General concept of thermal conductivity and its nature

If we answer in simple words the question of what thermal conductivity is in physics, then it should be said that the transfer of heat between two bodies or different regions of the same body is the process of exchange of internal energy between the particles that make up the body (molecules, atoms, electrons and ions). Internal energy itself consists of two important parts: kinetic and potential energy.

What is thermal conductivity in physics in terms of the nature of this quantity? At the microscopic level, the ability of materials to conduct heat depends on their microstructure. For example, for liquids and gases, this physical process occurs due to chaotic collisions between molecules; in solids, the main share of the transferred heat is due to the exchange of energy between free electrons (in metallic systems) or phonons (non-metallic substances), which are mechanical vibrations of the crystal lattice .

Difference between thermal conductivity and heat transfer

In addition to the thermal conductivity coefficient Lambda, there is also a heat transfer coefficient U. They sound similar, but mean completely different things.

So, if the thermal conductivity coefficient is a characteristic of a certain material, then the heat transfer coefficient U determines the degree of thermal insulation of a wall or partition. Simply put, the thermal conductivity coefficient is the initial one and directly affects the value of the heat transfer coefficient U.

If you are interested in getting more information on this topic, as well as finding out what materials are best to insulate your home, what are the differences between different types of insulation, we recommend reading this article.

Did you find this article helpful? Please share it on social networks: Don't forget to bookmark the Nedvio website. We talk about construction, renovation, and country real estate in an interesting, useful and understandable way.

Methods of transferring thermal energy

When considering the question of what the thermal conductivity of materials is, it is worth mentioning possible methods of heat transfer. Thermal energy can be transferred between different bodies through the following processes:

- conductivity - this process occurs without the transfer of matter;

- convection - heat transfer is directly related to the movement of matter itself;

- radiation - heat transfer is carried out due to electromagnetic radiation, that is, with the help of photons.

For heat to be transferred through the processes of conduction or convection, direct contact between different bodies is necessary, with the difference that in the process of conduction there is no macroscopic movement of matter, but in the process of convection this movement is present. Note that microscopic motion occurs in all heat transfer processes.

For ordinary temperatures of a few tens of degrees Celsius, it can be said that convection and conduction account for the bulk of the heat transferred, and the amount of energy transferred by radiation is negligible. However, radiation begins to play a major role in the process of heat transfer at temperatures of several hundred and thousand Kelvin, since the amount of energy Q transferred in this way increases in proportion to the 4th power of absolute temperature, that is, ∼ T4. For example, our sun loses most of its energy through radiation.

Thermal conductivity coefficient for solids

The coefficient of thermal conductivity for solids k has the following physical meaning: it indicates the amount of heat that passes per unit time through a unit surface area in a body of unit thickness and infinite length and width with a temperature difference at its ends equal to one degree. In the international system of SI units, the coefficient k is measured in J/(s*m*K).

This coefficient in solids depends on temperature, so it is usually determined at a temperature of 300 K in order to compare the ability to conduct heat of different materials.

Thermal conductivity coefficient Lambda. What it is?

Coefficient λ (lambda) is perhaps the most important parameter of all thermal insulation materials. Its value indicates how much heat the material can transmit through itself. That is, its thermal conductivity index.

The lower the value of the coefficient λ (lambda), the lower the conductivity of the material and, therefore, it is better insulated from heat loss. This means that under the same conditions, more heat will pass through a substance with greater thermal conductivity.

How is this coefficient calculated? According to the second law of thermodynamics, heat always goes to a region of lower temperature. For a body in the form of a heat-conducting cuboid under stationary conditions, the amount of heat transferred depends on the substance, proportional to the cross section of the body, the temperature difference and the time of heat transfer.

Thus, the calculation formula will look like this:

Q = λ (S ΔTt / d)

hence the lambda:

λ = (Q/t) (d/S ΔT)

Where:

- λ (lambda) — thermal conductivity coefficient;

- ΔQ is the amount of heat flowing through the body;

- t—time;

- L—body length;

- S is the cross-sectional area of the body;

- ΔT—temperature difference in the direction of thermal conductivity;

- d is the thickness of the partition.

The SI system is taken as the unit of measurement for thermal conductivity - [W / (m K)]. It expresses the amount of heat flow through a unit surface of a material of a given thickness if the temperature difference between its two sides is 1 Kelvin. All these indicators are measured in special construction laboratories.

Thermal conductivity coefficient for metals and non-metallic solids

All metals, without exception, are good conductors of heat, the transfer of which into them is carried out by electron gas. In turn, ionic and covalent materials, as well as materials with a fibrous structure, are good thermal insulators, that is, they conduct heat poorly. To fully explain the question of what thermal conductivity is, it should be noted that this process requires the presence of a substance if it is carried out through convection or conduction, therefore, in a vacuum, heat can only be transferred due to electromagnetic radiation.

The list below shows the values of thermal conductivity coefficients for some metals and non-metals in J/(s*m*K):

- steel - 47-58 depending on the steel grade;

- aluminum - 209.3;

- bronze - 116-186;

- zinc - 106-140 depending on purity;

- copper - 372.1-385.2;

- brass - 81-116;

- gold - 308.2;

- silver - 406.1-418.7;

- rubber - 0.04-0.30;

- fiberglass - 0.03-0.07;

- brick - 0.80;

- wood - 0.13;

- glass - 0.6-1.0.

Thus, the thermal conductivity of metals is 2-3 orders of magnitude higher than the thermal conductivity values for insulators, which are a clear example of the answer to the question of what low thermal conductivity is.

Thermal conductivity plays an important role in many industrial processes. In some processes, they try to increase it by using good thermal conductors and increasing the contact area, while in others they try to reduce thermal conductivity by reducing the contact area and using heat-insulating materials.

Thermal conductivity of brass and bronze

The table shows the thermal conductivity values of brass, bronze, as well as copper-nickel alloys (constantan, copel, manganin, etc.) depending on temperature - in the range from 4 to 1273 K.

Thermal conductivity of brass, bronze and other copper-based alloys when heated increases. According to the table, L96 brass has the highest thermal conductivity of the alloys considered at room temperature. Its thermal conductivity at a temperature of 300 K (27°C) is 244 W/(m deg).

Also copper alloys with high thermal conductivity include: brass LS59-1, tombac L96 and L90, tin tombac LTO90-1, rolled tombac RT-90. In addition, the thermal conductivity of brass is generally higher than that of bronze. It should be noted that bronzes with high thermal conductivity include: phosphorus, chromium and beryllium bronzes, as well as BrA5 bronze.

The copper alloy with the lowest thermal conductivity is manganese bronze - its thermal conductivity coefficient at a temperature of 27°C is 9.6 W/(m deg).

The thermal conductivity of copper alloys is always lower than the thermal conductivity of pure copper, all other things being equal.

In addition, the thermal conductivity of copper-nickel alloys is particularly low. The most thermally conductive of them at room temperature is cupronickel MNZhMts 30-0.8-1 with a thermal conductivity of 30 W/(m deg). Thermal conductivity table for brass, bronze and copper-nickel alloys

| Alloy | Temperature, K | Thermal conductivity, W/(m deg) |

| Copper-nickel alloys | ||

| Beryllium copper | 300 | 111 |

| Constantan of foreign production | 4…10…20…40…80…300 | 0,8…3,5…8,8…13…18…23 |

| Constantan MNMts40-1.5 | 273…473…573…673 | 21…26…31…37 |

| Kopel MNMts43-0.5 | 473…1273 | 25…58 |

| Manganin of foreign production | 4…10…40…80…150…300 | 0,5…2…7…13…16…22 |

| Manganin MNMts 3-12 | 273…573 | 22…36 |

| Cupronickel MNZHMts 30-0.8-1 | 300 | 30 |

| Nickel silver | 300…400…500…600…700 | 23…31…39…45…49 |

| Brass | ||

| Automatic brass UNS C36000 | 300 | 115 |

| L62 | 300…600…900 | 110…160…200 |

| L68 deformed brass | 80…150…300…900 | 71…84…110…120 |

| L80 semi-tompak | 300…600…900 | 110…120…140 |

| L90 | 273…373…473…573…673…773…873 | 114…126…142…157…175…188…203 |

| L96 tombak drawn | 300…400…500…600…700…800 | 244…245…246…250…255…260 |

| LAN59-3-2 aluminum-nickel brass | 300…600…900 | 84…120…150 |

| LMC58-2 manganese brass | 300…600…900 | 70…100…120 |

| LO62-1 tin | 300 | 99 |

| LO70-1 tin | 300…600 | 92…140 |

| LS59-1 annealed brass | 4…10…20…40…80…300 | 3,4…10…19…34…54…120 |

| LS59-1V leaded brass | 300…600…900 | 110…140…180 |

| LTO90-1 tombak tin | 300…400…500…600…700…800…900 | 124…141…157…174…194…209…222 |

| Bronze | ||

| BrA5 | 300…400…500…600…700…800…900 | 105…114…124…133…141…148…153 |

| BrA7 | 300…400…500…600…700…800…900 | 97…105…114…122…129…135…141 |

| BrAZhMC10-3-1.5 | 300…600…800 | 59…77…84 |

| BrAZHN10-4-4 | 300…400…500 | 75…87…97 |

| BrAZHN11-6-6 | 300…400…500…600…700…800 | 64…71…77…82…87…94 |

| BrB2, annealed at 573K | 4…10…20…40…80 | 2,3…5…11…21…37 |

| BrKd | 293 | 340 |

| BrKMTs3-1 | 300…400…500…600…700 | 42…50…55…54…54 |

| BrMC-5 | 300…400…500…600…700 | 94…103…112…122…127 |

| BrMTsS8-20 | 300…400…500…600…700…800…900 | 32…37…43…46…49…51…53 |

| BrO10 | 300…400…500 | 48…52…56 |

| BrOS10-10 | 300…400…600…800 | 45…51…61…67 |

| BrOS5-25 | 300…400…500…600…700…800…900 | 58…64…71…77…80…83…85 |

| BrOF10-1 | 300…400…500…600…700…800…900 | 34…38…43…46…49…51…52 |

| BrOTs10-2 | 300…400…500…600…700…800…900 | 55…56…63…68…72…75…77 |

| BrOTs4-3 | 300…400…500…600…700…800…900 | 84…93…101…108…114…120…124 |

| BrOTs6-6-3 | 300…400…500…600…700…800…900 | 64…71…77…82…87…91…93 |

| BrOTs8-4 | 300…400…500…600…700…800…900 | 68…77…83…88…93…96…100 |

| Aluminum bronze | 300 | 56 |

| Aged beryllium bronze | 20…80…150…300 | 18…65…110…170 |

| Manganese bronze | 300 | 9,6 |

| Production leaded bronze | 300 | 26 |

| Phosphor bronze 10% | 300 | 50 |

| Phosphor bronze annealed | 20…80…150…300 | 6…20…77…190 |

| Chromium bronze UNS C18200 | 300 | 171 |

Note: Temperatures in the table are given in degrees Kelvin!

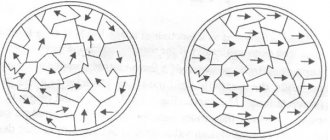

Convection in liquids and gases

Heat transfer in fluids occurs through the process of convection. This process involves the movement of molecules of a substance between zones with different temperatures, that is, during convection, mixing of a liquid or gas occurs. When fluid matter gives off heat, its molecules lose some of their kinetic energy, and the matter becomes denser. On the contrary, when fluid matter heats up, its molecules increase their kinetic energy, their movement becomes more intense, accordingly, the volume of matter increases and density decreases. That is why cold layers of matter tend to fall down under the influence of gravity, and hot layers try to rise up. This process causes the matter to mix, facilitating the transfer of heat between its layers.

We recommend: Inverter for a heating boiler: the most detailed instructions for choosing a voltage converter 12 V to 220 V, review of the best models for gas and solid fuel boilers, characteristics and prices

Factors affecting thermal conductivity

The thermal conductivity coefficient of a material depends on several factors:

- As this indicator increases, the interaction between material particles becomes stronger. Accordingly, they will transmit temperature faster. This means that as the density of the material increases, heat transfer improves.

- Porosity of a substance. Porous materials are heterogeneous in their structure. There is a large amount of air inside them. This means that it will be difficult for molecules and other particles to move thermal energy. Accordingly, the thermal conductivity coefficient increases.

- Humidity also affects thermal conductivity. Wet surfaces of the material transmit more heat. Some tables even indicate the calculated thermal conductivity coefficient of the material in three states: dry, medium (normal) and wet.

When choosing a material for insulating rooms, it is also important to take into account the conditions in which it will be used.

Material temperature

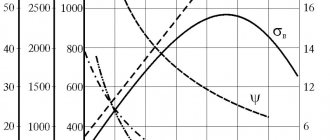

The effect of temperature on the ability to conduct heat differs for metals and nonmetals.

In metals, conductivity is mainly due to free electrons. According to the Wiedemann-Franz law, the thermal conductivity of a metal is proportional to the product of the absolute temperature, expressed in Kelvin, and its electrical conductivity. In pure metals, electrical conductivity decreases with increasing temperature, so thermal conductivity remains approximately constant. In the case of alloys, electrical conductivity changes little with increasing temperature, so the thermal conductivity of alloys increases in proportion to temperature. On the other hand, heat transfer in nonmetals is mainly associated with lattice vibrations and the exchange of lattice phonons. With the exception of high-quality crystals and low temperatures, the path of phonons in the lattice does not decrease significantly at high temperatures, and therefore the thermal conductivity remains constant over the entire temperature range, that is, it is insignificant. At temperatures below the Debye temperature, the ability of nonmetals to conduct heat, along with their heat capacity, decreases significantly.

Phase transitions and structure

When a material undergoes a first-order phase transition, for example from a solid to a liquid or from a liquid to a gas, its thermal conductivity may change. A striking example of such a change is the difference between this physical quantity for ice (2.18 W/(m*K) and water (0.90 W/(m*K).

Changes in the crystal structure of materials also affect thermal conductivity, which is explained by the anisotropic properties of various allotropic modifications of a substance of the same composition. Anisotropy affects different scattering intensities of lattice phonons, the main heat carriers in nonmetals, and in different directions in the crystal. A striking example here is sapphire, whose conductivity varies from 32 to 35 W/(m*K) depending on the direction.

Electrical conductivity

Thermal conductivity in metals changes along with electrical conductivity according to the Wiedemann-Franz law. This is due to the fact that valence electrons, moving freely throughout the crystal lattice of the metal, transfer not only electrical, but also thermal energy. For other materials, the correlation between these types of conductivity is not pronounced, due to the insignificant contribution of the electronic component to thermal conductivity (in nonmetals, lattice phonons play the main role in the mechanism of heat transfer).

Convection process

Air and other gases are, as a rule, good heat insulators in the absence of convection. This principle is the basis for the operation of many heat-insulating materials containing a large number of small voids and pores. This structure does not allow convection to spread over long distances. Examples of such man-made materials are polystyrene and silicide airgel. In nature, heat insulators such as animal skin and bird plumage work on the same principle.

Light gases such as hydrogen and gel have high thermal conductivities, while heavy gases such as argon, xenon and radon are poor conductors of heat. For example, argon, an inert gas that is heavier than air, is often used as an insulating gas filler in double-glazed windows and light bulbs. An exception is sulfur hexafluoride (SF6 gas), which is a heavy gas and has a relatively high thermal conductivity due to its high heat capacity.

Table of thermal conductivity of thermal insulation materials

To make it easier to keep your house warm in winter and cool in summer, the thermal conductivity of walls, floors and roofs must be at least a certain figure, which is calculated for each region. The composition of the “pie” of walls, floor and ceiling, the thickness of the materials are taken into account so that the total figure is no less (or better yet, at least a little more) recommended for your region.

Heat transfer coefficient of modern building materials for enclosing structures

When choosing materials, it is necessary to take into account that some of them (not all) conduct heat much better in conditions of high humidity. If such a situation may occur for a long period of time during operation, the thermal conductivity for this condition is used in the calculations. The thermal conductivity coefficients of the main materials used for insulation are given in the table.

Name of material /Thermal conductivity coefficient W/(m °C)

| Dry | At normal humidity | At high humidity | |

| Woolen felt | 0,036-0,041 | 0,038-0,044 | 0,044-0,050 |

| Stone mineral wool 25-50 kg/m3 | 0,036 | 0,042 | 0,,045 |

| Stone mineral wool 40-60 kg/m3 | 0,035 | 0,041 | 0,044 |

| Stone mineral wool 80-125 kg/m3 | 0,036 | 0,042 | 0,045 |

| Stone mineral wool 140-175 kg/m3 | 0,037 | 0,043 | 0,0456 |

| Stone mineral wool 180 kg/m3 | 0,038 | 0,045 | 0,048 |

| Glass wool 15 kg/m3 | 0,046 | 0,049 | 0,055 |

| Glass wool 17 kg/m3 | 0,044 | 0,047 | 0,053 |

| Glass wool 20 kg/m3 | 0,04 | 0,043 | 0,048 |

| Glass wool 30 kg/m3 | 0,04 | 0,042 | 0,046 |

| Glass wool 35 kg/m3 | 0,039 | 0,041 | 0,046 |

| Glass wool 45 kg/m3 | 0,039 | 0,041 | 0,045 |

| Glass wool 60 kg/m3 | 0,038 | 0,040 | 0,045 |

| Glass wool 75 kg/m3 | 0,04 | 0,042 | 0,047 |

| Glass wool 85 kg/m3 | 0,044 | 0,046 | 0,050 |

| Expanded polystyrene (foam plastic, EPS) | 0,036-0,041 | 0,038-0,044 | 0,044-0,050 |

| Extruded polystyrene foam (EPS, XPS) | 0,029 | 0,030 | 0,031 |

| Foam concrete, aerated concrete with cement mortar, 600 kg/m3 | 0,14 | 0,22 | 0,26 |

| Foam concrete, aerated concrete with cement mortar, 400 kg/m3 | 0,11 | 0,14 | 0,15 |

| Foam concrete, aerated concrete with lime mortar, 600 kg/m3 | 0,15 | 0,28 | 0,34 |

| Foam concrete, aerated concrete with lime mortar, 400 kg/m3 | 0,13 | 0,22 | 0,28 |

| Foam glass, crumbs, 100 - 150 kg/m3 | 0,043-0,06 | ||

| Foam glass, crumbs, 151 - 200 kg/m3 | 0,06-0,063 | ||

| Foam glass, crumbs, 201 - 250 kg/m3 | 0,066-0,073 | ||

| Foam glass, crumbs, 251 - 400 kg/m3 | 0,085-0,1 | ||

| Foam block 100 - 120 kg/m3 | 0,043-0,045 | ||

| Foam block 121-170 kg/m3 | 0,05-0,062 | ||

| Foam block 171 - 220 kg/m3 | 0,057-0,063 | ||

| Foam block 221 - 270 kg/m3 | 0,073 | ||

| Ecowool | 0,037-0,042 | ||

| Polyurethane foam (PPU) 40 kg/m3 | 0,029 | 0,031 | 0,05 |

| Polyurethane foam (PPU) 60 kg/m3 | 0,035 | 0,036 | 0,041 |

| Polyurethane foam (PPU) 80 kg/m3 | 0,041 | 0,042 | 0,04 |

| Cross-linked polyethylene foam | 0,031-0,038 | ||

| Vacuum | |||

| Air +27°C. 1 atm | 0,026 | ||

| Xenon | 0,0057 | ||

| Argon | 0,0177 | ||

| Airgel (Aspen aerogels) | 0,014-0,021 | ||

| Slag | 0,05 | ||

| Vermiculite | 0,064-0,074 | ||

| Foam rubber | 0,033 | ||

| Cork sheets 220 kg/m3 | 0,035 | ||

| Cork sheets 260 kg/m3 | 0,05 | ||

| Basalt mats, canvases | 0,03-0,04 | ||

| Tow | 0,05 | ||

| Perlite, 200 kg/m3 | 0,05 | ||

| Expanded perlite, 100 kg/m3 | 0,06 | ||

| Linen insulating boards, 250 kg/m3 | 0,054 | ||

| Polystyrene concrete, 150-500 kg/m3 | 0,052-0,145 | ||

| Granulated cork, 45 kg/m3 | 0,038 | ||

| Mineral cork on a bitumen basis, 270-350 kg/m3 | 0,076-0,096 | ||

| Cork flooring, 540 kg/m3 | 0,078 | ||

| Technical cork, 50 kg/m3 | 0,037 |

We recommend: Safety valve for a water heater: why is it needed, how to install

Some of the information is taken from standards that prescribe the characteristics of certain materials (SNiP, SP, SNiP II-3-79* (Appendix 2)). Those materials that are not specified in the standards are found on the manufacturers' websites. Since there are no standards, they can differ significantly from different manufacturers, so when purchasing, pay attention to the characteristics of each material you purchase.

Thermal conductivity values for various materials

You can compare how much a particular material can transmit heat using this table:

| Material | Thermal conductivity [W/(m K)] |

| Polyurethane foam | 0,025 — 0,045 |

| Air | 0,03 |

| Mineral wool | 0,031 — 0,045 |

| Expanded polystyrene | 0,032 — 0,045 |

| Felt, mats and mineral wool slabs | 0,042 — 0,045 |

| Tree | 0.16 - 0.3 (pine and spruce), 0.22 - 0.4 (oak) |

| Brick | 0,15 – 1,31 |

| Portland cement | 0,29 |

| Water | 0,6 |

| Plain concrete | 1 — 1,7 |

| Reinforced concrete | 1,7 |

| Glass | 0,8 |

| Wired glass | 1,15 |

| Polyester resin | 0,19 |

| Gypsum plaster | 0,4 — 0,57 |

| Marble | 2,07 – 2,94 |

| Stainless steel | 17 |

| Cast iron | 50 |

Application of thermal conductivity in practice

In construction, all materials are conventionally divided into thermal insulation and structural. Structural raw materials have the highest thermal conductivity, but it is precisely this material that is used for the construction of walls, ceilings, and other fences. According to the table of thermal conductivity of building materials, when constructing walls made of reinforced concrete, for low heat exchange with the environment, the thickness of the structure should be about 6 meters. In this case, the structure will turn out to be huge, cumbersome and will require considerable costs.

A clear example is at what thickness of different materials their thermal conductivity coefficient will be the same

Therefore, when constructing a building, special attention should be paid to additional heat-insulating materials. A layer of thermal insulation may not be needed only for buildings made of wood or foam concrete, but even when using such low-conductivity raw materials, the thickness of the structure must be at least 50 cm.

Need to know! Thermal insulation materials have minimal thermal conductivity values.

Application of thermal conductivity coefficient in construction

There is one simple rule in construction - the thermal conductivity coefficients of insulating materials should be as low as possible. This is because the lower the value of λ (lambda), the smaller the thickness of the insulating layer can be made to ensure a specific value of the heat transfer coefficient through walls or partitions.

Currently, manufacturers of thermal insulation materials (expanded polystyrene, graphite boards or mineral wool) seek to minimize the thickness of the product by reducing the coefficient λ (lambda), for example, for polystyrene it is 0.032-0.045 compared to 0.15-1.31 for brick.

As for building materials, the thermal conductivity coefficient is not so important in their production, but in recent years there has been a trend towards the production of building materials with a low λ value (for example, ceramic blocks, structural insulating panels, cellular concrete blocks). Such materials make it possible to build a single-layer wall (without insulation) or with the minimum possible thickness of the insulation layer.

Important: the thermal conductivity coefficient lambda depends on the density of the material, so when purchasing, for example, polystyrene foam, pay attention to the weight of the product. If the weight is too low, then the slabs do not have the declared thermal insulation. We add that the manufacturer is required to indicate the declared value of the thermal conductivity coefficient on each package.

What building material is the warmest?

Currently, these are polyurethane foam (PPU) and its derivatives, as well as mineral (basalt, stone) wool. They have already proven themselves as effective heat insulators and today are widely used in home insulation.

To illustrate how effective these materials are, we will show you the following illustration. It shows what thickness of material is enough to retain heat in the wall of the house:

What about air and gaseous substances? - you ask. After all, their Lambda coefficient is even lower? This is true, but if we are dealing with gases and liquids, in addition to thermal conductivity, we must also take into account the movement of heat inside them - that is, convection (the continuous movement of air, when warmer air rises and colder air descends).

A similar phenomenon occurs in porous materials, which is why they have higher thermal conductivity values than solid materials. The thing is that small particles of gas (air, carbon dioxide) are hidden in the voids of such materials. Although this can happen with other materials - if the air pores in them are too large, convection may also begin to occur in them.

When is the thermal conductivity coefficient taken into account?

Thermal conductivity parameters must be taken into account when choosing materials for enclosing structures - walls, ceilings, etc. In rooms where the walls are made of materials with high thermal conductivity, it will be quite cool in the cold season. Decorating the room won't help either. In order to avoid this, the walls must be made quite thick. This will certainly lead to increased costs for materials and labor.

Insulation scheme for a wooden house

That is why the construction of the walls requires the use of materials with low thermal conductivity (mineral wool, polystyrene foam, etc.).

Thermal conductivity coefficient of building materials: how it is used in practice and table

The practical value of the coefficient is a correctly carried out calculation of the thickness of the supporting structures, taking into account the insulation materials used. It should be noted that the building under construction consists of several enclosing structures through which heat leaks. And each of them has its own percentage of heat loss.

- Up to 30% of the total thermal energy goes through the walls.

- Through floors – 10%.

- Through windows and doors – 20%.

- Through the roof - 30%.

Heat loss at home

That is, it turns out that if the thermal conductivity of all fences is incorrectly calculated, then people living in such a house will have to be content with only 10% of the thermal energy that the heating system emits. 90% is, as they say, money thrown away.

“The ideal house should be built from thermal insulation materials, in which 100% of the heat will remain inside. But according to the table of thermal conductivity of materials and insulation materials, you will not find the ideal building material from which such a structure could be erected. Because the porous structure means low load-bearing capacity of the structure. Wood may be an exception, but it is not ideal either.”

A log wall is one of the most insulated

Therefore, when building houses, they try to use different building materials that complement each other in thermal conductivity. In this case, it is very important to correlate the thickness of each element in the overall building structure. In this regard, a frame house can be considered an ideal house. It has a wooden base, we can already talk about a warm house, and insulation that is laid between the elements of the frame building. Of course, taking into account the average temperature of the region, it will be necessary to accurately calculate the thickness of the walls and other enclosing elements. But, as practice shows, the changes being made are not so significant that we can talk about large capital investments.

Construction of a frame house in terms of its insulation

Let's look at several commonly used building materials and compare their thermal conductivity by thickness.

Thermal conductivity of brick: table by variety

PhotoType of brickThermal conductivity, W/m*K

| Ceramic solid | 0,5-0,8 |

| Ceramic slotted | 0,34-0,43 |

| Porous | 0,22 |

| Silicate solid | 0,7-0,8 |

| Silicate slotted | 0,4 |

| Clinker | 0,8-0,9 |

Thermal conductivity of brickwork at a temperature difference of 10°C

Thermal conductivity of wood: table by species

Wood speciesBirchOak across the grainOak along the grainSpruceCedarMapleLarch

| Thermal conductivity, W/m C | 0,15 | 0,2 | 0,4 | 0,11 | 0,095 | 0,19 | 0,13 |

Wood species Linden Fir Cork Pine across the grain Pine along the grain Poplar

| Thermal conductivity, W/m C | 0,15 | 0,15 | 0,045 | 0,15 | 0,4 | 0,17 |

We recommend: Thermocouple for a gas boiler: detailed instructions on the design and principle of operation, checking the serviceability of the thermoelectric sensor with a multimeter, restoration and replacement

The thermal conductivity coefficient of balsa wood is the lowest of all wood species. It is cork that is often used as a heat-insulating material when carrying out insulation measures.

Wood has a lower thermal conductivity than concrete and brick

Table of thermal conductivity of concrete

Concrete in its various variations is the most common building material today, although it is not the “warmest”. In construction, a distinction is made between structural and thermal insulating concrete. The former are used to build foundations and critical components of buildings with subsequent insulation, while the latter are used to build walls. Depending on the region, either additional insulation is applied to them or not.

Comparative table of thermal insulation concrete and thermal conductivity of various wall materials

Aerated concrete is considered the most “warm” and durable. Although this is not entirely true. If you compare the structure of foam blocks and aerated concrete, you can see significant differences. In the first, the pores are closed, while in gas silicates, most of them are open, as if “torn.” This is why in windy weather an uninsulated house made of aerated blocks is very cold. The same reason makes such lightweight concrete more susceptible to moisture.

Thermal conductivity of metals: table

This indicator for metals changes with the temperature at which they are used. And here the relationship is this: the higher the temperature, the lower the coefficient. The table shows the metals that are used in the construction industry.

Type of metalSteelCast ironAluminumCopper

| Thermal conductivity, W/m C | 47 | 62 | 236 | 328 |

Now, as for the relationship with temperature.

- Aluminum at a temperature of -100°C has a thermal conductivity of 245 W/m*K. And at a temperature of 0°C – 238. At +100°C – 230, at +700°C – 0.9.

- For copper: at -100°C –405, at 0°C – 385, at +100°C – 380, and at +700°C – 350.

The thermal conductivity of copper is almost seven times higher than that of steel

Thermal conductivity table for other materials

We will be mainly interested in the table of thermal conductivity of insulating materials. It should be noted that if for metals this parameter depends on temperature, then for insulation it depends on their density. Therefore, the table will display indicators taking into account the density of the material.

Thermal insulation material Density, kg/m³ Thermal conductivity, W/m*K

| Mineral wool (basalt) | 50 | 0,048 |

| 100 | 0,056 | |

| 200 | 0,07 | |

| Glass wool | 155 | 0,041 |

| 200 | 0,044 | |

| Expanded polystyrene | 40 | 0,038 |

| 100 | 0,041 | |

| 150 | 0,05 | |

| Extruded polystyrene foam | 33 | 0,031 |

| Polyurethane foam | 32 | 0,023 |

| 40 | 0,029 | |

| 60 | 0,035 | |

| 80 | 0,041 |

And a table of thermal insulation properties of building materials. The main ones have already been discussed; let us designate those that are not included in the tables and that belong to the category of frequently used ones.

Building material Density, kg/m³ Thermal conductivity, W/m*K

| Concrete | 2400 | 1,51 |

| Reinforced concrete | 2500 | 1,69 |

| Expanded clay concrete | 500 | 0,14 |

| Expanded clay concrete | 1800 | 0,66 |

| Foam concrete | 300 | 0,08 |

| Foam glass | 400 | 0,11 |

What is the thermal conductivity coefficient of the air gap?

In construction, windproof air layers are often used, which only increase the heat conductivity of the entire building. Also, such vents are necessary to remove moisture outside. Particular attention is paid to the design of such layers in foam concrete buildings for various purposes. Such layers also have their own thermal conductivity coefficient depending on their thickness.

Table of heat conductivity of air layers

What does thermal conductivity depend on?

So, as we have already seen, the thermal conductivity coefficient λ (lambda) characterizes the intensity of heat transfer through a specific material.

For example, metals are the most thermally conductive, and gases are the weakest. All conductors of electricity, such as copper, aluminum, gold or silver, also transmit heat well, while electrical insulators (wood, plastic, rubber), on the contrary, retain it.

What can affect this indicator, besides the material itself? For example, temperature. The thermal conductivity of insulating materials increases with increasing temperature, while for metals, on the contrary, it decreases. The presence of impurities may also affect it. Dissimilar metal alloys generally have lower thermal conductivities than their alloying elements.

In general, the thermal conductivity of substances depends mainly on their structure, porosity, and, above all, on their density. Therefore, if a manufacturer claims a low lambda value at a low material density, this information, as a rule, has nothing to do with reality and is simply a publicity stunt.

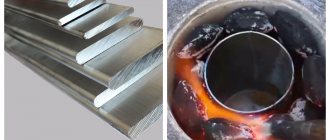

Disadvantages of the high thermal conductivity of copper and its alloys

Copper has a much higher value than aluminum or brass. But meanwhile, this material has a number of disadvantages that are associated with its positive aspects. The high thermal conductivity of this metal forces the creation of special conditions for its processing. That is, copper billets must be heated more accurately than steel. In addition, there is often pre- or auxiliary heating before starting treatment. We must not forget that pipes made of copper imply that careful thermal insulation will be carried out. This is especially true for those cases when the heating supply system is assembled from these pipes. This significantly increases the cost of installation work. Certain difficulties arise when using gas welding. To get the job done, a more powerful tool is required. Sometimes, to process copper with a thickness of 8 - 10 mm, it may be necessary to use two or even three torches. In this case, one of them welds the copper pipe, and the rest are busy heating it. In addition, working with copper requires more consumables.

Working with copper requires the use of specialized tools. For example, when cutting parts made of bronze or brass with a thickness of 150 mm, you will need a cutter that can work with steel with a large amount of chrome. If it is used for processing copper, then the maximum thickness will not exceed 50 mm.