Introduction

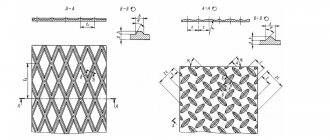

1. The shape and main dimensions of the corrugations must correspond to those shown in the drawing.

3. Steps of corrugations, mm, should be selected from the rows:

straight – 0.5; 0.6; 0.8; 1.0; 1.2; 1.6;

mesh – 0.5; 0.6; 0.8; 1.0; 1.2; 1.6; 2.0.

An example of a symbol for straight corrugation with a pitch of =1.0 mm.

Corrugation straight 1.0 GOST 21474-75

Corrugation mesh 1.0 GOST 21474-75

4. The height, angle and dependence of the corrugation pitch on the diameter and width of the rolling surface are given in the recommended application.

Tools and machine assembly

Chips are not formed during this process, since the groove is pressed through with a special tool. The following devices are used for turning knurling:

- various videos;

- gear knurls;

- universal knurls;

- standard balls

- thread rolling and other tools;

The components of the first device are a knurling roller and a holder. Using this tool, different patterns of corrugations are made on parts. A holder with a roller inserted into it, this is what this device looks like. This tackle can be double-sided or single-sided, it all depends on the reefing performed. A straight pattern is made with a single-roller device.

But the mesh shape can be obtained using a double-sided apparatus. Knurling turning rollers are made from tool steel grades that have the appropriate GOST standards. The corrugation pattern on them is made on a milling machine. Gear turning knurls are one of the most common options for cutting a cylindrical gear; you can do it yourself. Using such devices, you can get the desired product in one pass.

Universal knurling for a lathe - this equipment can perform thread cutting, notches, notches and other operations on cylindrical and conical workpieces. You can also make it yourself from steel or brass. A homemade holder is made from a hexagon. Threads using the rolling method are produced by cold deformation of the top layer of the workpiece using flat dies, threaded segments and other means.

Using the cold turning method, soft alloy threads, grooves and small teeth are obtained. There is no advantage to machining a large number of parts for threading that uses a cutter. This is due to the fact that the replacement plates are manufactured with a limited depth. To obtain the desired result, the cutter must perform several passes, as required by GOST.

Before starting work, the craft is cleaned with a wire brush, and during processing it is systematically lubricated with machine oil. A homemade and factory holder is installed in the place where the cutter is attached, and the overhang should be minimal. The operating procedure is that the knurling tool is brought close to the workpiece by manual or automatic feed by rollers and is pressed into the plane being processed to a certain depth.

Holders and rollers for knurling 21474-75

Supply and production of rollers and holders for rolling straight and mesh corrugations

Holders and rollers are designed for rolling straight and mesh corrugations in combination with a single-roller or double-roller support holder for knurling, GOST 13062-67. Roller dimensions: diameter x width x mounting hole - 20x9x8. The corrugation pitch is from 0.5 to 1.6 mm. Tooth angle from 60° to 90°. Special steel for rollers of the following grades: X12M, 9XC, XBG On request, we produce holders and rollers of non-standard sizes and angles of entry.

GOST 21474-75 Straight and mesh corrugations

GOST 13062-67 Single-roller caliper holders for rolling mesh reliefs.

6640-0001 25x16x140 6640-0002 25x16x140 6640-0003 25x20x150 6640-0004 32x20x150 6640-0005 32x25x150 6640-0006 40x32x200 664 0-0007 40x32x200

GOST 13063-67 Double-roller caliper holders for rolling mesh reliefs.

6640-0031 25x20x150 6640-0032 32x25x180 6640-0033 40x32x200

GOST 51760 Rollers for knurling with oblique corrugation

Single-roller support holder for direct knurling 16x16x120 Double-roller support holder for mesh knurling 16x16x150 Single-roller support holder for direct knurling 25x16x140 Single-roller support holder for direct knurling 6640-0003 25x16x150 Double-roller support holder for mesh knurling 6640-0031 25x20x150 Single-roller support holder for knurling 6640-0003 25x20x150 Double-roller caliper holder for mesh knurling 40x32x220

Roller for knurling straight knurling 20x6x2.5 Roller for knurling straight knurling 20x6x3 Roller for knurling straight knurling 20x6x6 Roller for knurling straight knurling 20x8x6 Roller for knurling straight knurling 20x8x9 Roller for knurling straight knurling 30x10x10 Roller for knurling straight knurling 30x8x10 Roller for straight knurling 30x12x12 Roller for knurling straight grooves 66x40x13

Roller for knurling mesh corrugation 20x6x2.5 Roller for knurling mesh corrugation 20x6x3 Roller for knurling mesh corrugation 20x6x6 Roller for knurling mesh corrugation 20x8x6 Roller for knurling mesh corrugation 20x8x9 Roller for knurling mesh corrugation 30x10x10 Roller for knurling mesh corrugation 30x8x10 Roller for rolling mesh corrugations 30x12x12 Roller for rolling mesh corrugations 66x40x13

Read also: Operating instructions for the modular machine K2M

Roller for knurling straight knurls 20x9x8 pitch t 0.5 mm x 60° Roller for knurling straight knurls 20x9x8 pitch t 0.5 mm x 70° Roller for knurling straight knurls 20x9x8 pitch t 0.5 mm x 90° Roller for knurling straight knurls 20x9x8 pitch t 0.6 mm x 60° Roller for knurling straight knurling 20x9x8 pitch t 0.6 mm x 70° Roller for knurling straight knurling 20x9x8 pitch t 0.6 mm x 90° Roller for knurling straight knurling 20x9x8 pitch t 0, 8 mm x 60° Roller for knurling straight knurling 20x9x8 pitch t 0.8 mm x 70° Roller for knurling straight knurling 20x9x8 pitch t 0.8 mm x 90° Roller for knurling straight knurling 20x9x8 pitch t 1.0 mm x 60° Roller for knurling straight knurls 20x9x8 pitch t 1.0 mm x 70° Roller for knurling straight knurls 20x9x8 pitch t 1.0 mm x 90° Roller for knurling straight knurls 20x9x8 pitch t 1.2 mm x 60° Roller for knurling straight knurls 20x9x8 pitch t 1.2 mm x 70° Roller for knurling straight knurling 20x9x8 pitch t 1.2 mm x 90° Roller for knurling straight knurling 20x9x8 pitch t 1.6 mm x 60° Roller for knurling straight knurling 20x9x8 pitch t 1, 6 mm x 70° Roller for knurling straight knurling 20x9x8 pitch t 1.6 mm x 90° Roller for knurling mesh knurling 20x9x8 pitch t 0.5 mm x 60° right Roller for knurling mesh knurling 20x9x8 pitch t 0.5 mm x 60 ° left Roller for knurling mesh knurling 20x9x8 pitch t 0.5 mm x 70° left Roller for knurling mesh knurling 20x9x8 pitch t 0.5 mm x 70°, right Roller for knurling mesh knurling 20x9x8 pitch t 0.5 mm x 90° left Roller for knurling mesh knurling 20x9x8 pitch t 0.5 mm x 90° right Roller for knurling mesh knurling 20x9x8 pitch t 0.6 mm x 60° left Roller for knurling mesh knurling 20x9x8 pitch t 0.6 mm x 60° right Roller for knurling mesh knurling 20x9x8 pitch t 0.6 mm x 70° left Roller for knurling mesh knurling 20x9x8 pitch t 0.6 mm x 70° right Roller for knurling mesh knurling 20x9x8 pitch t 0.6 mm x 90° left Roller for knurling mesh knurling 20x9x8 pitch t 0.6 mm x 90° right Roller for knurling mesh knurling 20x9x8 pitch t 0.8 mm x 60° left Roller for knurling mesh knurling 20x9x8 pitch t 0.8 mm x 60° right Roller for knurling mesh knurling 20x9x8 pitch t 0.8 mm x 70° left Roller for knurling mesh knurling 20x9x8 pitch t 0.8 mm x 70° right Roller for knurling mesh knurling 20x9x8 pitch t 0.8 mm x 90° left Roller for knurling mesh knurling 20x9x8 pitch t 0.8 mm x 90° right Roller for knurling mesh knurling 20x9x8 pitch t 1.0 mm x 60° left Roller for knurling mesh knurling 20x9x8 pitch t 1.0 mm x 60° right Roller for knurling mesh knurling 20x9x8 pitch t 1 .0 mm x 70° left Roller for knurling mesh knurling 20x9x8 pitch t 1.0 mm x 70° right Roller for knurling mesh knurling 20x9x8 pitch t 1.0 mm x 90° left Roller for knurling mesh knurling 20x9x8 pitch t 1.0 mm x 90° right Roller for knurling mesh knurling 20x9x8 pitch t 1.2 mm x 60° left Roller for knurling mesh knurling 20x9x8 pitch t 1.2 mm x 60° right Roller for knurling mesh knurling 20x9x8 pitch t 1.2 mm x 70° left Roller for knurling mesh knurling 20x9x8 pitch t 1.2 mm x 70° right Roller for knurling mesh knurling 20x9x8 pitch t 1.2 mm x 90° left Roller for knurling mesh knurling 20x9x8 pitch t 1.2 mm x 90° right Roller for knurling mesh knurling 20x9x8 pitch t 1.6 mm x 60° left Roller for knurling mesh knurling 20x9x8 pitch t 1.6 mm x 60° right Roller for knurling mesh knurling 20x9x8 pitch t 1.6 mm x 70° left Roller for knurling mesh knurling 20x9x8 pitch t 1.6 mm x 70° right Roller for knurling mesh knurling 20x9x8 pitch t 1.6 mm x 90° left Roller for knurling mesh knurling 20x9x8 pitch t 1.6 mm x 90° right

Read also: Connecting electrical installations to electrical networks

The surface deformation processing process has become widespread in industrial production. The turning knurling method is based on the plastic qualities of the metal. This makes it possible to obtain residual deformation without compromising the integrity of the material. This method makes it possible to simplify processing, reduce the amount of waste, and comply with GOST.

Rolling process, types and purpose Shaping during the rolling procedure is performed without producing chips. It consists in the fact that a tool (roller, cutter, etc.) is pressed into the body of the material and, due to surface deformation, a corresponding profile is obtained. As we can see, knurling is a cold method of processing the surface layer of a part in a process in which a mesh, threads, marks, notches and other roughness are formed without violating GOST.

This allows the surface of a number of parts (handles, handles, screw heads) of machines and devices to have roughness in the form of a certain corrugated pattern for ease of use. At the moment, two main types of turning knurling are practiced: • shaping; • strengthening; The first option is used in shaping teeth on wheels and shafts, threads on products, and applying scales on devices. Hardening rolling of the surface of the material is used to increase strength and wear resistance. During lathe rolling, a hardening is formed on the surface of the workpiece, which helps to improve the performance properties of the material, and GOST is maintained. In this way, plastic deformation of shafts, bushings, axles and other products is performed. The turning knurling procedure is carried out quickly, and taking into account the additional properties obtained, the production of such parts in mass production becomes economically profitable. The turning knurling method is used for crafts due to increased requirements for the performance characteristics of equipment: strength, high productivity, speed, accuracy and other qualities. This method is used only on crafts with a pre-prepared surface.

Types of knurling rollers for corrugation Hardening of the surface layer is required to improve the performance characteristics of parts, as required by GOST. After turning, they are less sensitive to damage from fatigue, wear resistance and anti-corrosion abilities increase, microcracks and risks are removed. The workpiece acquires the desired size and shape. Lathes are most often used to perform this type of work. Tools and installation on machines No chips are formed during this process, since the groove is pressed through with a special tool. The following devices are used for turning knurling: • various rollers; • gear knurls; • universal knurls; • standard balls • thread rolling and other tools; The components of the first device are a knurling roller and a holder. Using this tool, different patterns of corrugations are made on parts. A holder with a roller inserted into it, this is what this device looks like. This tackle can be double-sided or single-sided, it all depends on the reefing performed. A straight pattern is made with a single-roller device.

But the mesh shape can be obtained using a double-sided apparatus. Knurling turning rollers are made from tool steel grades that have the appropriate GOST standards. The corrugation pattern on them is made on a milling machine. Gear turning knurls are one of the most common options for cutting a cylindrical gear; you can do it yourself. Using such devices, you can get the desired product in one pass. Universal knurling for a lathe - this equipment can perform thread cutting, notches, notches and other operations on cylindrical and conical workpieces. You can also make it yourself from steel or brass. A homemade holder is made from a hexagon. Threads using the rolling method are produced by cold deformation of the top layer of the workpiece using flat dies, threaded segments and other means. Using the cold turning method, soft alloy threads, grooves and small teeth are obtained. There is no advantage to machining a large number of parts for threading that uses a cutter. This is due to the fact that the replacement plates are manufactured with a limited depth. To obtain the desired result, the cutter must perform several passes, as required by GOST.

Read also: Al1814cv screwdriver charging circuit

Before starting work, the craft is cleaned with a wire brush, and during processing it is systematically lubricated with machine oil. A homemade and factory holder is installed in the place where the cutter is attached, and the overhang should be minimal. The operating procedure is that the knurling tool is brought close to the workpiece by manual or automatic feed by rollers and is pressed into the plane being processed to a certain depth. The processing speed depends on the type of cutter and workpiece material used.

GOST 51760 Rollers for rolling straight corrugations

GOST 51760 Rollers for rolling mesh corrugations

Rolling process, types and purpose

Shaping during the rolling procedure is performed without producing chips. It consists in the fact that a tool (roller, cutter, etc.) is pressed into the body of the material and, due to surface deformation, a corresponding profile is obtained. As we can see, knurling is a cold method of processing the surface layer of a part in a process in which a mesh, threads, marks, notches and other roughness are formed without violating GOST.

This allows the surface of a number of parts (handles, handles, screw heads) of machines and devices to have roughness in the form of a certain corrugated pattern for ease of use. At the moment, two main types of turning knurling are practiced:

- formative;

- strengthening;

The first option is used in shaping teeth on wheels and shafts, threads on products, and applying scales on devices. Hardening rolling of the surface of the material is used to increase strength and wear resistance. During lathe rolling, a hardening is formed on the surface of the workpiece, which helps to improve the performance properties of the material, and GOST is maintained. In this way, plastic deformation of shafts, bushings, axles and other products is performed.

The turning knurling procedure is carried out quickly, and taking into account the additional properties obtained, the production of such parts in mass production becomes economically profitable. The turning knurling method is used for crafts due to increased requirements for the performance characteristics of equipment: strength, high productivity, speed, accuracy and other qualities. This method is used only on crafts with a pre-prepared surface.

Types of knurling rollers for corrugation

Hardening of the surface layer is required to improve the performance characteristics of parts, as required by GOST. After turning, they are less sensitive to damage from fatigue, wear resistance and anti-corrosion abilities increase, microcracks and risks are removed. The workpiece acquires the desired size and shape. Lathes are most often used to perform this type of work.

GOST 21474-75

STATE COMMITTEE OF STANDARDS OF THE COUNCIL OF MINISTERS OF THE USSR Moscow

DEVELOPED, INTRODUCED AND PREPARED FOR APPROVAL by the All-Union Scientific Research Institute for Normalization in Mechanical Engineering (VNIINMASH)

And about. Director Gerasimov N.N.

Topic leader and performer V.P. Piven

APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated November 24, 1975 No. 3571

UDC 621 At—408.8(083.74] PO Group

STATE STANDARD OF THE USSR UNION

STRAIGHT AND MESH RIFLES Shape and main dimensions

Straight and diamond knurl. Form and basic dimensions

OST 26B16 n OST 26017

Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated November 24, 1975 No. 3571 established the validity period

from 01.01. 77 until 01.01. 87

Failure to comply with the standard is punishable by law

1. The shape and main dimensions of the corrugations must correspond to those indicated in the drawing.

Corrugation profile in direction A

2. Chamfer - according to GOST 10948-64.

3. The pitch of the corrugations P, mm, should be selected from the rows: straight—0.5; 0.6; 0.8; 1.0; 1.2; 1.6;

mesh—0.5; 0.6; 0.8; 1.0; 1.2; 1.6; 2.0.

An example of a symbol for straight corrugation with a pitch of P = 1.0 mm.

Corrugation straight 1.0 GOST 21474—75

Reproduction is prohibited © Standards Publishing House, 1976

The same, for mesh corrugation with a pitch of P = 1.0 mm:

Corrugation mesh 1.0 GOST 21474—75

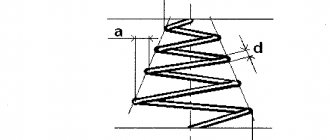

4. The height L, angle a and the dependence of the corrugation pitch on the diameter D and width B of the rolling surface are given in the recommended appendix.

APPENDIX Recommended

HEIGHT hf ANGLE a AND DEPENDENCE OF RIFLE PITCH P ON DIAMETER D AND WIDTH IN THE ROLLING SURFACE

1. Corrugation height h: for steel 0.25–0.7 R;

for non-ferrous metals and alloys 0.25-g 0.5 R.

2. a = "70° for corrugations on steel, i = 90° for non-ferrous metals and alloys.

3. The dependence of the pitch P on the diameter and width of the rolled surface is indicated in table. 1 and 2.

Goals and purpose

Rolling is a cold method of processing products. Under the influence of the tool, a different pattern is obtained on the surface - mesh, corrugation, scratches, notches. There are no special requirements for surface preparation. The part is ground to the required diameter, then the corrugation is rolled.

- Improving performance properties.

- Removing cracks and other defects.

- Increased corrosion resistance.

- Improvement of product performance characteristics.

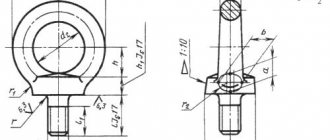

For some parts, knurling is necessary due to their operational characteristics. Corrugation is made on screw heads and handles. For ease of use, rolling is done on the handle on machines and other mechanisms.

Rolling process technology

Thread rolling with rolling rollers is performed on semi-automatic and two- or three-roller machines, which are designed for cold rolling of various types of threads. The speed at which knurling occurs depends on the strength of the workpiece material, the type of thread and lies in the range of 15÷90 m/min. The higher the tensile strength of the material, the lower the speed at which rolling is performed. In this case, the radial feed can vary from 0.03 to 0.3 mm. The rolling force also depends on the material of the workpiece and is usually selected experimentally or according to special nomograms.

The thread rolling machine includes a drive that generates the necessary force to deform the workpiece, and a rotation device.

The rolling of threaded notches on the workpiece occurs due to the forced rotation of the knurling rollers. During the operation, the equipment performs radial movement using force from a hydraulic drive. The workpiece can be located between knurling rollers or in the chuck of the gripping device. Rotation occurs under the influence of friction. Many machine models are equipped with additional devices, which significantly expands their capabilities and increases labor productivity. The presence of a rotating mechanism of the spindle assembly allows knurling not only with radial feed, but also with axial feed. Many models are built into automatic lines; for this purpose they are equipped with devices for automatic loading and unloading of workpieces.

Rolling machines are produced by Russian and foreign manufacturers, including program-controlled equipment. The most popular models are:

- A9527, A9524, AA9521.02 (03) Azov plant of forging and pressing equipment;

- B28, B28-80, B28-630 from Belarusian manufacturer;

- PEE-WEE, PROFIROLL manufacturers from Germany.

The video shows the process of rolling M10 threads using rolling rollers.

We ask those who have dealt with rolling threads of varying complexity and type to share their experience in performing the operation and talk about the nuances of the cutting process in the comments to the text.