First acquaintance with gas cylinders

A modern gas cylinder complies with GOST 949-72 and is a durable all-welded element made of carbon or alloy steel. According to the standard, the thickness of the cylinder walls cannot be less than 2 millimeters. In order for the gas inside to press equally on the upper and lower parts, they are made concave and convex. The cylinders themselves, depending on the substance in them and its quantity, can have different sizes, shapes and colors. But one thing remains unchanged - any gas cylinder must have passport data assigned at the factory. In the upper part there is a neck equipped with a thread into which the valve is inserted.

Shut-off valves for gas cylinders

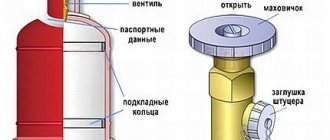

A valve is a shut-off device used to fill gas cylinders, supply gas to a burner or cutter and allow storing compressed and liquefied gases in the cylinder. Valves are divided into balloon and ramp valves . The operating principle of cylinder valves is the same, but they differ in the material from which they are made, the connecting thread and the method of sealing. Valves are also divided according to the type of gas.

Oxygen valves are made of brass , since brass, unlike steel, does not burn in a compressed oxygen environment. Flywheels and plugs can be made of steel, aluminum alloys and plastics.

The design of the oxygen valve is shown in Figure 1. The valve consists of a body 9 with a fitting. An oxygen reducer is connected to a fitting with a right-hand thread using a union nut. The body contains a valve 11 with a seal 12. A union nut 6 is screwed onto the upper part of the body, tightly pressing the fiber gasket 7. A handwheel 3 is placed on the protruding part of the spindle 5, which is secured using a spring 2 and a flywheel nut 1 and is sealed with a fiber gasket 4. Valve is equipped with a plug 10. In order to open the valve for the release of oxygen from the cylinder, it is necessary to turn the handwheel 3. The valve opens by turning the handwheel counterclockwise, and closes by turning it clockwise. Rotation from spindle 5 to the valve is transmitted by connecting coupling 8. The valve has an oil seal in the form of a fiber gasket 7. To reduce friction of the spindle collar, a fiber gasket is installed after impregnation with paraffin for 40 minutes at a temperature of 70°C.

a - oxygen, b - acetylene, c - propane-butane

Figure 1 - Shut-off valves

During operation, all parts of the oxygen valve must be thoroughly degreased, since contamination with fats and oils is unacceptable.

Acetylene valves are made of steel ; the use of copper alloys containing more than 70% is unacceptable, since upon contact with acetylene, explosive acetylene copper appears.

The acetylene cylinder valve consists of a housing 10, the reducer is connected to the acetylene cylinder with a clamp equipped with a special pressure screw. To rotate spindle 5, a socket wrench is used, placed on the protruding square of the tail spindle. The lower part of the spindle has a seal 6 made of ebonite, which is a valve. Leather gaskets 3 are used as a gland, pressed by a gland nut 1 and washer 2 to the gland ring 4. A felt gasket 9 is inserted into the threaded tail of the valve, which acts as a filter. Felt filter 9 and mesh 7 are fastened with a steel ring 8. On the side face of the valve body there is an annular recess into which the fitting gasket 11, made of leather or other elastic material, is inserted. The inlet fitting of the acetylene gearbox is pressed against this gasket. The acetylene valve has a thread different from other types of valves, which excludes the possibility of installing it on other cylinders.

The valve for a propane-butane cylinder consists of a steel body 1, inside of which there is a rubber stocking nipple 3. The nipple is put on the spindle 2 and the valve 4 and clamped with a stuffing box nut 5.

The following details should alert you when purchasing a cylinder

- Valve malfunction - the flywheel does not turn or there are other problems;

- Corrosion, dents or other damage on the body of the cylinder and valve part;

- The inspection date has expired;

- You can feel the gas in the air;

- A crooked or damaged cylinder shoe;

- There is no plug on the fitting.

Important! Under no circumstances should the contents of the gas cylinder be completely used. During cessation of operation, the residual pressure inside should remain at 0.5 kgf/cm2.

Device

The acetylene gas cylinder is made from seamless pipes in accordance with GOST 949-73 .

Wall thickness 7 – 8 mm. The ends of the container are spherical. The top part has a hole into which the valve is screwed. A cylindrical shoe is placed on the lower part, giving the container stability. The neck in acetylene cylinders is wider than in others where gas is stored. Through it, the container is filled with a porous mass: cast porous filler, activated birch carbon and basalt fiberglass. The loose substance absorbs acetone well and promotes uniform dissolution of acetylene in it.

Foreman of the acetylene cylinder filling section of the SpetsBallonMash plant Kurnikov A.I.: “The Americans fill the inside of an acetylene cylinder with asbestos cord. At the end of the last century, the Russian Federation abandoned such material as carcinogenic. Small particles of asbestos evaporate along with argon. In Russia, they switched to natural materials that absorb acetone: silk, leather, mineral wool, sawdust. Currently, some manufacturers use asbestos in small quantities as an additive to quartz sand and calcium hydroxide. In Germany, charcoal is mixed with magnesium carbonate and kieselguhr. When purchasing a cylinder, you should pay attention to its filling. Asbestos causes lung cancer."

Valve device

As we said above, the valve in a propane cylinder is practically no different from what is on a container containing oxygen or other gas. They all have approximately the following structure:

- A durable cylinder made of steel with three holes. Each of these holes is threaded and is intended for screwing onto the cylinder, mounting a plug and a valve nut fitted in the upper cylindrical part;

- A handwheel mounted to the valve stem via a nut;

- Locking device with a rod and a bypass valve. This valve transmits torque from the flywheel. The pressure that this part can withstand varies from 15 to 190 atmospheres;

- Gaskets designed to maximally seal the connections between all parts of the assembly.

Features of the device and marking of the gas valve

The manufacture and use of gas cylinder installations is carried out according to the still valid Soviet GOST NoNo 15860, 949-73, 9731-79 and 12247-80. The vessels are made from steel grades: 45, 30KhMA, 30KhGSA and 34CrMo4. The maximum permitted pressure varies from 1.6 MPa to 19.6 MPa, and the wall thickness ranges from 1.5 to 8.9 mm. The cylinder is equipped with a cap that screws onto a special thread and completely protects the valve. In some designs it is welded and thus protects the valve from damage.

- metal or composite body of the gas cylinder installation;

- shut-off and control valves;

- protective cap;

- transport fixing rings;

- shoe for structural stability;

- metal plate with technical data.

The standard GB valve is made in the form of a tee with three outlet threaded fittings. The latest models are available with safety devices in the form of an additional protrusion to relieve excess pressure generated by heating or incorrect filling. The fitting at the bottom is connected to the GB, the flywheel is attached to the top, and the one installed on the side is for technological filling and discharge of the medium.

Valve for propane gas cylinder

Types of valves are classified according to the type of reagents being filled:

- Acetylene - white with a special valve for contact with chemical active substances.

- Oxygen - blue, intended for filling: O2, Ar, H2, N2 and CO.

- Liquefied gas – red for flammable hydrocarbons. They are equipped with a crane brand – VB-2.

DIY Gas Valve Troubleshooting Guide

The cylinder itself is solid, and it’s unlikely that anything will break there. Therefore, the majority of malfunctions concern gas valves.

Procedure:

- Repairs are carried out in a well-ventilated area;

- We open the shut-off assembly to allow the remaining gas to escape;

- To turn the valve manually or with a gas wrench, you need to warm up this element. In this case, there is no danger, since the cylinder contains only gas vapors, and not their mixture with air, which is explosive in the first place. The only thing that needs to be monitored is moderate heating of the structure, since overheating can increase the pressure in the cylinder. The point of warming up is that the metal expands and it becomes possible to unscrew the valve even manually, or with a slight lever force in the form of the same gas wrench;

- After removing the element, the conical fitting is sealed - a sealant or fluoroplastic tape is applied to it;

- A new valve is installed, after which the fact and time of repair are entered into the cylinder passport. Installation is carried out with a special torque wrench, which makes it possible to correctly dose the forces and not break the thread. The maximum pressure allowed in this case is 480 Nm for steel and 250 for brass valves;

- Having removed the valve from the cylinder, it is necessary to drain the condensate from it, if we are talking about propane-butane, which we widely use. This procedure is practically never performed by anyone, despite the fact that it is extremely desirable. However, it is necessary to drain it away from residential buildings, since this condensate has an extremely unpleasant odor.

Important! Working with gas cylinders is potentially dangerous. Moreover, there is a strict ban on removing taps in artisanal conditions. Remember that it is best to entrust this matter to professionals, and you should proceed with independent actions only if you are confident in your abilities, ready to strictly follow the rules, and, of course, the urgency of repairs. If there is even the slightest opportunity to transfer this task into the hands of a specialist, it is strongly recommended to take advantage of it.

In general, the gearbox, which is non-separable, must be replaced every six years. As for the hoses, they must be reinforced and subject to inspection no earlier than once every six months when replacing the cylinder.

Installation and replacement of valve on a gas cylinder

When starting to install a shut-off unit for a liquefied gas cylinder, you must remember that this element will operate under high pressure conditions. Therefore, all work on installing or replacing such a unit should be carried out in strict accordance with the instructions.

Technically, changing the valve on a gas cylinder is quite easy - the outdated unit is simply unscrewed from the inlet hole in the container, like a regular fitting, and a new shut-off element is screwed into its place. What does the BC Melbet promo code give? Melbet promo code - gives a starting bonus upon registration of up to 10,500 rubles. Using the promotional code you can get: Sports bonus 100%. To receive a welcome bonus, you must top up your balance by at least 100, maximum by 19,500 rubles. The Melbet casino promotional code is entered when registering a new account. Thanks to it, you receive an increased bonus on your first deposit; the system adds 30% to the maximum amount. The standard bonus for the first deposit is 7,000 rubles, after entering the promotional code - 9,100 rubles. However, special precautions must be taken.

After all, we repeat, this unit is under pressure (for example, as much as 30 atmospheres of pressure are applied to the valve of an acetylene cylinder), therefore, the process of dismantling and installation itself should be organized according to the following scheme:

- At the very beginning, the valve shut-off unit should be moved to the “open” position. That is, unscrew it all the way to the uppermost position. As a result, the remaining contents of the cylinder will go either into the atmosphere or into some container.

- Once the cylinder is free of hazardous contents, you can begin to remove the valve body from the threaded hole in the top of the cylinder. For these purposes, you can use either a special tool or a regular adjustable wrench. It is necessary to understand that the valve was screwed in very tightly and, possibly, using a liquid sealant, therefore, before dismantling, the body of the shut-off element must be heated with a hair dryer.

- Having removed the old valve from the cylinder, you need to prepare a new shut-off unit for installation. That is, you just need to apply a gel or polymer seal to the conical fitting at the bottom of the body. As the latter, most often, ordinary FUP tape is used.

- After preparation, the valve is screwed into the hole on the cylinder body, first by hand, and then with a key. Moreover, as a key, it is best to use a special tool - a torque wrench, which allows you to adjust the tightening force. After all, for steel cases you need to create a torque of 480 Nm, and for brass - 250 Nm.

After completing the installation of the valve, you should put information about the date of the operation on the cylinder passport - a special plate mounted in the container body.

Safety precautions and installation quality control methods

Upon completion of the valve installation process, it is necessary to check the quality of the work performed.

To do this you need to do the following:

- A hose from the supercharger (compressor) is connected to the side fitting of the housing.

- The valve is moved to the “open” position and a portion of compressed air is pumped into the cylinder. After this, the cylinder valve is moved to the “closed” position.

- Next, a pressure gauge valve with a screwed-in measuring device (pressure gauge) is connected to the side fitting of the housing.

After this, the cylinder valve is moved to the open position and the same operation is performed with the pressure valve. As a result, the pressure in the system is displayed on the pressure gauge and, based on its fluctuations observed over a certain period of time, the degree of tightness of the cylinder-valve assembly is determined.

Of course, a hermetically mounted valve must maintain the pressure at the same level for a sufficiently long time.

Simplified control method

This technique is practiced in the field or in the absence of measuring instruments at hand.

To implement it you need to do the following:

- Compressed air is pumped into the cylinder and the valve is closed.

- Whipped soap foam is applied over the valve with a shaving brush.

- The tightness of the balloon-valve assembly is controlled by the absence of “bubbles” in the soap “cap” on the valve.

Despite its simplicity, this method is considered quite effective and is used by most pressure pipeline specialists.