Types of jobs

Experts distinguish two riveting technologies - hot and cold. Each of them is used in different situations.

Hot riveting

Before connecting the parts, the rod of the fastener is heated. The craftsman determines the heating temperature by color - the metal must be red-hot. Rods with a thickness of 8 mm or more are suitable for hot riveting.

Cold riveting

Standard technology used in different situations. More often, cold riveting is carried out at home, in small workshops for the manufacture of products that will not be subject to heavy loads. To perform this, rods with a thickness of no more than 8 mm are used.

Sheet of metal with rivets

Types of rivets

Types of rivets for metal:

- Semi-tubular. They have a low strength rating, but are easy to install. Suitable for connections that will not be subject to heavy mechanical stress.

- Piston. Made from soft metals, easy to install. Designed for simple connections.

- Exhaust, mortgages. Consist of two parts. Easy to install.

- Standard. Suitable for creating different types of seams.

Another type is nut or threaded. Suitable for fastening parts with thin walls.

Riveting

Riveting is the production of permanent connections using rivets used in the manufacture of metal structures (trusses, beams, various types of containers and frame structures). A rivet is a cylindrical rod made of ductile metal, at one end of which there is a head, called an embed. During the riveting operation, a second rivet head is formed on the second side of the rod installed in the holes of the workpieces being connected, which is called the closing head. The mortgage and closing heads are mainly semicircular and countersunk (Fig. 5.14). The need to use ductile metal for the manufacture of rivets is due to the fact that its heads are formed as a result of plastic deformation of the rivet rod. When making riveted joints, the rivets should be selected from the same material from which the parts to be joined are made. This prevents the appearance of galvanic couples, leading to corrosion at the point of contact between the rivet and the part. The riveting process consists of two stages - preparatory and riveting itself.

The riveting preparation process involves drilling or punching a hole for the rivet and forming a recess in it using countersinking for the rivet and closing heads, if necessary. The actual riveting includes installing the rivet into the prepared hole, tensioning the riveted workpieces, forming the closing head, and cleaning up after riveting. Depending on the nature of the rivet joint, riveting is performed in a cold (without heating) and hot (with preheating of the rivet to a temperature of 1000 ... 1,100 ° C) method. In practice, hot riveting is used in cases where steel rivets with a diameter greater than 12 mm are used.

Types of cores and filling heads

Based on the type of shank, rivets are:

- Hollow. Inside the rod there is a free cylindrical cavity. They do not withstand high loads, but are easily riveted.

- Semi-hollow. In the area of the mounting head the rod is solid.

- Solid rod. Rivets are difficult to install, but they can withstand high loads.

Possible types of heads are conical, cylindrical, semicircular.

Rivets for metal (Photo: Instagram / stroimarket_erme)

Types of seams

Types of riveting seams:

- Lasting. It is used if you need to obtain a high-strength connection. The finished part will be subject to heavy loads during operation.

- Dense. They are used in the manufacture of sealed containers for storing or pumping liquids. Withstands slight pressure.

- Durably dense. They are used in the assembly of metal structures and products that will be subject to high pressure.

Depending on the location of the fasteners, the seams can be multi-row, double-row, or single-row.

Types of rivets and rivet seams

The types of rivets with a semicircular and countersunk head are most often used during installation work. Due to the fact that rivets with a countersunk head do not firmly connect the parts at the riveting site, their use is limited. This type of rivet is used only in cases where, according to the operating conditions of the structure, their heads should not protrude above its surface. Depending on the purpose and operating conditions, it is possible to use rivets with other head shapes (Fig. 5.15).

The choice of rivet sizes depends on the thickness of the parts being riveted. The diameter of the rivet should, as a rule, be equal to the total thickness of the parts being connected. The length of the rivet rod is determined taking into account the formation of the closing head, the shrinkage of the rod during the riveting process and the need to fill the gap between the rivet rod and the wall or the hole for it.

Let's consider the procedure for determining the length of the shank of rivets with countersunk (see Fig. 5.14, a) and semicircular (see Fig. 5.14, b) heads. In both cases, the length of the rivet / is determined based on the thickness of the parts being riveted S and the length /0 of the part of the rivet rod protruding from the hole above the surface of the parts to be joined. The length of the protruding part of the rod depends on the diameter of the rivet and the shape of the closing head. For rivets with a semicircular head 10 = (1.2... 1.5)d, for rivets with a countersunk head 10 = (0.8... ,2)d.

To ensure free but sufficiently tight installation of the rivet, the diameter of the hole should be slightly larger than the diameter of the rivet:

Rivet diameter, mm 2.0 2.3 2.6 3.0 3.5 4.0 5.0 6.0 7.0 8.0

Drill diameter, mm:

precise assembly... 2.1 2.4 2.7 3.1 3.6 4.1 5.2 6.2 7.2 8.2

rough assembly... 2.3 2.6 3.1 3.5 4.0 4.5 5.7 6.7 7.7 8.7

In cases where it is impossible to form a closing head in the connection, explosive rivets are used (Fig. 5.15, f). Such a rivet, filled with an explosive, is installed in the hole of the parts being connected and pressed down with light blows of a hammer in a cold state. After this, it is heated from the side of the rivet head with some kind of heating device (for example, a soldering iron), as a result of which the substance placed in the rivet rod explodes and its end expands, forming a closing head.

To connect thin metal sheets and parts made of non-metallic materials, tubular rivets are used (Fig. 5.15, g), the closing head of which is formed by flaring.

The place where parts are joined using rivets is called a rivet seam. Depending on the nature of the connection and its purpose, rivet seams are divided into three types: strong, dense and durable.

A strong seam is used in cases where it is necessary to obtain a connection of increased strength. As a rule, these are connections in various load-bearing structures: beams, columns, lifting structures and other similar structures.

A tight seam is used for riveting tanks and vessels for liquids, pipe connections for transporting gases and liquids under low pressure.

A strong-tight seam is used to connect parts in devices and structures operating under high pressure, for example in steam boilers.

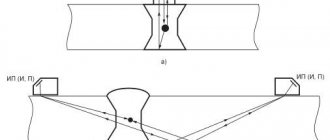

According to the relative position of the connection parts, two types of seams are distinguished : butt and overlap (Fig. 5.16, a). The parts are connected end-to-end using overlays. The connection uses one (Fig. 5.16, b) or two (Fig. 5.16, c) pads. Rivets for any type of connection can be arranged in one, two, three or more rows. Depending on the number of rows of rivets in the connection, single-, double- and multi-row rivet connections are distinguished (Fig. 5.17).

The distance between the rivets in the connection is selected depending on the type of connection (single-row or double-row). In single-row seams, the distance between the axes of the rivets (pitch) must be equal to three diameters of the rivet, and the distance from the edge of the parts being joined to the axes of the rivets in the connection must be at least one and a half diameters. When making double-row seams, this distance should accordingly be equal to four rivet diameters and one and a half, as in a single-row connection. The distance between rows of rivets in such connections should be two diameters.

Principles for choosing rivet sizes

You need to choose rivets for connecting metal parts depending on the thickness of the sheets being joined. In this case, you need to take into account the diameter of the rod.

To determine the required diameter of the fastener, you need to double the thickness of the metal blanks that will be connected. The length of the rod should not be less than 2 diameters.

Standard size ranges:

- diameter - 1–36 mm;

- length - 2–180 mm.

The opinion that the larger the diameter, the higher the strength, is erroneous. The strength indicator depends on the material of the rivet.

Riveters and riveter (Photo: Instagram / suburbblues)

Metal rivets

In what cases do specialists use rivet joints? This type of fastening is used when metal parts are difficult to weld or the assembly unit will be actively used during operation and subject to loads.

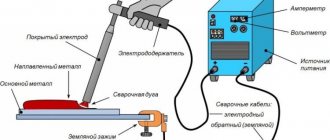

Riveting. Basic Concepts

The process by which elements are connected is called riveting. This process can be divided into two stages: preparatory and riveting.

Riveting is the installation of rivets into a pre-prepared hole, tensioning the workpieces, creating a closing head and final cleaning.

Rivets

The riveting process is carried out using rivets made of mild steel and representing rods in the form of cylinders with two heads. One of these heads is a mounting head, and the other is a closing head, providing fastening of parts.

Riveted connections are classified into the following categories:

- durable (designed for rigid connection under power loads);

- tight (designed for tanks with low pressure, where complete tightness is necessary);

- durable and dense.

Currently, the quality of metal products, as well as their chemical composition, can be thoroughly examined through modern and multidisciplinary (see variety of options) Metal and alloy analyzers

For the sake of a hermetic joint, the joining surface area is treated with a reliable sealant. There are three types of riveting :

- cold,

- hot,

- mixed.

Mortgage heads have different shapes. There are two methods for forming a closing head: direct and reverse.

The direct method involves striking from the side of the closing head and pressing firmly, which is necessary for a tighter joint of the parts.

The reverse method involves striking from the side of the closing head; reliable connection of several surfaces occurs simultaneously with the formation of a closing head.

Riveting technology

For manual riveting, a special tool is used: a sledgehammer, a special pneumatic hammer. Although in recent years, riveting presses have increasingly begun to be used to increase productivity.

Basic tools:

- crimping (mandrel, punch);

- hammer;

- anvil - support.

Advantages of riveted joints

Blocks the formation of fatigue cracks, which increases the reliability of the product. Using riveted joints, it is possible to join materials that are difficult to weld or cannot be welded at all.

Disadvantages of rivet joints

Riveting work is a rather labor-intensive process that requires special skills from a specialist. You can also add to the disadvantages: noise and vibration during operation, ensuring tightness, and the material consumption of the connection.

Voltages allowed in connections

There are indicators of stress tolerance for the material of the rivet itself and the parts.

Under variable loads, the permissible stresses are reduced by 11 - 26%, and with cold riveting - by 30%.

Hand rivets

One of the simplest and most actively used types of rivets, most often used for those connections that will not be disassembled in the future.

Riveting process:

- A hole is created where the rivet is placed.

- The recess houses the head of the rivet.

- Using a hammer, the surfaces are pressed tightly.

- The second head is flared with circular blows of the tool, giving the desired shape.

Types of rivets (by head shape):

- with a convex head. Diameter 1-36 mm; length 2-180 mm.

- with a hidden head. Diameter 1-36 mm; length 2-180 mm.

Types of work : fastening visible plates, thin sheets of metal, etc.

Stages of work

Stages:

- Preparation of parts to be joined.

- Marking holes.

- Drilling holes.

- Countersinking of finished nests.

- Installation of fasteners.

- Crimping

Before starting the main stages of work, you must:

- Clean surfaces from plaque, dirt, and rust.

- Mark the locations of future holes. Before drilling, they need to be marked so that the drill does not go to the side.

Preparation of metal structures (Photo: Instagram / start_blasting)

Drilling holes

You can drill holes in metal surfaces using a drill press or hand-held power tool. It is better to use a drill press because it can drill holes in thicker parts.

When using a hand-held power tool, it is important to accurately control its position when drilling so that it does not deviate to the sides. When drilling, it is necessary to use special coolants. You can only work with a sharpened drill.

Inserting rivets

Stages:

- The fastening element is inserted into the hole with the rod from bottom to top.

- A support is installed under the embedding head. If it is hidden, it is necessary to use flat support.

- The parts are compacted. They are seated at the riveting site. Gaps between metal sheets are eliminated with a hammer.

Formation of the closing head

How to do it:

- Direct method. Hammer blows are applied to the rivet shaft from the side where the closing head is formed.

- Reverse method. The hammer blows are applied to the mortgage head.

Bench hammers (Photo: Instagram / inforce_tools)

Pereosnastka.ru

Manual and mechanized riveting techniques

TO

category:

Riveting

Manual and mechanized riveting techniques

Depending on the conditions for the formation of the closing head, two riveting methods are distinguished: direct and reverse. With a free approach to the rivet from both sides, a direct (or open) riveting method is used, in which blows are applied from the side of the rod; The mounting head rests against the support (Fig. 1,a).

Recommendations

If the installation of rivets on metal is performed by a beginner, a person without practical experience, he may make various mistakes. Defects and their causes:

- The closing head does not adhere tightly to the metal surface. Distortion during crimping.

- The heads are shifted in one or different directions. The holes were drilled with a slight slope.

- The closing head has ragged edges. Low-quality material was used to manufacture the fastening element.

- The head is shifted to the side. The rod is uneven or longer than required.

When carrying out work, you must adhere to safety rules:

- The pneumatic tool cannot be used until the adjustment is completed. It will be difficult to hold the crimp with your hands due to the powerful pneumatic shock. This may cause hand injuries.

- When riveting, sharp, loud sounds are heard that negatively affect the nervous system and hearing. You need to use thick headphones.

- The tool must be checked before starting work. It must be in good working order. The desktop should not be cluttered with unnecessary objects or tools.

- The parts to be fastened should be fixed in a vice.

There are often situations when it is necessary to first remove old fasteners and then reattach the part to the same place. A sharp chisel can be used to remove the round head of the rivet. The remaining fasteners must be knocked out with a punch.

When riveting metal, you must use protective gloves and goggles. The parts should be secured in a vice or console so that they do not move. When working, do not touch the crimp with your hands. Compliance with safety precautions will help to protect yourself from injuries and perform better work.

Hot riveting

Here I found (but not much): Philip Isaakovich Gringauz ( Higher School Publishing House, 1975 ) Sanitary and technical work.

There is a section: Riveting and soldering

Riveting.

Riveting is the process of joining two or more parts using rivets, which are cylindrical rods with heads. Rivets are made from mild steel. One head is called the embedded head, and the second head, which rivets at the other end of the rod and serves to fasten the parts, is called the closing head. Closing heads are made semicircular, flat and conical (countersunk). The rivet connection is permanent.

The thickness of the rivets is calculated and indicated on the drawings.

Sheet material is most often riveted with rivets up to 9-10 mm thick. To obtain a closing head, the length of the rivet shank must be equal to the thickness of the materials being riveted and the size of the protruding part. To obtain a semicircular closing head, the protruding part of the rod should be from 1.3 to 1.5 times the diameter of the rivet rod, and the conical part should be from 0.8 to 1.2 times the diameter.

Rivets in the seams are arranged in one, two, three or more rows. Depending on this, rivet seams are called single-row, double-row, etc.

In double-row and multi-row rivet seams, the rivets are arranged in parallel rows or in a checkerboard pattern.

Sheets and parts connected by a rivet seam are placed end-to-end with overlays or overlapped.

The distance between the centers of the rivets is called the rivet seam pitch. For single-row seams, the step / is taken equal to three diameters of the rivet, and the distance a - from the center of the rivet to the edge of the sheet - is 1.5 diameters with punched holes.

For a double-row seam, the pitch is taken equal to four rivet diameters. The distance between two rows of rivets should be equal to two rivet diameters.

Riveting can be cold, hot or mixed.

Cold riveting is one in which the closing head of the rivet is set in a cold state. Cold riveting is used when the thickness of the rivet rod is up to 8 mm.

Hot riveting is one in which the rivet rod is preheated to a red-hot temperature. Hot riveting is performed with a rod thickness of 8 mm or more.

Mixed riveting is usually done with long rivet shanks. The end of the rod is heated to seat the closing head.

Riveting can be manual or mechanized. Manual riveting is performed using hand and pneumatic tools, and mechanized riveting is performed using riveting machines and various presses. To rive parts manually, a mechanic's hammer, a bit, tension, crimping and support are used. The plumber's hammer is selected according to its weight according to the thickness of the seal. Bench bits are used for straightening holes for rivets, punching small holes in thin sheet steel, and knocking out a rejected rivet.

The holes in the parts to be joined must match exactly, and the rivets must be correctly selected according to the thickness and length of the rod.

To avoid bruises and injuries, the parts to be riveted must be positioned so that they do not fall during operation.