Device features and purpose

The design of the ball valve is extremely simple and at the same time effective. A shutter made in the form of a ball with a through hole is placed inside a metal or plastic body (seat). The size of the hole corresponds to the dimensions of the device inlet and outlet.

The ball element is rigidly connected to the handle and rotates following its rotation. If the ball is in the open state (the axis of the hole runs parallel to the axis of the body), the flow of liquid or gas passes through the device unhindered, without experiencing hydraulic resistance. When rotated 90°, the ball turns with a blank wall towards the flow of the working medium, and the media supply completely stops. Turning to a smaller angle makes it possible to regulate the intensity of the passage of the working medium.

Note! Strictly speaking, the term “ball” is more of a slang term, although it is used much more often. The correct name is “ball valve”.

Experts note the following advantages of such devices:

- Relatively small dimensions.

- Light weight.

- Ability to work in any orientation in space.

- Excellent tightness performance.

- Favorable price-quality ratio.

There are also some disadvantages:

- A high torque is required to turn the tap 90°.

- When opening the tap quickly, in some models there is a possibility of water hammer occurring.

- To prevent the ball element from “sticking” and losing its seal, it is advisable to open and close the valve at least once a week.

How the system is repaired

To begin, prepare:

- spanners;

- a screwdriver (almost no repair can be done without it);

- pliers.

To repair a water tap you need:

- Turn off the cold or hot water in front of the tap.

- Remove the screw that holds the swing arm in place.

- Remove the lever and unscrew the threaded part with a screwdriver.

- Use pliers to remove the faucet dome and remove the plastic part.

- If a water tap leaks due to wear or clogging of the seal, then it is either completely replaced with a new one or thoroughly cleaned.

- Remove the ball from the mount and replace it if there is visible damage.

- Dismantle the seals that secure the rotating part. All springs and seals are removed with a flat-head screwdriver.

- If the gaskets are deformed or damaged, new ones are installed.

Related article: Paint a veneer door: painting rules

After completing the repair of the ball valve, reassemble it in the reverse order, simultaneously applying a thin layer of lubricant. Lubricant may vary from manufacturer to manufacturer and may not be suitable for a particular type of ball valve, which will lead to its failure.

The repair of the ball valve is completed by checking the tightness of all elements and connections; for this, it is connected to the water supply and tested.

Types of ball valves and their application

Ball locking elements are used everywhere, so their classification is quite broad. In general, modern industry produces more than 4,000 various modifications of such shut-off valves. Products are divided into several categories.

According to the case material:

- Brass. The best option for gas and water supply networks with a good price-quality ratio. Not intended for high media temperatures.

- Steel. The most affordable. They have a wide range of standard sizes. They do not work well in cold water supply networks. Subject to corrosion.

- Made from stainless steel. More expensive and efficient compared to steel devices.

- Cast iron. Previously considered almost the only available option, today they are almost completely crowded out of the market. Inferior to modern models in all respects.

- Polypropylene. Mounted in plastic pipeline systems. In terms of strength and durability, they are almost as good as brass. They are characterized by relatively low weight and cost, and are not subject to corrosion.

We recommend that you read: Features of clips for fastening PVC pipes and rules for installing clamps

By connection type:

- Couplings. They have a huge selection of standard sizes and are equipped with threaded connections, which makes them extremely popular in private construction and public utilities.

- Welded. Lightweight and small devices. The welded connection to the pipeline provides excellent tightness, but significantly complicates the procedure for servicing and replacing the valve.

- Flanged. Bulky products that are used mainly on large backbone networks with a diameter of over 40 mm. Easy to maintain and install, require periodic monitoring of the condition of the tightening bolts.

By body type:

- Collapsible. The structure can be easily disassembled and, if necessary, damaged parts can be replaced.

- All-welded. Cheaper than collapsible analogues. If they fail, they must be completely replaced. Considering the service life of about 15-20 years, they often seem to be a more profitable option.

By control method:

- Manual. The most common type of ball valve in everyday life. The flow of media is blocked by turning the lever or “butterfly”.

- Electrically driven. Control is carried out remotely using electrical signals.

- With pneumatic drive. Another option for remote control. It is used where the use of electricity is associated with a certain danger.

- With gearbox. The device is mounted on taps with a cross-section over 30 cm and on some smaller models, where it is necessary to ensure a smooth change in the intensity of the media flow.

By type of passage:

- Full bore. The diameter of the hole in the ball coincides with the dimensions of the inlet and outlet openings of the faucet. They are used where even small losses in liquid pressure will be critical.

- Standard passage (reduced). The nominal diameter of the product is slightly higher (as a rule, by one standard size) than the size of the hole in the ball. The cost of such devices is lower, which is why they are widely used. An important advantage of this type of product is that the likelihood of water hammer formation is much lower in them.

Markings on ball valves

Markings on a ball valve

Markings on products contain a lot of important information, just like labels on clothing. The ability to decipher the markings on the device will help in choosing a suitable faucet.

Information indicated on ball valves:

- D.N. Indicates the nominal diameter and defines the dimensions of pipelines. These indicators apply to all plumbing elements. Dimensions in centimeters – DN 50, DN 32, 20, 40, and DN 15 mm, .

- P.N. Indicates nominal pressure and is measured in bars. PN shows the permissible maximum pressure at a temperature of 20 degrees, at which long-term operation of the device is possible. The WOG mark indicates that the device can be mounted for various liquids (water, gas and gasoline). It also indicates the maximum vapor pressure of water at 100 degrees Fahrenheit.

The WSP marking indicates steam and water pressure. It also indicates at what maximum temperatures the device is able to properly perform its functions.

It is not uncommon to see a MOP mark on devices. These letters are similar to PN indicators and are also calculated in bars. Often such valves are used in gas pipes. Adding a number to the end of the abbreviation indicates the highest pressure in bar.

- CW617N is the marking of brass according to the European standard. This abbreviation denotes the materials from which the body of the product is made.

- NL and LF. Indicates products made of brass or copper, but without the addition of lead.

- CE marking means that the product is created in accordance with all European standards and requirements.

Explanation of symbols on the tap

Important! Compared to other types of connecting devices, the technical characteristics of any ball valve are quite high.

As for WOG and WSP, we can say that these letters indicate that such taps can be used for both low and high temperatures. Their valve is rated at 600WOG/150WSP. Thanks to these characteristics, such devices can withstand up to 600 pounds per 1 square inch in both water and gas pipes.

Depending on the manufacturer, there may be other markings on the valves indicating the date of manufacture and various additional information. The clarity of the engraving of abbreviations must be in perfect condition. Otherwise, you can judge the wear of parts.

How to choose a faucet

In order not to make a mistake when choosing a crane, you should consider a number of important points:

- Purpose of the device. In accordance with GOST, products for gas pipelines are identified by the black or yellow color of the handle, for cold water supply networks - by blue. Ball valves intended for hot water supply networks are marked in red.

- Part installation method. On highways intended for transporting acidic, alkaline media, or liquids with high temperatures, preference is given to devices for welding.

Note! The nominal diameter of the ball valve is indicated by the letters DN.

In addition to the nominal bore, the product marking contains information about the values of the nominal (PN) and operating pressure, the maximum permissible operating temperature, and the date of manufacture of the part.

We recommend that you read: What is the difference between HDPE corrugation and PVC and which is better to choose?

When purchasing the device, you should carefully inspect it for defects - nicks, chips, dents. It is also worth checking the package, which must include:

- Frame.

- Steel or brass ball.

- Sealing washer.

- Control knob.

- Adjusting nut.

- Seal rod.

Also, you should be careful so that instead of an expensive and durable brass product, you do not buy for the same money a low-quality fake made of silumin , which will last, at best, 2-3 years. You can recognize an attempt to deceive by its weight - real brass is very heavy.

To connect shower cabins, washing machines and dishwashers, and internal wiring of the water supply system, collapsible taps with threaded fastening are suitable. In general, when choosing between all-welded and collapsible parts, it is better to give preference to the latter, since they are easy to repair, easy to operate, compact, and are also characterized by a good level of tightness.

As for cost, this is not an issue where you should try to save money in any way. A cheap faucet of poor quality will not only last an order of magnitude shorter, but also has every chance of causing serious trouble - from flooding the neighbors below to a life-threatening gas leak.

As expected, the cheapest are the products of craftsmen from the Middle Kingdom, the most expensive are Italian devices. Russian cranes belong to the middle price category, offering a reasonable compromise between savings and quality.

Note! A unique sign of the quality of the product is the characteristic shine of the metal case. The shine appears after the brass alloy is pollinated with expensive chromium or nickel.

What are the functions of a water ball valve?

A ball valve for water is called a valve with a shutter or a valve with a spherical shut-off element.

For a long time, craftsmen used valves and gate valves as shut-off elements when installing pipelines. But their use required regular monitoring of their condition and constant maintenance. This was quite complex and expensive, and in addition, the classic piping elements were heavy and large. Constant encounters with difficulties led to the invention of an alternative option that was simpler and more convenient to use.

At the beginning of the 20th century, the first ball valve appeared, but technology had not yet made it possible to make it reliable in terms of tightness. The discovery of fluoroplastic materials made it possible to successfully solve this problem. The wear of a seal made of fluoroplastic is much lower than that of rubber gaskets used in valve valve construction. This virtually eliminates the leakage of liquids and gases.

Ball valves for cold and hot water are made in accordance with GOST 9544-2005, which regulates the standards and tightness classes of all types of valves. Shut-off valves can be class A, B, C or D. When testing equipment, water or air is used. More stringent requirements apply to ball valves for gas.

What are the consequences of selection errors?

Choosing the wrong ball valve model can have serious consequences.

So, if a steel product is installed in a cold water supply system, it can quickly (within 3-6 months) become unusable. The reason is the increased oxygen content in the liquid, which promotes intensive rust formation. For such networks, it is better to prefer products with a rubber-coated wedge.

We recommend that you read: Where is PPR (polypropylene) pipe used?

If, on the contrary, the system operates with a medium at high temperatures (150°C and above), it will be a mistake to use products with a fluoroplastic seal. To maintain tightness, taps with a metal-to-metal seal are better suited here.

It is not recommended to install household ball valves in pipeline networks through which process water containing solid fractions circulates. Impurities will quickly damage the O-rings and the device will no longer function properly.

Repair procedure

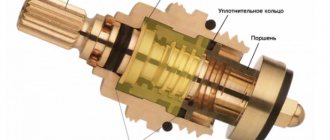

Ball valve assembly diagram.

Despite the fact that ball-based faucets are durable, they sometimes fail. A faulty faucet can be replaced or repaired, the main thing is to know its structure.

To repair the fittings, you should prepare the following tools: pliers, hex wrench, minus screwdriver and hammer. The first thing to do is turn off the water supply. Use a hex wrench to loosen the screw that holds the lever. Then it needs to be removed. Next, use a screwdriver to turn the threaded ring counterclockwise. Then use pliers to remove the chrome dome.

Next, you need to remove the ball mechanism and inspect it for rust and signs of metal wear. If all these defects are present, the ball should be replaced. The sealing springs must be replaced.

Before putting the faucet back together, you should lubricate all sealing elements with a special non-toxic silicone grease suitable for plumbing fixtures.

Assembly follows the same pattern in reverse order.

If the mixer cannot be repaired or the ball mechanism is severely worn out, you should purchase a new one.