Hammers

Rating of the best drills for a rotary hammer in 2021 to buy. TOP 10

Hammers

review of the best reviews. Rating of the best drills for rotary hammers in Russia list 2021 - 2021.

Hammers

There comes a time for every person when a major overhaul begins. And it won't end with just changing the wallpaper. Such an event involves destruction, drilling, creating new holes and many other construction “fun”. And the main assistant in this matter will be a hammer drill. After all, this tool combines the qualities of an impact drill and a jackhammer. And in order for the work process to proceed easily and without interruptions, you should carefully consider the choice of equipment for the rotary hammer. Many people mistakenly assume that they can get by with regular drills. But, before the process begins, this element will quickly become unusable. Unable to withstand the load, such drills instantly become dull and bend.

Drill hole: features

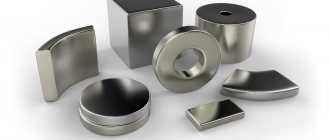

Drills are used exclusively for working with a hammer drill. They are not used for drills. There are a number of different types of drill bits available, depending on the material you plan to work with. Metal, masonry and wood can be drilled using specially designed structures. They are adapted to the properties of a specific material and will help achieve the desired result with minimal effort and time. The range of drills also includes special products, for example for creating holes in glass surfaces or tiles. For these purposes, manufacturers produce drills with diamond tips made of tungsten carbide.

The quality of drills is determined by the material from which they are made. Accordingly, the type of material that they can drill is determined. Most often, drills are made from materials such as high-speed steel, with the addition of carbide, titanium, cobalt and other substances that improve the properties of the material.

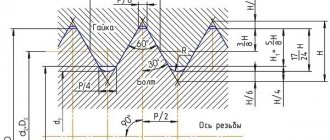

Drills differ in the type of shank. Thus, straight shanks are used for chucks with and without a key for holes with a diameter of 10-13 mm. SDS shanks are used for corresponding rotary hammers. Hex shanks are used for screwdrivers.

Drills for stone and metal can be spiral-shaped, drills for wood can be twisted or flat. Drills come in different diameters and lengths. Extensions can be used if necessary.

How to choose metal drills?

To start working with a drill, you need to determine the characteristics of the metal that you will drill. All metals have different levels of density. The density of the metal determines the design of the drill, as it must be harder than the metal into which it is pointed.

Manufacturers take this rule into account, so they are made from different materials containing different elements to increase hardness and improve cutting ability. Conventionally, there are two groups of metal drill materials:

- made of high-speed or alloy steel: it is an alloy consisting of a metal element combined with a chemical element that gives the steel certain properties;

- made of hard metal or carbide. powdered forms of tungsten carbide are heat treated with binder metals such as titanium or cobalt to produce a solid.

Popular types of metal drills

Drills are classified by type, cutting method, and connecting element. The following types of drill according to the material used are available on the market:

- made of high-speed steel. The most popular steel, characterized by high hardness, strength and sharpening ability;

- from colbate. provides strength and resistance, increases the hardness of the drill. Cobalt retains its properties better at higher temperatures than titanium, so a higher operating speed of the hammer drill is acceptable;

- titanium. Titanium coated drill bits provide a stronger and more stable alloy. When choosing titanium drills, pay attention to the percentage of the auxiliary component;

- Wolfram carbide. This component gives drills an increased level of strength and hardness. The combination of tungsten and carbon produces a harder or softer metal depending on the percentage of carbon in it.

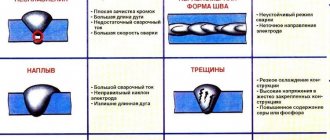

Drill bits should be used with cutting fluid at low speeds using even and constant pressure. Monitor the condition of the crown, which should always be sharpened. If the drill is used incorrectly, it will quickly become unusable.

With different ratios of components in the mixture, metals with different properties are formed. A low percentage of impurities will have little effect on the quality and durability of the drill. The quality of the drill is also influenced by its processing and production processes.

The drill hardness rating is determined using the Brinell scale. The indicators are determined in newtons per square millimeter. A higher indicator means a more stable and reliable drill.

Types of drills for hammer drills for drilling concrete

Drill bits for hammer drills for concrete and other materials vary depending on the type of shank. All modern products are marked SDS, and the further name is indicated by the manufacturer depending on the type of shank:

- The drill for the SDS-plus hammer drill (SDS plus) has 4 open grooves for insertion into the chuck. This type of shank is the most common. It is used for professional and household equipment of relatively small size. They can be purchased at a fairly affordable price, depending on the size. Concrete drills with a length of 110 mm of various thicknesses are often used, one of the most common diameters is 12 mm.

- Large diameter drills SDS-max (SDS max). They are almost as often used as SDS-plus, but are intended for much larger-scale work. Buying an SDS-max drill bit for a large concrete hammer drill will, accordingly, cost much more, since the price depends on the size of the products. Breakthrough drills SDS-max 45x990, 55x990 are very widely used, but in general the most common diameters are 32, 40, 45, 55 mm.

- SDS-top (SDS-top). Very rarely used drills. They have 2 closed and 2 open grooves. It is used on medium-power hammer drills, but is not widely used.

- SDS-quick (SDS-quick). The shank has a hexagonal shape. In practice, such drills are practically never used.

The online store "Building Materials-Cheap" works with hammer drills SDS-plus (SDS plus) and SDS-max (SDS max). These products are designed for intensive use, have a long service life without sharpening and are optimal for use over a long period of time. They are made from special steel, which has the highest strength and resistance to deformation.

Creating holes with drills in stone and concrete

When choosing a drill bit for a stone hammer drill, it is not so difficult. It is important to determine how soft or hard the material needs to be drilled. Most rock drill bits are made from tungsten carbide.

Tungsten carbide drills are effective on concrete, granite, silicate masonry and natural stone. The overall quality of concrete drills depends on the quality of their tip and the number of cutting edges - 2,3,4.

The most effective will be a drill with four cutting edges made of carbide. Less durable drills have no more than 2 edges. Reinforced concrete must be hammer drilled using a standard or impact drill.

For concrete work, drills with the following types of shanks are used:

- straight shank;

- Slotted Drive SDS: A drill with a knurled shank that snaps into the chuck. Used in most hammer drills;

- hexagonal. More suitable for screwdrivers. These drills are designed for use with impact-type screwdrivers

Most concrete drills have SDS+ shanks. SDS Max shanks are used for heavy duty applications.

To work with a stone drill, various product designs are used. They most often differ in the type of groove. There are: a double L-shaped groove - this is a universal option, a U-shaped one - for better chip removal, with four teeth - to increase the stability of the drill. Grooves differ in the number of edges.

The best drills for a hammer drill

Bosch 2608833778 6*160 mm

This unit is suitable for tools with an SDS-plus chuck. "Bosch 2608833778" has a centering tip, which ensures deep, accurate and stable drilling in concrete. The head has an asymmetrical design, which provides good dust removal during drilling. This quality also ensures minimal tool wear. The product has four cutting edges. Their geometric arrangement will prevent the drill from jamming in the reinforcement. The edges are made of tungsten carbide. Thanks to this, the unit has increased impact resistance and increased wear resistance. The manufacturer also guarantees that this drill will not break during operation.

The total length of “Bosch 2608833778” is 160 mm, where the working length is 100 mm. The outer diameter is 6 mm.

The average cost is 160 rubles.

Advantages:

- Reliable manufacturer;

- Does not break when drilling;

- Suitable for working with concrete, brick and reinforced concrete.

Flaws:

- Price.

Makita D-00050 6*100 mm

"Makita D-00050" is intended for rotary hammers with the SDS-plus chuck type. The product has two carbide cutting edges that function evenly, so the drilling process is fast and without delays. The tip has a centered point. Thanks to this, the process goes in a precisely specified direction. Also, when working with such a tool, you will not feel much vibration that will interfere with drilling.

The total length of "Makita D-00050" is 110 mm, and the working length is 50 mm. diameter is 6 mm. Used when working with concrete, brickwork or natural stone.

The average cost is 80 rubles.

Advantages:

- The product is wear-resistant;

- Minimal vibration during operation;

- Price.

Flaws:

- Some products may be crooked.

DeWalt DT9571-QZ 14*600 mm

“DeWalt DT9571-QZ 14*600 mm” is characterized by high strength during drilling, this is due to the presence of a hardened tool core. This model is compatible with units that have an SDS-plus cartridge. Optimized cutting edge placement increases drilling speed, reduces vibration and ensures durability. This unit is also suitable for long-term use. It is possible to work with reinforced concrete, brick or stone masonry. Dust generated during drilling is quickly removed through special grooves.

The total length of the “DeWalt DT9571-QZ 14*600 mm” is 60 cm, where 54 cm is the working length. The outer diameter of the product is 14 mm.

The average cost is 610 rubles.

Advantages:

- Carbide brazing;

- Increased wear resistance and operating speed;

- Price.

Flaws:

- No.

BISON 29380-340-12 12*340 mm

This model is designed for high-performance professional rotary hammers with an SDS-max chuck. It is designed for impact drilling in concrete, brick and masonry. “ZUBR 29380-340-12” has a screw spiral; there is a large free space here, which facilitates the rapid removal of dust from the hole. For the manufacture of “ZUBR 29380-340-12” high quality tool steel is used. The tip of the product has two cutting edges and is made of VK8S tungsten alloy. This guarantees the tool's resistance to wear and ensures a long service life. It is also worth noting the presence of a reinforced core, which reduces vibration during drilling, and the holes will have smooth walls. When a drill collides with reinforcement, there will be no displacement or jamming of the tool; this is ensured by the cross-shaped geometry of the cutter.

The length of “ZUBR 29380-340-12” is 340 mm, where 200 mm is the working length. The diameter of the tool is 12 mm.

The average cost is 550 rubles.

Advantages:

- Fast dust removal;

- High-quality manufacturing materials;

- Reinforced core.

Flaws:

- Sometimes breakdowns occur during operation.

Granite 425100 25*1000 mm

This product is suitable for all tools with an SDS-plus chuck. The head of the unit has four cutting edges, which are made of an alloy of carbide and tungsten. For quick removal of dust and sludge during drilling, a double spiral is provided. It also helps relieve the load from the base of the equipment and increases the speed of work. The base “Granite 425100” is made of alloy steel. In its production, high-temperature soldering and hardening are used. Thanks to such modern technologies, the service life of the product is extended. This tool is suitable for drilling ordinary and reinforced concrete, sand-lime brick and masonry.

The total length of “Granite 425100” is 1000 mm, and the length of the working part is 950 mm. outer diameter is 25 mm.

The average cost is 1800 rubles.

Advantages:

- Good dust removal;

- Long service life;

- Increased operating speed due to the double helix.

Flaws:

- Not available in all stores.

Creating holes with a drill in wood

Most wood drill bits are made from hardened steel. There are several types of drills for wood processing:

- flat drills are used for drilling large diameters over 13 mm;

- spiral drills are supplied with a diameter of up to 17 mm, although there are exceptions;

- auger drills designed to remove chips when drilling wide holes;

- Triangular drills are suitable for drilling small holes.

Spiral drills are more suitable for working with denser materials, flat drills for smaller ones. Drills have different types of shanks. The straight shank is considered the most versatile.

How else are there drills?

In addition to the most popular types of borom, there are other types. They will be useful for effectively solving specific problems. The list of universal drills for metal, concrete, and wood is supplemented by the following types:

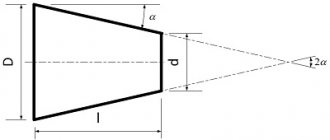

- stepped drills – conical-shaped products with different diameters;

- short drills - for drilling very hard metals and spot welding;

- Forstner drills - for drilling large holes;

- sliding drills – suitable for creating holes in wooden structures. Available in diameter sizes from 13 to 45 mm;

- drills with countersinks - for creating new holes with a drill or working with thin materials, for example, chipboard;

- installation drills are long products designed to create holes for pulling wire.

How to choose a good drill bit for a hammer drill?

It all depends on what tasks the user faces. For home use, the most popular diameters are 6-10 mm. You can buy an SDS-plus concrete drill with a diameter of 6 mm, for example, if you need to hang a picture or shelf, or attach a floor plinth when laying laminate flooring. A hole is drilled with a hammer drill into which a dowel is inserted and a self-tapping screw is screwed in, or a dowel-nail is used.

In order to create holes for fasteners intended for more severe loads (for example, to which cabinet furniture will be attached), you will need a drill with a larger diameter, from 8 mm. If large structures are being installed, it is better to buy an SDS-plus concrete drill with a diameter of up to 20 mm.

The most commonly used concrete drills are 100-110 mm long. This is enough to install a dowel or dowel-nail. In order to completely go through the wall, you will need to buy a longer drill bit for a hammer drill (500 to 1000 mm long).

Drilling with a rotary hammer

A hammer drill is one of the most important power tools in the repair industry. Without it, it is difficult to imagine major repairs and solving everyday problems. When choosing a rotary hammer, it is important to pay attention to several factors that determine the quality and efficiency of its operation.

If you are looking for a rotary hammer, first, better determine its technical and mechanical features:

- Hammer Size: Determines the size of drill bits you can use with this tool. The larger hammer drill is designed for industrial projects, while the smaller hammer hammer is typically used at home.

- Motor Speed: The motor speed of a hammer drill determines the power of the motor. A faster spinning motor usually results in higher hammer drill performance. The description of the hammer drill should contain information about the number of revolutions per minute.

- Motor power: It is imperative to check the motor power of the rotary hammer before purchasing. Like various other power tools, the motor power of a hammer drill is usually specified in amps. Universal size - 6 or 7 amperes.

- Durability and build quality. The high-quality plastics and metals used to make the hammer drill allow it to last a little longer.

- Type of food. Although all hammer drills are electric, they may use a different method of power delivery. Most popular impact drill options are corded hammer drills that charge by plugging into an outlet. Another method is battery power. This tool can be used regardless of the power source.

An advantage when choosing a hammer drill is the set of drills included. Different drills are suitable for specific conditions and applications. The hammer drill may also be sold with a carrying case. It will come in handy when using the tool.

Comparison table of the best drill bits for rotary hammers

| Name | Main characteristics | Price |

| DeWALT | SDS-plus shank, diameter - from 5 to 12 mm, length - 110 and 160 mm, suitable for stone, concrete and brick. | ₽ 2 320 |

| Matrix | The kit includes 13 items: 9 drills with a diameter from 6 to 14 mm with a working part length from 160 to 260 mm, a lance 250 mm long, two chisels for 20 and 40 mm. | ₽ 1 500 |

| CALIBER | A set of equipment (9 drills with a diameter of 6-14 mm and a length of 160-260 mm, a lance, chisels for 20 and 40 mm, a stroker), the same SDS-plus format with a bore diameter of 10 mm. | ₽ 1 340 |

| BOSCH | A set of 5 drills in a transparent plastic box, a shank with a diameter of 10 mm, chambered in SDS-plus format, included drills ranging in size from 5x110 mm to 10x160 mm. | ₽ 579 |

| GRANITE | Diameter 45 mm with a working part length of 450 mm and a total length of 570 mm, with an SDS-max standard shank with a diameter of 18 mm. | ₽ 5 125 |

Review of the best drills for rotary hammers 2021

- Bosch 2608833778. This product is suitable for working on hard surfaces. It is used for rotary hammers with an SDS-plus chuck. This model is equipped with a reinforced tip, which provides a centering position when drilling. The manufacturer wisely approached the shape of the head, making it asymmetrical. Due to this, less dust is generated during the drilling process.

During operation, the drill withstands any manipulation and is considered wear-resistant. The drill also contains four edges responsible for cutting the material. They are located in such a way that the drill will not jam in the hammer drill. High-strength carbide and tungsten are used to produce drills. This composition is responsible for wear resistance and impact resistance. The benefits of products from a well-known brand will be guaranteed for the entire operational life of the product. Such drills cost around 160 rubles, so the only downside is their price.

- Makita D-00050 is compatible with SDS-plus type chucks. The average price on the market is around 80 rubles. The cost is quite justified. The design has two cutting edges. Due to this, the drills take a little longer to make a hole than the previous model. Despite this, the drill is quite functional, and the drilling itself proceeds without delay. The tip is weighted due to its pointed shape. Therefore, you can count on drilling in a given direction. No vibration will be felt while working with the drill. This version of the drill is suitable for working with materials of increased hardness, such as concrete, brick or stone.

- DeWalt DT9571-QZ 14 costs around 600 rubles. The main feature of the drill is increased strength due to the reinforced core structure inside. There are several advantages of the drill:

- Excellent carbide alloy for long life and better strength;

- optimized groove design to eliminate debris and formed chips;

- hardened case for added strength and reduced risk of breakage;

- 160 degree tip design provides better penetration, increased drilling speed.

The drill is suitable for models with SDS-plus chucks. This is an example of a modern drill with excellent mechanical properties.

- ZUBR 29380-340-12 is a product adapted for working with SDS-max rotary hammers. The domestically produced drill has a screw spiral. It provides increased space through which dust is removed. Durable steel is used to produce the drill. The tip has two cutting grooves. This is the standard option. The advantage of the drill will be the presence of a reinforced core. Minimal vibration during operation and extended service life attract buyers. When used in a hammer drill, jamming of the drill is excluded.

- Granite 425100. Drills of this model are compatible with hammer drills with SDS-plus cartridges. The presence of four cutting edges made of carbide and tungsten provides increased wear resistance of the drill. The issue of dust formation and edge accumulation was resolved thanks to the double helix. It also guarantees increased operating speed of the tool. Alloy steel is used to produce drills. Granite drills are suitable for working with all types of concrete and brick. According to customer reviews, this model is not always found in stores. Overall, the drill is worth its price and is considered a popular model with a good service life.

- DeWalt Extreme Kit. The drill bits in this case have No-Walk tips for clean, precise drilling. High quality work is achieved thanks to recessed cutting wings. They are suitable for drilling alloy and non-alloy steel, and can be used to create holes in wood and plastics, thin metals and sheet metals. The set includes 6 Extreme drills and 11 drill bits for screwdrivers and 2 holders for quick drill replacement. The cost of the case is 2300 rubles including a suitcase made of high-strength plastic.

Top 5 drills for hammer drills

DeWALT EXTREME 2 DT7935B-QZ

A set of 10 drills from a famous American brand in a nice yellow case with a secure latch. SDS-plus shank, diameter - from 5 to 12 mm, length - 110 and 160 mm. Equally suitable for stone, concrete and brick. The drills are made in Germany and are ready to do their job for many years - with proper care and respect, of course. The best thing for home use: with this set in your home, you most likely will not need any other. For this you can give 2,500 rubles in your blood without a twinge of conscience.

Price: ₽ 2,320

Matrix 71098

A set of drills and chisels in a hard plastic case. The kit, priced at about 1,500 rubles, includes 13 items: 9 drills with a diameter of 6 to 14 mm with a length of the working part from 160 to 260 mm, a peak 250 mm long, two chisels for 20 and 40 mm (each 250 mm long) and a channel chisel 22 by 250 mm. Shank type - SDS-plus with a diameter of 10 mm. Inexpensive for such a rich set, made in Germany, from a well-known manufacturer. The choice of a home craftsman who not only hangs shelves, but also, say, lays the wiring himself..

Price: ₽ 1,500

CALIBER NB-13

An analogue of the previous set made in China: a similar case, a similar set of equipment (9 drills with a diameter of 6-14 mm and a length of 160-260 mm, a lance, chisels for 20 and 40 mm, a stroker), the same SDS-plus format with a bore diameter 10 mm, but the price is slightly lower - around 1300 rubles. Unfortunately, for a lower price you will have to pay for the quality of the drills: there is a chance of running into defects, so check the product before purchasing. But for those who do not plan to load their drills with back-breaking labor, this set can be a good way to save money.

Price: ₽ 1,340

BOSCH 2608833910

Set of 5 drills in a transparent plastic box. Designed for concrete, reinforced concrete and brick. Shank with a diameter of 10 mm for an SDS-plus format chuck. The set includes drills ranging in size from 5x110 mm to 10x160 mm. Not the biggest, although you usually don’t need more for a home. They are made in China, but the vaunted German quality is still there: the quality of workmanship of both the case and the drills themselves is excellent, the steel is of high quality, so they will last a long time. The asking price is 600 rubles and kopecks, which is not at all expensive for Bosch.

Price: ₽ 579

GRANITE Quadro-X 845570 45 x 570 mm

A real Tsar drill with a diameter of 45 mm, a working part length of 450 mm and a total length of 570 mm. The only drill in our selection with an SDS-max shank with a diameter of 18 mm, which immediately speaks of the professional character of the baby. The 4 cutting edges are made of tungsten carbide, the main part is made of structural alloy steel. The double spiral quickly removes dust and significantly speeds up work. This monster costs more than 5,000 rubles - more expensive than some hammer drills - but it inspires respect with its appearance alone. Professional equipment for a serious tool in the hands of an experienced craftsman.

Price: ₽ 5,125

Drills for rotary hammers: what you need to know about their use

Despite manufacturers' claims about the durability of drills, they can fail. Most often, the period of use depends on the materials with which it comes into contact. The cause of a drill malfunction may also be considered to be improper use. Also, the owner of a hammer drill should not forget about the mandatory lubrication of tools.

The drill is practically not subject to restoration and repair. This is a consumable item, so it will be easier to buy a new drill. During the working process, the drill does not need to be removed from the hammer drill and cooled. There will be no overheating, and the drill itself heats up to a temperature that it can withstand.

Choose high-quality drills and use them for the specified purposes.

Popular questions about drill bits for rotary hammers

Is there any service life for a drill? A good drill made from the right materials can last a very long time, but even its approximate lifespan cannot be predicted. It all depends on the intensity of use, on the care of the builder, on the materials with which the drill comes into contact, on the quality of the lubricant used and dozens of other variables.

Is it possible to restore a drill for a hammer drill if it is damaged? In principle, nothing is impossible, but the drill is a disposable consumable. If it is worn out or bent, you just need to buy a new one. And fixing something that’s broken is like washing toilet paper.

Is it necessary to cool the drill bit during prolonged drilling? As a rule, no. It is very difficult to heat a drill to a temperature that will affect its properties, and almost impossible with an ordinary household tool.