How to use a jack: general operating rules

Like any other technical device, the jack requires compliance with safety precautions during operation. Its use is not difficult, the main thing is to know where to put the jack and what to do with it next. This is far from a new device; most samples have been tested by time and personal experience.

Classic rack and pinion jack

Driver's courses do not teach how to properly use and install this device. You need to study everything yourself. In addition, most people, not knowing clear rules, believe that with its help you can not only lift and lower a load, but also hold it for a long time. To avoid possible health risks, you need to learn how to install a jack correctly.

A specially developed list of rules can help with this:

- The vehicle must only be placed on a level surface. There should not be any slopes or other irregularities. The machine must be parked in such a way that there is no likelihood that it will move.

- All wheels must be locked very securely. Bricks, wooden wedges, stones or any other objects are suitable for this.

- The car should rise and fall very smoothly, without sudden movements or jerks.

- It is important to clearly know where to place the jack correctly. To lift the car on the bottom there are special mounts for the jack hook. Under no circumstances should you attach it to the front or rear bumper, or to any other parts of the car that are not intended for this purpose.

- It is necessary to engage reverse or forward gear, put the car on the handbrake and block the wheels on the opposite side from the side being lifted.

- It is necessary to use a support because the jack can only lift loads, but not hold them. A do-it-yourself jack stand is suitable, but it is important that it is made of wood, iron or any other material other than brick or other unreliable material.

- Before lowering yourself under the car, it is important to check the security of the machine and the device several times. To do this, you can simply rock the car in different directions.

- After completing the work, you need to know how to lower the jack along with the car. The same rules apply here - no sudden movements, smoothness.

Jacks exist in three types: mechanical, hydraulic and pneumatic (inflatable). Each of these types has its own specific operating rules.

Zheka147 › Blog › HOW TO JACK A CAR CORRECTLY

Where to put the jack A jack is used only for changing wheels. Before placing the vehicle on a jack, be sure to unload the vehicle. You should never lift a loaded car. Place the vehicle on a horizontal surface and block the wheels well. Never lift the car without first blocking the wheels. If you jack up the front wheels, then the rear ones must be blocked, and, conversely, in the process of raising the rear wheels, the front ones must be blocked.

Before using the jack, engage reverse or first gear and apply the handbrake (if you are jacking the front wheels). The jack should be installed only in specially designated places so that at the stop its recess fits into the edge of the sill closer to the wheel being replaced. On the thresholds, special stamps mark the places for the correct installation of the jack.

If there are side trims on the car, simply remove them. To do this, press on the edge and pull out the pads. Place the bumper pads as close to the wheel as possible, approximately 30 centimeters from the end of the bumper.

How to Use a Rack and Screw Jack

When using rack and screw jacks, the above rules and recommendations, plus some specific ones, apply.

Screw device

Rack and pinion devices, like screw devices, have become widespread due to their simplicity of design. They are mainly popular among off-road enthusiasts. The design of such devices allows you to lift a lot of weight, which plays a decisive role. They can be used in any conditions due to their unpretentiousness and small dimensions, which is an advantage compared to hydraulic lifts, which are massive and take up a lot of space in the trunk.

Safety precautions when working with rack and pinion devices:

- Install the lift at an angle so that it does not rest against the hood.

- Place the jack perpendicular to the surface of the support.

- Check fixation and tightness.

- Press the switch firmly with your whole hand, since it moves tightly.

How to use a hydraulic jack

Hydraulic devices have become widespread in auto repair shops. They can be rolled or bottled, have a lot of weight, but are easy to move. They can lift a car to a height of 40 centimeters. For the correct use of such devices, the following set of recommendations must also be observed:

- Before lifting it is necessary to check the fixation. The surface should be as level as possible and the wheels should be locked.

- When working with the front wheels, it is necessary to block the rear ones and vice versa. If you need to move the device to another location, you need to make sure that the strength is sufficient to hold the machine.

- Do not lift more weight than specified in the instructions.

- The hydraulic jack operates smoothly, but do not raise or lower the vehicle too quickly.

Hydraulic lift

How to use an inflatable jack

This type of lift is a pneumatic device. In this case, a special pillow is installed under the bottom of the machine, which is subsequently inflated with a special device. To work with such a device you need:

- Place the cushion under the car and spread it evenly.

- Place special mats on top and bottom that are included in the kit. They are designed to avoid pillow punctures.

- Close the lock connecting the valve and hose tightly. This is necessary to avoid air leakage from the pillow.

- Connect the end of the hose to a source of air or gas supply. Special compressors are used.

- The pillow is inflated with air or vehicle exhaust gases.

It is important to monitor the process of inflating the pillow. It should pass evenly in all directions. If any side lags, then it is necessary to check and correct the position of the pillow or lower it and start the process again.

Maintenance Recommendations

Any maintenance should be carried out in a specialized service center, especially for complex hydraulic mechanisms that require periodic oil changes, and for this the jack will have to be disassembled, so it is better to entrust this work to professionals.

Using a jack is simple, but you should know safety precautions and be careful, because human health depends on its proper operation. A rack and pinion jack such as a hi-jack is especially dangerous.

Rolling jacks are characterized by ease of use, high load capacity, smooth lifting and running. Today, there are a huge number of manufacturers and brands under which hydraulic rolling jacks are produced. They are suitable for use in both professional service stations and private garages. In addition, many car owners manage to make these devices themselves in order to enjoy all its advantages at a lower price. Next, we will analyze all aspects related to rolling jacks for a passenger car, and also provide information that we hope will help you make your choice when buying a jack.

Rolling jack device

The operating principle of a rolling hydraulic jack is based on a hydraulic drive . That is, the use of a working fluid (oil) that transmits force from the regulating body to the executive body. In this case, the regulating body is a handle with a system of gearboxes, valves and cylinders, in which the operator’s force is accumulated and transmitted to the executive body - the rod.

The system is based on the use of communicating chambers and shut-off valves. Based on the principle of hydraulic accumulators, they repeatedly enhance the initial movement, thanks to which the jack can lift loads of 2-3 tons or more (depending on the specific model). However, during operation it is necessary to monitor the serviceability of the shut-off valve and rubber sealing rings (gaskets). The normal operation of the jack, as well as the absence of oil leakage, depend on their integrity. But we will talk about this in the section on repairing hydraulic rolling jacks.

The design also provides for the presence of additional devices that facilitate its operation and reliability. One of these is the locking dog, thanks to which the weight is held at the required height.

Principle of operation

The operating principle of hydraulic jacks is based on two physical laws. The first law is the flow of liquid in communicating vessels . The second law is an increase in power due to a change in the area of the applied force . This method is used in presses. This device is called a multiplier.

With the help of a multiplier, the fluid pressure created by the pump increases several times. This is enough to lift a load that weighs no more than a ton. The applied load is several kilograms .

Pumping of the working fluid is carried out by a hand pump . The plunger is moved by a lever. The check valve, made of a screw, prevents the reverse movement of liquid. When turned counterclockwise, it stops working.

Advantages and disadvantages of this type of jacks

Like any technical device, a rolling jack has both its advantages and disadvantages. Let's start with the first ones. So, their advantages include:

- High coefficient of efficiency (efficiency). With its help, you can lift a car of considerable weight with minimal physical effort.

- High load capacity. This was made possible by the use of a horizontal cylinder and a removable handle.

- Slow lifting ensures neat operation and safety. And the shut-off valve ensures that the load is secured at any selected height.

- The presence of a support platform provides good stability and safety.

- Convenience and ease of use of the jack.

- Be careful and clean when working with the jack. The operator does not need to lie down on the ground or garage floor in order to place the jack under the car.

However, rolling jacks also have several disadvantages. These include:

- The slow lifting speed can be considered a drawback, especially when working with vehicles with high ground clearance.

- In some cases, when using the jack for a long time under load, the pressure may be released, and accordingly, the car will lower.

- When operating a hydraulic trolley jack in severely frosty conditions, the liquid inside it may freeze.

- The need to perform periodic repairs and preventative maintenance. Without them, there is a risk of its failure and a reduction in service life.

- Maintenance and repairs are more expensive than other jack designs.

- Low lifting height. Suitable only for passenger cars and low SUVs and minibuses.

- To work with a rolling jack, you need a flat and hard surface (for example, asphalt, concrete).

However, the balance of advantages and disadvantages of rolling jacks is still shifted towards the former. They are very convenient and reliable, so they have found wide popularity among car owners not only in our country, but also abroad. Next, let's move on to the question of what criteria should be used to choose a jack.

Lada Granta Red Lux Mechanics › Logbook › Stay alive. Raising the car with a jack

Everyone knows what a jack is and why it is needed. But, it’s amazing! Some people here sometimes use jacks, if not illiterately, then rather frivolously.

And this can lead to the car falling off the jack. Moreover, this may cause the car to fall directly on you, dear reader.

And nowadays, thanks to the widespread use of phones with FullHD cameras, you can’t really count on help.

How not to drop a raised car is the first question of this post.

Second question: What qualities should a car jack, which is so necessary on the farm, have? I'll start with this.

It is believed that it should be stable, durable, reliable, comfortable, light, small and cheap. Everything is clear, I think.

Durable and reliable means heavy and expensive. Light and cheap means it will collapse at any moment. And so on.

I'll say something blasphemous - the jack can be anything. If only it didn’t fall apart without declaring war. You just need to be able to use them correctly, and also know the weaknesses of different types of jacks.

The only caveat is that the passion for ultra-reliable rolling jacks, capable of lifting ten to fifteen Grants at a time and weighing over a hundred kilograms, is irrational. This type of jack is simply inconvenient! Due to the huge gear ratio, it will take half a day to pump the lever. And moving it across the floor does not apply to any other sport except weightlifting.

Which of the constantly carried jacks is the most versatile and convenient?

Personally, it has long been clear to me that there is nothing better than a diamond jack. When executed correctly, it is closest to the ideal.

In general, to put it simply, it is from the diamond jack that the car will fall last. From anyone, even not ideal.

The second place is deservedly occupied by the semi-diamond jack, a sample of which is available for study to every owner of the Grant. This type of jack has at least two weaknesses. The first is a small margin of lateral stability. Due to the rocking bottom heel, you need to use it wisely. When lifting a machine, it always moves by some amount from the lifter. The upper support of the jack moves along with the car. If initially the vertical axis of the jack was strictly perpendicular to the surface, then after lifting it will turn out to be inclined, so to speak, inside the car.

What to look for when choosing

The choice of a particular automobile rolling jack is based on several aspects, including:

Maximum height value

- Maximum lift height . This is especially true for SUVs and crossovers. This value in this case should be from 450 mm and above.

- Minimum height . It provides the opportunity to “crawl” under the bottom of the car. This parameter must be selected based on the technical data of your car, in particular, the ground clearance height.

- Lifting speed . Some models of rolling jacks have an additional pedal that allows you to increase the lifting speed.

- Load capacity . This parameter is often the key. For most passenger cars, a jack with a lifting capacity of up to 2 tons is suitable, but owners of SUVs and crossovers are better off buying a jack capable of lifting a load of 3 tons. In any case, when choosing a particular model, ask the technical documentation how much your car weighs, and buy a jack that can lift more weight (that is, with some margin so that the mechanism does not work in critical conditions).

Minimum working height

The following additions will be useful:

Protective caps on plungers

- rotating handle for safely lowering the car;

- safety valve, whose task is to protect the mechanism from overload;

- composite coating on the drive handle, which ensures comfortable operation;

- built-in tray for storing small parts;

- polyurethane coating on metal jack rollers;

- caps on the plunger (or plungers, depending on the model), which protect the mechanism from dust, dirt, and corrosion;

- additional oilers on heavily loaded areas;

- a latch that ensures safety when performing work.

Gear and cardan transmissions in jacks

Also, when choosing, you need to pay attention to the length of the handle. If you have an SUV, then it is better to buy a rolling jack with a long handle. And for a passenger car, a short handle is more practical. A convenient option are models with a compound handle.

As for the material, it is better to choose a jack made of steel .

Aluminum models cannot withstand significant loads and there is always a risk of mechanical failure, which can end very sadly. As for manufacturers, you can buy both domestic and foreign models here.

Main design parameters

Every person who decides to purchase a rolling hydraulic jack should definitely think about what design parameters are important to him. This refers to its structure and technical characteristics.

The main characteristic of the device is its load capacity. It most often starts from 2 tons, but you can find models that can work from 750 kg. They are specially designed for small-sized equipment, namely motorcycles and ATVs. Models with a carrying capacity of 3, 5 and 10 tons are considered standards for ordinary cars.

For owners of an ordinary passenger car, a carrying capacity of 2 tons will be sufficient. It can be easily placed in the garage, and, if necessary, even taken on the road.

Diagram of a park hydraulic jack.

Fans of SUVs should consider models that have a more substantial carrying capacity. It should start from 3 tons, of course, if this value does not exceed the mass of the device itself.

Not only load capacity is an important characteristic of such devices. Each model has its own lifting range. It usually varies from a minimum value of approximately 100 mm to a maximum value of approximately 500 mm. You definitely need to consider what ground clearance your car has. It is worth taking into account the distance not only from the body to the ground, but also from the heel of the device to the body.

Review of popular models of hydraulic rolling jacks

We list several popular rolling jacks in our country. Both imported and domestic.

| Name | Minimum height, mm | Maximum height, mm | Load capacity, tons | Note |

| Nordberg N3203 | 133 | 465 | 3 | Distributed to domestic service stations |

| “Bison Master” | 135 | 385 | 2,1 | Missing rubber heel |

| “Matrix 510335” | 130 | 410 | 3 | Overload protection available |

| Ombra OHT203 | 192 | 533 | 3 | An original repair kit is included with purchase. |

| Airline AJ-3F-390P | 135 | 390 | 3 | Weight - 13 kg |

| "Stealth" | 100 | 350 | 2 | Weight - 12 kg |

| “Sorokin 3.520” | 125 | 300 | 2 | Weight - 6.5 kg |

| Biloxxi GTJ2004 | 130 | 336 | 2 | Good value for money |

| Forsage TH22501CB | 140 | 387 | 2,5 | There are three fixed levels at a height of 222, 285, 340 mm |

| “Ermak” | 135 | 385 | 2 | A very popular jack among car enthusiasts |

The choice must be made based on its technical characteristics . You should not buy a jack that is too cheap, but you should not overpay either. It is better to buy a mechanism from the middle price category. However, if you need it for professional work (for example, at a service station), then it is better to buy a professional rolling jack, the price of which will be slightly higher than that of conventional garage analogues.

Repair of rolling jack

Before moving directly to repair issues, it is necessary to determine possible malfunctions and the reasons that could lead to them. So, the malfunctions include:

- complete failure of the device, which consists in the fact that it is impossible to raise or lower the working rod;

- incorrect operation (most often jamming) when lifting;

- spontaneous lowering of the jack under load;

- complete or partial leakage of working fluid (oil).

Repair kit for rolling jack

You can repair a rolling jack yourself. However, to do this, you need to buy a repair kit or separate spare parts, depending on what is broken. Most often, various gaskets fail, causing oil to leak out. For repairs, a suitable repair kit is required.

In any case, it is necessary to disassemble the device and drain the oil from it. This must be done carefully, and the oil must be poured into a pre-prepared container. It is unlikely to be suitable for reuse. It's better to replace it with a new one. You will find the brand of oil in the operating instructions for the jack. However, in most cases, standard motor oil (such as 5W-40) or hydraulic oil is suitable. It does not corrode rubber, does not harm the piston surface, has a medium consistency and is harmless to humans.

How to make a rolling jack with your own hands

Some craftsmen and car enthusiasts make a rolling jack with their own hands. Oddly enough, this does not require complex equipment. As a rule, the basis of a rolling jack is a regular bottle jack, which works according to a similar scheme - on a hydraulic drive. A diagram of one of these homemade devices is presented below.

A homemade jack is suitable for use in garage conditions and for lifting a passenger car (the exact lifting capacity depends on the bottle jack used and its location in the welded structure).

Safety precautions

Any jack is not only an auxiliary tool when repairing a car, but also a potential source of threats both for the car and the people around it.

Car latches at height

If you need to crawl under the bottom of the car, be sure to place wheel chocks, bricks or other objects under the wheels in order to reliably immobilize the wheels. If you are not sure of the serviceability of the jack or even a small amount of oil leaks from it during the lifting process, then you should not leave the car suspended on such a device for a long time. Be sure to replace the jack with a secure support and remove the jack.

Results

A rolling hydraulic jack is a very convenient tool used both at service stations and by private car owners. The choice of a particular model should be based on its technical characteristics, the authority of the manufacturer and reviews of real owners of these devices.

First of all, pay attention to the load capacity . This is especially true for service stations, as well as owners of large cars - SUVs, crossovers and minibuses. Also look at the minimum and maximum heights that the jack can operate from. To do this, find out in the technical documentation the ground clearance of your car.

As for the price, it is better not to buy very cheap jacks, but you should not overpay. It is better to stay with a device from the mid-price segment. For most ordinary car owners it will be enough. If you need a jack for a service station, then you should take a closer look at more expensive professional devices.

The rolling jack is suitable for servicing almost any vehicle. Its versatile design allows it to lift both low and standard vehicles, as well as SUVs, vans and trucks.

Ground clearance can be as little as 10 cm! And due to the pneumatic or hydraulic drive, it is easy to lift cars weighing 5-10 tons .

That is why it is most often used in car repair shops, service stations, tire shops, and in the repair area of automobile and bus fleets.

It would seem that there could be no difficulty in lifting a vehicle with a rolling jack... Could this really cause any problems? Unfortunately yes. And in most cases this happens due to neglect of the basic rules of working with lifting equipment.

For example, you can often see the following picture in roadside tire shops: a car is standing on the street in front of the garage door, they jack it up and immediately begin to remove the wheels. The entire time the mechanic is servicing the wheels in the garage, the vehicle is supported on a jack.

How many cases have there been when a car fell off such a support? Damage to the body and deformation of the bottom are unpleasant consequences of such negligence. It is also possible that the jack itself may break. But more tragic consequences can occur if there is a person nearby when the car falls. Why take such a risk? And all because they neglected the rules described in the instructions.

But those who have not yet purchased a jack do not have the opportunity to read the instructions. And sometimes it is difficult for a beginner to understand what is described in it, because there are no examples, or often the instructions are even written in a foreign language.

mathvich › Blog › I can jack up like crazy. Instructions for beginners on jacking up a car.

In this post, I want to share my experience mixed with factory recommendations on how to and should NOT jack up your favorite cars.

First: in any tire shop, in any service, always check BEFORE lifting the car where the workers put the jacks/lift legs. The threshold can only be crumpled or not crumpled, and between these states there is exactly one act of lifting the car. If the lifter's foot slips off the seam, the threshold will immediately be pressed through (I've seen this more than once). A straightened threshold and an initially intact one are not the same thing.

What you definitely can’t

:

1)

Jack up the center of the sill to change both wheels on one side at a time.

The tire fitter is too lazy to push the jack twice, and your threshold may come to an end (maybe not the first time, but you definitely can’t

). At risk: schoolchildren who have watched enough on YouTube where cool guys change tires at races in one lift. There are several explanations: either they have a missl with overcooked reinforced thresholds, or the car is so lightweight that it doesn’t push through, or they don’t care. If you try to lift your poor GX81, 90 or 100 like this, then the sill edge deflection will not take long to occur. Don't ever do that.

2)

Use a rolling jack without a sufficiently thick rubber cushion. Most jacks are sold without a cushion. Hamsters think that it is not needed. But if they sold you skis without boots, would you squeeze your fingers into the bindings just like that? The pillow is a consumable and is sold separately (it costs 150 rubles). The jack manufacturer doesn’t care about your thresholds, they have a different goal - the jack should jack you up and cost as little as possible. So buying a pillow is your task. The same thing happens at tire shops and services - if there is no cushion on the lift or jack, or it is very worn out and the threshold rises iron on iron - abandon the repair idea in this place. Or offer to change the pillows before the lifting procedure. Again, nothing noticeable will happen at one time, but do you need to get it fixed in such a service? And begin the destruction of your threshold, which is either intact or not.

3)

Use a standard diamond-shaped jack. This little thing is placed in the car as a last resort. If you have a flat tire on the highway and just can’t get to the tire shop, then you can lift the car and put it on. But I would prefer (let’s say in the city) to do nothing and get there on a broken tire. Maybe 5, maybe 10 km (although in fact I drive a rolling jack with a cushion and could change a tire, but only if the road is not busy and it is daylight). I don’t care about punctured tires; they may not be repairable anyway. But the threshold will not be damaged. And I won’t have to change a tire on the side of the road; even a small chance of being hit by some idiot doesn’t suit me. I don’t care about this tire, I’d rather live and buy a new one than drive on a sealed one with holes and squirm under the car on the side of the road.

How to jack correctly:

An obvious point, but nevertheless useful for absolute beginners: the threshold of a car is a box-shaped section of the body, located at the bottom of the doorways between the wheels. At the bottom there is usually a seam, a piping:

The jack is inserted exactly into the edging and only along the edges of the threshold in places marked with small cutouts. Attention: the rear part (trunk) is not a threshold! You cannot place a jack behind the rear wheel (I wouldn’t write this if I hadn’t seen the trunk niches dented by the jack). Although the threshold looks generally uniform, on many cars it is reinforced only in designated areas. If you place a jack in the middle, the threshold will not hold up and will collapse. This is unsightly, besides, it reduces the safety of the car in an accident and causes corrosion.

Also, before jacking the car, it is important:

1) Make sure that the car is not standing on an inclined plane and does not roll on its own in neutral and without the handbrake. 2) Turn on the handbrake. 3) Loosen the wheel nuts in advance before lifting. A small shift of half a turn is enough. This is done to prevent the car from falling off the jack due to a jerk. 4) Place wheel chocks (or at least any lugs) under the wheels.

The main principle of raising a car:

An old joke from traffic rules exams: - What to do if you are standing in the center lane, and you needed to turn right from the right lane?

- Nothing. Go straight! If you are not already in the turning lane, then you CANNOT turn. Same with a jack. If you do not have a suitable jack, then you simply should not lift your car under any circumstances (except for emergencies that affect people's health).

Source: www.drive2.ru

How to use a rolling jack?

Do you need to remove the wheel to have it balanced? To do this, the part of the vehicle on which the wheel is located needs to be raised slightly so that it just lifts off the ground. Are you planning to inspect your muffler or suspension? Then you need to raise the car much higher - up to 70-80 cm.

In any case, to avoid problems during work, you need to follow simple rules:

- Rule 1 . The rolling jack may only be placed on a level, solid base. It must be asphalt or concrete floor. If you buy this device for tire mounting, and the removal of wheels from vehicles will be carried out on the street, then the parking lot must be paved so that you can work with the jack without any problems in any weather. This way you can be sure that it will not budge and the car will not fall off.

- Rule 2 . Observe the permissible load capacity of the device and compare it with the actual weight of the vehicle. For example, for the jack BISON MASTER 43052-2.1-K this value is 2 tons (can serve passenger cars), and for the Pfaff HRH S 5 L Silverline 40008534 - 5 tons (suitable for working with SUVs and minibuses). The weight of the vehicle being lifted must not exceed the permitted load, otherwise the lifting mechanism and vehicle body may be damaged.

- Rule 3 . Wheels standing on the ground must be secured with locking shoes to prevent the body from moving. While the car is on a jack, maintenance and repairs cannot be carried out. The device is simply not designed to support a lifted load. After the car is raised to the desired height, it is necessary to support it with safety stands and remove the jack. Only after this can you proceed to work.

Each type of jack has its own approach!

Above we have listed general rules that are important to follow when using all rolling jacks, but there are some features of using the equipment depending on the type of its drive. It can be hydraulic or pneumohydraulic .

The first operates the lifting mechanism by creating oil pressure in the piston; the second, in addition to oil pressure, uses the force of compressed air to create the movement of the plunger and lift a heavy load.

Hydraulic rolling jacks, as a rule, have a small load capacity, up to 3-4 tons, and those that operate on compressed air - up to 10 tons, which makes it possible to service freight vehicles with their help.

The algorithm for using a hydraulic rolling jack is as follows: first, tighten the bypass valve, then install the device under the car so that the hydraulic cylinder with the lifting platform fits exactly under the standard pick-up point, and begin to press the lever. For greater lifting speed, it is better to use the full stroke of the lever.

Simultaneously with the lifting of the plunger, the jack rolls under the car, creating reliable support during lifting. After installing the safety stand, the jack can be removed. Upon completion of servicing the vehicle, the jack is rolled under the vehicle again, the hydraulic cylinder is again raised to the desired height when the user presses the handle, and the safety stand is removed.

The load is lowered when the shut-off valve opens.

When working with a pneumatic-hydraulic jack , you need to organize a compressed air supply system from the compressor, ensure cleaning from dust, moisture and oil by integrating additional equipment into the system - a moisture separator, a device for draining condensate, and also using a lubricator. It is also very important to monitor the air pressure in the system.

For example, the SOROKIN 3.650 jack has a permissible operating pressure of 7.5 - 8.5 atm. This means that the compressor air pressure parameter must be no less than this value. To do this, a pressure regulator must be installed at the outlet of the compressor. The jack is connected to the compressed air supply system with a hose, after which the air valve is opened by turning the flywheel on the handle - the lifting of the load begins. The valve closes when the desired lift height is reached.

To lower the load, the handwheel that controls the opening/closing of the air valve must be turned counterclockwise to the minimum air supply position. Of course, the preparatory work before using such a jack requires a little more time compared to a hydraulic one, but you can lift heavier vehicles without much effort: buses, trucks, special equipment.

Proper pumping of a rolling and bottle-type hydraulic jack with your own hands

A jack is a device for lifting loads to the desired height. This simple and compact mechanism is widely used in industry and everyday life. There are several types of jacks; they are highly reliable, but sometimes they require repair, refueling and bleeding.

Application of hydraulic jacks

Lifting devices are used for fixing, moving and lifting heavy loads: building slabs, machine tools, cars, columns. Their carrying capacity can be hundreds of tons. Depending on the purpose, the design and dimensions of the machine vary.

High performance and ease of maintenance have made jacks indispensable in manufacturing, car service stations, the processing industry, power plants, warehouses and other production areas. Car enthusiasts also cannot do without their own compact lifts.

And the ability to move loads vertically and horizontally is used everywhere on construction sites.

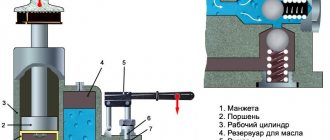

Hydraulic lift device

The main components of the system are the housing, the movable piston and the liquid medium (machine oil). The body is made of durable metal in the shape of a cylinder. It serves as both a guide for the rod and a container for technical fluid. Additional elements that bring the device into operation:

The use of valves makes it possible to increase the force applied to the lever tens of times. The plunger is necessary to move the piston by transporting the working fluid into the container below it.

The valve prevents liquid from flowing back into the common container. Gradually, the plunger pumps more and more liquid under the piston, raising it.

And in order for the load to drop, you only need to allow the oil to return to the common container by slightly opening the valve.

Pros and cons of hydraulic jacks

Advantages:

- high power;

- ease of operation and maintenance;

- high level of efficiency - about 80%;

- ability to move cargo weighing up to 200 tons.

Flaws:

- are not able to lift loads from low heights;

- the level of lowering the load cannot be determined;

- requires constant monitoring and maintenance: adding oil, replacing gaskets and seals;

- they can only be transported and stored in a vertical position, otherwise the working fluid will leak out;

- they work quite slowly, cyclically, lifting the load to a small height each time;

- quite expensive;

- they break down more often and repairs are more expensive than their mechanical counterparts.

Types of hydraulic jacks

Several types of devices have been created that are convenient for use in various fields:

- bottled;

- hybrid;

- rolling;

- diamond;

- hooked.

The bottle jack is the most common and simplest design. It is capable of lifting from two to hundreds of tons, has a large support area and a compact body. Therefore, such mechanisms are usually used when repairing various types of vehicles, especially trucks.

Bottle jacks can have a double-rod or single-rod design. Single-rod, simpler devices, are used in the maintenance of railway cars, in construction, mechanical engineering, and in the production of pipe cutters and pipe benders.

Double rod models work vertically and horizontally.

https://www.youtube.com/watch?v=7bBd-1_rRjM

The design of a rolling jack resembles a trolley, which during operation moves under the lifted load. Operated by a hand lever and regulated by an oil valve.

To open the valve, you must turn the valve screw handle. Very convenient for one-sided lifting of loads. Therefore, it is good when changing a wheel. But it works exclusively on hard and flat surfaces.

There is a transmission type that has a rotating frame in its design.

Hybrid jacks are also called two-level jacks and are used in car repair shops. Their convenience is the presence of a couple of platforms for cargo. In fact, it is a combination of bottle and roll-on models. The machine is controlled by a foot pedal and lever.

A hook jack is good where it is necessary to lift a load from a small height: moving machine tools, railway rails. The design is based on a bottle design.