adjusted in the same way.

Partner 351 differs only in that its factory settings initially supply the optimal amount of mixture, that is, everything should work correctly right away. But, if necessary, the above instructions will help you set up the carburetor correctly.

Adjustment of the Urals

It is slightly different in that it should not be carried out at sharp maximum speeds, but should be ensured that the chain picks them up quickly, but smoothly, without moving along the tire.

In any case, you should take the adjustment very seriously, because if it is done incorrectly, the saw will not stay with you for a long time. Take care of your tools and if you are not confident in your abilities, it is better to take them to a professional.

Any of them, even strong Friendship, needs attention and care. And then the chainsaw will be your faithful assistant for many years to come.

When purchasing a HUS365 chainsaw, you should be prepared for the fact that after a month of using it, you will not want to deal with any saw other than this brand. This is explained by its reliability, affordability, and most importantly, ease of operation.

Related Posts

Do-it-yourself chainsaw carburetor adjustment

For an independent carburetor option, you need to familiarize yourself with its structure and understand the procedure for the work that is carried out to adjust the parts responsible for the proper functioning of the components of the device and parts close to it.

It is necessary to carefully handle items for the system option, and also to determine whether the set characteristics correspond to very acceptable values.

About the carburetor design

The carburetor serves to mix the flammable mixture with air while maintaining predetermined proportions. If clear doses are not followed, the proper operation of the engine is at risk. When a huge amount of air enters during mixing of the components, but there is not enough fuel, then such a mixture is considered “lean”.

Oversaturation should not be allowed, because with a larger amount of fuel compared to air, malfunctions or engine wear are also likely. Carburetor adjustment is needed not only before initial use, but also when any differences in its operation are detected. Before working with a chainsaw, do not forget to run it in.

Carburetor components

The carburetor design contains a standard set of parts, but may vary slightly depending on the manufacturer. Components:

- The basis . This is a special tube that is visually similar to an aerodynamic design. Air passes through it. In the transverse direction, a damper is located in the middle of the pipe. Its position can be changed. The more it is extended into the passage, the less air enters the engine.

- Diffuser . This is the constricted part of the tube. Adjusting the carburetor of the Partner 350 chainsaw. With its help, the air supply speed increases precisely in the segment from which the fuel comes out.

- Channels for fuel supply. The fuel mixture is contained in the float chamber, then passes into the nozzle, from which it flows into the atomizer.

- Float chamber . It is a separate structural element, reminiscent of the shape of a tank. Designed to constantly maintain the optimal level of fuel fluid before entering the channel from which air enters.

Don't know which chainsaw to choose? Read our article.

Are you looking for cheaper models, but reliable and time-tested? Pay attention to Russian-made chainsaws.

Or explore foreign chainsaw manufacturers such as Shtil.

What you need to have for setup

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed, in most cases used for experiments.

Chainsaw air filter

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs, and turns off when starting work (see how to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T until it stops (see chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully place the device and turn the chain in the opposite direction. Need a tachometer. It determines whether there is a malfunction in the carburetor. When turning the screws, the sound should be perfect and absolutely smooth. If you notice squealing notes, the mixture is oversaturated.

Setup instructions

Carburetor adjustment is divided into two main stages. The first one is called basic. It is performed with the engine running. The second is performed when the engine is warm.

To carry out the carburetor setup procedure successfully, you need to read the operating instructions for a specific model in advance to identify additional features of setting up the device.

First stage

The adjusting screws for the highest and lowest speeds should be moved clockwise until the highest resistance is met. When the screws reach the stop, you need to move them in the opposite direction and leave them 1.5 turns.

Main stage

PARTNER 350 Correct carburetor adjustment.

Partner chainsaw does not start

.

Carburetor

for 7 bucks, disadvantages, how to fix.

Chainsaw Partner. Carburetor repair, adjustment.

Carburetor adjustment

on the

Partner

chainsaw

using THL screws .

The engine is turned on at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed should move clockwise. It is released only when the engine reaches stable operation mode. It is necessary to ensure that the chain does not move during this process.

In idling mode, the engine may stall (the reason is here). In this case, you must immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

What kind of carburetor is used on the Partner 350 chainsaw

Partner 350 chainsaws use carburetors from the Japanese company Walbro, which is the world's largest manufacturer of fuel units for gasoline-powered vehicles.

This is a specialized company that constantly works to improve the design and quality of its products and values its reputation.

On the body of the carburetor from this company there is the Walbro inscription cast in large letters, and there is also a product number. If such an inscription is missing, this means that a particular Partner 350 chainsaw has exactly the same carburetor, but from a different, less well-known manufacturer. In Russia, Partner 350 chainsaws are found with both Walbro carburetors and unmarked products. They are identical in design and operating parameters.

Operating principle and design of the Partner 350 carburetor

The carburetor receives fuel from the gas tank, atomizes it in the diffuser nozzle and supplies the fuel-air mixture to the combustion chamber.

The supply of fuel from the tank to the carburetor storage tank is metered by a membrane, which opens and closes the needle valve. A calibrated hole in the jet and adjusting screws dose the flow of fuel from the carburetor into the combustion chamber.

The engine speed depends on the amount of fuel-air mixture entering the combustion chamber. This amount is regulated during operation by the throttle valve, which opens when the throttle is pressed, and vice versa.

The air damper regulates the air flow from the air filter. During a cold start, it is closed, which makes starting the engine easier. When you press the throttle it opens.

To operate in idle mode, an idle mode is provided, when a minimum amount of fuel mixture enters the combustion chamber without pressing the throttle.

To start a cold engine, the carburetor is equipped with a manual primer pump (suction). Main carburetor components:

This is what the original carburetor looks like removed from the Partner 350 chainsaw

Use a screwdriver to indicate the injector valve

Adjusting the carburetor of Stihl and Partner chainsaws

General view of Stihl and Partner:

Stihl chainsaw carburetor:

Partner chainsaw carburetor:

Despite the external differences, the carburetor design of gasoline saws from these manufacturers is the same. The minimum rotation speed of the internal combustion engine crankshaft is 700…800 rpm. At this frequency the chain does not move.

Adjustment is recommended when installed on a horizontal support.

- Warming up is carried out until a stable operating mode is achieved. If the adjustments are violated, you have to periodically press the throttle lever.

- Using the XX screw, the chain begins to move, and then by reverse rotation, the mode is set when the chain does not move.

- Screws L and H set the maximum speed and mixture quality. Turn it all the way, and then turn it back half a turn.

The video shows the Shtil carburetor adjustments:

Attention! On Stihl carburetors, sticking of the valve in the nozzle is quite often observed. Most often, this phenomenon occurs when the saw is stored improperly. Some users forget to completely drain the fuel before long-term storage. The valve sticks to the body. When gasoline evaporates, only oil remains. It promotes adhesion. You have to carefully disassemble the device and wash it thoroughly.

Carburetor repair video Partner:

Do-it-yourself adjustment of the Partner 350 chainsaw carburetor

All carburetors on Partner 350 chainsaws are factory tuned at special stands. The adjusting screws are securely fixed by springs and are extremely rarely unscrewed during operation of the chainsaw. But adjusting the carburetor on your own is sometimes required, although not often.

For example, if the piston group is heavily worn, the loss of compression and power can be compensated by increasing the fuel supply. This will lead to excessive fuel consumption, and the piston group will still have to be changed. But the chainsaw can still work for some time.

In some cases, adjustment is required after running in the engine and when switching to a different brand of gasoline.

Signs that the carburetor needs to be adjusted:

- The chainsaw stalls at idle speed (low speed) or the speed is too high, the chain spins. The idle speed needs to be adjusted using screw T.

- When you press the throttle, the engine does not develop speed and “fails.” There is not enough fuel, the mixture is too lean (not enough gasoline - too much air). Adjustment is required with screws L and H.

Adjusting the carburetor of the Partner P340S chainsaw

It is necessary to adjust the carburetor of the Partner chainsaw in cases when its engine suddenly loses power or begins to consume too much fuel. To carry out the work, the operator will need an instruction manual, a wrench and a Phillips screwdriver.

The procedure should look like this:

- First you need to find the chainsaw's adjusting screws. In the Partner chainsaw they are located on the left side of the body under a protective plastic cover. Then screws H and L must be turned clockwise until they stop and unscrewed 1/5 of a turn in the opposite direction. During this, the saw engine must be turned off;

- Next, you need to start the chainsaw engine and wait for it to warm up. After this, the operator must begin turning the screw L in different directions until the tool motor operates as stably as possible. Immediately after this, screw L must be turned 1/4 turn in the opposite direction;

- If the chain then rotates on the saw bar, it will need to be stopped by turning screw T;

- Then all that remains is to configure the engine to operate at maximum speed. To do this, with a tachometer connected to the saw, you need to start turning screw H until the readings on the tachometer and the recommendations in the saw manual match.

After setting, the operator must check the operation of the chainsaw. If the tool’s motor quickly picks up speed and operates stably in different modes without making any extraneous sounds, it means that the Partner chain saw has been adjusted correctly.

Carburetor features, pros and cons

The Partner 350 chainsaw carburetor has a standard (classic) design, identical to almost all modern chainsaw carburetors of similar power. It is quite reliable, fully ensures optimal engine operation in all modes and economical fuel consumption. It does not have any unique features that radically distinguish it from other carburetors.

The pros and cons depend not on the design of the carburetor itself, but on the manufacturer. Original carburetors from Walbro of high quality. Carburetors from unknown manufacturers leave much to be desired, depending on your luck.

DIY chainsaw carburetor repair Partner 350

The carburetor parts of the Partner 350 chainsaw do not experience strong mechanical and thermal loads during operation, unlike, for example, a piston system. Therefore, in theory, there is nothing to break in it. In practice, after many years of operation, gaskets most often depressurize and the elastic membrane fails. Over time it can become tough.

Failures of counterfeit carburetors are unpredictable. Anything can break in them at any time - damper axles, needle valve, pump, diffuser, etc.

In addition to breakdowns, the carburetor of the Partner 350 chainsaw may fail due to contamination. For repairs and cleaning, the carburetor is removed and disassembled.

It is worth noting that the accelerator pump of the Partner 350 carburetor is its weak point.

How to remove and disassemble: step-by-step algorithm

Before removing, the carburetor of the Partner 350 chainsaw and the space around it must be cleaned with a brush so that dirt does not get inside the engine. After which they remove:

- Air filter.

- Fuel hose.

- Throttle linkage.

- Then the screws securing the carburetor to the engine body are unscrewed.

After removal, place the carburetor on a clean surface and unscrew the screws securing the cover to the body. Remove the cover and gasket. Parts and fasteners are laid out sequentially. Disassembly is carried out slowly, remembering well which part was removed from where. It is extremely important not to confuse screws H and L when assembling. They are the same in shape, but different lengths.

After the operations have been completed, the Partner 350 carburetor is available for cleaning.

This is what a half disassembled carburetor looks like

Cleaning the carburetor: basic points, how to clean it correctly

Whether the carburetor is clean or not is usually determined immediately, visually.

First of all, the smallest holes become contaminated - in the nozzle, diffuser, channels. There may be dirty sludge in the chambers. The disassembled carburetor body and parts are washed in a bath of gasoline or kerosene. Then the channels and holes are blown out with a car pump or air compressor. It is best to use a special nozzle with a thin channel at the end. Wash again.

During assembly, if necessary, replace the gaskets and membrane with new ones from the repair kit.

When cleaning the carburetor, be sure to clean the hole in the cover under which the membrane is located. Marked in the photo with a red square

Repair kit: what is included in it and where to buy

Repair kits are sold with two sets of configurations.

The first includes gaskets and a membrane, that is, non-metallic spare parts. The second one additionally comes with a crosspiece with a needle valve.

Repair kits cost approximately from 300 to 370 rubles. and are sold in specialized stores and on many online platforms.

Adjusting the carburetor of a Chinese chainsaw with your own hands

Adjustment is not provided on all carburetors of Chinese chainsaws. Today there are many models of household chainsaws, including European brands, whose carburetors simply do not have adjusting screws. Or there is only one idle speed adjustment screw.

Such carburetors require adjustment only when the chainsaw at idle makes too few emissions (revolutions) and sometimes stalls. Below in the text we will discuss the algorithm for adjusting the idle speed of the carburetor on a Chinese chainsaw.

Required Tools

Adjustment requires a screwdriver that fits the slots of the adjustment screws. On different carburetors they are flat, cross-shaped, with an internal or external hexagon, an asterisk, etc.

Carburetor adjustment algorithm

Before making adjustments, make sure it is necessary. All Chinese carburetors on each chainsaw undergo factory settings, which rarely go wrong. A new carburetor, or in rare cases an old one, may require adjustment.

The cause of deterioration in engine performance with symptoms similar to poor supply of the fuel mixture is, in most cases, the following:

- clogged air filter,

- exhaust windows and muffler clogged with carbon deposits,

- bad fuel.

If this is not the problem, then try adjusting the carburetor.

The engine must be warm. A cold engine and one warmed up to operating temperatures operate differently. Therefore, adjustment in cold conditions will be incorrect.

- Provide access to the adjusting screws. On some chainsaws, it is enough to remove the cover and air cleaner. On others you have to remove part of the body. On the third, the housing has holes for a screwdriver.

- The screws are marked on the carburetor or near the holes - T (or LA) L and H. The T (or LA) screw is designed to adjust the idle speed. Always located away from screws L and H, which are next to each other.

- If the chainsaw stalls when gas is supplied, the engine does not have enough fuel to develop speed. The amount of fuel is adjusted using screw H (main screw). Unscrew it 1/4 turn and give gas. If the engine begins to work better, unscrew it another 1/4 turn. (If worse, then tighten it 1/4 turn in the opposite direction).

- If the engine starts to idle, it means there is a lot of fuel, screw H is screwed back.

- The peak speed is controlled by ear or using a tachometer. The maximum speed for each chainsaw is indicated in the instructions. (10,000 – 12,500 rpm). In practice, 10,000 – 11,000 rpm in the “full throttle” position are normal values.

- By increasing the amount of fuel supplied with screw H, the quality of the fuel mixture is adjusted with screw L. It increases and decreases the amount of air in the mixture. If there is not enough air, the fuel will not burn out; as a result, the engine smokes, does not develop power and consumes excess fuel. Screw L also affects engine operation at low and medium speeds.

- After adjusting screw H, screw L is unscrewed 1/4 turn. If there is smoke in the exhaust and the engine moves from low to medium and high speeds with dips, screw L is unscrewed some more.

- Adjustment of screw L is stopped when the engine runs smoothly, moves smoothly from low to high speeds and does not smoke.

The location of the adjusting screws is highlighted with a red square. To access them, a screwdriver is enough. There is no need to disassemble anything.

Idle speed adjustment

Idle speed adjustment sequence:

- The engine is started and warmed up for 5-7 minutes.

- The screw is unscrewed, increasing the speed until the chain begins to rotate.

- Then the screw is screwed back 1/4 turn.

If you have an electronic tachometer, you need to use its readings when making adjustments. Most chainsaws should idle at 2500 rpm.

Nuances that arise in the process

Screw L should not be unscrewed too much relative to screw H. This will lead to the formation of a lean air-fuel mixture (not enough gasoline - too much air). With such a mixture, the piston is dry during operation, gets very hot and can fail.

New carburetors on Chinese chainsaws, sold separately, are adjusted at the factories to a standard number of revolutions or arbitrarily. Therefore, they may require adjustment after installation on the chainsaw.

Adjustment video

The author of the video shows the process of adjusting a classic Chinese chainsaw with a power of 2.8 kW and a working volume of 45 cubic meters. see. The author talks in detail about all the stages of setup, what screws are there, what they are responsible for and how to adjust them correctly. The whole process takes place without removing the carburetor itself from the chainsaw.