What is wheel balancing?

Wheel balancing is the procedure for preventing imbalance between wheels, rims, hubs, suspension parts and fasteners.

The need for periodic operation is due to centrifugal force. During the balancing process, the mass of the wheel is located evenly relative to its center. When the procedure is performed correctly, vibration during vehicle operation is reduced and the service life of bearings and car tires is increased.

Benefits of wheel balancing:

- Comfortable ride on roads of any type and quality.

- No unnecessary noise from car wheels.

- Increased wheel usage.

- Ease of driving at various speeds.

- Car tires wear out equally and evenly on all sides.

Wheel balancing is required for any car, regardless of the condition of the wheels, tires or the newness of the model.

Consequences of not balancing wheels:

- Frequent bearing failures.

- Steering wheel vibration during vehicle operation.

- Early and uneven wear of car tires.

- Noise in the cabin.

- Immediate shock absorber failure.

- Unsafe movement due to each wheel acquiring its own centrifugal force.

- In advanced cases, the vibration of the wheels causes the bolts to become unscrewed and the ball joint to fly out or fall off.

Equipment for balancing

Conventional tire stations use balancing machines. The assembled wheel is installed on a special cone and unscrews. The wheel balancing machine automatically aligns it in the desired direction, and at this time the master can only shift the load there until the wheel stops in the most random position.

There are also computer balancing stands. They allow the most accurate alignment of the center of gravity thanks to modern laser technology. At the stand, by setting the wheel parameters, you can determine all possible causes of imbalance that are invisible to the human eye. These could be minor defects in the disk or tires, an incorrectly seated tire, etc. The computer will identify them with mathematical precision, display all the information on the screen, and also indicate exactly where the load needs to be placed.

Why do you need wheel balancing?

Static and dynamic wheel imbalance

As already mentioned, wheel balancing is needed to evenly distribute the mass of the wheel relative to its axis or, in other words, to eliminate imbalance. Experts divide wheel imbalance into two types:

- Statistical. The center of gravity shifts along the axis, resulting in an uneven distribution of the wheel mass along its length.

- Dynamic . This is when the axis of inertia does not coincide with the axis of rotation. In this case, the intersection of the axes occurs at an angle, which leads to uneven distribution of the mass in width.

The existing imbalance can be determined visually by lifting the car on a jack and spinning the wheel, as well as using special diagnostic equipment. The second option guarantees a more accurate result, and is provided as an available service at any tire shop or service station.

Causes of imbalance

Imbalance can arise for various reasons. So, for example, you could hit a hole, hill or obstacle at high speed, which led to mechanical deformation of the wheel. Also, imbalance occurs due to poor quality, heterogeneity of the valve material. In other words, if your wheel doesn't look like a perfect circle, the more likely it will be out of balance.

Imbalance options:

- Static, when the axis of rotation is parallel to the axis of inertia, which is characterized by a displacement of the center of gravity from the axis of rotation and an uneven distribution of the total mass occurs. If you spin a rim with a tire, you can easily notice such a deviation; the wheel will seem to “jump” as it rotates.

- Dynamic, when the axis of inertia does not coincide with the axis of rotation. In this case, the center of gravity does not shift, but both axes intersect at a certain angle. In simple words, the weight of the wheel due to dynamic imbalance is incorrectly distributed across the width.

Dynamic imbalance often occurs on wide profile tires. But it is not uncommon for a disc to be affected by two types of imbalance simultaneously. But they can be easily eliminated if you use a balancing machine. The manufacturer of the equipment in this case is completely unimportant. The quality of the repair will be influenced not only by the qualifications of the specialist, but also by the condition of the working machine and the wheel alignment cone, that is, it is important to regularly care for the equipment, carry out maintenance, calibration and testing.

In the case of racing cars, finishing balancing is carried out. How do experienced craftsmen do this? The car is suspended on a special stand and the wheel is spun up to 90 km/h. Using a computer, all the necessary measurements are taken and the location for installing the appropriate weight is determined. Although this type does not at all serve as a replacement for stationary balancing, and before the finishing procedure, the disk of a racing car must be processed on a stationary stand.

In addition, it is worth noting the existence of another type of balancing - automatic, it is used for small wheels of a truck, motorcycle, and bus. The inner part of the disk is covered with special granules. When driving, these substances stick to the inside of the tire. This is how automatic balancing is carried out.

There is a separate category of cars without a central hole. Balancing in this case is carried out according to the holes for the bolts. This uses a flange adapter.

Effects of vibration

- The action of undesigned loads on the load-bearing parts and mechanisms of the vehicle’s suspension system causes accelerated wear and, first of all, the bearings in the hubs are destroyed. The destruction of the bearings threatens the loss of the wheel in motion, which can lead to a traffic accident with serious consequences.

- Wheel vibration transmitted to the tires reduces traction as the characteristic contact patch becomes inconsistent and unstable. At the same time, the braking distance lengthens and the vehicle's handling deteriorates. Thus, driving safety suffers.

- Vibrating mechanical load on the tread causes rapid and uneven wear. This reduces its technical parameters and leads to the need for frequent tire replacement.

- Increased vibration of the wheels during movement, transmitted to the steering wheel, causes discomfort and rapid fatigue of the driver.

Balancing is not just weights. How to properly balance a wheel without ruining anything

To be honest, when I asked my friend a tire fitter about balancing, I expected to get something very standard in response, but with some details that I didn’t know about before. But everything went wrong in life, and in response messages in the messenger I received a total of just over an hour of voice messages. Maybe a little less than an hour, if you remove the unprintable vocabulary (the reason for which I will give below), but still a lot. And I decided that there would be two materials. One is just about balancing (which, it turns out, I knew only superficially), the second is about how, based on some signs, to distinguish a normal tire mechanic from a crooked ghoul and extortionist of money.

Why is balancing needed?

Balancing is necessary to preserve three things: money, security and comfort. Money means taking care of the chassis. There is no mechanism in nature that would benefit from extra vibration. There are enough parts in the chassis that do not like unnecessary rhythmic impacts, even if they are not very strong. These include wheel bearings, silent blocks, and ball joints. In addition, the tire itself wears out quickly. So balancing is a clear manifestation of care for these elements, and therefore for the means to replace them prematurely.

As for security, everything is also simple. Remember what happens to a phone that just lies on the table. Nothing happens to him. But if you call it, it will start crawling on the table in vibrate mode. It just doesn't have enough grip on the table surface. The situation with an unbalanced wheel is the same: it bounces along the road, there is no question of a uniform contact patch, and the grip deteriorates rapidly. It smacks of latent suicide, although many don’t even think about it.

And last but not least – comfort. Here, too, everything is clear: shaking and the steering wheel jumping in your hands is very annoying. You have to be too calm a person not to pay attention to this. True, the lack of balancing is not felt on all cars, so if there is no shaking, this does not mean that everything is in order with the wheels. A shaking steering wheel is already an extreme degree of disregard for balancing, and it is better not to lead to this situation.

What's a motor, what's a wheel?

The question arises: when should balancing be done? Is it really before the steering wheel starts to shake? Strange, but yes. There are several situations in which balancing is necessary.

The first is assembling a new wheel. Each newly assembled wheel needs to be balanced. It is obvious. The second situation is related to seasonal “re-shoeing”. If the wheels were stored assembled, they also need to be checked for balance. It happens that balancing is not required, but more often it still has to be done.

This is where the obvious situations end and not so obvious, but no less vital ones begin.

Oddly enough, very often a wheel with a new tire has to be balanced twice. The first time is during wheel assembly, the second time is after running in. The fact is that during storage of the tire it may lose its round shape. A slightly “squared” tire is placed on a rim and balanced, but over time the tire returns to its shape. Sometimes the balancing is maintained after this, sometimes it is not. Therefore, it is recommended to check the wheel with a new tire for balancing again; the recommended mileage is 1000 kilometers.

Now let's move on to the run. It turns out that the wheels need to be checked every maintenance. For some reason they don’t think about this, but it’s better to check the balancing at the same time as maintenance. Changed the oil - check the wheels. And 10 thousand kilometers is not so little if the car has to drive on broken Russian roads.

The fifth reason to go for balancing is precisely those very broken roads. More precisely, pits. It is very advisable to follow the rule: if you fly into a hole, go for balancing. The driver himself may forget about this hole the next day, but the wheel remembers it for a long time. It happens that the balancing does not change, but it doesn’t hurt to check the wheel. If only for the reason that, for example, it is difficult to bend a cast disk from the outside, but from the inside it’s like two fingers on the asphalt. And this moment also needs to be controlled.

In general, it's better to be safe than sorry. There is no such thing as too much attention.

Just out of interest: is it possible to not balance the wheels at all? We do not consider the situation with innate idiocy. And then there is only one option left to tighten the balancing bolt: drive at a speed of no more than 40 km/h. It is believed that at this speed balancing is not necessary.

What and how?

Now let's move on to the most interesting part: how balancing is done and what is often done wrong.

Captain Obvious tells us: the wheels are balanced on a balancing machine. The cost of the machine can be different: you can buy dead junk for 10 thousand rubles, or you can snatch a top-end Hofmann for 1.4 million. But in general, many people don’t like to save money on a balancing machine: the client doesn’t really care how or what they used to put the tire on the rim, and he will easily notice a balancing error. Therefore, it happens that balancing machines are installed at the top level, and the rest of the equipment is simpler.

Theoretically, a wheel can be balanced normally on a cheap machine. Not ideal, but okay. It all depends on the degree of crookedness of the master. Too crooked and on a machine with automatic measurement of parameters it can cause trouble.

Pay attention to how the master will center the wheel on the machine. By the way he does this, you can estimate the radius of curvature of his hands. There are three ways in total. The first is the simplest and most undesirable. In this case, the cone, which fits into the central hole of the disk, is installed outside the disk. That is, the wheel is hung on the machine shaft, then the cone is put on, then pressed with a nut. For alloy wheels, this is the most undesirable method of centering. The fact is that on the outside this disk is simply cast, but on the inside it is milled. And the inside of the central hole is noticeably more accurate than the outside. Therefore, it is better to install the cast disk differently: the cone should fix the inner part. In this case, the sequence of arrangement on the machine will be as follows: a cone is put on the shaft, then a wheel, and then it is pressed against the faceplate with a plate. By the way, for stamping, both methods will be normal: with the accuracy of making a stamp “plus or minus a tram stop”, the side of application of the cone does not matter at all.

What determines which method the master will choose? Only from the master himself. Any machine allows you to center the wheel in both ways. But the first one requires fewer body movements, and the lazy person will choose this one. You can also lose some parts, without which the second method cannot be applied. This also happens, and this is a sign of a very mediocre tavern.

There is another way of centering - using a flange adapter. This method was invented by the Haweka company (where, in fact, modern balancing was invented). The method is based on the fact that the wheel is centered on the hub not by a central hole, as many people think, but by conical (or spherical) nuts or bolts. Here, first a cone is put on the machine shaft, then a wheel, and then a flange adapter, which centers the wheel with mounting holes. In this case, the centering is perfect: the wheel sits exactly the same as on the hub. But this method has a small drawback: it is labor-intensive, takes more time, and balancing with an adapter costs 30 percent more than balancing using the first two methods.

And finally, the most fantastic method. It is not a cone that is placed on the shaft, but a bushing that matches the diameter of the central hole of the disk. The disk itself is clamped not by a cone, but by a flange adapter. This is the most accurate and complex method. They say it is used in a parallel Universe by sober and clean-shaven tire fitters wearing white gloves. In our life, this, alas, does not happen.

Consumables for balancing are primarily weights. They are stuffed (spring) and self-adhesive (adhesive). Which ones are better? Both have their advantages and disadvantages.

Padded weights are attached closer to the edge of the rim and are more accurate. And since they are attached mechanically, they stay on the rim better. Such weights are good where strength is needed, not aesthetics. For example, on SUVs. Padded cargo also has disadvantages. First of all, they are not very beautiful. Secondly, the spring of such a load fits between the disk and the tire, and if the disk is old, air will leak in this place. However, if tires with rims bleed along the spring, they will soon begin to bleed everywhere. This is a disk problem (its corrosion), not a weight problem.

Self-adhesive adhesive weights also do not fall off the disc, although it is easier to tear them off if desired. And sometimes the Chinese ones fall off on their own, it happens. But they do not spoil the appearance of the disc.

What if he cheats?

I’ll tell you next time how to distinguish a normal master from a fake one. It's very interesting, but very long. For now, you’ll just have to see how a specialist will balance the wheels and how a low-skilled fraudster will do it (for simplicity, let’s just call him a “ghoul”).

A good specialist will never balance a dirty wheel. Firstly, the weight of the wheel, not the dirt, is important for balancing; secondly, it’s easier to wipe a clean wheel with solvent before gluing the weight; thirdly, it’s just more pleasant to work with. If a tire shop doesn’t wash wheels, it’s better not to balance anything there.

You need to balance a straight wheel. The ghoul does not know this and does not check the geometry of the disk and the tire itself before balancing. A good master will check them, and if it turns out that the disk is crooked, he will first offer to straighten it. And if the new tire is crooked, return it to the store. Also, a good specialist will first check the disk on the machine, and only then the wheel assembly, so as not to once again torment the tire during installation. This is especially true for low profile tires.

The ghoul removes the tape from the old weights from the disk with a knife. Usually - along with paint. A good specialist can use a special plastic spatula or an attachment on a drill (a circle for removing stickers).

The ghoul will jump around the machine for a very long time. Most likely, the reason for his dancing is an uncalibrated machine. A normal technician, using a well-maintained and working machine, balances a tire in about a minute.

Before installing the wheel on the hub, a specialist will check the adjacent surfaces. There can't be any dirt there. By the way, a small note to those who like to paint the brake drums on their VAZs: the paint falls off the drum (yes, this “high-temperature” one too), and the wheel begins to wobble. With such wheels you can only go for a Darwin Award.

The ghoul, of course, will not check anything: he will remove the wheel from the machine and screw it to the dirty hub. And he will also tighten the nuts (or bolts) with a wrench with a wild torque. And since the wheel is centered precisely with the nuts, what will happen to the balancing after such an installation is a mystery. A normal master uses a warm lamp torque wrench for broaching.

And lastly: a good specialist will balance everything that has a central hole (and sometimes even does not, as on some Peugeots and Citroens). The phrase “the wheel isn’t balanced” is only uttered by a ghoul. By the way, there were cases when, for fun, they balanced an old bucket and a stool. The humor is, of course, specific, but that’s what it is.

And the words “rubber, sixteenth radius, balloon, slope and nipple” belong to the vocabulary of ghouls. But, as agreed, we’ll talk about this next time.

Survey

How long have you had your wheels balanced?

Your voice

Total votes:

How to carry out balancing

This operation is not particularly difficult, but to perform it you need a specialized balancing machine with a special fastening cone that automatically centers the wheel. The wheel is spun on a machine and, with the help of lead weights attached to the disk, its position is achieved as randomly as possible when stopping. This is called rough balancing.

For accurate balancing, you need an electronic machine into which the wheel parameters are loaded. With the help of such a stand, balance is automatically measured in different positions of the wheel, and information is displayed on the screen about the places where the weights should be installed and their weight.

Weights are made of lead and can be padded or adhesive. The latter are glued inside the wheel rim, they are not visible to the eye, they do not spoil the appearance of the wheels.

But for winter it is better to use padded weights. The thing is that in winter, due to increased temperature fluctuations, the linear dimensions of the disks change. And such fluctuations do not have the best effect on the properties of the adhesive tape that secures the balancers. It will be easy to knock off such a “played up” weight with a stream of water at the sink. But, there are disks on which it is not possible to put weights; their balancing is carried out only with adhesive balancers.

To perform high-quality work on wheel balancing, it is necessary not only to correctly configure the machine itself, but also to have a certain skill. These two factors together influence the final result.

And, if you can also evaluate the work of a tire fitter visually, then here is the accuracy of the equipment settings, the date of its last calibration, etc. you won't determine. It is for this reason that balancing should only be done in a trusted place that you trust.

Equipment

It is important to prepare the wheels for the balancing procedure, namely, thoroughly clean the tread and disk from sand and dirt. If this rule is neglected, the operation may be performed inaccurately and will have to be repeated. If the car has already been balanced, the technician must remove the balancing weights before starting.

It is very important to check the tire pressure: the tires should not be flat. Before balancing the wheels, the center of gravity is determined, which is monitored by balancing machines. Devices can range from ordinary computers to huge systems with laser sensors and measurement mechanisms. Once determined, the machine automatically installs the balancing weight.

To carry out the procedure, a balancing machine is used, which aligns the position of the wheel along the center of the rotation axis during the procedure.

The type of balancing weight depends on the type of discs. Weights with fastening brackets are installed on steel disks, and with landing on the inside - on cast disks. They are mainly made from zinc, lead or steel.

Weight also depends on the level of imbalance. The weight of the balancing weight with bracket fasteners varies from 5 to 100 g. The weight of the weight for alloy wheels is from 5 to 60 g.

The complexity of the procedure also depends on the mass. The larger the weight, the more likely it is that the wheel needs to be checked for its external qualities: tread condition and general geometric qualities such as symmetry.

In the cold season, due to temperature fluctuations, adhesive weights may come off, which cannot happen with padded ones.

There are special types of weights for stamped wheels. They are stuffed between the disk and the tire, installed on the edge of the disk. Padded weights are not suitable for low-fusible discs. For this type, there are Velcro - self-adhesive weighting agents with an adhesive base. They are practically invisible, because they practically do not stand out from the general appearance. However, they are used only on a perfectly flat surface.

The process of balancing car wheels

The procedure for balancing a car starts with removing the discs, regardless of the characteristics of the model. Balancing occurs according to the following method: remove the wheel, balance it, put it back, then move on to the next one. This completes the procedure for all wheels.

The result depends mostly on the artist, and only a small part is due to the equipment. If the device is modern, then the specialist can only monitor the condition of the rubber and the progress of the procedure.

After cleaning the tread from stones and dirt, a plate is selected, depending on the number of holes in the disc. The specialist places the plate on the disk, tightening the nuts well. After that, he goes to the machine to balance the wheel.

Before balancing, remove any dirt or stones from the tire tread.

After identifying the problem area, the process of installing weights begins. Upon completion, the master returns to the equipment and re-checks the geometric condition of the wheel. If the procedure is successful, the wheel is installed in its place and the next one is taken. Otherwise, the procedure is repeated.

What errors can occur during balancing?

- The imbalance cannot be determined unless the tire is cleared of stones and dirt.

- Installing new weights without removing old ones.

How to check wheel balance

You can check it yourself. If you feel that on a flat road, when you release the steering wheel, the car immediately throws to the side, or you feel that the steering wheel vibrates with a certain frequency, then this is a sign of imbalance.

Place the car on a jack. Draw a transverse line on the rubber with chalk. Spin the suspended wheel. A bent wheel, a figure eight, you can see right away.

Video

Training video for those who want to purchase a machine and engage in this business. How to learn how to balance wheels.

One of the options for a balancing machine.

Boarding and balancing.

Balancing methods

Using the advice of experienced drivers, you can carry out balancing yourself the old fashioned way without using a special machine. This will take more time than a service technician would spend, but it will help save money.

If desired, wheel balancing can be done independently in a garage.

To perform the procedure yourself, you will need the following equipment and materials:

- jack;

- balancing weights;

- chalk or marker;

- a set of keys.

Interesting! To balance wheels on cast or forged wheels, it is advisable to purchase self-adhesive weights. But in winter, such weights can come unstuck due to temperature changes.

Balancing weights are required for balancing

Without removing the wheel

The self-balancing process consists of the following steps:

- Preparatory. The wheels are cleaned of dirt and stones stuck in the tires, the caps are removed, the pressure in the tire is reduced, and old weights are removed. The jack is installed on one side of the vehicle, freeing 2 wheels. Check the free rotation of the wheels. If the wheel is difficult to spin, you need to undo the cotter pin and loosen the hub nut.

- Determination of an easy point. The wheel is turned counterclockwise and waited for it to stop. Mark the top point. Then turn the wheels clockwise and mark the top point again. The midpoint between the two marks is the light point.

- Installation of weights. Using a hammer, weights weighing from 10 to 45 grams are placed on the found point, starting with the light ones. After this, they spin the wheel and wait for it to stop. The weights should be at the bottom. If it turns out wrong, the light weights are removed and heavier ones are added. It is not recommended to use more than 60 grams of weight on one wheel.

- Static balancing. As soon as the weights are at the bottom after stopping, they begin to move them apart in different directions. The wheel begins to rotate and the weights move apart. The goal of the process is to ensure that the wheel stops in a different position each time. Once this starts to happen, the weight is distributed evenly, that is, static balance is achieved.

The procedure is carried out in this sequence with each wheel. To check the correctness of the balancing, you need to drive the car at least ten kilometers at a speed of more than 90 km/h. If you don’t feel any jolts or tapping while moving, it means everything was done correctly. If the procedure is performed incorrectly, specific shocks to the steering wheel appear.

For your own confidence, at the first self-performed balancing, you can undergo diagnostics at a service station. If the specialists confirm that everything was done correctly, in the future you can carry out the procedure yourself.

Important! Self-balancing in the garage is only permissible if there is a static imbalance. Eliminating dynamic imbalance requires the use of equipment. Experts recommend contacting a service center if your car has worn tires and old bent wheels. Without special equipment, it is impossible to balance such wheels yourself.

At a homemade stand

You can make the balancing process easier by making a homemade stand in the garage. In this case, you do not have to remove the brake pads from the wheel and loosen the step nut.

A homemade stand simplifies the process of wheel balancing

The stand is mounted from an old hub with a working bearing. The hub is installed on the frame so that the wheel rotates freely and the entire structure is firmly held on the surface. It is convenient to use vertical metal posts as a frame, between which the wheel is attached. Further balancing actions coincide with the previous method of performing the procedure.

On the machine

Even an experienced motorist in a garage carries out balancing “by eye”. Therefore, there can be no complete confidence in the correctness of the process. In specialized workshops, balancing is performed on computer-controlled machines.

Modern service stations are equipped with CNC balancing machines

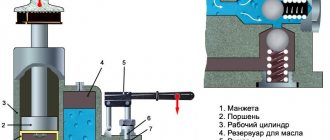

The machine consists of a cone-shaped support for mounting a wheel, a rotating electric motor and sensors. The wheel rotates when performing tire mounting, and at the same time the computer detects vibration and pressure. Sensor readings help to accurately calculate the weight and location of weights.

The workshops are equipped with two types of machines:

- Manual - in which the master measures the wheel with a ruler and manually enters the data.

- Automatic - information is read by sensors and displayed on the monitor in digital or graphical form.

Based on the type of supports used, machines are divided into:

- Soft, measuring wheel parameters, taking into account the vibrations of the supports.

- Rigid, measuring pressure and rotor phase.

Interesting! On rigid machines you can test various parts, but the quality and accuracy of measurements is reduced for this reason.

Most modern services are equipped with automatic balancing machines. The master puts the wheel on the shaft, tightens it with bolts and unscrews it. Sensors determine the points of axial runout. The computer determines the intensity of the push and calculates the mass of the load that must be attached to the calculated point. The computer will also inform you if the wheel cannot be balanced.

Balancing with granules

One of the newest methods of wheel balancing is the use of special granules instead of weights. The essence of the technique is to pour special granules into the tire, which slide while driving in the internal space. This free movement eliminates imbalance when driving at speed.

Modern wheel balancing techniques involve the use of microbeads

The advantage of this method is that the granules are poured once, and they perform their intended function throughout the life of the tire. The disadvantage of this balancing method is the high cost of the granules. Therefore, balancing in this way has not gained popularity at present.

Video: DIY wheel balancing

How much does it cost to balance wheels?

Here, of course, everything depends on the tire service or the tariff schedule of the car service. In principle, wheel balancing is not that expensive. First of all, the wheel diameter affects the cost of wheel balancing. It is logical that the larger the wheels, the more expensive it is to balance them.

The cost of wheel balancing is also affected by the type of disc used on the wheel. Typically, it costs less to balance a wheel with a steel rim than a wheel with an aluminum rim. In addition, the final cost of balancing will be influenced by the type/type of weights (counterweights) used.

When the seasonality of tires changes at a tire shop, as a rule, wheel balancing is included in the total bill for services.

On average, the cost of balancing one 15-inch wheel with a steel disc in Russia is 170 rubles. Accordingly, to check and balance four wheels you will have to pay an average of 680 rubles.

There are, of course, many garage tire shops in Russia that are ready to provide this service at a cheaper price. But don’t forget that there are also premium tire shops where wheel balancing usually costs a hefty sum (even more than tire fitting at a dealer).

Please note that this average cost does not include wheel removal and installation. So feel free to add an average of 50-100 rubles to the cost of balancing for a 15-inch wheel.

Types of imbalance

Today there are two main types of wheel imbalance:

- Static imbalance. This implies an uneven distribution of the mass of the product along the axis; the wheel begins to “beat” in the vertical plane. In fact, there is no center of gravity on the wheel axle at all. This problem sooner or later leads to destruction of the suspension.

- Dynamic imbalance is unevenness in the plane of the wheel. In this case, there is a center of gravity, and it is on the axis of rotation (where it should be). The only difference is that the axis of inertia and the center of gravity do not coincide.

The cause of the imbalance may be the design features of the wheel (tread pattern, location of the valve hole, inaccuracies in geometry, dimensions, and so on).

In this case, the greatest imbalance can be caused by the car tire itself. Here, a lot depends on the rubber material, weight, structure, and so on.

How often should your car wheels be balanced?

Most often, the question of how often a car's wheels need to be balanced also arises for beginners. There are no clear standards for when to balance or after what mileage. But experienced drivers still make some suggestions when it is worth balancing car wheels.

The first and most important rule is that every time you change tires, whether they are new or used, the car’s wheels are balanced in order to equalize the centrifugal force, since changing wheels or tires shifts the center of traction. In terms of mileage, it is recommended to carry out balancing after every 5,000 kilometers of a vehicle running on the same wheels.

In case of suspension repairs or frequent driving on bad roads (hitting potholes), it is worth balancing the wheels more often than 5000 kilometers; it is usually recommended after 1000-1500 kilometers. If vibration occurs in the body, in the cabin, on the gearshift lever or steering wheel, often at speeds of 60 km/h and above, balancing should not be postponed.

The conclusion is quite simple, car wheels need to be balanced every time you change shoes or tires, plus, given the condition of the roads, wheel balancing needs to be done more often.

Signs that your wheels need to be balanced

- When driving at speed, noise appeared, this was especially noticeable at speeds above 100 km/h. The car began to drift away from its straight path.

- There were unpleasant vibrations on the steering wheel, which increased when accelerating.

- The tread depth varies in different areas, or uneven wear is noticeable on at least one of the wheels. Very often, due to imbalance on the front wheels, the edges of the tires are eaten away.

Before we consider the standard wheel balancing technology, let’s get acquainted with the types of imbalance.

Static imbalance

It occurs due to the fact that the center of gravity shifts some distance from the axis of rotation. That is, there is an uneven placement of weight around the circumference of the wheel, as a result of which the axes of rotation and inertia become parallel.

In order to check for static imbalance, just hang up the car wheel and spin it by hand. When the wheel stops spinning, its lowest point will be the heaviest place. For reliability, the experiment must be repeated several times; if the wheel stops in the same position, this indicates the presence of a static imbalance.

Dynamic imbalance

It is formed due to the mismatch of the axes of inertia and rotation. As a result, when the wheel rotates, significant radial runout is observed, since the mass is distributed unevenly across the entire width of the tire. To eliminate such phenomena, wheels are balanced using special equipment. Moreover, it should be noted that it is only possible to completely get rid of dynamic imbalance; coping with static imbalance is an impossible task for most auto repairmen.

Is balancing necessary every season when replacing wheel assemblies?

When changing tires seasonally, some drivers balance the wheels, believing that this procedure eliminates steering wheel wobble or suspension problems. Other motorists, on the contrary, believe that when replacing wheel assemblies it is not at all necessary to carry out balancing, and the need for it is simply explained by the desire of service shops to earn more money.

The benefits of wheel balancing. Wheel balancing is a useful procedure that allows you to align the center axis of the wheel with respect to both sides. To do this, small weights are hung on the disks. As a result, the driver receives several advantages:

- Improves vehicle handling

- Eliminates the possibility of steering wheel beating

- Knocks in the suspension are prevented

- The trip becomes more comfortable

Most masters consider the balancing procedure necessary, because without it, at speed you will feel discomfort due to the beating of the steering wheel, subsequently the suspension will fall apart, and the car will be difficult to control. It is unlikely that any master will voluntarily refuse to carry out the balancing procedure, because this is a good additional income for him.

Most showrooms offer wheel balancing using special equipment; it helps determine wheel deviations and eliminate them. By placing small weights on the rims, the craftsmen achieve the ideal position of the wheel; the owner can be sure that the wheel will not spin out at speed or fall off while driving, and the suspension will last much longer.

Problems with wheel balancing. Despite the benefits, wheel balancing is not a repair solution to solve all problems. In addition, it should be borne in mind that the quality of the procedure largely depends on the experience of the master. It happens that motorists immediately after balancing go to another workshop, carry out a second check and it turns out that the wheels are unbalanced and require urgent balancing.

In this case, most likely, low-quality equipment was used. As a result, drivers pay twice and wonder why they should carry out balancing at all if they do it poorly. Not very large service stations, as a rule, use cheaper equipment; moreover, it can be adjusted instead of replaced, which also leaves a mark.

To avoid problems, it is best to carry out balancing in a center where masters use modern equipment and constantly test and improve it. This way you can be sure that the procedure will be carried out correctly and efficiently. It’s still not worth giving up balancing completely, since the safety of the driver and passengers on the road directly depends on it.

Bottom line. Although many motorists consider wheel balancing to be a completely optional procedure, you should not refuse it. It would be better to contact a specialized tire center, where they only balance wheels, use the most modern equipment, test and constantly improve.

It is worth remembering that not only driving comfort, but also the safety of passengers and the driver depends on the position of the wheel rims.

How to balance a wheel yourself using a cone

You will need : a cone, which can be made from a construction pin and several washers of a certain diameter.

The old-fashioned way of balancing a wheel:

- Secure the cone strictly in the center of the wheel.

- Place the wheel on a protrusion (for example, a stump) with the tip of the cone.

- Place a weight on the side of the wheel that is higher.

- Rock the wheel a little and wait until it stops.

- If one of the sides of the wheel is higher, repeat the procedure from point No. 3 until the wheel is balanced.

Video example:

This is interesting: Do-it-yourself replacement of front shock absorbers

Reasons for mandatory work

It is imperative to check and perform balancing in the following cases:

- when transferring the car to summer and winter operating modes (seasonal tire replacement);

- after sharp impacts on the wheel when falling into a hole or hatch, hitting a curb, speed bump at high speed, etc.;

- mandatory balancing every 15,000 km (manufacturers' requirement);

- before planning a long trip to regions where there are no service stations;

- If you have an aggressive driving style, it is recommended to carry out work every 7-8 thousand km. Remember that wheels are one of the factors for your safety and the safety of other road users.

Frequency of wheel balancing work

Balancing weights can move out of place as a result of sharp impacts on the rim from oncoming stones or when the wheel falls into a hole. In addition, glued loads can fly off during pressure washing.

An aggressive and sporty driving style with sharp turns, braking and acceleration leads to rapid and uneven tire wear, which disrupts the original balance. Sudden impacts on speed bumps and road curbs do not leave their mark on the wheel geometry, which also negatively affects the balance of forces acting on the wheel.

All of the above reasons are a reason for an unscheduled visit to a service station in order to re-perform balancing work. In principle, ideally zero wheel balancing, which requires advanced equipment, is not particularly required in practice, since in urban driving the destructive force of imbalance manifests itself only in particularly severe cases. The effectiveness of their destructive action increases when driving at high speeds on suburban and high-speed routes.

When do you need to balance your wheels?

When a car has all-season tires, wheel balancing is done once a year. This is only if there were no serious impacts on the suspension while overcoming potholes.

A serious transmission breakdown can disrupt the balance. It also needs to be done when installing tires on a disk during installation and after traveling 500 km. on new tires. When replacing winter tires with summer tires, wheel balancing is mandatory.