In addition to iron and carbon (the main components), steel consists of various additives and inclusions. They can be divided into two groups – harmful and beneficial impurities. The first category includes substances and compounds that negatively affect the consumer qualities of steel. Elements of the second group have a diametrically opposite effect; they help improve certain characteristics of the metal. In order to obtain steel that has optimal values of the main characteristics (hardness, impact strength, yield strength), it is necessary to understand in as much detail as possible about both groups of impurities, what elements are included in them and what is the impact of individual components on the quality of steel.

Phosphorus

Iron ores, fuels, and fluxes contain some amount of phosphorus, which during the production of cast iron remains in it to one degree or another and then turns into steel. Phosphorus dissolves well in ferrite and austenite, and at high content it forms phosphide Fe3P (15.62% P). Dissolving in ferrite, phosphorus distorts the crystal lattice and increases the strength and yield limits of steel, greatly reducing ductility and toughness; every 0.01% P increases the cold brittleness threshold by 20...25 0C. Phosphorus is a harmful impurity in steels.

Impurities: permanent, hidden and random

Manganese, silicon, aluminum, sulfur and phosphorus

classified as

permanent impurities

.

Aluminum, together with manganese and silicon, is used as a deoxidizer and therefore they are always present in small quantities in deoxidized steels. Iron ores, as well as fuels and fluxes, always contain a certain amount of phosphorus and sulfur, which remain in cast iron and then pass into steel

.

Nitrogen

called

a hidden

impurity - it enters steel mainly from the air.

To random

impurities include

copper, arsenic, tin, zinc, antimony, lead

and other elements. They end up in the steel with the charge - with ores from various deposits, as well as from iron scrap.

All impurities - permanent, hidden and accidental - are inevitable to varying degrees due to steel production technology. Thus, mild steel usually contains these impurities within the following limits: 0.3-0.7% manganese; 0.2-0.4% silicon; 0.01-0.02% aluminum; 0.01-0.05% phosphorus, 0.01-0.04% sulfur, 0.-0.2% copper. In these quantities, these elements are considered as impurities, and in larger quantities, which are intentionally added to steel, they are already considered alloying elements.

Sulfur

Like phosphorus, sulfur enters the metal from ores, as well as from furnace gases - a product of fuel combustion (SO2). Sulfur is very limitedly soluble in ferrite, and almost any amount of it forms a sulfur compound with iron - iron sulfide FeS, which is part of the eutectic, which has a melting point of 988 0C. It is located mainly along the grain boundaries. When steel is heated to rolling or forging temperatures (1000...1200 0C), the eutectic melts, breaking the bond between grains. During deformation, tears and cracks form in these places. This phenomenon is called red brittleness. The introduction of manganese into steel reduces the harmful effects of sulfur, since when it is introduced into liquid steel, manganese sulfide is formed, which has a melting point

1620 0С:

FeS + Mn -> MnS + Fe.

MnS particles are located in the form of separate inclusions and, during deformation, are pulled into lines along the rolling.

Sulfur compounds greatly reduce the mechanical properties of steel under static and cyclic loading, especially toughness, ductility, and endurance limit. Sulfur is a harmful impurity in steels.

Harmful impurities in steel

The name of this group of impurities has a negative connotation, but do not think that this is an absolute evil. The fact is that some of them, in addition to having a negative effect on the quality of the metal, also have a positive effect. It is also necessary to take into account that it is in principle impossible to get rid of some elements from this group - they are present in varying quantities in any grade of steel.

Antimony

A negative property of this component is the segregation on the grain surface that occurs during steel solidification. This feature of antimony increases the temper brittleness of alloy steels. The presence of antimony in the chemical composition of the alloy has a particularly negative effect on the surface quality of ingots that are cast continuously.

Nitrogen

The presence of nitrogen leads to the formation of nitrides in the steel structure - non-metallic foreign inclusions that reduce the quality of steel. However, nitrogen cannot be classified only as harmful impurities, since this element also has a positive effect on the metal. The fact is that thanks to nitrogen, the austenitic region of the iron-carbon phase diagram increases. Expensive nickel has a similar quality, so using nitrogen can replace this alloying element, but not completely.

Sulfur

This component is considered the most harmful for steel. In steel, the impurity forms copper sulfide, which reduces the main characteristics: weldability, ductility, impact strength. In addition, sulfur makes steel cold brittle, since sulfide eutectics are formed at the crystal boundaries. Because of these qualities, the sulfur content in steels is limited to certain standards. For example, in high-quality brands the sulfur content does not exceed 0.02-0.03%. In general purpose steels, the mass fraction of this impurity varies between 0.03-0.04%. To keep the content to a minimum, the steel undergoes special treatment, after which the mass fraction of sulfur is reduced to 0.005%.

Phosphorus

It is not for nothing that this substance comes after sulfur, since it is also considered the most harmful. Phosphorus leads to an increase in the cold brittleness of steel and a decrease in the impact strength of the metal. The presence of phosphorus in steels alloyed with chromium, nickel and manganese helps slow down the decomposition of martensite and increases the hardening of steel. Corrosion of austenitic stainless steel upon contact with a strong oxidizing agent is also the fault of phosphorus.

Carbon

The inclusion of this component of steel in this category may be surprising, since, along with iron, carbon is the main component of any grade of steel. However, you need to understand that an excessive amount of carbon contributes to the transition of the metal into a cold-brittle state - the hardness increases and the tensile strength decreases. In addition, an increase in the percentage of carbon leads to an increase in the metal's electrical resistance and coercive force.

Tin

Due to segregation at the grain boundaries of tin in the steel composition, it reduces the ductility of the metal in the austenitic-ferritic region. Even a minimal amount of tin in the chemical composition leads to temper brittleness of the metal. It is especially important to minimize the content of this element when casting ingots using a continuous process.

Oxygen

For steel, such a characteristic as ductility, which decreases due to the oxygen content, is extremely important. Oxygen can enter the composition not only during smelting, but also during welding. To prevent this, welding is used in shielding gases - argon, helium. Deoxidation is used to reduce the oxygen content.

Improving steel quality

To remove gases and non-metallic inclusions dissolved in it from liquid steel, vacuum treatment is used. To do this, a ladle with liquid steel is placed in a hermetically sealed chamber, where a vacuum of 267...667 Pa (2...5 mm Hg) is created. The rapidly released gases carry with them non-metallic inclusions and remove them from the metal. Within 10...15 minutes, the amount of dissolved gases decreases by 3...5 times, the number of non-metallic inclusions - by 2...3 times.

To protect the metal from oxidation, steel is cast in an inert atmosphere, for example, argon, under a layer of synthetic slag. To produce steels of particularly high quality, electroslag remelting (ESR), plasma arc remelting, electron beam remelting, and electric arc vacuum remelting are used. The metal is well cleaned (refined) from gases and non-metallic inclusions by treatment with slag and directed crystallization of the liquid melt, creating a deep vacuum.

Classification of carbon steels > Continue >

The influence of aluminum on the properties of steels

Aluminum (Al) is widely used for deoxidation of liquid steel, as well as for grain refinement of steel ingots. The harmful effects of aluminum include the fact that it promotes the graphitization of steels. Although aluminum is often considered an impurity, it is also actively used as an alloying element. Because aluminum forms solid nitrides with nitrogen, it is usually an alloying element in nitrided steels. Aluminum increases the resistance of steels to scaling, and therefore it is added to heat-resistant steels and alloys. In dispersion-hardening stainless steels, aluminum is used as an alloying element that accelerates the dispersion precipitation reaction. Aluminum increases the corrosion resistance of low-carbon steels. Of all the alloying elements, aluminum is the most effective for controlling grain growth when heating steels for hardening.

Bioavailability of iron and the influence of calcium ions on its effectiveness

The iron content in the human body averages 4.2 g. About 75% of its total amount is included in the hemoglobin of red blood cells, which carry oxygen from the lungs to the tissues, 20% of iron is reserve (bone marrow, liver, macrophages), 4% is part of myoglobin, about 1% is contained in respiratory enzymes that catalyze respiration processes in cells and tissues, as well as in other enzymatic structures. Iron carries out its biological function by being part of biologically active compounds, mainly enzymes. Iron-containing enzymes perform the following main functions:

- electron transport (cytochromes);

- transport and storage of oxygen (hemoglobin, myoglobin);

- participation in the formation of active centers;

- redox functions (oxidases, hydroxylases, superoxide dismutases, etc.);

- transport and deposition of iron in blood plasma (transferrin, ferritin).

Iron has several special properties that distinguish it from other biologically active ions and substances.

The human body does not have any special mechanisms for removing iron. Iron is mainly excreted through the skin and intestines (I. Guinote et al., 2006). In addition, it is also lost in hair, nails, urine and sweat. The total amount of iron excreted in a healthy person (male) is about 1 mg per day. The same amount is normally absorbed from food consumed (Linder, 1991). The difference is during the menstrual period, when intake should be about 4 mg of iron per day. Thus, the concentration of the element in the blood serum depends on its absorption in the gastrointestinal tract, on its accumulation in the spleen, bone marrow and skeletal muscles (myoglobin), as well as on the synthesis and breakdown of hemoglobin and its release from the body. Iron can be present in food in two forms - heme and non-heme, which are characterized by different absorption mechanisms. Heme iron (a porphyrin ring with an iron atom in the center, bound to 4 nitrogen atoms) is released from protein chains in the gastrointestinal tract and is absorbed by intestinal enterocytes in the form of metalloporphyrin. There, nonspecific endosomal penetration of heme into the cell occurs, followed by its destruction. Next, with the help of the protein transport system IREG1, iron ions are oxidized to ferric iron, bind to transferrin and leave the enterocyte, entering the bloodstream (Linder et al., 2006). In the blood plasma, iron moves in conjunction with the same protein, which performs both the depot and transport functions. The presence of free iron ions in the blood is not typical and is a pathology. Absorption of heme iron occurs in the range of 15–50% (average 20–30%).

Non-heme ferrous iron in the stomach is bound by the protein gastroferrin and transported to the intestine. Once in the duodenum and proximal part of the jejunum, iron enters the enterocyte using the nonspecific ion transporter DMT1 (Divalent metal transport). This proton-dependent transporter is also involved in the transport of many other divalent cations, such as Mn, Cu and Zn (M. Arredondo et al., 2006). In addition, it has been shown that this carrier can also transport some monovalent ions, such as Cu+1, which is formed by the action of ascorbate on Cu+2 (M. Linder et al., 2006). Thus, it can be assumed that depending on the concentration of these ions in the diet or multivitamin tablet, they may compete for the DMT1 transporter. At the same time, there is evidence that there is specificity of the DMT1 transporter in relation to various divalent ions, associated with their location along the gastrointestinal tract, which was shown by transcription of various iron-independent mRNAs of the DMT1 transporter, and there is no competition for the transporter.

The literature describes several mechanisms of iron transport within the enterocyte, based mainly on experiments carried out on tissue culture Caco2 (M. Linder et al., 2006). According to the first theory, divalent iron, which enters the enterocyte using the DMT1 transporter, is delivered through vesicles with transferrin (some assign it the role of an intracellular receptor) or in a free state to the basolateral membrane of the enterocyte, where another transporter is present - IREGI/ferroportin/MTP1 (Donovan et al. al., 2000). This transporter oxidizes ferrous iron to ferric iron and transports it into the blood, where it combines with plasma transferrin. According to the second theory, iron is transported inside the enterocyte, apparently in vesicles along with apotransferrin, which enters the enterocyte from the bloodstream by endocytosis (endo-/exocytosis) (Ma et al., 2002). During this transport, divalent iron is oxidized to ferric iron and enters the blood through the basilar membrane of the enterocyte through exocytosis. The already mentioned IREG system may participate in this process. According to the literature, it is the mechanism of iron transport through the basolateral membrane of the enterocyte into the blood that is limiting in the process of iron adsorption (Roy and Enns, 2000). Absorption of inorganic ferrous iron usually occurs in the range of 6–15%.

Non-heme ferric iron can be reduced by ferrous reductase to ferrous iron and absorbed by DMT1. The recovery of ferric iron is highly dependent on the acidity of gastric juice. Unreduced iron can be absorbed through the specific integrin-mobiferin IMP system. The absorption of ferric iron is the least complete and rarely exceeds 4%.

The amount of iron entering the effector cell, where it is transported with the blood, is directly proportional to the number of membrane receptors. The cell releases iron from transferrin. Plasma apotransferrin is then returned to circulation. An increase in the need of cells for iron during their rapid growth or hemoglobin synthesis leads to the induction of the biosynthesis of transferrin receptors and, on the contrary, with an increase in iron reserves in the cell, the number of receptors on its surface decreases. Iron released from transferrin inside the cell binds to ferritin, which delivers the trace element to the mitochondria, where it is incorporated into heme. In addition to heme synthesis, ferrous iron is used in mitochondria to synthesize iron-sulfur centers. There is a constant redistribution of iron in the human body. In quantitative terms, the metabolic cycle is of greatest importance: plasma - red bone marrow - red blood cells - plasma. Typically, 70% of plasma iron goes to the bone marrow. Due to the breakdown of hemoglobin, about 21–24 mg of iron is released per day, which is many times higher than the intake of iron from the digestive tract (1–2 mg/day).

There is a pronounced inverse relationship between the body's supply of iron and its absorption in the digestive tract. Iron absorption occurs primarily in the duodenum and proximal jejunum and is absent in the ileum.

The absorption of iron depends on the following reasons: age, the body's supply of iron, the state of the gastrointestinal tract, the amount and chemical forms of incoming iron and other food components. For optimal absorption of iron, normal gastric juice secretion is necessary. Taking hydrochloric acid promotes the absorption of iron in achlorhydria. The table shows the main substances found in human foods that can enhance or reduce the absorption of iron contained in that food or multivitamin tablet. Ascorbic acid, which reduces iron and forms chelate complexes with it, increases the availability of this element in the same way as other organic acids. It is one of the most powerful stimulators of iron absorption. Another food component that increases iron absorption is “animal protein factor,” which contains myoglobin and hemoglobin. Simple carbohydrates improve iron absorption: lactose, fructose, sorbitol, as well as amino acids such as histidine, lysine, cysteine, which form easily absorbed chelates with iron.

The most powerful inhibitors that block iron absorption are phytates and polyphenols. Phytates are a storage form of phosphates and minerals found in cereal grains, vegetables, seeds and nuts. They actively inhibit iron absorption, acting in direct proportion to the dose. Iron absorption is reduced by drinks such as tea containing tannin, as well as other polyphenolic compounds that bind this element tightly. Phenolic compounds exist in almost all plants and are part of the defense system against insects and animals. Therefore, tea is used to prevent increased iron absorption in patients with thalassemia. Various diseases have a great influence on the absorption of iron. It increases with iron deficiency, with anemia (hemolytic, aplastic, pernicious), hypovitaminosis B6 and hemochromatosis, which is explained by increased erythropoiesis, depletion of iron reserves and hypoxia.

Of the listed substances that can reduce iron absorption, calcium ion attracts special attention. Calcium is highly biologically active, is found in significant quantities in staple foods, and is usually present in one multivitamin tablet with iron.

| Table. Activators and inhibitors of iron absorption contained in the human diet |

In this regard, the question of the possible effect of calcium on the bioavailability of iron has been studied for a long time, both in animal experiments and in human studies.

It should be noted that the cellular mechanisms of absorption, i.e., the flow of iron and calcium ions from the intestinal lumen into the bloodstream through intestinal enterocytes, are different. Numerous studies have shown that various cellular transporters are involved in this process (J. Hoenderop et al., 2005). In addition, there is evidence that calcium reduces the intake of both heme (L. Hallberg, 1991) and non-heme iron. Taken together, this indicates that calcium may influence the bioavailability of iron by exerting an inhibitory effect either on its transport in the gastrointestinal tract or on binding to receptors located on the apical membrane of enterocytes.

Experiments on an isolated intestinal loop in vivo in rats showed a decrease in the absorption of iron from a FeCl2 solution injected directly into the loop with the addition of calcium. Moreover, the effect depended on the absolute concentration of calcium in the duodenum, and not on the molar Ca/Fe ratio (Barton et al., 1983). A study of the effect of various calcium-containing salts on cellular iron transport showed that the greatest inhibitory effect is caused by CaCO3, while the effects of CaSO4 and Na2CO3 are present, but to a lesser extent (Prather, 1992). This calcium salt, added in an amount of 500 mg, can reduce the absorption of non-heme iron contained in foods by 32% when consuming foods that do not contain additional inhibitory substances, and by 42% when consuming foods in combination with eggs, coffee, etc. (Cook et al., 1991). CaCO3 also reduces the absorption of iron when used together in one tablet. In this case, 300 mg of calcium salt, when taken together with 37 mg of iron, present as FeSO4, reduces iron absorption by 15% (Seligman et al., 1983; Cook et al., 1991).

Volunteers were tested on the absorption of iron when combined with calcium-containing foods. Iron absorption was determined by the radioisotope method using Fe55 and Fe59. Healthy women (21 subjects) consumed additional milk and cheese (~930 mg calcium per day) for 10 days. This resulted in a 30–50% reduction in iron absorption (Hallberg, 1995). Based on the data obtained, the authors suggest that inhibition of iron absorption occurs at the intestinal lumen-enterocyte stage.

Human studies also examined the effects of artificial mineral supplements: ferrous sulfate, calcium citrate and calcium phosphate, etc. The work was carried out on 61 healthy subjects. The dual radioisotope method was also used to assess absorption. When calcium citrate (600 mg) was consumed, iron absorption was reduced by 49% and phosphate by 62% (Cook et al., 1991). Interestingly, in this study, the effect of calcium supplementation was observed only in the presence of food intake. It is likely that competition between cations occurred when the intestine was full. It is theoretically possible that high concentrations of calcium may alter the rheological properties of the bolus in the lumen of the upper small intestine (Conrad et al., 1993). The differences in the effects of calcium on heme and non-heme iron intake have also been studied in humans. Thus, in a study on 27 volunteers using a complete colonic lavage to measure iron absorption, calcium supplementation (450 mg) showed a 20% reduction in the absorption of heme iron alone. In this study, calcium supplementation did not affect the absorption of non-heme iron (ZK Roughead, 2005). Another study conducted on 44 men and 81 women observed a decrease in the absorption of heme iron from the diet with calcium supplementation in doses ranging from 40 to 300 mg. The maximum reduction was observed at a dose of 300 mg and amounted to 74%. A further increase in calcium content to 600 mg did not lead to an increase in iron ion inhibition (L. Hallberg et al., 1991). The conflicting results obtained in different studies are likely due to the difficulty of replicating the accuracy of methodological approaches carried out in humans.

All of the above studies showed, to one degree or another, a decrease in iron absorption in the gastrointestinal tract by 20–60% when combined with calcium-containing products during a single meal or tablet preparations. It is characteristic that the doses of calcium used did not exceed the daily norm for an adult (in all the described cases, the total intake of calcium per day was less than 1000 mg). However, the direct mechanism of the antagonistic effect of calcium on iron absorption remains unclear.

A series of studies conducted on volunteers with long-term joint meals containing a certain amount of iron and calcium did not provide a clear answer about the effect of calcium ion on the bioavailability of iron, and most importantly, on the hemoglobin level in these subjects. An effect was often detected (19% inhibition) but was not statistically significant (Reddy et al., 1997). Long-term studies in humans appear to be complicated by dietary controls and dietary controls (SR Lynch, 2000).

An analysis of the literature allows us to conclude that experimental studies on animals and work carried out on subjects have confirmed that calcium ions can reduce the level of iron absorption. The extent to which the effect was detected depended on the methodological approaches used, which differed from one study to another, making it difficult to interpret the results. However, the possibility of such interactions may be most relevant and should certainly be taken into account for people suffering from iron deficiency conditions (anemia) or who are at risk for this condition (children, pregnant women, etc.). To treat and prevent such conditions, it is necessary to increase iron intake, both through an appropriate diet and through mineral supplements. But it should be remembered that the effectiveness of these measures may be significantly reduced by the consumption of dietary calcium or calcium-containing vitamin complexes. It is not advisable to limit calcium intake, since in many cases (pregnancy, age 12–18 years) there is an increased need for both elements. A way out of the situation can be the separate use of calcium and iron. Experimental data have shown that an interval between calcium and iron intake of even 4 hours eliminates the inhibitory effect (A. Gleeprup et al., 1993). In addition, while taking an iron supplement, you should refrain from consuming any foods containing calcium, i.e. you need to exclude the entire range of dairy products, as well as green parts of plants.

In this case, it is convenient to use vitamin-mineral complexes, which provide for the separate use of iron and calcium in advance. And this is not the only combination of vital micronutrients that exhibit antagonistic properties. Thus, proper separation of the components of vitamin-mineral complexes according to the time of administration is a necessary condition for the effectiveness of their use.

Literature

- Arredondo M., Martinez R., Nunez MT et al. Inhibition of iron and copper uptake by iron, copper and zinc. Biol. Res. 2006; 39: 95–102.

- Barton JC, Conrad ME, Parmley RT Calcium inhibition of inorganic iron absorption in rats. Gastroenterology. 1983; 84:90–101.

- Conrad ME, Umbreit JN A concise review: iron absorption- the mucin - mobilferrin - integrin parthway. A competitive partway for metal absorption. Am J Hematology. 1993; 42:67–73.

- Cook JD Adaption in iron metabolism. Am J Clin Nutrition. 1990; 42:67–73.

- Cook JD, Dassenko SA, Whittaker P. Calcium supplementation: effect on iron absorption. Am J Clin Nutrition. 1991a; 53: 106–111.

- Donovan A., Brownile A., Zhou Y. et al. Positional cloning of zebrafish ferraportin identifies a conserved vertebrate iron exporter. Nature. 2000; 403:776–781.

- Gleerup A., Rossander-Hulten L., Hallberg L. Duration of the inhibitory effect of calcium on non-haem iron absorption in man. Eur I Clin Nutr. 1993; 47:875–879.

- Guinote, Fleming R., Silva R. et al. Using skin to assassinate iron accumulation in human metabolic disorders. Ion Beam Analysis. 2006; 249:697–701.

- Hallenberg L., Brune M., Erlandsson M. et al. Calcium: effect of different amounts on nonheme- and heme-iron absorption in humans. Am J Clin Nutrition. 1991; 53: 112–119.

- Hoenderop J. Gj., Nilius B., Bindels RJM Calcium absorption across epithelia. Physiol. Rev. 2005; 85:373–422.

- Linder MC Nutrition and metabolism of the trace element. Nutritional Biochemistry and Metabolism. 1991: 151–198.

- Linder MC, Moriya M., Whon A. et al. Vesicular transport of Fe and interaction with other metal ions in polarized Caco2 Cell monolayers. Biol. Res. 2006; 39: 143–156.

- Lynch SR The effect of calcium on iron absorption. Nutr. Res. Rev. 2000; 13: 141–158.

- Ma Y., Specian RD, Yen KY et al. The transcytosis of divalent metal transporter 1 and apo-transferrin during iron uptake in intestinal epithelium. Am J Physiol. 2002; 283:965–97.

- Prather Ta and Miller DD Calcium carbonate depresses iron bioavailability in rats more than calcium sulfate or sodium carbonate. J Nutrition. 1992; 122:327–332.

- Reddy MB and Cook JD Effect of calcium on nonheme-ironabsorption from a complete diet. Am J Clin Nutrition. 1997; 65: 1820–1825.

- Roughead ZK, Zito CA, Hunt JR Inhibitory effects of dietary calcium on the initial uptake and subsequent retention of heme and nonheme iron in humans: comparisons using an intestinal lavage method. Am J Clin Nutr. 2005; 82(3): 589–597.

- Roy CN and Enns CA Iron homeostasis: New tales from the crypt. Blood. 2000; 96: 4020–4027.

- Seligman PA, Caskey JH, Frazier JL et al. Measurements of iron absorption from prenatal multivitamin-mineral supplements. Obstetrics and Gynecology. 1983; 61:356–362.

N. A. Medvedeva , Doctor of Biological Sciences, Professor of Moscow State University, Moscow

The influence of nitrogen on the properties of steels

The harmful effect of nitrogen (N) is that the rather large, brittle non-metallic inclusions it forms - nitrides - worsen the properties of steel. A positive property of nitrogen is that it is capable of expanding the austenitic region of the phase diagram of steels. Nitrogen stabilizes the austenitic structure and partially replaces nickel in austenitic steels. Nitride-forming elements vanadium, niobium and titanium are added to low-alloy steels. When controlled by hot working and cooling, they form fine nitrides and carbonitrides, which significantly increase the strength of the steel.

Marking

When designating carbon steels of ordinary quality, the letters St are used, which are accompanied by numbers characterizing the carbon content. One digit shows the quantity multiplied by 10, and two digits by 100. When guaranteeing the mechanical composition of the alloy, B is added before the designation, and compliance with the chemical constituents is B.

At the end of the marking, two letters indicate the degree of deoxidation: ps - semi-quiet, kp - boiling state of the alloys. For calm metals this indicator is not indicated. An increased amount of manganese in the structure of the product is designated by the letter G.

When designating high-quality carbon steels used in the manufacture of tools, the letter U is used, next to which a number is written confirming the percentage of carbon in a 10-fold amount, regardless of whether it is two-digit or single-digit. To highlight higher quality alloys, the letter A is added to the designation of tool steels.

Examples of designation of carbon steels: U8, U12A, St4kp, VSt3, St2G, BSt5ps.

Hydrogen in steel

Hydrogen and nitrogen are components of steel that attract metallurgists due to the fact that, at a certain content, they significantly affect the properties of steel, changing them for the worse.

The hydrogen content in steel at the end of melting depends little on the type of process and is usually (3-6) cm3/100 g of metal [13]. This is significantly higher than its solubility in a

-Fe. In addition, elements have not yet been found that could form strong hydrides in steel, insoluble in liquid iron, so hydrogen is released from the metal in the form of gas, as a rule, in the temperature range below 800-950 oC (after rolling or forging is completed) . This release of hydrogen can cause the formation of internal cracks called flakes. Alloy steels usually have a significant tendency to form flakes.

To assess the level of hydrogen content in the metal at the technological sites of its smelting and casting, special samples were taken. Samples were taken during the smelting, processing and casting of steel 09G2S and RSD 32 before (on 16 heats) and after (on 14 heats) the commissioning of the ladle furnace installation. The results of determining the hydrogen content in the metal are presented in Table 3.

Table 3

– Hydrogen content in metal at various technological stages of production

The data obtained show that the hydrogen content in the metal at the outlet of the steel-smelting unit is on average the same (6.9-7.0) cm3/100 g, both during the smelting of the semi-product and in the finished steel. Subsequently, during finishing at the CPC and casting at the continuous casting machine, the hydrogen content decreases significantly and reaches an average of (4.4-4.8) cm3/100 g. The spread of hydrogen content values at all stages of production is approximately the same.

It should be noted that in the final product of steel production (in slabs) we obtain rather low values of hydrogen content. This level of hydrogen content in the main range of steel we produce does not affect its quality. At the same time, Povolotsky D.Ya. and Morozov A.N. It has been established that the formation of flakes is excluded when the hydrogen content in steel is no more than (1.5-2.0) cm3/100 g.

It is impossible to obtain such a low hydrogen content by open steel smelting processes, therefore, to reduce the possibility of formation of flakes in steel, it is necessary to degas the metal by evacuation or slow cooling of the workpieces (ingots) in special chambers (usually for three days). In the latter case, the evolution of hydrogen occurs at such a low rate that the formation of flakes is excluded.

In the practice of our steelmaking shop, due to the relatively low hydrogen content in the cast metal, as well as the absence (this is the main thing) in the assortment of flake-sensitive steel grades, special systematic measures are not taken to reduce the possibility of flake formation in steel.

The influence of copper on the properties of steels

Copper (Cu) has a moderate tendency to segregate. The harmful effects of copper include a decrease in the cold brittleness of steel. With an increased copper content, it negatively affects the quality of the steel surface during hot processing. However, with a content of more than 0.20% copper increases its resistance to atmospheric corrosion, as well as the strength properties of alloy and low-alloy steels. Copper in amounts greater than 1% increases the resistance of austenitic stainless steels to sulfuric and hydrochloric acids, as well as their resistance to stress corrosion.

Nitrogen in steel

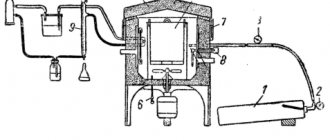

At the first stage, to study the dynamics of nitrogen content along the path from steelmaking unit to rolling stock, to clarify the technological period and the source of nitrogen entering the metal, experimental melts were carried out and metal samples were taken: from the furnace at the outlet, from the ladle upon arrival at the processing plant, at the beginning and end of processing at UPC, at the beginning and end of casting on a continuous caster from a steel-pouring ladle, during casting from a tundish (3 samples) and a mold, as well as from finished rolled products. The technological parameters of the melts performed are almost identical. A significant difference is that melt No. 60170 was not purged with nitrogen at the outlet. The dynamics of changes in the nitrogen content in the metal during the periods of smelting (end of melting), finishing at the CPC, casting at the continuous casting machine and rolling are presented in Figure 3. From the given data it can be seen:

- the overall increase in nitrogen content along the path between the steelmaking unit and rolled products is (40–70) ppm;

- in melts there is an increase in the nitrogen content at the outlet of the steel-smelting unit (10–30) ppm abs. or (20-33)% rel. (sq. no. 30218, 40173);

- significant increase in nitrogen content (20–30) ppm abs., or (43–50)% rel. in general, observed during the passage of metal from the steel-pouring to the tundish;

- there is no increase in the nitrogen content during the tapping period at smelter No. 60170, which is apparently due to the lack of nitrogen purging on this melt;

- a slight increase in nitrogen was noted on the path between the tundish and the crystallizer. The nitrogen content (pl. No. 60170) in the crystallizer is 10 ppm higher than in the simultaneously taken sample from the tundish; it is 90 ppm and coincides with the nitrogen content in two samples from the rolled product.

Rice. 3

— Dynamics of changes in nitrogen in the metal during the periods of smelting in a steel-smelting unit - finishing at the processing plant - casting at the continuous casting machine - rolling: KR. – crystallizer; PC. – tundish; S.K. – steel-pouring ladle

Thus, as a result of the research, the technological periods of steel production, the reasons and sources of saturation of the metal with nitrogen were established. The main increase in nitrogen occurs in the steel-pouring ladle during the period of metal release from the open-hearth furnace and its mixing, and in the tundish when the metal passes from the steel-pouring ladle into the tundish.

Sources of nitrogen entering the metal during release from a steel-smelting unit are:

- atmospheric air entrained by the flow of metal moving along the chute and falling into the steel-pouring ladle;

- nitrogen gas used to stir metal in a ladle.

The reason for the saturation of the metal with nitrogen during casting on a continuous caster is the injection of air into the metal stream in the area of its exit from the steel-pouring ladle due to a leak in the connection of the submersible pipe with the slide gate manifold.

At the second stage, the main goal of the work was to study the dynamics of nitrogen content and the level of its increment in the metal at technological production sites under various options for the production of semi-products from a steel-smelting unit, casting steel on a continuous caster and in molds, and to study the technological possibilities of reducing the mass fraction of nitrogen in steel.

We studied the dynamics of nitrogen content and its increment in the metal for the following technological options:

- without the use of nitrogen gas to blow through the metal in the ladle when discharging from the steel-smelting unit (5 heats);

- with nitrogen purging at a pressure of 2.0 atm (10 melts);

- with nitrogen purging at a pressure of 2.5-3.0 atm (5 heats).

In the group of heats with nitrogen purging at a pressure of 2 atm, on 5 heats out of 10, to protect the metal stream in the steel ladle-tundish and tundish-crystallizer sections, sealing rings were installed on the protective pipe and immersion nozzles. O-rings were also installed on 2 heats of the group with nitrogen purging at pressure (2.5-3.0) atm.

On all heats carried out according to various options, incl. and without nitrogen purging during release during processing on the UPC, satisfactory operation of the purge plugs was observed.

Figure 4 shows averaged comparative data on the nitrogen content in steel at various technological sections of melts carried out with metal blowing in the ladle with nitrogen pressure of 2.0 and (2.5-3.0) atm and without blowing.

Rice. 4

— Dynamics of changes in nitrogen content in the sections steelmaking unit - UPC - continuous caster with different production options

The nitrogen content in the steelmaking unit before release differs slightly and averages (20-23) ppm.

For all options for producing melts, the previously established patterns of increase in nitrogen content are preserved. The main areas of greatest growth are the steelmaking unit - UPC, i.e. release, and UPC - continuous casting machine. A slight increase in nitrogen content is also observed in the tundish-crystallizer section.

Thus, as a result of studying the dynamics and level of nitrogen content in the metal on the path from steelmaking unit to rolling stock:

- It has been confirmed that additional saturation of the metal with nitrogen occurs:

- when discharging from a steel-smelting unit into a ladle and pouring into molds, mainly due to the entrainment of air by a stream of metal, and the use of homogenizing nitrogen blowing through porous plugs;

- when casting on a continuous caster due to

- air injection at the connecting points of the protective pipe with the steel ladle manifold and the submersible nozzle with the tundish nozzle;

- absorption of air by the surface of open metal in a tundish;

- entrainment of air by an unprotected stream of metal when exiting the protective pipe to the surface of the metal (the lower level of the pipe is not buried in the metal).

Based on the results of the work carried out, a set of measures was developed to reduce the level of metal saturation with oxygen and nitrogen:

- The release of semi-products from a steel-smelting unit of ordinary assortment for finishing at the UPC should be carried out without homogenizing purging in the ladle with gaseous nitrogen, with the protection of the purge plugs from metallization with staurolite concentrate. For critical-use melts (RSD 32, etc.), it is advisable to carry out purging at a nitrogen pressure of no more than 3 atm.

- The release of melts without treatment at the CPC is carried out with purging with nitrogen gas at a pressure according to the pressure gauge of no more than 4 atm.

- To protect the metal stream in the steel ladle-tundish section, use protective pipes with the lower part buried in the metal during casting and sealing rings at their junction with the ladle manifold.

- At the beginning of casting, after filling the tundish to (10-12) tons and installing a protective pipe on the metal surface, create a protective layer of slag using a low-melting mixture. The metal stream in the tundish-crystallizer section is protected by installing submersible cups with sealing rings at the junction with the dosing cup.

- Maintain a stable and required level of metal in the crystallizer, to ensure stable operation of the automated control system with the level of metal in the crystallizer.

Currently, almost all activities have been implemented into production. In addition, to reduce air leaks, tests are being carried out on corundum-graphite protective pipes with a conical joint with a collector cup, containing elements of an argon supply system to the joint zone.