Types of sound insulation for sewer networks

There are several ways to suppress noise in city sewer pipes:

- The use of so-called “quiet” pipes, which have a multilayer configuration and are made of high-density polypropylene. This makes it possible for excellent sound muffling without the use of additional devices and materials, however, the disadvantage of such products is their high cost.

- The use of soundproofing materials, which include polyethylene foam, fiberglass, synthetic rubber, mineral wool and a number of other porous substances.

- Use of soundproofing tapes and rolls.

Video: how to soundproof heating pipes with your own hands

Thus, in the retail chain today there are quite a lot of proven soundproofing materials that can almost completely eliminate background noise in an apartment from working plumbing fixtures.

But still, the most correct thing would be to take care of sound insulation at the time of design, providing for vibration compensators.

They not only remove sound vibrations, but are also able to protect the heating system from water hammer and displacements from pipe elongation caused by changes in temperature conditions.

Soundproofing a sewer riser in an apartment

The best solution in any case would be to replace the pipeline and fittings in general throughout your apartment. Operational wear also affects the condition of the pipes, so in the end you will both solve noise insulation problems and make repairs. Old cast iron pipes are very noisy. If you simply replace them with plastic ones, you will already get a strong effect.

Option No. 1: sound-absorbing pipes

You can buy and install special noise-absorbing pipes, for example, those available from companies like Osterdorf and REHAU. Here, experts have already thought about how to make the passage of drainage through the pipe as quiet as possible.

Option No. 2: comprehensive sound insulation

Soundproofing in general may involve creating a special plasterboard box, which will be decorated with tiles, like a regular wall in the bathroom. Such a box can be from floor to ceiling, hiding absolutely all the pipes.

When installing, you need to take into account three types of noise: acoustic (which is removed by the partition), structural (here you just need not lean the pipe against other pipes or the wall) and impact (you need to buy high-quality pipes and all fasteners that will be securely fastened).

There are also special mounting clamps that reduce noise insulation. You can also replace the doors to the bathroom with a tighter-fitting one so that noise is not heard from the corridor. Equally important is a complete search and streamlining of communications.

The most important problem arises with the replacement of cast iron pipes. They cannot be changed if the neighbors above have not yet changed theirs. If they do this after, say, a year, you'll have to tear down your trim to replace the rest.

If you still decide to cut a cast iron pipe, you first need to make two transverse cuts to the maximum depth at a distance of 1.5 meters, and then knock out a segment of the pipe. Only then will you be able to cut the back wall of the pipe, since cast iron pipes are very stubborn.

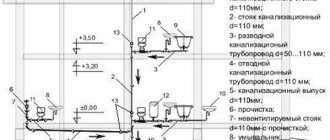

Soundproofing the entire riser

To soundproof a sewer riser, you need to take a number of measures: install clamps, add polyethylene foam to the free space, then check whether the pipe or its fittings are in contact with anything.

You can use any insulation or mineral wool, wrap it around the pipe and then secure it on top. You can see the options for such sound insulation below:

If there are special mounting casings with connections. They are more expensive, but are intended specifically for pipes. The result is a reliable fastening (see photo below).

How to choose the best sound insulation

PVC is a material that, according to its physical and technical characteristics, is already an excellent material for sound insulation. Its ability to absorb noise is well known to everyone, since when installing a plastic pipe there is no need to use additional sound insulation. Nevertheless, such a need sometimes arises if it is necessary to reduce the degree of vibration. In this case, you should “dress” the place where the pipe comes into contact with the ceilings, regardless of what material is used. The space between it and the pipe must be filled with sealant!

Please note that when carrying out work on noise insulation of a sewer riser with your own hands, you first need to reduce the level of infrasound. This can be done by partially replacing the riser or damping it as a whole.

The first option is optimal. When the riser is made of cast iron pipes, then individual parts can be replaced with plastic, and at the same time, fragments of the old pipe that have crosses will be in place, and the plaque inside such areas can be removed using standard means like “Mole” or “Shumanite” . Between them it will be possible to install sections of PVC pipes. With this method, the basic structures will remain unaffected, and the work of replacing a cast-iron pipe with plastic will be greatly simplified, and the cost of repairs will be lower than if it were necessary to completely change the riser.

This method will also be good in terms of sound, because the pipes will be divided into sections with a length of 3 to 5 meters. This can lead to a sharp drop in the resonance islands, and the gaps between the “islands” themselves will be wider than the resonance zone. It turns out that the unpleasant sound will not only be reduced, but its character will also be changed. From a psychophysical point of view, it will be safe for human health. Also, an additional advantage is that if it breaks, you can easily replace only one fragment.

If the riser has already been replaced, you should not break it to install cast iron fragments with crosspieces.

An entire PVC riser will be perfectly insulated from resonating structures in this way:

From the walls using damping clamps.- From ceilings using polyethylene film and polyurethane foam. In this case, it is not at all necessary to look for special cylinders on sale. Any hardware store has a large assortment of inexpensive alternatives to pipes for fan noise insulation, scraps of which with a large diameter can be used as a glass. To do this, you should cut everything vertically and “tighten” the pipe. It is also worth considering that it is not recommended to fill the space between the glass and the pipe with anything other than polyurethane foam, since it is polyurethane foam that can reduce the level of sound waves.

And finally, it makes sense to get rid of the unpleasant “gurgling” and “rumbling”. To do this, the pipes need to be wrapped in a foam shell. It is quite simple to install, and we note that the installation only involves securing it, snapping it into place and securing it with construction tape. This method is ideal for straight pipes. But if for some reason there are curved surfaces on the pipe, then it is better to give preference to polyurethane foam, which can take any shape. It is somewhat more expensive, so sometimes people try to buy polyurethane foam, which perfectly insulates sound. But keep in mind that such material is short-lived, and after one season it will begin to sour, and soon it will completely disintegrate.

Please note that you should think carefully about whether to use this material, since sound insulation should not be installed for 1 year, and certainly not for 2.

Another mistake most people make is using mineral wool to improve noise absorption. It’s worth starting with the fact that, in accordance with the sanitary standards that are currently in force, this material is strictly prohibited from being used inside any residential premises. The fact is that it begins to release microneedles, which can even lead to skin diseases and respiratory system problems. Moreover, mineral wool does not dampen infrasound at all, so its use is not only dangerous for human health, but also pointless.

Types of noise and causes of their occurrence

In modern sewer “acoustics” there may be various sources of noise and the reasons for their occurrence.

The most common are:

- noise of resonant origin. The sounds are based on the phenomenon of resonance, where the plastic pipes themselves act as a resonator;

- atmospheric sounds. They occur during the penetration of air currents into the drain pipes, which are discharged onto the roof;

- vibration noises. Their occurrence is associated with the specifics of the construction of a sewer system, in which each part sounds the same as the whole pipeline. Not only risers vibrate, but also elbows, couplings, joints, and fastening clamps;

- impact type noises. They are among the loudest and most unpleasant. Anything that enters the sewer system falls from a certain height, causing a loud sound. Such a sewer vertical can be compared to a resonant-oscillating system.

Noise Removal

Before eliminating noise, it is necessary to determine its cause. If noise causes resonance of the collector or impacts of the collector on the ceiling, it is enough to install 1-2 additional fasteners on the pipe. If the noise is caused by the thin walls of a plastic pipe, it is necessary to wrap them with soundproofing material, cover them with a soundproofing panel, and install thick-walled plastic or cast iron pipes.

To eliminate noise from excessive (improper) ventilation, contact the management company. Serious intervention in the sewer system will be required, so specialists must work.

Sewer pipe fastening with sound insulation

Possible sound insulation options

Depending on the type of problem, there are several options for dealing with noise interference, the main ones are:

- It was established that the noise caused by the passage of water flows through the riser was practically not present in houses of old construction due to the use of massive cast iron pipes, therefore one of the ways to eliminate it is to increase the weight of the riser pipeline.

- A popular method is associated with soundproofing the riser and includes a lot of different ways to combat noise using soundproofing materials or engineering structures.

- To combat structural defects caused by poor-quality fasteners of the riser pipeline, special clamps with elastic damping gaskets are used.

- And the last, less common method of eliminating interfering sounds is to replace a lightweight thin-walled polymer pipeline with a special noise-insulating one (the cast iron option is not considered); such products have appeared on the construction market relatively recently.

Why is sound insulation needed?

Unfortunately, a method has not yet appeared that would help completely rid an apartment of the sounds of drainage, but it is possible to reduce this to a minimum. As a rule, for this purpose, either silent pipes are installed in the toilet, or they do the soundproofing of sewer risers with their own hands, which are already installed.

The main task of all measures for soundproofing sewer pipes is the following:

Remove harmful vibration of the pipe walls.- Completely get rid of any transmission of elastic vibrations of pipes to the overall structure in the room.

- Reduce the level of audibility of the sounds of water that were drained by neighbors and you.

Please note that any insulation will cost money, with costs increasing exponentially depending on how much noise is absorbed. In order not to sacrifice health and comfort, but also not to spend too much, you should know exactly how much all vibrations of sound waves should be dampened.

In this case, you should remember some facts from the school physics course. So, sound intensity is measured in bels, and in practice the main indicator will be its 1/10th part - decibels. Thus, the hearing threshold will be 0 dB, a quiet voice or whisper from approximately 20 to 39 dB, a highway or metal shop from 70 to 89 dB, a rock concert approximately 100 dB, and an airplane takeoff up to 120 dB. When the sound reaches a threshold of 130 dB, the ears begin to hurt, and at 140 dB, the eardrums completely burst, and blood begins to flow from the ears. From the above, we can say that the level of noise insulation of an apartment riser in an apartment should reduce everything to a sound that is safe for human health and comfortable living - 30 dB maximum.

Causes of noise formation

The reasons for the appearance of noise in the sewer riser are various, here are some of them:

- Insufficient strength in pipe walls.

- The material from which the drainage system is made.

- Incorrect placement of pipes inside the apartment.

- Poorly chosen seal.

The main source of unpleasant noise from the sewer system is the riser. The drainage streams that move through it usually begin to create strong vibrations, which can cause severe discomfort. In addition, it is even unsafe for the mental and physical health of the person living in the apartment.

Interestingly, the strength of the volume will depend on the number of floors of the building. The lower the apartment is, the stronger the noise level.

This phenomenon is quite simple to explain - when the masses move down, the wastewater comes into contact with each other, as well as with various elements of the drain system and with pipe walls. This can lead to strong vibration, which, due to water drainage, is transmitted to all main floors. In addition, the drain water also comes into contact with the air inside the riser. The faster the liquid drains, the louder the sound, and it is for this reason that residents of apartments on the first floors experience much more discomfort than those whose apartments are under the roof.

There are several types of noises inside the sewer:

They appear due to the fact that water enters and comes into contact with elements of the drainage system. There is no way to eliminate this type of sound, and the only thing that can be done is to reduce it to a minimum.

Drums.- Airborne. Their formation is possible due to the contact of water and air inside the pipes. This type of noise occurs very rarely, and its intensity is very weak.

- Structural. This is a rather unpleasant type of sound variation when the source is represented in the form of the inside of pipes, parts of the sewerage system, ceilings and walls that are in constant contact with the riser. They appear due to the fact that vibrations are transmitted from the pipe to the structural elements of the building. It is this type of noise that needs to be eliminated as much as possible, and from the point of view of installation technology everything is done quite simply.

To soundproof a sewer riser with your own hands in a house, you should first find out what can affect the level of unpleasant sounds. In addition to the number of floors, this parameter will also be affected by the material from which the pipes are made. According to experts, plastic products usually create more pronounced noise than cast iron ones. This is due to the fact that there is a high degree of mechanical quality factor of the metal alloy. It consists of small particles that rub together and can absorb the main vibrational flow, which is the root cause of sound “effects”. Another important point is plaque, which often appears on the inner surface of cast iron pipes, which plays the role of a sound insulator.

But plastic does not have such characteristics, and it is for this reason that such pipes can be compared with musical instruments that actively transmit the sounds of drains and also reflect all vibrations due to drainage. Moreover, PVC pipes are free of deposits. On the one hand, this greatly increases their service life, and on the other, it eliminates the possibility of the appearance of any insulating layer of natural convergence of the sewerage system.

Please note that the thickness of the pipes will also play an important role. The larger it is, the better the sound insulation. A similar pattern can be traced in relation to the mass of the material - the greater the specific gravity of the sewer pipe, the higher its ability to absorb excess dB as strongly as possible.

The location of the pipes also plays a role. From the point of view of noise insulation, the most correct solution is to place the sewerage system in the space between floors, outside the living space. When designing houses, it is strictly forbidden to make the riser pass through the interior floors; only the intersection between floors is permissible, which makes it possible to significantly reduce the level of vibration. The sealing gasket will also affect the audibility of unnecessary sounds. Most often, during construction and repair work, polyurethane foam is used to equip the sewerage system - this is a mistake that occurs very often, since foam is not a soundproofing material, but on the contrary, it even increases the noise coming from the pipe.

Important! Experts advise using rubberized gaskets or polystyrene (foam).

Types of materials used

The ideal solution, which will make it possible to get rid of noise in the sewer pipe, would be mixing the riser. If you remove it outside the apartment, then the sounds will not bother you, but such issues must be resolved during the design of construction work. As practice has shown, such a system is not in every house, not even in every new building. As a rule, the riser is placed in a bathroom or sanitary unit, so this article will only consider ways to increase the sound absorption of pipes that are located in the living space of an apartment building.

These are several ways to create soundproofing for a sewer riser with your own hands:

Install silent pipes.- Soundproof the riser yourself.

- Use special clamps to secure the pipes.

- Attach sound insulation material.

- Make a decorative box, which will be filled from the inside with material for sound insulation.

Silent pipes for sewer risers have appeared on the construction market relatively recently. They differ in that they have increased density and thicker walls, as well as special components. The most commonly used fillers are chalk, limestone and microcalcite, i.e. fine-grained grinding of carbonate minerals. All this makes it possible to significantly reduce the sounds of drains discharged by neighbors in the riser. Such pipes make it possible not only to dampen noise, but also infrasound. But their prices will be much higher than conventional PVC pipes, and their service life does not exceed 20 years.

Please note that if the apartment has a sewer pipeline system, and there is no way to replace it, then there is only one option - to use sound insulation materials. They will help to significantly reduce the severity of the acoustic effect. To minimize the sound of drainage from neighbors, you should pay attention to fasteners with special gaskets for clamps that are rubberized.

Their use will help prevent noise transmission to walls, which means it can reduce vibration and the release of infrasound vibrations. The place where the riser is installed, as well as the places in contact with the ceilings, must be sealed with porous rubber. This will also help reduce the transmission of acoustic effects to floors and load-bearing elements in the building.

Not every person wants to “enjoy” the look of a riser that is wrapped in insulating material, and in this case, you can create a box and then cover it with finishing materials. By the way, this also creates additional insulation from noise. But you should not completely cover the riser with a box, especially if there is an audit in your apartment. In addition, you should ensure free access to the water supply, which usually runs almost close to the sewer riser, so that, if necessary, repair work can be carried out on the drainpipe. This is very important if for some reason an emergency or breakdown occurs, as this will make it possible to provide quick access to places of damage and promptly remove all defects. Otherwise, you will need to dismantle the entire box and only then begin repairs.

Soundproofing the toilet and laying a silent sewer system

All work on soundproofing pipes in the toilet is carried out after determining the location of the noise and its causes. In particular, if noise occurs in an already installed sewer riser, then its sound insulation is carried out using special sound-absorbing materials, securing them with special tape, as mentioned above.

Soundproofing of other pipes in the system that are a source of noise is carried out in approximately the same way. Foam rubber or foam plastic, which are placed on the pipe in the form of a casing, are often used as roll materials for soundproofing sewer pipes in the toilet. Such coatings, along with the sound-absorbing effect, perfectly protect pipes from damaging external influences (mechanical, corrosive and others). This type of sound insulation for pipes is very easy to install: the casing is simply cut lengthwise with a sharp knife, then the structure is wrapped with it, after which the joint sections are fastened with construction tape.

If you need to lay a silent sewer system from scratch or replace sewer pipes, you should take into account the sound-absorbing features of the materials used in their manufacture. In particular, steel pipes are considered the noisiest products for laying a sewer system. In contrast, cast iron pipes are almost completely silent, which is facilitated by their large mass and significant wall thickness. Polymer sewer pipes, in particular those made of plastic, are also practically silent.

Causes of sounds from the sewer riser

Sounds in the riser can occur due to various factors. Depending on the reason, you can solve the problem as quickly and effectively as possible. There are many reasons for the noise of plastic pipes, they can be:

@Shumka_Trub

- Impact, if some object inside the riser hits the walls;

- Atmospheric, resulting from the passage of wind through a ventilated riser;

- Resonant when the pipe transmits extraneous sound;

- Vibration occurring during vibrations of the building structure.

The trumpet itself is an acoustic object and bears some resemblance to a speaker from a music center. Even if something hits the pipeline on the top floor, the whole house will hear it clearly. It is problematic to protect the sewer system from the ingress of objects or contaminants, and all that remains is soundproofing of the sewer drain.

There is another type of sound that, compared to others, is absolutely harmful - infrasound. The main difference with this sound is that it is heard at a frequency of 7 Hz. Such noise can not only infuriate or drive a person crazy, but even kill a person. When choosing sound insulation for sewerage, this aspect should be given special attention.

@Shumka_Trub

There can be many reasons for the appearance of noise in risers, and it is pointless to find out their occurrence. If there is a problem, then it needs to be solved immediately and for this the market offers a large abundance of goods. Properly performed soundproofing of sewer pipes in the toilet will prevent you from listening to unpleasant noises while visiting the bathroom.

Why do cast iron pipes not make noise?

If we compare the noise from plastic and cast iron pipelines, the second material produces much less noise. The whole secret is hidden in the composition of cast iron. It consists of microscopic grains, which reduces vibration vibrations. In addition, the porous structure of the product contributes to the rapid fouling of plaque, as a result of which the mass increases and the resonant vibration decreases.

Types of sound insulation for sewer networks

In hardware stores you can find several types of soundproofing materials:

- sound-absorbing pipes;

- foil foam rubber;

- polyethylene foam shells;

- foamed polymer pipes;

- soundproofing tape.

Sound absorbing pipes

Sound-absorbing pipes have a complex structure that dampens sound waves in their mass. Microcalcite (marble powder), limestone, chalk and dolomite are used to make products. Pipes are made with thick walls

Soundproofing polymer dampens the entire spectrum of sound waves, which is especially important - it effectively copes with infrasound

Main advantages of the product:

- High resistance to overgrowth and corrosion of the internal surface.

- With proper operation, the service life of pipes is more than 25 years.

- A light weight.

- Rubber seals expand under pressure, creating a tight connection between pipeline parts.

- At average noise levels, no additional sound insulation is required.

Foiled foam rubber

Rolls of products are designed for soundproofing car interiors. As practice has shown, rubber has proven to be an effective insulator for sewer risers. It is covered with two layers of aluminum foil and three layers of plastic film.

Features of rubber insulation:

- Sound waves get stuck in the elastic mass of rubber. The coating has high thermal insulation values, due to which condensation does not appear on the surface of the insulated sewer riser.

- Foil rolls have an adhesive base covered with a protective film. Before installation, the protective coating is removed from the cut sheets. The pipes are wrapped with overlapping sheets of rubber.

Polyethylene foam shells

The insulating pipes seem to be cut lengthwise into two parts. The riser is “huddled” with shells on both sides. The longitudinal edges of the shells are made in the form of a locking system (tongue and groove). After installing polyethylene foam shells, carefully check the tightness of the joints. For greater reliability, the seams are treated with sealant.

Advantages of soundproofing shells:

- The material has a low specific gravity.

- Easy to install - does not require much effort.

- High levels of noise absorption and thermal insulation.

- Long service life - more than 25 years.

Foamed polymer pipes

Shells made of foamed polymer have a soft structure. Pipes are made with a longitudinal section. They are easy to put on the riser. The foam material is adjusted to the desired length using a sharp knife and scissors. The seam is taped with tape or soundproofing tape.

Product advantages:

- A light weight.

- The porous structure of the shell provides a high degree of viscosity for sound waves.

- The material can be processed in any way without requiring special tools.

- Provided UV protection is provided, foam shells will last 30 years or more.

Due to the porous structure of the shells, pipes require additional coating. You can use foil insulation or simple plastic film.

Soundproofing tape

The adhesive tape serves as a good heat insulator, not allowing noise of 10 to 15 dB to pass through. This is a low figure, but when combined it creates a highly effective sound barrier.

Advantages of soundproofing tape:

- Thanks to its tape form, the coating can be applied to fittings and couplings of any configuration.

- The tape has a long shelf life. Within a year - one and a half years it does not lose its properties.

- Easy to cut with ordinary scissors.

Why is sound insulation needed?

The human ear perceives noise in the range from 10 to 120 dB. But the sound is different. The sound of water in a stream, the rustling of leaves on trees or the singing of birds have a beneficial effect on the psyche. But man-made noise, even short-term, increases aggression, irritability, and ultimately has a harmful effect on health.

Sewage is certainly a benefit of civilization, but it brings with it noise pollution in residential areas adjacent to bathrooms. Residents of the lower floors in apartment buildings, where the intensity of wastewater flow is much greater than at the upper level, especially suffer from annoying sounds.

If during the construction of the house no measures were taken to soundproof the sewer risers, this will have to be done by the owners themselves. The work is not as difficult as it seems, and the result will be silence in your apartment.

Ways to soundproof a sewer drain pipe

High-density materials effectively dampen sounds by dissipating vibrations and reducing the speed at which they pass through. Cast iron, steel or concrete pipes, which are used to make sewer networks, muffle noise well, but are not practical enough.

Plastic pipes have many advantages, but sound travels through thin walls very easily. Moreover, noise is transmitted both by air in the form of a sound wave, and through the contact of the riser with building structures in the form of impact noise and vibrations. The transmission range is 30-60 dB, which significantly exceeds the comfort limit.

To get rid of this undesirable phenomenon, sound insulation methods are used:

- winding of pipes, including places of contact with other surfaces, soundproofing materials;

- installation of sound-absorbing boxes around communications;

- fixation using damper fastenings.

A combination of these methods provides better noise protection than using any one method. If the sewer system is subject to repair, it can be constructed from modern “silent” pipes, which reduce the sound volume by almost 3 times.

Soundproofing sewer pipes in an apartment, find out which is better

Soundproofing sewer pipes in an apartment is a pressing problem. A high rate of sound transmission in city apartments is a well-known fact, and the noise of water passing through pipes greatly reduces the comfortable living of residents.

Therefore, drastic measures have to be taken to reduce the sound produced by the sewage system.

Noise in sewer pipes occurs for many reasons, these are:

- insufficient wall thickness of the drain system pipes.

- Material of manufacture.

- Incorrect placement of walls and pipes in the apartment.

- Incorrectly selected seal.

What affects the noise level

We have already said that the main reason for the formation of noise is the peculiarity of the material. In addition, over time, a layer of plaque of a certain thickness formed on the inner surface of the old cast-iron pipe, which served as an additional sound insulator.

As you know, such a coating does not form on the smooth inner walls of plastic pipes.

Other factors also affect the noise level:

- Wall thickness. The thicker the pipe, the higher its ability to dampen sounds;

- Pipe weight. This parameter directly depends on the thickness of the pipe. The higher it is, the heavier the pipe, which increases its ability to absorb noise;

- The proximity of the pipe to the wall. In many houses, the risers are mounted in such a way that in some places it is barely possible to stick your hand between the wall and the pipe. Due to the close proximity to the wall, the pipe may vibrate and make sounds;

- Absence tough fixation pipes. If building vibrations occur and are transmitted to a loose pipe, their audibility will increase significantly;

- Lack of damping gasket where pipes pass through the ceilings. Many installers neglect the need to lay special rubber layers in places where the riser enters the floor or ceiling. In addition, the gap around the riser, which is formed when replacing cast iron crosses with plastic ones, is often filled with polyurethane foam. This is fundamentally wrong, since foam not only does not have sound-absorbing or damping properties, but, on the contrary, can make any vibrations louder.

Cast iron or plastic

Today, plastic pipes are gradually replacing sound-absorbing products made of cast iron. Although cast iron risers have a great advantage over their plastic counterparts: they are not a source of noise, which means they almost completely absorb sound.

Not every person’s psyche can withstand the high noise level of uninsulated plastic pipes of the sewer system, especially in a panel house. And if it were not for high-quality sound insulation of sewer pipes in the apartment, then ensuring comfort in the living rooms would be a big question.

Advantages of plastic risers:

- ease;

- thinness;

- elasticity;

- ease of installation;

- long service life;

- resistance to sudden temperature changes;

- low cost.

In addition, build-up cannot form on the inner surface of perfectly smooth plastic pipes. Thanks to this, plastic products are cleaned much less frequently than their metal or asbestos-cement counterparts.

Disadvantage: appearance of structural noise.

What needs to be done or how to cover the sewer pipe so that unpleasant noises are not heard? What materials need to be purchased to completely soundproof a drain pipe? These and other questions related to getting rid of noise in pipes in the kitchen, toilet, bathroom and generally with soundproofing work can be answered in more detail in this article.

Why do you need soundproofing of a sewer riser?

The human body is extremely sensitive to noise levels. Loud, sharp sounds of discharged sewage can cause serious illness. Their range begins in the infrared spectrum.

To understand why soundproofing of a plastic sewer riser is needed, you should take a short excursion into physics, into the section of building acoustics.

Sound is a wave that is created by vibration. A sound wave is transmitted over a distance through any medium, be it air, water or solid objects (in our case, pipes, walls, ceilings and floors). Sound intensity is measured in decibels (dB).

For the human ear, audibility is represented as follows:

- 0 dB – threshold of audibility of sound for the human ear;

- 20-30 dB – a person perceives it as a whisper or silence in nature;

- a threshold of 40 dB is considered a normal noise level in everyday life;

- about 60 dB – the noise of a busy highway;

- 100 dB noise level in a forge shop or at a rock concert;

- 130 dB is the pain threshold for humans.

Note! According to sanitary standards, the sound level in a residential area should not exceed 30 dB at night and 40 dB during the day. These maximums are recorded in SanPiN 2.1.2.2645-10.

Infrasonic waves cause the greatest harm to the human body. Such vibrations are produced by a building when the mechanical vibration of the sewer riser is transmitted to the walls and floors to which the riser is rigidly connected. These waves are beyond human hearing. Their harmful effects on humans are evidenced by the fact that Nazi Germany experimented with deadly infrasonic weapons.

We recommend that you read: Instructions for connecting a toilet to the sewerage system

There is only one way to protect yourself from infrasound radiation - to prevent its occurrence.

Sound protection of sewer pipes recommended coatings

Sound insulation of PVC and polypropylene sewer pipes in an apartment is made with a variety of materials. At the same time, roll films, soundproofing tape and foamed polyethylene products are very popular. Main! Do not use installation foam for soundproofing. It can strongly transmit sound vibrations throughout the house or apartment. This type of noise protection option will cause more problems than benefits.

The most effective material for sound insulation is polyethylene foam. It will not only protect you from foreign sounds, but also eliminate the possibility of mold and mildew forming in the toilet, and condensation on the drain pipes. Moreover, such a coating acts as a good insulator. Polyethylene foam is produced in the form of a film with inner and outer layers. There is one point here. If you want to achieve the best results from noise protection measures, purchase material with a hard outer layer. This type of coating will be used for a really long time.

Polyethylene foam is the most effective for sound insulation.

Soundproofing tapes are also very popular among our consumers. They are the easiest to work with. All measures to protect the bathroom from noise are carried out with your own hands. All you need to do is wrap several layers of sewer pipes or risers with this tape to get rid of the annoying hum of the system. There is only one main thing here. The tape should be wrapped as tightly as possible. Also, when choosing the material to be described, you need to look at the amount of decibels that the coating can absorb. This indicator precisely determines the effectiveness of the use of noise protection tapes.

You can also use classic roll insulation to protect the sewer from noise. It is more affordable in cost than more innovative materials (tape, polyethylene foam), and the effect of its use is often not worse at all. Materials in rolls are wrapped around the pipes and then secured with a plastic clamp and adhesive metallized tape.

Recommendations from experts

You should follow these important tips in order to improve the sound insulation of sewer pipes:

- Remember that the thicker the walls of the sewer riser, the less noise.

- The best option for a house with a huge number of apartments is to use plastic pipes.

- When installing noise absorption, you cannot install monolithic plugs that will tightly grip the pipes.

And remember that even after all the procedures, the noise will not disappear completely, it will only become less and will also stop causing discomfort. But if you want to achieve perfect silence, then you should carry out additional sound insulation of the ceiling, walls, floor, and also elements of the plumbing and heating system.

Soundproofing the riser of the main source of hum

Very often, third-party loud sounds and vibrations come from the riser. It is through this that drains from all apartments pass. Therefore, soundproofing a sewer riser with your own hands must be done carefully and competently. We will explain the entire execution algorithm.

The riser is very often considered a source of foreign sounds and vibrations

Do-it-yourself sewer soundproofing

First of all, you need to select a soundproofing material (depending on the coatings recommended above). Cut it to the size of the riser. The insulator must completely bend around the main sewer pipe. If roll-type products are used, they must overlap the riser. After installing the soundproofing, first secure it with construction tape. Materials in rolls, as noted, are secured with a specialized aluminum tape. It is recommended to additionally secure the polyethylene foam with plastic fasteners or tie it tightly with thin but strong wire. When installing fasteners, maintain a distance of 0.25 m between them.

As a rule, at this point the noise protection of the riser can be considered complete. However, if the area of your bathroom is very large, it makes sense to hide the pipe in insulation so that it does not spoil the interior with its unattractive appearance. This can be done using plastic wall panels or by improving the plasterboard box. The last of these structures will provide additional protection against noise.

The box is installed like this:

- Mark the dimensions of the masking structure on the surface of the walls. Decisive moment. The walls of the box should be 55–60 mm away from the riser.

- Using dowels or screws, install metal profiles in selected areas.

- Fix another profile product from the wall surface to the floor surface. The location of its placement is determined by the intersection of lines drawn perpendicular to the two previously installed profiles.

- Place the jumpers (the distance between them is about half a meter) on the metal frame.

- Screw the gypsum board sheets to the completed skeleton. Advice. Buy products that are moisture resistant. For use in plumbing units, they are better than the usual gypsum properties and thickness. Don't forget to cut out a small window. It will act as an inspection hatch.

The space between the riser and the box can be filled with mineral wool. But do not forget that it will play the role of insulation. Mineral wool does not protect against foreign sounds. The ideal option is to fill empty spaces with the same polyethylene foam. Soundproofing costs will increase in this case. But the effect from them will be impressive. Unpleasant sounds from sewer pipes will no longer bother you and your family members!

Thematic publications:

Installing a shower tray with your own hands - the main methods

Installing a sink - good DIY installation

Clearing a sewer in a privatized house - how to remove a blockage at home

Sound insulation of sewer riser and waste pipe

The most questions usually arise about the noise that comes from the sewer riser, as well as about the sound insulation of the drain pipe connecting the sewer riser to the atmosphere. The sewer riser is where the greatest amount of noise occurs.

The sounds generated during its operation are conventionally divided into several types:

- shock, formed when a fluid flow passes through the walls of pipes;

- air, appearing when water flows pass through the air;

- structural, resulting from vibrations and contact of pipes and other elements of the sewer network with each other.

Airborne noise creates less inconvenience compared to other types. Impact sounds can be significantly reduced, although they cannot be eliminated completely. But it is usually structural noise that creates the most problems, and in practice we have to deal with them first.

To do this you will need to do the following:

- Prepare a piece of soundproofing material that matches the circumference of the indicated pipes.

- Fasten the soundproofing material to the pipe using construction tape. It is important to ensure that its edges are positioned end to end to achieve greater efficiency.

- It is recommended that the pipes be tightly lined with soundproofing material in several layers to maximize the damping of sound vibrations.

- If necessary, a box can be built around the sewer riser, improving the appearance of the structure and enhancing the noise-reducing effect.

The meaning of the procedure

Unfortunately, it is not possible to completely get rid of annoying noises. Creating sound insulation for sewer pipes is carried out with the aim of reducing them to the lowest possible level. Taking into account the causes of noise in the apartment and the essence of the work being performed, the goals can be divided into three main areas:

- Reducing the degree of vibration of plastic pipes.

- Preventing the transmission of vibrations from the sewer riser to the structural elements of the building.

- Creating a barrier to sound generated when draining water.

Why is the sewer noisy?

Extraneous sounds that come from the sewer system do not allow a person to sleep or simply irritate him. Thanks to this, many owners of residential real estate in high-rise buildings are concerned about how to effectively and, if possible, affordably soundproof the drainage pipes in the living area. There are no big difficulties here. Currently, the construction services market offers a lot of materials for sound protection of pipelines. But before we begin work on soundproofing the system we are interested in, we need to figure out why it makes noise that irritates people. The appearance of foreign sounds in the sewer system is caused by the following factors:

- Vibration of pipes, their internal defects, poor-quality fastening of individual elements of the system. Such noises are called resonant or structural.

- Leakage of water from taps, high (when compared with the calculated) speed of movement of drains along the riser. This is, to put it another way, a weather background noise.

- The appearance of deposits in the pipe, which leads to a decrease in its diameter.

The currently in demand polypropylene pipes and plastics are considered quite loud

There is also the concept of impact noise. It will appear in variants when sewer pipes are in contact with adjacent pipe products (for example, plumbing) or with wall surfaces.

The volume of sounds emitted by the sewage system depends on what pipes were used for its improvement.

Previously, cast iron products were installed in most apartments and houses. Such pipes were thick. Thanks to this, they absorbed sounds that irritated humans. There was no need for additional sound insulation of pipelines. The situation changed when much cheaper and easier-to-install polypropylene and plastic (PVC) products appeared on sale. They certainly have many positive characteristics, but they are really loud. This became the basis for the need for sound insulation of sewer pipes in an apartment for many people.

Ways to reduce sewer noise

Of course, no matter what method a person uses to soundproof a sewer, it is almost impossible to completely get rid of noise of this nature.

But with the right approach, you can minimize the noise level as much as possible and make it less noticeable.

The first way to soundproof sewer systems is to install silent pipes.

Installing silent sewer pipes is one of the methods of sound insulation

Of course, this method is only advisable at the stage of laying or replacing a sewer system. It is quite expensive, both in terms of finance and time.

This method of sound insulation is possible thanks to special silent pipes, which differ from ordinary pipes in the thickness of the walls and the material from which it is made.

Advantages of sound-absorbing pipes

It is thanks to this structure that such pipes reduce noise levels. Considering these features of the first method of sound insulation, it is not surprising that it is not suitable for every person.

Quiet Pipe Efficiency Test Results

But fortunately, there is an alternative and simpler way to soundproof a sewer system - soundproofing an existing pipeline.

For independent sound insulation, you can use, for example, foamed polyethylene

This method does not require much time and effort and can be done on your own.

But before soundproofing sewer pipes, it is very important to choose the right soundproofing material, since the level of noise absorption depends on it.

How to make sound insulation with your own hands

Soundproofing a sewer riser with your own hands is a completely doable task for any home craftsman.

Silent pipe structures are installed as follows.

- The vertical height of the pipe network is measured and pipes of the required length are cut.

- The cut areas are cleaned with a file. And they do this at an angle of 45 degrees.

- Mounting clamps with damping gaskets are placed on the wall.

- The assembly is carried out taking into account the individual characteristics of the silent network.

- The holes in the ceilings are sealed with polypropylene sleeves. Their diameter should be 0.5-1 cm larger than the cross-section of the silent drain pipeline.

IMPORTANT! It is strictly forbidden to install monolithic plugs that tightly compress the sewer network. It is advisable to use components that have the properties of absorbing vibration

Materials for soundproofing sewer risers

Very dense materials can reflect sound - heavy concrete, sand-lime brick, pressed rubber and other analogues. It is inconvenient to use them in the bathroom.

“Dampening”, noise absorption, is designed to ensure that a layer of sound-absorbing material is placed around the pipe, with the closest possible fit to it. This includes loose, loose and fluid substances; both dense liquid and sand can absorb noise. But taking into account the design features of the sewerage system, porous materials in the form of a “shell” or winding are convenient.

Soundproofing membranes and roll materials

To absorb and partially isolate noise coming from utilities, the industry offers membranes with additional layers of protection made of foam rubber or polymers, as well as a layer of foil. Usually the material has an adhesive fastening, is pressed close to the pipe and wrapped around it so that the edges of the sheet do not meet end-to-end, but overlap.

| Alufom R-TK | Material composition |

In fact, this material simultaneously performs the functions of thermal and sound protection.

In addition to the named material, you can use almost any rolled materials for sound and heat insulation, for example, Zvukoizolo, Folgoizol, Stopzvuk, Penofol, Energoflex, foamed polyethylene.

Their effectiveness will depend on:

- composition, quantity and thickness of layers;

- fastening method - simple wrapping or installation with glue, with a tight fit to the pipe (a more effective solution).

If the noise level is significant, you can use two layers of the same material or one layer at a time. For example, foamed polyethylene in two layers with glue and a soundproofing membrane on top in one layer (overlapping).

The proposed master class shows a ready-made solution for sound insulation based on rolled foil material, suitable metallized tape and special ties for installation.

Shown here is an option with independent cutting and fastening of the rolled material with tape over the entire surface of the riser and adjacent areas.

Shell made of mineral wool or polystyrene foam

This type of soundproofing of a sewer riser in an apartment is selected precisely according to the diameter of the riser and requires additions to protect the joints and adjacent sections of the pipeline.

The pipe is enclosed in a “shell”, connecting the halves of the hollow cylinders using a special adhesive edge (pictured above) or tape. The installation of such insulation is shown in the video, but the effectiveness of the system specifically for absorbing sound is not too great - heat losses are removed much better.

Soundproofing a sewer riser using a duct

In this case, the rigid structure performs two functions - it serves as an additional barrier to noise penetration and gives an aesthetic appearance to communications. If a bulk noise absorber is used, the third function of the box is to limit the specified volume for the filler.

Creating a box from plasterboard or similar sheet rigid materials is discussed in detail in the article “How to cover pipes in a toilet.” Moreover, if it is necessary to make a duct only for the sewer riser, it is advisable to use an option with a reduced cross-section of the structure.

The sound insulation itself is carried out using mineral wool or specialized materials, for example, Knauf Acoustic wool. After this, a box is mounted - it will protect the loose winding from mechanical stress and hide its unsightly appearance. The box installation process is discussed in detail in the video.

Filling a box with bulk materials is a rarely used method. In this case, sand, sawdust, polystyrene foam granules and other similar materials are used as a noise absorber.

It is important to understand that inspection and repair of the riser in this case is very difficult, and the appearance of a leak may not be noticed in a timely manner.

This method of soundproofing a sewer riser with your own hands in an apartment is not very appropriate; it is more suitable for a private house.