For the answer to this question, people often turn to the Internet.

On the websites of other companies you can find different information on the question asked. Reading these publications, you understand that some articles do not provide clarity, and sometimes even deliberately mislead the reader.

To begin with, what types of steel pipes are there? Steel pipes, according to the manufacturing method, are divided into seamless (solid drawn) and seam (welded). Welded pipes are cheaper than seamless pipes, but less reliable and durable.

When asking the question which casing pipe is best to use for a well, many companies offer to use casing pipes that are convenient for them for the job in terms of labor intensity during installation or price, presenting this as the most reliable and high-quality choice for the Customer. We decided to make a short review of all currently used casing pipes for wells and casing installation technologies , without trying to impose on you a solution that is convenient for us.

You need to understand why casing pipes are needed; the main task of the casing pipe is to restrain the soil from falling off the well wall.

Conversion pipes (galvanized)

Drilling companies also offer conversion pipe PMTP-150 (in everyday life – galvanized pipe), which is made from ST-10, as a casing pipe. PMTP-150 is a field main prefabricated pipeline with a nominal diameter of 150 mm, a pressure of 6 MPa, manufactured according to TU 4193-001-48522239-04. They are used for transporting oil and petroleum products, technical and drinking water and other liquids. The pipes used for the casing of water wells were in the state reserve and were not in use anywhere, which is easily determined by their appearance.

The galvanized pipe is 6 meters long. Although the wall thickness of this pipe is 3.2 mm, sockets 10 mm thick are welded at the ends of the pipe at the factory, which allows for high-quality penetration when installing the casing. Due to the fact that the pipe is galvanized, regardless of the wall thickness, its service life increases significantly compared to a black pipe. And no one doubts the quality of materials produced in Soviet times.

Welded pipe connection 152 mm.

Compare with threaded connection of 133 mm diameter steel casing pipes.

Threaded connection of casing pipes

An example of thread failure on a 133 mm steel pipe.

This is what happens with threads

on electric welded pipes

Purpose, features and requirements for casing columns

Tasks of the casing:

- Protection of well walls from collapse;

- Ensuring the integrity of the structure under ground pressure and displacement of soil layers;

- Prevents the penetration of surface groundwater and wastewater into the water intake part;

- Helps not to silt;

- When a well is cased with one pipe, it acts as a production string and contains a column of water.

The entire life of a water intake well is primarily affected by the quality of the casing pipes:

- High-quality material, its strength and resistance to deformation during the entire period of use;

- 100% sealing of walls and pipe connections;

- The pipe material should not affect the chemical composition of groundwater;

- Non-corrosive to chemical elements.

What pipe diameter should I choose for the well?

To correctly select the material, it is necessary to correctly evaluate not only the particular features of the site, but also the tasks for which the wells are created, the power and diameter of the pump. The diameter of the casing pipe is calculated from the submersible pump used.

Household submersible pumps for wells come in two diameters:

- 3 inch (74 mm)

- 4 inch (100 mm)

Therefore, it is necessary to pay special attention to the diameter of the service pipe.

Pipes for a 74 mm pump should be selected as follows: 74 mm (pump diameter) + 4 mm gap between the pump and pipe + 15 mm (P/E pipe wall thickness) = 93 mm.

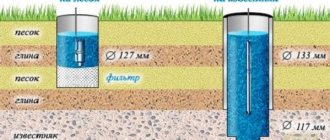

The nearest existing minimum outer diameter of a PE pipe for a production casing for such a pump will be 95 mm. Accordingly, the diameter of the nearest casing pipe (steel) is 127, 133 mm.

Pipes for a 100 mm pump are also calculated as follows: 100 mm + 4 mm + 15 mm = 119 mm. The final diameter of the PE pipe production string for such a pump is 125 mm. Accordingly, the diameter of the nearest casing pipe (steel for a 125 mm PE pipe) is 152.159 mm.

We gave an example of an ideal option, but... a well is a complex hydraulic structure, the design of which is influenced by many factors, in particular the hydrogeological section of the drilling area. Therefore, several casing strings may be required, with different pipe diameters, which will lead to an increase in the initial diameter of the casing string or a decrease in the final diameter.

The design of a water well is adjusted during the drilling process, and the skill of its execution directly depends on the qualifications of the drilling foreman and the contractor’s company.

What is the difference between a 3 and 4 inch pump?

In most cases, the customer’s choice of contractor is usually influenced by the lower cost of 1 linear meter of a drilled well. Therefore, in pursuit of the customer, some contractors, in order to offer a lower price, reduce the initial diameter of the casing pipes, as a result of which we obtain the final diameter of the well only for a 3-inch pump.

Often the customer only finds out about this when he is faced with purchasing a pump. Although 3-inch and 4-inch pumps are approximately the same in their performance indicators (pressure and water supply), they differ significantly in price.

- For example, the cost of a 3-inch pump from Grundfos is 40 thousand rubles and more. Not counting the Chinese pumps.

- The cost of a 4-inch pump starts from 10 thousand rubles and their choice is huge.

Fits good:

- For a well that will be used to supply water to a residential building year-round, we recommend a 3-inch reliable pump, which undoubtedly justifies its cost. There are many other brands of 4-inch pumps that are of good quality and cost significantly less than the Grundfos pump.

- For a small plot of land with a summer house, where you come on weekends during a short summer season, it may not be practical to install expensive equipment used from time to time.

You can learn more about the types of pumps and their differences HERE.

Selection of casing pipes by parameters

There is no single correct well design for drilling. For each specific area, the drilling engineer selects the design individually, taking into account many factors:

- The structure of the geological section of the soil at the drilling point;

- Aquifer and groundwater levels;

- Characteristics of the well pump;

- Depth and diameter of well drilling.

To make a decision, it is necessary to take into account the important parameters of casing pipes:

- Material.

The cost of implementing the project, whether repairs will be possible and the reliability of the structure depend on the material of the pipes. - Pipe connection option.

The connection of the pipes to each other is selected depending on the material of the column, to what depth the well is being drilled, and what diameter of the casing pipe is used. The connection must be airtight, because during use, groundwater and other impurities may enter the water. In this regard, the well pump may fail and the well itself will become unusable. - Diameter.

The optimal pipe diameter is calculated taking into account peak water consumption per day. A larger pipe diameter gives a higher well flow rate.

How not to make a mistake when choosing a reliable drilling company?

You should also keep in mind that if you save several thousand rubles on drilling a well once, you can lose much more by purchasing an expensive pump.

Over the last 2-3 years, many drilling companies have appeared that write on their websites: “Our company has existed for 10-15 years,” without specifying how long they are directly engaged in water drilling. A company can exist for 10–15 years, while engaging in another type of activity , and water drilling is a new direction for them.

Such companies are often managed by people who do not have not only a special, but simply a technical education, relying on the experience and knowledge of their drilling crews.

How to check how long a company has been engaged in drilling operations?

It is easy to check how long a company has been engaged in this type of activity using the documents:

- SRO certificate of admission to a certain type or types of work with the names of these types of work attached;

- Information letter from the State Statistics Committee on the presence of a legal entity or individual entrepreneur in the Unified State Register of Enterprises and Organizations (USRPO), indicating the name of the type of economic activity.

Trying to attract customers, the companies described above offer lower prices for water drilling at the expense of quality, violating the technology of the work being carried out. In the market for these services, some customers choose the lowest drilling prices, without thinking that low price means low quality. It is clear that a good product does not come cheap.

Why should you contact our company?

Currently, there are worthy companies in the water drilling services market that have extensive experience and developments in this area. Our company has been on the drilling market since 2001.

During this time the following were created:

- Own production base

- Drilling rigs are equipped with all necessary equipment

- Highly qualified specialists with related professions.

Our service:

- We are ready to carry out work from any materials you choose, with high quality and on time.

- Drilling crews have a mobile place of residence, thereby creating a minimum of inconvenience for the customer.

- If your site does not have power supply, we also undertake to provide electricity for the work we carry out.

Casing connection options

- Seamless pipes with spiral or longitudinal welding seam.

They are used if the formation pressure is no more than 16 kg/cm2 and the temperature is less than 300 degrees. Service life 40-45 years. - Seamless pipes are called seamless pipes.

Produced using special high-tech machines. The cost of seamless pipes is 500 rubles more per 1 linear meter. The temperature and pressure characteristics are slightly greater than those of a seamed pipe.

Since there are no such temperatures and pressures in the underground environment, you can install seam pipes and not overpay for seamless ones.

Types of casing connections:

- On the thread.

The conical internal and external threads are connected to each other, the pipe fits into the pipe. - On the thread through the coupling.

There is an external conical thread on both ends, and an internal thread on the coupling. This connection is called reinforced. - Welding.

The quality and tightness of the seam depends on the professionalism of the welder.

Our experts advise choosing a conical connection, when the internal and external threads are connected to each other, the pipe fits into the pipe. Do not save money when choosing a welding connection, since the quality of the weld depends on the experience of the welding master, and the benefit is not great at all.

General points to consider

There are a variety of pipes available on the market, made from three types of material:

- become;

- asbestos cement;

- plastic.

But among them it is difficult to find a universal option that is suitable for any well.

The conditions in which drilling will be carried out vary, so for each specific situation you need to look for the best option. When choosing which pipe to use for a well, you should consider a number of factors:

- drilling depth;

- drilling technology;

- well diameter;

- soil structure.

The fact is that the soil is heterogeneous and has some mobility, so the casing pipes experience significant loads from the outside and inside. That is why it is very important to decide from which aquifer it is intended to extract water. You should also evaluate the possibility of sewage entering the pipe and the level of upstream water carriers.

Tip: The easiest way to find out the condition of the soil, as well as the depth and location of the aquifer, is to find out how your neighbors solved a similar problem. To do this, it is enough to find an active well that is located as close as possible to the site.

Steel option: reliable and expensive

Steel pipes have a well-deserved reputation as the most reliable structures for wells. A durable six-millimeter pipe can easily withstand almost any load, keeps water clean and faithfully serves its owners for fifty years. A well with such a casing can be easily cleaned without worrying about possible damage. This is a completely suitable pipe for a well pump.

When drilling deep and on difficult soils, it is recommended to use reliable steel pipes

In addition to the traditional steel pipe, there are varieties on the market:

- enameled;

- galvanized;

- made of stainless steel.

Unfortunately, it is almost impossible to install enameled structures without chipping, and damage to the enamel leads to fairly rapid corrosion. Some experts believe that the use of galvanized metal in prolonged contact with water can cause very dangerous zinc oxide contamination.

The main disadvantage of steel structures is the very high price. Therefore, manufacturers are constantly looking for alternatives to expensive steel.

Please note: If black steel structures are used, rust particles may appear in the water over time. The problem can be easily solved using a regular household filter.

Asbestos-cement pipes: inexpensive, but fragile

Asbestos cement is chemically neutral, incredibly resistant to corrosion and has no restrictions on its service life.

Pipes made from this material will cost much less than steel. They would have ousted all metal structures from the market long ago, if not for one drawback: it is a rather fragile material.

Asbestos-cement pipes are a classic. They are great for use in wells and boreholes

As a result, in order to ensure sufficient strength, asbestos cement pipes are made with very thick walls, for which it is necessary to drill a hole of a larger diameter. In addition, work with asbestos cement should be done very carefully, but not all installers have a high enough professional level for this.

Can I use plastic?

Many companies that drill wells like to use plastic pipes for casing. The basis for such pipes can be low-density polyethylene, unplasticized PVC and polypropylene. The service life of such pipes can reach hundreds of years. Polymers do not interact with well water, so they do not decompose or corrode. Bacteria contained in the soil are also not able to decompose plastic in a short time. The listed types of polymers do not release any substances into the water, so there is no danger to health. But this is only provided that the pipes are purchased from a responsible manufacturer. Delivery and installation of pipes made of polymers is much easier than their metal counterparts.

The limitation on the use of plastic casing pipes is the maximum well depth. The products are suitable for a maximum of sand wells that do not exceed 60 meters. Plastic also does not withstand low temperatures. It becomes brittle and can be easily damaged. A plastic casing can be installed if it is known that there is no heavy ground movement in the area.

Use of threaded water-lifting channels

Threaded connections are used in 90% of cases when it comes to metal products. Many managers are silent about maintaining the relevance of the rules only for pipes whose diameter is up to 146 millimeters and whose wall thickness is at least 6 mm.

Columns do not last as long if threaded technologies were used.

There are several methods to join seams:

- Bell-shaped The thread is present on the inner and outer sides of the segments equally. Thanks to this, docking does not require additional elements.

- Coupling. When only external threads are made on both sides. For joining, a patch coupling is used. Because of this, the diameter of the penetration increases.

- Nipple. With threading on both sides, using plastic pipes. The connection is made using a nipple, which is supplied to the outside. There is no increase in the diameter of the hole.