Transformer steel composition

The material is made not only from silicon, but also an alloy with iron. The addition of this element causes the force coefficient to increase and the electrical power resistivity to increase when compared to grades without silicon.

If you add a certain amount of silicon to the composition, this will lead to a decrease in the individual weight of iron oxides.

According to the chemical composition, this material can be classified as an alloy metal due to the presence of silicon in an amount of up to 0.5%.

In transformer iron, the addition of foreign impurities is in the range of 3-4.5%.

Classification

It is based on differences in steel in such parameters as purpose, magnetic properties, and chemical composition. Metal is classified according to the following indicators:

- Depending on the rolling method and structural condition, steel is divided into first, second and third classes.

- According to the quantitative composition of silicon. If it contains less than 0.4%, then this steel is not alloyed.

- Depending on the main standard characteristics, steel is divided into groups: from “0” to “7”.

- The numbers indicated in the steel grade indicate: first - class depending on the type of rolling and structural condition; the second is the amount of silicon; the third - a group of main characteristics, the fourth - the type of steel by serial number.

GOST electrical steel meets the standards and is designated by numbers: for sheets - 11036, for strips - 3863.

Properties of silicon

Silicon is called the main material of semiconductor electronics. It is used to manufacture integrated circuits, diodes, transistors, solar panels, photodetectors and other devices.

It is a semiconductor whose electrical properties depend on impurities. It is transparent to infrared rays. At low temperatures it exhibits chemical inertness and a thin oxide film forms in air. Oxidation of silicon occurs when heated to 400 degrees. Soluble in many molten metals.

Distinctive features of isotropic and anisotropic steels

What properties a compound will have depends on how much silicon was added to it during the manufacturing process. Hot rolled and cold rolled steel have different cell sizes. If a material has large crystals, then its magnetic permeability is greater, but the coercive force is insignificant when compared with materials with small crystals. The grain size depends on the mechanical or heat treatment used.

During annealing, the internal stress in the metal decreases, and at the same time the crystals increase, forming a structure. If you do hot rolling, you will not be able to form the grains stable in a certain position, so they are placed randomly. This is isotropic steel. It has magnetic properties that are independent of direction.

In order to obtain a textured material, they resort to cold rolling of steel a second time, accompanied by annealing under special conditions. This makes it possible to obtain anisotropic steel. The ribs in it are located as they were rolled. Placing the material in the correct position helps to increase magnetic permeability and reduce coercive force, improving the performance of devices.

Electrical steel is produced and sold in coils or individual sheets. Their length is from 720 to 1000 mm.

Electrical Oriented Steel

Oriented steels are used in energy-saving transformers and small generators.

Thanks to its grain structure, which is formed by a complex manufacturing process, grain-oriented electrical steel has excellent magnetic properties.

Methods for measuring the thickness and width of electrical steel are regulated by international standards EN 10107 and IEC 60404-8-7.

Magnetic and mechanical properties

| Brand | Maximum specific losses, W/kg | Typical specific losses, W/kg | Polarization, J at H=800 A/m 1 | ||||||||

| 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | |||||||

| 1.5T | 1.7T | 1.5T | 1.7T | 1.5T | 1.7T | 1.5T | 1.7T | Min, T | Type, T | ||

| M110-23S | 0.73 | 1.10 | 0.96 | 1.45 | 0.70 | 1.07 | 0.92 | 1.41 | 1.78 | 1.83 | |

| M120-23S | 0.77 | 1.20 | 1.01 | 1.58 | 0.73 | 1.15 | 0.96 | 1.51 | 1.78 | 1.83 | |

| M110-27S | 0.75 | 1.10 | 0.98 | 1.44 | 0.72 | 1.06 | 0.94 | 1.38 | 1.85 | 1.91 | |

| M115-27S | 0.79 | 1.15 | 1.03 | 1.50 | 0.76 | 1.11 | 0.99 | 1.45 | 1.85 | 1.90 | |

| M120-27S | 0.80 | 1.20 | 1.06 | 1.57 | 0.78 | 1.14 | 1.03 | 1.50 | 1.78 | 1.83 | |

| M115-30S | 0.79 | 1.15 | 1.03 | 1.50 | 0.75 | 1.10 | 0.98 | 1.44 | 1.85 | 1.89 | |

| M120-30S | 0.84 | 1.20 | 1.11 | 1.57 | 0.80 | 1.16 | 1.05 | 1.51 | 1.84 | 1.89 | |

| M130-30S | 0.85 | 1.30 | 1.11 | 1.71 | 0.84 | 1.21 | 1.11 | 1.59 | 1.78 | 1.83 | |

| M140-35S | 1.00 | 1.40 | 1.31 | 1.84 | 0.94 | 1.33 | 1.24 | 1.75 | 1.78 | 1.83 | |

Explanation of markings

Each grade of steel is designated by certain numbers that carry the following information:

- At the beginning of the marking there is a number indicating the structural structure and type of rolling. The first class includes hot-rolled isotropic, the second – cold-rolled isotropic, and the third – cold-rolled anisotropic.

- The second is the amount of silicon in the material from 0.4 to 4.8%.

- The third is belonging to a standardized group.

- The leading digits are used to indicate the type.

The fourth and fifth digits show the main standardized characteristics in quantitative terms. The marking provides basic information about the material.

ETS production

Electrical steel is smelted in blast furnaces at a temperature of 1500-16500 C using the complete oxidation method, which reduces the content of oxygen and harmful impurities in the material to a minimum. Mild steel is obtained, which is cast into ingots or platinum weighing from 0.5 tons or slabs measuring 140X630 mm and 140X1000 mm.

The most popular grades of non-alloy steel: 10880, 10895, 10850, 10860, 11880, 11895, 20880, 21880, 21895 and others, where the first digit indicates the class according to the type of pressure treatment:

- Digit 1 (hot rolled and forged),

- Number 2 (calibrated) shows that the steel has undergone additional processing by cold drawing with a change in the size of the workpiece using roll compression.

The second number shows the silicon content in the workpiece:

- 0 – unalloyed with a silicon content of up to 0.03% without an established aging coefficient (changes in the properties of the metal over time),

- 1 – the aging coefficient is set, that is, the absence of changes in the properties and microstructure of the material is guaranteed.

The number 8 indicates the main qualitative indicator, for this type it is the coercive force.

The fourth and fifth digits establish a quantitative indicator of the coercive force for a given class of steel in whole units of ampere/meter.

Types, ferromagnetic properties and physical quality indicators are formed during the process of rolling blanks into thin sheets or strips.

At the stage of obtaining rolled sheets from steel blanks, two production technologies are used: hot-rolled and cold-rolled processing.

The hot-rolling method involves preheating the slabs to a temperature of 800-13000 C. Then the heated billets are fed to the rolling mill. A rolling mill is a set of alternating rolls with different gap thicknesses between them. The heated workpiece, passing alternately between them, under pressure with the help of plastic deformation, changes the thickness from 7.5 mm-60 mm to 0.05 mm-2 mm. Preheating increases the ductility of the material, but the increased temperature changes the properties of the steel.

Hot rolled electrical steels contain the maximum possible amount of silicon from 3.5% to 4.5%. It has a coarse-crystalline structure with a random arrangement of grains, which reduces its magnetic characteristics. After rolling, the physical properties are the same in all directions, so hot-rolled steel is only isotropic.

Cold-rolled electric steel is produced at ambient temperature in two stages. At the first stage, sheet metal is rolled to a thickness of more than 0.5 mm. Then the steel is cut into sheets or rolled into a roll and annealed at a temperature of 1150-11800 C, followed by rolling to the required thickness. Cold rolled steel can be isotropic or anisotropic. Anisotropic materials have physical properties that are enhanced along the movement of the rolls, which leads to strict structuring of electromagnetic fluxes along the horizontal axis of the metal grains.

Main brands

There are two main brands.

Sulphurous

Brand 2212. For industrial production, thin sheets subject to cold rolling are used.

Unalloyed

It differs from carbon steel in that it contains less than 5% alloying elements.

Both types are used in the production of transformer steel.

Electrical steel grades

Each sheet is stamped with numbers. It denotes the purpose of the steel.

- The poles of electric machines operating on direct current, engine parts whose power reaches less than 100 kW, and the magnetic cores of devices are made from low-textured cold-rolled steel grade 2211 or non-textured hot-rolled metal grades 1211-1213. The metal has high ductility.

- The rotors and stators of engines with a power of 100-400 kW are made of non-textured hot-rolled electrical steel of grades such as 1312 and 1311. The metal has good ductility.

- Rotors and stators of engines with a power of 400-1000 kW, low-power power transformers, and engines with increased frequency are made from low-textured cold-rolled steel grade 2411 or non-textured hot-rolled steel grades 1412, 1411.

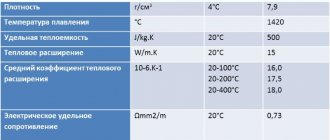

Main properties and characteristics

The steel used for transformers is stainless, magnetic and has sufficient permeability. It is so popular in the production of electrical equipment due to the fact that it has high electromagnetic characteristics and loses a minimal amount of energy as a result of sterility.

Various elements for transformers and other electrical equipment are made from metal. It is also ideal for creating magnetic wires.

Transformer cores cannot do without this special type of steel because the material contributes to a higher resistivity. This allows less power to be lost from eddy currents. This problem usually affects the cores of electrical equipment. Thanks to its use, excessive heating of the core does not occur.

To reduce losses from eddy flows, reduce the thickness of the plate. Therefore, the steel thickness should be 0.5 mm at a frequency of 50 Hz. If the device operates at a higher frequency, then it is necessary to make a core from sheets of 0.1-0.2 mm.

Metal helps reduce magnetization reversal losses. This is another reason for the popularity of electrical steel for transformer core production.

Since losses and the process of cyclic magnetization reversal can be reduced by adding silicon to the metal, alloys with a high content of this element are called transformer steel. Thanks to the application, it was possible to reduce losses by a third. This also makes it possible to reduce the mass of the transformer by 10% and metal consumption by 20%.

Electromagnetic steel is used in almost all electromechanical products due to its unique properties.

Properties of steel

Electrical sheet steel has the following properties:

- Specific resistance. The quality of the material is better if this indicator is high. Due to resistance, electric current experiences obstacles as it passes. For the production of conductors, steel with minimum values of this indicator is used. But for their shielding, as well as for the manufacture of cases, on the contrary, it is important that the electricity is kept inside and its losses along the way are minimal. Therefore, steel as a raw material must meet these requirements.

- Low coercivity. The indicators of this parameter determine how capable the magnetic field inside the material is of demagnetization. Electrical steel for transformers and electric motors must be well demagnetized, that is, have a high ability to do so. Electromagnets, on the contrary, are made from steel, which has a high coercive force. This metal is called anisotropic electrical steel.

- The corresponding width of the hysteresis loop. This indicator affects the ability of the elements involved in the operation of the electrical circuit to return to their initial state again after the device is turned off. When the supply of electricity to the circuit is stopped, voltage, which is called mechanical, remains in its components for some time. In the device parts, the original state will be restored much faster if the hysteresis loop has a smaller width.

- Magnetic permeability. If this indicator is high, this means that the material copes with its functions perfectly.

- A significant indicator, especially in electronics, is the thickness of the sheet, which should not exceed one millimeter.

Manufacturers

This material is produced all over the world. Its main consumers are Japan and China. They consume and produce up to 50% of all electrical steel. The main producer is China, and Japan mainly exports this type of steel.

Much more metal is produced on the territory of the Russian Federation than is necessary for use within the country. The cost of this species on the Russian market is 80-180 rubles per kilogram. In recent years, the Russian Federation has managed to reach production volumes that amounted to 10% of global steel imports. The main producers are:

- Severstal.

- VIZ-Steel.

- Novolipetsk Metallurgical Plant.

These institutions produce products in quantities several times greater than the needs of the domestic market. This makes it possible to sell the material to Western countries such as Italy, Switzerland, and also send steel to India.

If you pay attention to a specific type of steel in the total production volume, then the emphasis is on the dynamic range of metal. Steel for creating electrical equipment makes up only 30% of the total production volume, since it is not needed in unlimited quantities. Its cost is in the range of 120-180 rubles/kg.

Contents Previous § Next

2.7. Properties of electrical steel

Electrical steel has high magnetic permeability and low losses in an alternating magnetic field.

In the USSR, steel with a thickness of 0.5 is produced; 0.35; 0.2; 0.15; 0.1; 0.08; 0.05 and 0.025 mm, which allows it to be used at frequencies up to 20 kHz.

Reducing eddy currents is achieved not only by making steel from thin sheets, but also by adding silicon to the steel, which increases the electrical resistivity:

Unfortunately, the addition of silicon increases the brittleness of the steel, making stamping difficult. Typically, stator and rotor sheets are stamped from steel with a silicon content of 1...2%. in large machines - up to 3%; in sheets of relatively simple shape for magnetic cores of transformers - up to 4...4.5%. With an increase in silicon content, the magnetic permeability of steel at low inductions increases, but the maximum induction decreases (in Fig. 2.30 curve A

- 1.8% Si, curve

B

- 4.8%).

The magnetic properties of steel depend on its structure: the grain size of the crystals, their direction, deformation, etc. For example, plastic deformation of steel leads to an increase in coercive force and, consequently, to an increase in losses.

With increasing grain size, losses due to eddy currents increase slightly, but losses due to hysteresis decrease.

Rice. 2.29. Vector diagram for eddy current loop

The magnetic properties of steel improve dramatically when it is possible to create a crystalline structure of steel such that the easy magnetization axes of most crystals are directed in one direction and coincide with the direction of magnetization. This type of steel is called textured steel and is obtained by cold rolling.

Cold-rolled grain-oriented steel has increased magnetic permeability (Fig. 2.31) and reduced losses, since

Rice. 2.30. Magnetization curves of hot-rolled steels

it sharply reduces (compared to hot-rolled) hysteresis losses.

In the production of cold-rolled textured steel and other steels, the following are sequentially carried out:

hot rolling to a sheet thickness of 2.5...2.8 mm;

cold rolling from 2.5 to 0.7 mm;

intermediate annealing at a temperature of 75О…85О°С;

cold rolling up to 0.35 mm.

is annealed several times

in order to remove residual plastic deformation of the crystals.

The role of cold rolling is that when annealed and slowly cooled, the crystals grow in the direction in which they were deformed. In other words, after heating cold-rolled steel to 11OO...12OO°C, i.e. above the Curie point, seeds remain in it,

promoting the growth of undeformed crystals with ribs oriented in the rolling direction. The resulting electrical steel with a rib texture has a greater anisotropy of magnetic properties: when magnetized across rolling, the magnetic permeability is worse and losses

Rice. 2.31. Magnetic characteristics of hot-rolled and cold-rolled steels

higher than with magnetization along rolling. Therefore, when designing magnetic cores from textured cold-rolled steel, they strive to ensure that the magnetic flux does not close across the rolling: they make oblique joints, steel cores twisted from tape, etc.

In laboratory conditions, it has already been possible to obtain cold-rolled steel with a cubic texture, in which the magnetic properties along and across the rolling are almost equally good. However, at present, industrial production of only strips made of such steel has been established.

Cold-rolled grain-oriented steel is used mainly in the production of transformers.

For the production of electrical machines with a rotating rotor, cold-rolled low-textured steel

isotropic steel. It has the following advantages compared to hot-rolled steel:

less variation in thickness;

more convenient transportation and processing technology;

less waste as cold rolled steel is supplied in coils rather than in

sheets;

as a result of several annealings, the quality of steel improves by 10...20%, losses are reduced and the maximum induction slightly increases.

The designation of steel grades consists of four numbers characterizing the basic properties of steel:

the first digit is the structural state and type of rolling: / - hot-rolled isotropic; 2

— cold-rolled isotropic;

3

- cold-rolled anisotropic with rib structure;

the second number is the silicon content: 0

— absence of silicon;

I -

up to 0.8% silicon;

2—up to 1.8%; 3 -

up to 2.8%;

4

- up to 3.8%;

5 - UP TO 4.8%;

third digit - group according to the main standardized characteristic: 0

— specific losses at magnetic induction 1.7 Tesla and frequency 50 Hz;

/ - specific losses at 1.5 T and 50 Hz; 2

- specific losses at 1.0 T and 400 Hz;

6

- magnetic induction at a field strength of 0.4 A/m; 7 - magnetic induction at 10 A/m;

the fourth digit is the serial number of the steel type; the higher this figure, the lower the specific losses (if the standardized characteristic is specific losses).

The properties of some grades of electrical steel produced in the USSR are given in Table. 2.1.

In table 2.1 shows the guaranteed induction at a field strength // = 2500 A/m and losses in one kilogram of steel with a sinusoidal change in flow with a frequency of 50 Hz for two values of induction amplitude - 1.0 and 1.5 Tesla.

From the table 2.1 it can be seen that with the same silicon content, grain-oriented steel has a 25% higher induction and 3...4 times lower losses than hot-rolled steel.

Table 2.1

| Specific losses | |||||

| W/kg, no more | |||||

| Brand | Thickness | IN, Tl, | |||

| become | steel, mm | Steel type | no less | ||

| R1D'5O | Р1.5/50 | ||||

| 1213 | 0,5 | Hot rolled | 1,50 | 2,8 | 6,5 |

| 1312 | 0,5 | » | 1,48 | 2,2 | 5,3 |

| 1412 | 0,5 | » | 1,46 | 1,8 | 3,9 |

| 1514 | 0,5 | » | 1,44 | 1,15 | 2,7 |

| 1514 | 0,35 | » | 1,44 | 0,9 | 2,2 |

| 2211 | 0,5 | Cold rolled | 1,55 | 2,5 | 5,8 |

| lightly textured | |||||

| naya (isotropic) | |||||

| 2411 | 0,5 | Same | 1,48 | 1,5 | 3,4 |

| 3414 | 0,35 | Cold rolled | 1,85 | 0,5 | 1,1 |

| textured | |||||

| 3415 | 0,35 | Same | 1,85 | 0,44 | 1,0 |

| 3415 | 0,3 | 1,85 | 0,4 | 0,9 | |

To determine losses at other values of induction and frequency, you can use the extrapolation formula

R

=

Po

(o//50 + p/2/502)

(B/B0U,

(2.103)

where p0

— specific losses at a frequency of 50 Hz and induction Bo. given in the reference book; air are coefficients that take into account the relative value of losses due to hysteresis Pr and eddy currents Pvi*. The loss components for some grades of electrical steel, determined experimentally, are given in Table. 2.2.

| Table 2.2 | ||||||

| steel grade | R 1.5/50, W/kg | W/kg | R whirl1 W/kg | Hg % | ^вХх- % | Steel type |

| 1213 | 6,2 | 4,35 | 1,85 | 70 | 30 | Hot rolled |

| 1312 | 4,8 | 3,65 | 1,15 | 76 | 24 | » |

| 1412 | 3,6 | 2,40 | 1,20 | 67 | 33 | » |

| 1514 | 2,7 | 1,40 | 1,30 | 59 | 48 | » |

| 3413 | 1,16 | 0,35 | 0,81 | 30 | 70 | Cold rolled |

| 3414 | 1,08 | 0,28 | 0,80 | 28 | 74 | Textured |

From the table 2.2 it can be seen that in hot-rolled steels at a frequency of 50 Hz, losses due to hysteresis predominate, they account for 60...76% of all losses. In cold-rolled steels, on the contrary, losses due to eddy currents predominate, they account for 70...74% of all losses. In accordance with this, in formula (2.104) for non-textured (hot-rolled) and cold-rolled isotropic steels, a" 0.7 and p" 0.3 should be taken. For cold-rolled grain-oriented steel during magnetization along the rolling, a" 0.3 and p" 0.7.

To reduce losses due to eddy currents in cold-rolled steel, production of steel of smaller thickness - 0.3 and 0.28 mm - for the production of transformers began

During mechanical processing, plastic deformation of the metal occurs and losses in steel can increase significantly, especially in cold-rolled steel. Therefore, after mechanical processing, it is recommended to anneal the steel at a temperature of 750-950°C

In cold-rolled textured steel, repeated annealing does not completely restore the magnetic properties of the steel, since at the cut (where hardening of the metal occurred) the texture is disrupted and after repeated annealing, new grains with random orientation grow. In this regard, sometimes unannealed electrical steel is supplied to electrical machine-building plants. After machining, this steel must be high-temperature annealed (at 1150°C) to create a magnetic texture

Particularly large deformations occur when winding a magnetic conductor from a steel strip. Therefore, cold-rolled strip with a thickness of 0.08–0.15 mm is supplied in an unannealed state (hard-rolled)

After high-temperature annealing, the losses in the strip are 5-15% lower, and the induction is the same amount higher than that of the strip supplied in the annealed state, which has undergone low-temperature annealing (750-850°C) after stamping. Annealing must be carried out in an inert gas atmosphere to prevent the appearance of scale, which significantly reduces (by 10-20%) the magnetic permeability of steel. With low-temperature annealing in

continuous furnaces,

which lasts less than 3 minutes, there is no fear of oxidation

High alloy steel usually comes from factories descaled (pickled)

When assembling the magnetic circuit, the steel sheets are subjected to lateral compression, as a result of which losses in the steel increase, mainly due to an increase in eddy current losses

In grain-oriented steel, losses increase by 10–25%; in non-textured - by 3-6% In addition, additional losses may occur in the assembled magnetic core due to disruption of the insulation between the sheets and the short circuit of adjacent sheets with burrs. These losses are usually taken into account statistically, using correction factors. With good manufacturing technology of electrical machines losses in steel of the assembled machine do not exceed the calculated values by more than 1.5 2.0 times

The higher the frequency, the thinner the steel must be used to reduce losses from eddy currents. However, with a decrease in the thickness of the tape, the coercive force and hysteresis losses increase. The coercive force increases especially strongly with a tape thickness of less than 0.05 mm, as a result of which the minimum thickness of the eddy current steel 0.025 mm, and the maximum frequency is 20 kHz

For example, specific losses in cold-rolled textured

| 0,35 | 0,2 3,5 3,5 7,0 | 0,1 4,0 2,0 6,0 |

| Warmth on hystepesis W/kg…… | 32 | |

| Eddy current losses, W/kg…..Total losses. W/kg………. | . 8 . 11,2 |

steel 3416 at a frequency of 400 Hz and induction W = 0.75 T, with a sheet thickness from 0.15 to 0.08 mm, they are minimal and almost identical, and with a further decrease in thickness they increase sharply.

The dependence of specific losses on the thickness of the sheet and other grades of steel, including hot-rolled steel, has a similar nature.

Below are data on specific losses in hot-rolled steel 1515 at / = 400 Hz and 5t = 0.75 T.

When the sheet thickness changed from 0.35 to 0.1, hysteresis losses increased by 0.8 W/kg, i.e. by 25%; at the same time, eddy current losses decreased by 6 W/kg, as a result of which the total losses decreased by almost 2 times.

In Fig. Figure 2.33 shows the dependence of specific losses in steel on frequency for grades 3416 (Fig. 2.33, a) and 1515 (Fig. 2.33,6) at induction W = 0.2 T. From these curves it is clear that at frequencies greater than 5 kHz, the specific losses of steel are very high even with relatively low induction (5t = 0.2 T), as a result of which the use of electrical steels becomes ineffective and ferrites

or amorphous steel.

Ferrites are made from a mixture of oxides of iron, nickel, manganese and other metals. The oxides are crushed and mixed in a certain proportion, and then cores are pressed from the mixture (at a pressure of (1... 3) • 105 kN/m2) and annealed at a temperature of 1200... 1400°C. The electrical resistance of ferrites is very high, and therefore eddy currents are small and ferrites can be used up to a frequency of 100 kHz.

When calculating a magnetic circuit on alternating current, you can use magnetization curves taken at direct current, if the effect of eddy currents is not too strong, such as at a frequency of 50 Hz, a sheet thickness of 0.5 mm or less. From these curves it is possible to determine the amplitude of the magnetic induction at the amplitude value of the field strength or MMF.

When the magnetic induction changes sinusoidally over time, which usually occurs, the magnetizing current curve is nonsinusoidal; its shape is affected by the nonlinearity of the magnetization curve and the hysteresis loop.

Rice. 2.32. Dependence of losses in steel 3416 on sheet thickness at Vsh = 0.75 T, / = 400 Hz

When steel is remagnetized very slowly, a static hysteresis cycle

(solid line in Fig. 2.34), the area of which is proportional to the hysteresis losses.

When a steel sample is remagnetized in an alternating field, a dynamic hysteresis cycle

(dashed line in Fig. 2.34), the area of which is proportional to the total losses. At the same time, the current amplitude also increases.

Rice. 2.33. Dependence of losses in steel on the frequency of magnetization reversal at Vsh = 0.2 T for grain-oriented steel 3415 and hot-rolled steel 1516

The plotting of the magnetizing current curve using a dynamic loop is shown in Fig. 2.35.

The shape of the magnetizing current curve has large peaks corresponding to the maximum induction, as a result of which the ratio of the current amplitude to the effective value is much greater than with a sinusoidal change in current.

When calculating the winding - determining the cross-sectional area of the conductors, heating the winding, etc. - the effective value of the current is usually important. Therefore, the magnetization curve for alternating current is often depicted in the form 5m = / (Poison), where Ha

- field strength corresponding to the effective value of the winding current.

In Fig. 2.36, the magnetization curve of electrical steel is depicted in two forms: the solid line - B - f (H),

as usual, is taken for direct current and the dotted line -

W -

=/(#d). which is more convenient for calculations with alternating current.

At first glance in Fig. 2.36 - magnetization curve on different scales. However, the ratio of the maximum magnetizing current to the effective current does not remain constant and, therefore, the “scale” changes. For example,

for electrical steel

3413

at inductions of 0.2...0.5 T Yat/Vad "1.42, and at W" 1.8 T this ratio reaches a value of 2.43. Therefore, determining the effective value of the magnetizing current

according to magnetization curves for direct current, it is in principle possible (with a weakly expressed reactive effect of eddy currents), but very difficult. Therefore, it is advisable to have a magic

Rice. 2.34. Hysteresis loops

Rice. 2.35. Circuit for determining the instantaneous value of magnetizing current

thread characteristics of steel taken on alternating current, i.e. in the form W=/(Poison).

At high frequencies, not only losses in steel increase, but also the reactive (demagnetizing) effect of eddy currents.

In Fig. Figure 2.37 shows the magnetization curves of 1515 steel under alternating current at various frequencies. The figure shows that at a frequency of 400 Hz (middle curve), the magnetic field strength H

more than at a frequency of 50 Hz (upper curve), 1.5 ... 2 times. Even more I at a frequency of 1000 Hz (lower curve).

In Fig. Figure 2.38 shows the magnetization curves of hot-rolled steel 1515 at a frequency / = 10 kHz (Fig. 2.38, a) and for cold-rolled textured steel 3416 with a thickness of 0.08 mm

Rice. 2.36. Magnetization curves of steel 3413 at alternating current W = ((Ha)

and

Bm=f(m)

(Fig. 2.38, b)

at different frequencies, especially clearly illustrating the reactive effect of eddy currents.

When calculating the magnetic system of a transformer, a method based on measuring reactive power is often used,

necessary for magnetizing steel.

For the simplest case of a closed magnetic wire with a constant cross-sectional area, the effective value of the magnetizing current is

It = HJnlw,

(2.104)

where /m is the length of the magnetic line; w

- number of turns of the winding.

From the formula E=

Rice. 2.37. Magnetization curves of steel 1515 =4.44/pft determined by a thickness of 0.35 mm at various frequencies NUMBER OF TURNS

where Qf€

— cross-sectional area of the magnetic circuit.

The found value is substituted into (2.104) and the result is

Rice. 2.38. Magnetization curves W = [(Nl)

steel 1515 at /=10 kHz and for steel 3416 at d = 0.08 and different frequencies

Since in the E&U

and

UQFe=VFe

is the volume of steel equal to

V=G/y,

where G is the mass of the magnetic circuit;

y

is the density of the steel

whether, then from (2.106) it follows

where specific magnetizing power q=y(Bm, f)

is determined experimentally for each grade of steel intended for the manufacture of magnetic wires of transformers.

In Fig. Figure 2.39 shows the dependences q = (f(Bm)

at / = = 50 Hz for the most commonly used electrical steels with a thickness of 0.35 mm.

To operate at high frequencies (3.00...20 kHz), very thin tapes with a thickness of 0.03 are used; 0.02 and 0.01 mm. In thin tapes, hysteresis losses can increase sharply. To eliminate this effect, a material with a special structure and texture is created.

The finest anisotropic tape, supplied in an annealed and cold-worked state, has a crystallographic texture of a high degree of perfection with an axis

Fig. 2 39 Dependence of magnetizing power on induction amplitude for steel of various grades

easy magnetization along the rolling direction.

Additional alloying of electrical steel with a high silicon content (2.8 ... 4.0%) with aluminum (0.2 ... 0.4%) or molybdenum (0.2 ... 0.5%) made it possible to obtain thin isotropic tapes, in which almost identical magnetic properties in the longitudinal and transverse rolling directions Tapes made of steel grade 2421

can be used at frequencies up to 20 kHz

Recently, steels with a cubic texture have been developed, with low specific losses in any direction of the strip plane (P

1.5/400^ 17 W/kg) and high saturation induction (SS>1.8 T). Such properties are achieved by alloying steel containing 2.8...3.2% silicon with nickel and phosphorus and using special production technology. A new type of soft magnetic materials includes amorphous steel and amorphous magnetic materials that have high magnetic and mechanical properties, which is due to the peculiarities of their structure. They are disordered magnets in which

there is no periodicity in the arrangement of atoms, i.e., a crystal-like state exists only at distances comparable to interatomic ones. Amorphous magnetic materials can only exist at temperatures not exceeding the limit 7=125...150°C. At higher temperatures, the transition of amorphous alloys to the crystalline state begins; it completely ends at a temperature of 5OO...4OO°C. To obtain an amorphous state, the liquid melt is squeezed through a quartz nozzle onto a steel drum, cooled by water, the linear speed of which is approximately 20 m/s. The cooling rate must exceed 10″ deg/s. The cooling operation is carried out under argon atmosphere to prevent oxidation. The thickness of the tape is 30...50 microns.

The magnetic and physicochemical properties of amorphous magnetic materials and their stability depend on the chemical composition. The most promising are iron-nickel (40% Fe, 40% Ni, 14% P, 6% B), high-cobalt (70% Co, 5% Fe, 15% Si, 10% B) and high-iron (80% Fe, 16% P, 3% C, 1% B) amorphous alloys.

The cobalt alloy 85KSR-A is characterized by a rectangular hysteresis loop; it is used in memory devices.

Iron-nickel alloy 45NPR-A can be used for cores of devices operating in the frequency range up to 50 kHz.

High-iron alloy 94ZhSR-A has a saturation induction of 5*= 1.6 T and specific losses Р1.3/50=0.46...0.26 W/kg, i.e. 2...3 times less than the best cold-rolled steels .

Amorphous magnetic materials are anisotropic. Their mechanical properties are superior to crystalline steels; they are characterized by a combination of high hardness, strength and ductility.

Contents Previous § Next

Application

Transformer steel is used to make important transformer components. Its popularity is associated with increased properties due to the addition of silicon to the composition.

Rod magnetic circuit

This element is a rod on which windings and yokes are placed to complete the magnetic circuit. They are always made laminated. This element has a simpler design than the armor rod and allows you to obtain the necessary insulation for the windings.

Rod magnetic cores are necessary for powerful transformers, since they have half a winding on each rod. Devices that have a rod magnetic core have a low magnetic leakage flux, less wire consumption and a large winding cooling surface.

Armored

Armored magnetic cores are most suitable for low power ratings. This applies to devices producing from one to several tens of volt-amperes. They operate when the voltage level does not exceed 1000 V and the power supply frequency is 50 or 400 Hz. Transformers with an armored magnet rod differ from rod transformers in their lower power density per unit volume and weight. But their main advantage is cost.

Armored magnetic circuits are distinguished by rectangular rods located in a horizontal position; rectangular windings are located on them.

The armored magnetic circuit has a number of design advantages. When using it, you will only need one set of windings, which contains a yoke to protect against negative environmental factors.

Application of sheet steel

The industry produces sheets reaching a width of 240-1000 mm, a length of 720-2000 mm, and a thickness of 0.1 to 1.0 mm. In addition, narrow tapes 0.15 - 1.0 mm thick are produced. The properties of sheet steel allow it to be used in electronics. Cores, magnetic circuits, chokes, rotors and stators for dynamos, relays, electric motors, stabilizers, current transformers and much more are made from it. In most cases, grain-oriented steel is used, since its magnetic characteristics are more important.

Conclusion

Transformer steel is produced with the addition of silicon. This element provides improved electromagnetic characteristics; it is used to create transformer cores, core and armor magnetic cores. Product markings contain information about the type of steel and the main standardized characteristics. The cost of the material on the Russian market is 120-180 rubles. per kg.

Various companies are involved in the production of this material, but the largest amount is produced in Kitara, if we consider indicators around the world. Russia managed to enter the market and produce up to 10% of the world's steel.

Magnetic steel

Magnetic steels are used for the manufacture of electrical measuring instruments, electromagnets, permanent magnets, transformer cores, etc. There are two main types of magnetic steel: soft magnetic and hard magnetic.

Hard magnetic steel

Hard magnetic steels are alloyed with chromium (Cr) or cobalt (Co) and are used to make permanent magnets. Designated with the letter "E". Grades of hard magnetic steels: EX, EX3, E7136, EX9K15M.

Soft magnetic steel

Soft magnetic steel is one of the types of magnetic steel, characterized by very high magnetic permeability and used for the manufacture of cores of transformers, electrical measuring instruments, and electromagnets. It is designated by the letter "E" and contains a high percentage of silicon (Si). Brands: E1, E2, E3, E4, E1AA.