Installation of internal hot and cold water mains from polypropylene pipes is relevant for a large number of private country houses and communal apartments; during the work, pipeline sections are connected to each other by soldering. The specialist installing polypropylene pipes must know the heating time of the parts being connected; usually, the instructions for the welding machine contain a table for soldering polypropylene pipes and the heating temperature at which this process should occur.

In addition to information about the time and temperature parameters of soldering, to carry out the work correctly, you need a high-quality tool and a study of installation technology, taking into account the characteristics of various brands of polypropylene pipes. The installer will also need knowledge not only about the time intervals for heating the parts being joined, but also about the cooling time of the welded assembly, the dimensional parameters of the chamfers, and the optimal insertion depth of the joined elements.

Rice. 1 PP pipes and fittings for polypropylene pipes

What are polypropylene pipes, their types

Polypropylene (abbreviated PP or PPR) is a thermoplastic, that is, changing its dimensional parameters at different temperatures, propylene polymer obtained by its polymerization in the presence of metal-containing catalysts; its manufacturing technology is close to the process of production of low-density polyethylene (HDPE). The physical and chemical parameters of the resulting polypropylene material depend on the chemical composition of the catalyst used.

Polypropylene pipes are used for laying cold and hot water supplies, heating networks, piping boiler equipment, installing risers, laying sewers to drain high-temperature wastewater and aggressive chemicals from industrial enterprises.

The main parameters of polypropylene that influence its scope of application are as follows:

- Polypropylene as a thermoplastic expands when heated to high temperatures, for example, the length of a three-meter pipe increases by 3 cm.

- When the temperature parameters of the transported medium are 140 °C, the material softens, PP melts at 170 °C, the upper threshold of its operating temperature is considered to be 120 °C.

- The service life of polypropylene reaches 50 years.

- The material is afraid of direct exposure to ultraviolet radiation, so ordinary polypropylene pipes are used in enclosed spaces or laid in grooves if sunlight penetrates into the room.

- The material can withstand pressure up to 25 bar.

- Polypropylene pipes have a thick shell with low thermal conductivity - this determined their main scope of use as cold and hot water supply pipelines, and also made their use in heated floors irrational.

- The outer diameter of polypropylene pipes used in individual housing construction does not exceed 110 mm, typical sizes for laying water and heating pipelines are 20, 25, 32, 40 mm; in industrial construction, PP pipe diameters of 50, 63, 75, 90, and 110 are used mm.

- The color range of manufactured products is white, gray, green (painted products resist ultraviolet radiation); to indicate the scope of application in cold and hot water pipelines, blue and red stripes are applied to the outer shell of the products.

Rice.

2 Dimensional parameters of PP pipes According to the internal structure, PP pipes are divided into:

- Single-layer, entirely polypropylene, has high thermal expansion characteristics and relatively low tensile strength at high pressures.

- Multilayer, are products in which there is a layer of reinforcing material between the inner and outer polypropylene shells. Solid or perforated aluminum foil or fiberglass is used as the middle layer, sometimes reinforced with a composite consisting of a mixture of polypropylene and fiberglass.

Currently, one of the popular types of polypropylene pipes are two-layer products with an inner layer of aluminum.

Manufacturers supply the market with the following types of PP pipes:

PPH (PPH, PP-1) is a homopolymer, which is a pure polymer with a minimum amount of additives modifying its strength characteristics, and is used in the manufacture of large-diameter free-flow pipelines for ventilation, water supply and drainage systems.

PPR (PPR, PPRC, PP-3, PP-random) is a static copolymer, most often used for laying water supply and heating utilities in individual housing construction, communal apartments, it is characterized by high heat resistance and resistance to shock loads.

RRV (PP-type 2, PP-2) is a blocksomer with increased physical parameters, used in high-pressure communications of heating systems and water supply.

PPs (polyphenyl sulfide) is a high-strength, wear-resistant polymer with increased resistance to physical stress and high temperatures. Used for laying industrial and utility communications for cold and hot water supply, heating, pipe diameter can reach up to 1200 mm.

Rice. 3 Construction of aluminum-reinforced multilayer PP pipes

The pressure and temperature characteristics of polypropylene pipes have an inverse relationship - the higher the temperature of the working fluid, the lower the threshold of the maximum retained pressure; this relationship affects the scope of application of PP pipes.

The markings of polypropylene pipes indicate their pressure characteristics; according to this parameter they are divided into the following groups:

PN-10 - a nominal pressure of 10 bar (10 atmospheres, 1 MPa), pipes are used for organizing cold water supply, rarely for installing heated floors with a coolant heating temperature of no more than 45 ° C.

PN-16 - pipes designed for a working pressure of 16 bar, are used for the installation of cold and hot water supply with a maximum working fluid temperature of + 60 ° C.

PN-20 - operated at an operating pressure of 20 bar with a carrier temperature of 80 - 90 ° C in systems with protection against water hammer.

PN-25 - products with a working pressure of 25 bar are used in pressure heating networks for transporting hot water and steam with temperatures up to 120 °C.

Rice. 4 Types of PP pipes

Technological description of the soldering process

In everyday life, plastic pipes with a diameter of 16 to 40 mm are used. The range from 50 to 110 mm is used in industrial facilities.

Products are available in several versions, which can be distinguished by markings:

- PN-10 - for systems with a pressure of no more than 10 bar and a media temperature not higher than +45 ° C;

- PN-16 - designed for a pressure in cold water systems of no more than 16 bar and a heating temperature of no higher than +65 °C;

- PN-20 - withstands 20 bar and +80 °C (which is the limit for polyethylene pipes) in hot water supply and cold water systems;

- PN-25 - used for heating and can withstand 25 bar at +95 °C.

Preparation of tools and material

Before starting installation, prepare materials (pipes, fittings, couplings, tees, shut-off valves) and a welding machine. For one-time work, it is more profitable to rent a soldering station. You will also need a tape measure, a level, and a marker of any color.

Marking, cutting, stripping

At this stage, measurements are taken along the laying route, the set of fittings is specified, and markings are made. Next, using a special cutter that does not leave burrs, pipes of the required length are formed perpendicular to the longitudinal axis. The ends of the parts are chamfered.

The parts to be welded are washed, wiped, and degreased with ethyl or isopropyl alcohol. They must be clean and dry before soldering. It is worth trying on all the parts and numbering them before disassembling in order to avoid installation errors and speed up the assembly process.

Soldering

This stage of work is best done with an assistant, especially when connecting long sections.

The prepared parts are tightly placed on the welding sleeves, which by this moment should have the temperature specified in the instructions for the soldering iron. For the most common types of pipes, this figure is +260 °C.

The heated parts are removed from the sleeves and coaxially inserted into each other using a screwing motion with pressure. They are held in this position for the time indicated in the “Soldering” and “Cooling” columns of the table (see below).

After a few seconds, during which the plastic cools, the structure is ready for use. There should be an even flow at the junction.

Types of fittings

A variety of connecting parts allows you to quickly and reliably conduct wiring in any room or outdoors.

The following types of fittings are available:

- angular, with or without thread, rotating the system at angles of 45°, 90° and 135°;

- adapters for 2, 3, 4 directions (smooth or with internal/external thread);

- bypasses - used to bypass already laid pipes;

- compensators in the form of a loop - designed to smooth out pressure in the system, reduce shock loads on pipe walls and joints;

- shut-off valves in the form of taps and valves - used to regulate the flow in the pipeline;

- plugs - used during repairs and for permanent closure of pipeline branches;

- fastening elements - allow you to fix the pipes at the base.

Technological process of welding PP

Welding polypropylene pipes is based on the ability of this type of plastic to soften when heated to a certain temperature, acquiring a state similar to soft plasticine. When two molten parts come into close contact, a process of mutual penetration (diffusion) of materials occurs, resulting in a strong connection that is not inferior in durability to the entire structure.

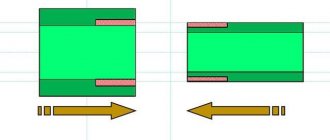

There are two main methods of connecting polypropylene pipes: butt and coupling. In the first option, the ends of the parts are heated simultaneously with a special disk soldering iron, after which they are joined together; this technology is widely used when joining large-diameter pipes in industrial construction.

When using polypropylene pipes of small diameters (up to 63 mm) in the construction industry for laying water supply and heating networks, the butt method is absolutely unsuitable for the following reasons:

- welding of polypropylene pipes of only one diameter can be realized;

- after joining, a convex seam is formed inside the pipeline, reducing the cross-section of the passage channel - this significantly increases the hydraulic resistance of a small-diameter pipeline and reduces the efficiency of its use, increasing the likelihood of blockages.

- the connection has less strength than a coupling connection.

Technological features of the process.

There are types of soldering of polypropylene pipes:

1.butt type.

2. coupling type.

The butt type is rarely used when installing communications in a house, because it is difficult to install independently. It is used for laying main networks with large pipes.

Attention! In apartments, welding is used using couplings, which reaches to connect pipes with a cross-section of at least 16 millimeters and a maximum of 63 millimeters.

Socket welding is based on the principle: two products are connected using sockets, heated using a special tool. They must be equal in cross-sectional size and wall thickness

Important! Before heating, the coupling must have a smaller diameter in relation to the pipe.

Soldering steps:

1.connect the soldering iron to the part.

2.heat to melting temperature.

3. achieve a sealed unit.

The melted polymer zone should only cover those surfaces that will be joined.

The main thing is to remove the parts from the tool during the process, connecting them to each other. The result is a single part with polymerization. The quality of the connection is affected by the melting temperature, as well as the time spent on the process.

Polypropylene soldering tool

The generally accepted technical name for this type of tool is a welding machine for soldering polypropylene pipes; installers often call the device a welding iron.

Structurally, the device consists of the following components and components:

The heating element (heating element), made in the form of a flat plate with mounting holes, or a rod, in the standard device there are two heating elements, the second is connected when soldering large pipes.

A housing with a handle , on which there are two buttons for turning on the heating elements, two indicators of operation (when the heating elements reach the set temperature) and a regulator with a scale (sometimes it is duplicated by pipe diameters) for setting the temperature regime, usually the temperature of the soldering iron does not exceed 300 C. Deciding at what temperature for soldering plastic pipes, experienced specialists, thanks to a thermostat, can vary the heating of pipes over a wide range. For example, if joining occurs with some delay, the parts are heated above the standard of 260 °C, observing the time intervals specified in the instructions, and then soldered.

A set of nozzles used for soldering polypropylene pipes, their standard sizes are 20, 25, 32, 40, 50, 63 mm, the number in the set can vary from 3 to 6 standard sizes.

Rice. 6 Apparatuses for welding polypropylene pipes

There are two designs of welding machines:

- Sword-shaped with a flat iron, the unit has a double-sided heating platform in which 3 through holes are made. A threaded bolt is inserted into them and two nozzles are screwed in on opposite sides - a sleeve for heating the outer surface of a pipe of a smaller diameter and a mandrel for softening the inner surface of a larger coupling.

- Rod type, in appearance they resemble a woman’s curling iron for curling hair; 3 attachments can be simultaneously attached to the rod, made in the form of clamps with fixing bolts and having a sleeve and mandrel for softening PP pipe casings. The rod devices are also equipped with two buttons for turning on the heating elements, LED indicators of operating modes and a thermostat.

Rice. 7 Marking of PP pipes

Detailed installation instructions

The soldering process is fast. You can verify this by analyzing the data in the table. For example, to connect two elements with a diameter of 20 mm, at room temperature it will take 5 seconds to heat up, another 4 seconds to connect, then 180 seconds to cool down. Total – 3 minutes 9 seconds.

In this regard, it is important to practice all movements so that there is no hitch in the process of joining already heated elements. Let's consider the nuances of each stage of installation of polypropylene pipes separately.

Stage #1 – preparation of special tools

For soldering at home, you will need equipment designed only for welding polypropylene parts - pipes, angles, couplings, tees, plugs.

Image gallery

Photo from

Iron for welding polypropylene

Pipe cutter for cutting pipes

Shaver for removing reinforcement

Soldering iron stand

It makes sense to purchase a new tool if you plan to assemble a water supply system from scratch with further maintenance. For one-time work, you can rent equipment for welding PP pipes or borrow it from friends. In addition to special tools, you will need a level, marker, ruler or tape measure.

Stage #2 – marking and cutting pipes

The pipes are cut in advance, before the first soldering begins. We recommend preparing all the elements and putting them together according to the diagram. It is part of a heating system or plumbing installation project.

Often pipe routing is a complex system of straight and rotary sections. Assembly is easier when small sections of pipe are initially connected with fittings into separate units

We measure out pieces of pipes of the required length and carefully cut them with a pipe cutter. Then we select fittings of suitable diameter - most often these are couplings, tees and angles. If the elements are reinforced, remove the aluminum layer.

As a result, the edges of the parts to be welded must be perfectly smooth, cut perpendicular to the axis of the pipeline, cleaned and degreased.

Stage #3 – connecting elements and heating

We install the device, select couplings and mandrels of the required diameter. We plug it into the network and heat it up, since we already know at what optimal temperature polypropylene pipes should be soldered - +260 °C. This is exactly what is indicated in the operating instructions for soldering irons.

Please note that some manufacturers produce devices with a scale up to +320 °C. This does not mean that you need to heat it to maximum. Read the instructions carefully - they indicate the conditions under which high heating values are permissible.

At the ends of the parts that need to be connected, we make marks indicating the heating depth. We check once again that the working surfaces are dry and free of grease, since moisture or a slippery surface can cause the connection to depressurize.

We use both parts at the same time: we insert the end of the pipe into the coupling up to the mark, and we put the connecting element on the mandrel until it stops

From the moment the parts are installed, we begin counting the seconds - according to the values indicated in the table. After the required time, remove the parts and quickly insert the pipe into the fitting - up to the same mark. We try to position the parts coaxially; only a couple of seconds are given to correct the position. Distortions and rotation of elements must not be allowed!

We hold the knot in the correct position until polymerization occurs. Usually this is 3 minutes or more - we check the cooling time according to the table. Cooled and properly welded parts form an integral connection, tight and durable.

We weld the key components one by one, so that we can then assemble and weld them together at the installation site of the heating circuit, sewer or water distribution.

Soldering table for polypropylene pipes and their heating temperature

One of the main tasks of the installer when carrying out joining work is to accurately maintain the welding time of polypropylene pipes. Deviation from time intervals in one direction or another, as a rule, will lead to two main troubles:

- the shells of the welded pipes will not warm up enough, as a result, diffusion connection will not occur and during operation the pipes will become undone - water leakage and flooding of the room will occur.

- The pipe shells will overheat and an influx will form at the junction of the ends - this will narrow the passage channel, increase the hydraulic resistance of the line, and lead to financial losses in individual water supply or heating due to poor conductivity of the line.

When carrying out work, any installer will benefit from a table of temperatures for soldering polypropylene pipes, indicating the time for heating the shells with a soldering device. The need for the table is due to the fact that large-diameter pipes have a higher heated surface area, mass and volume; accordingly, it takes more time to warm them up in comparison with small products at the same temperature.

When compiling the table, the main criterion was the experimentally determined optimal welding temperature of polypropylene pipes, equal to 260 °C.

Rice. 8 Table for soldering polypropylene pipes

Also in the instructions for any welding machine there is a table that shows the time for soldering polypropylene pipes in the docked position. Similar to the heating time of pipe shells, the holding time of the connected parts together also increases with increasing their diameters.

When carrying out soldering work, it is useful to know at what temperature to solder plastic pipes, because the state of the environment significantly affects the cooling rate of the parts being connected, and if the air is too cold, the tabular data will indicate incorrect values. When carrying out installation work, the permissible lower temperature limit is -10 °C, and the optimal ambient temperature indoors or outdoors is from 0 to +25 °C.

The last indicator that is useful for an installer to know when soldering plastic pipes is the heating depth of polypropylene parts. In principle, it is specified by the sleeve and mandrel, which have the appropriate length, therefore, when the abutting pipe sections are completely immersed in the nozzles, the correct dimensional parameters will be observed automatically.

At what temperature should polypropylene pipes be soldered?

The table below clearly demonstrates the dependence of heating and cooling times on the pipe diameter.

The optimal soldering iron temperature for joining polypropylene pipes is considered to be 260 °C. It is permissible to increase this indicator to 280 °C, but it should be remembered that in this case the outer layer of the polymer will heat up more than the inner one, and the quality of the seam will deteriorate somewhat.

Soldering of fiberglass-reinforced pipes is carried out with the same parameters. Before starting work, they must be treated with a shaver to remove the outer reinforced layer.

Having figured out how much to solder polypropylene pipes, you should pay attention to the following

features of the work :

- It is unacceptable to violate the order of work when the contractor skips the last joint due to the impossibility of installing a soldering iron between the pipes. This leads to the appearance of deformation and static stress.

- Individual parts cannot be heated sequentially. Their temperature during docking must be the same, otherwise the diffusion process will be uneven.

- There should not be a large distance between the soldering point and the soldering iron to prevent heat loss. Optimally – up to 1.4 m.

Maintaining compliance of temperature conditions with established technological requirements and using a high-quality soldering iron are the key to high quality of work performed. Ready-made communications will last a long time, and the occurrence of problems during operation will be minimized.

Source

Soldering polypropylene pipes - step-by-step instructions

One of the main advantages of joining polypropylene pipes by soldering is the speed of installation work; the process of joining and readiness for further installation of pipes with the most common diameter of 25 mm takes no more than 15 seconds. In order to complete the work without unnecessary time expenditure, all preparatory operations are carried out responsibly and then the pipeline is installed, strictly adhering to the technological process of the operations.

Rice. 9 Tool used to weld PP pipes

Preparing tools and components

Before soldering polypropylene pipes, prepare the components: pipe sections, tees, corner bends, couplings, adapters from plastic to metal, valve shut-off valves.

To carry out the work, you will need a soldering iron and a set of nozzles, as well as auxiliary tools, some of which are included with the device:

- Pipe cutters, usually scissors with a maximum permissible cutting diameter of 40 mm are used for cutting pipes; for larger sizes, more powerful scissors or roller cutters are used.

- Tape measure for measuring dimensions, marker or pencil for marking the length on the pipe casing.

- Gloves to protect your hands from burns while working.

- Level for checking the horizon when installing water sockets.

- A screwdriver or hex wrench for securing attachments to the heating iron.

Welding temperature ppr

To join pipes, fittings are used - original adapters that are soldered directly to the pipes. The process is carried out using a special soldering iron or iron. The soldering temperature depends on the type of pipe. A version of such a product is marked along the length of the pipe by the manufacturer.

PN10 are thin pipes; they are used almost exclusively for cold water supply. The ambient temperature should not exceed 20 degrees. Sometimes they are laid for slight heating of heated floors.

PN16 is used under operating pressure conditions of no higher than 16 atmospheres. The maximum temperature is 60 degrees, at higher values it deforms. The most popular pipe in cold water supply and easy to install.

PN20 are pipes for heating. Withstands temperature loads up to 95 degrees. Just a few years ago it was believed that plastic was not capable of this.

PN25 – reinforced pipes of increased strength. Withstands strong heat and temperature changes.

Based on the above characteristics, not only the temperature is selected, but also the soldering time, since some types of polypropylene pipes can withstand only short-term exposure to high temperatures, after which they begin to soften.

The soldering process itself is simple:

- the parts to be connected are put on a special tip of the iron;

- the joints are maintained until visible softening;

- connection occurs.

The entire process must occur quickly and in strict sequence. It is very important to check the desired temperature. Both when the connection is too hot, and when, figuratively speaking, it is cold, polypropylene pipes lose some of their qualities, or even break completely at the seam site.

During soldering, the pipe may begin to rapidly melt or crumble. Most often this occurs from the use of recycled materials in the manufacture of pipes or the presence of foreign impurities. The only way out is to replace the material. It can no longer be corrected; it does not meet the stated technical specifications.

As a rule, during the process an average temperature value is used to melt the material. Usually this is 260 degrees, but a range from 255 to 280 degrees is allowed, it all depends on the type of pipe, as mentioned above.

There is also a cold welding method. It is used in low pressure household water supply systems. Then the parts are simply connected with special glue. The strength of such a connection is much lower, and so is the quality of the seam.

Soldering as a method of connecting PPR pipes

In the welding process, everything is important: diameter, soldering temperature of PP products, exposure time to the welding machine. But first you need to get acquainted with the basics of technology and learn how to use the tools.

You cannot begin the soldering process without determining the type and dimensions of the material. We invite you to familiarize yourself with useful information that will help you choose the right polypropylene pipes and fittings, as well as install them, knowing the nuances and sequence of the process.

What do you need to know about polypropylene pipes?

Welding technology (or soldering - both terms are equally applicable) is ensured by the properties of polypropylene, a universal-purpose technical polymer. It is fusible, but after cooling and hardening it returns the characteristics of strength and tightness.

Pipes differ in diameter, wall thickness, color, and characteristics. Thanks to the range of diameters – 16-110 mm – any technical solution can be implemented.

You can ignore the color of the polymer, since it is chosen by the manufacturer at its discretion, but the color of the stripes matters:

- blue – for cold water supply;

- red - for hot water supply and heating.

However, the basic information that you should rely on when purchasing and soldering pipes is indicated on the labeling. Polypropylene pipe material is designated by the letter combinations PPR , PP-H , PP-B , PPRC .

Classification according to the nominal pressure, the maximum permissible for installation in specific conditions, helps to select products for home or industrial systems.

Based on this, there are 4 types of PPR pipes:

- PN-10 (with a nominal value of 1.0 MPa) - designed for transporting cold water. Sometimes they are used to install heated floors, provided that the coolant does not heat up above +45 °C.

- PN-16 (with a rating of 1.6 MPa) - used for assembling hot/cold water supply systems. The maximum permissible temperature is +60 °C.

- PN-20 (with a rating of 2.0 MPa) - can withstand temperatures up to +80-90 °C in pipelines protected from water hammer.

- PN-25 (with a rating of 2.5 MPa) - suitable not only for autonomous, but also for centralized water supply. The recommended maximum temperature is +95 °C, but higher temperatures can be tolerated.

How to weld pipes by hand?

For work, a special welding machine for polypropylene pipes is used. On its flat heating element, called the “iron,” paired adapter bushings are attached to the diameter of the pipe. The edges of the parts to be soldered are cut exactly at 90°, and a chamfer is removed from them, making the connection easier.

Next, the edges and the adjacent 15-20 mm area are cleaned of dust, chips and other contaminants. For this, organic solvents such as alcohol or trichloroethane are used. When choosing a solvent, you must follow the manufacturer's instructions.

The chamfer parameters and the width of the stripping zone are selected based on the diameter of the elements being connected.

Parameters for cutting edges and cleaning depending on the diameter.

The heating temperature is set taking into account the manufacturer's recommendations and adjustments for room temperature . After the welding machine has warmed up, the prepared edges are put on the bushings and begin to heat up. It is recommended to check the actual temperature of the electric heater with a contact thermometer or pyrometer.

On the outside, longitudinal marks are applied to pipe sections or fittings. They will allow you to accurately combine elements without displacement. After waiting the necessary time for warming up, both parts are removed from the adapter sleeves and immediately inserted into one another so that the marks coincide.

In this position, a holding period is allowed for the duration of welding, while the parts must be securely fixed. There is mutual penetration of the softened surface layers of the edges of the two parts and the formation of new molecular bonds. After the welding time has passed, the connected elements must cool naturally, without immersion in water or blowing with cold air. Such an impact will lead to thermal deformation and breaking of newly established bonds.

After welding is completed, a section of the pipeline (or the entire system) is tested under operating fluid pressure . Each joint is carefully inspected; if drops of water or evaporation are observed, the joint is rejected and must be resoldered.

[stextbox of different types of polymers, manufacturers recommend their operating heating temperature ranges.

To improve the understanding of the physical phenomena occurring during soldering, a time diagram of changes in temperature and pressure of parts is provided.

Diagram of temperature and pressure during different stages of welding.

The time scale in the diagram is given on a nonlinear scale; the actual ratio of pressing and cooling time can be taken from the table.

How to connect a metal-plastic pipe with a polypropylene pipe

Due to various circumstances, it happens that it is necessary to connect different types of pipes, for example, PPR and steel, metal-plastic with polypropylene, and so on. Such situations happen in apartments where it is difficult to change a section of a common water supply or heating riser laid with a steel or metal-plastic pipe, but you need to connect to it. This is not a big problem, you just need to take into account that all such connections are made through threaded fittings.

Since metal-plastic pipes can be connected using press and dismountable fittings, for joining with polypropylene it is more convenient to use a detachable fitting with an external thread. In turn, a fitting with an external thread is soldered to the end of the polypropylene pipe, after which the connection is twisted in the traditional way, with flax or fum tape wound up.

Detachable fitting for connecting pipes

When you need to cut into metal-plastic pipes, it is most convenient to install a tee with a threaded outlet, where you can subsequently screw the fitting, and then solder the polypropylene pipe to it. True, you will have to tinker with the installation of the tee: you need to turn off the water or empty the heating system, and then cut the metal-plastic and carry out the installation.

Soldering mode and its effect on the process

The technology for soldering polypropylene pipes involves heating them, after which the plastic contained in them softens. When two heated products are connected, diffusion (interpenetration) of polypropylene molecules of one technical product into the molecules of the other occurs. As a result, a strong molecular bond is formed, making the resulting material airtight and durable.

If there is an insufficient mode, then sufficient diffusion will not occur when two materials are combined. As a result, the joint of the technical product will turn out to be weak, which will lead to a violation of the tightness of the entire material.

Excessive overheating of the fitting and pipe technical product during welding causes deformation of the parts. Their geometry is disrupted, and a roller influx occurs in the internal section.”

The output is a pipeline with a minimal internal hole at the junction, the diameter of which does not meet technological standards.

It is necessary to take into account not only the heating temperature when welding polypropylene pipes, but also time, temperature conditions of the environment and the diameter of technical products. The heating time of pipe materials is directly dependent on their diameter.