Any construction and finishing work is not complete without drilling holes of various diameters and depths for installing communication systems, ventilation, electrical wiring, interior decoration elements or hanging furniture. Almost everyone has encountered the process of creating holes in walls, however, not everyone knows how to properly drill a brick wall, what tools and technologies to use. There is nothing complicated in the process itself, if you take into account in advance the fact that brick is a fairly durable material, so to work with it you need to have some theoretical knowledge.

Drilling holes is necessary for repair work

Construction of houses

Quite often there is a need to drill holes in brick walls. However, the technology for carrying out this process directly depends on the drilling location and the size of the required hole. Let's look at how to drill a hole in a brick wall below.

Table of contents:

- Drilling holes in a brick wall: technology and methods

- Technology for punching holes in a brick wall

- Instructions for making a hole in a brick wall

Drilling holes in a brick wall: technology and methods

Most often, drilling holes in brick walls is associated with the improvement of a house or apartment whose walls are made of brick. In order to build an internal outlet or hang shelves, mirrors, or a TV, you need to make holes in the wall.

However, for installing small items such as photo frames or small paintings, a small nail is sufficient. In this case, there is no need to drill the wall.

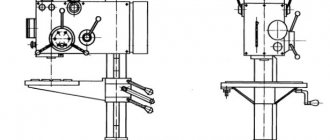

In order to drill a wall, all you need is a modern electric tool, such as an electric drill, and the skills to work with it. With the help of a special conductor, it is possible to get rid of dust generated during drilling.

In order to drill into a wall made of brick or concrete, a hammer drill is most often used. However, the cost of this tool is very high, and most often, in its absence, an impact drill is used.

When choosing this tool, special attention should be paid to its power. The drill must have a power of at least six hundred watts. At the same time, the minimum number of revolutions for an electric drill is 2500 rpm. Also, preference should be given to a device that has the ability to smoothly adjust the power. With the help of reverse mechanisms, it is possible to regulate the rotation of the drill in one direction or the other. In order for drills to be clamped efficiently and quickly inside the mechanism, you should choose a drill that has a quick clamping function.

The main quality of an electric drill that is suitable for drilling holes in a brick wall is the ability to impact drill. By turning on this function, the drill becomes completely identical to a hammer drill. The ease and speed of drilling walls increases. Since a brick wall is quite resistant to static loads, to drill it it is necessary to use a blow, which is based on a dynamic load.

If you drill a wall without the impact function, the cutting edge of the drill does not have the ability to engage the inside of the brick, so the process takes longer and is unproductive. In addition, there is a possibility of overheating of the drill and damage to the tool. Using the impact function, it is possible to knock out part of the brick and form a depression.

Holes in a brick wall photo:

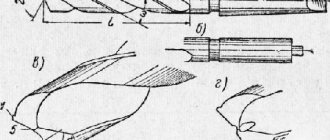

For drilling plasterboard or foam concrete walls, standard drills are sufficient. However, to drill a hole in a brick wall, you must use drills of a certain diameter and strength. First of all, the drill must be made of carbide material. Its difference from ordinary steel is that cutting carbide edges, most often pobedite or made of artificial diamond material, are welded onto the standard metal.

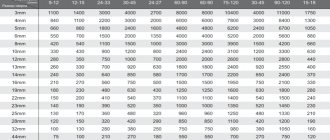

The most popular are drills with pobedite inserts at the end; the diameter of the drills is 0.6 and 0.8 cm. However, these drill options are relevant only if the depth of the hole in the brick wall does not exceed fifteen centimeters.

In order to perform through drilling, the use of a drill is recommended. The length of the drill used in the process can reach one meter. They are installed exclusively on the hammer drill. To ensure that the wear resistance of this tool remains at a high level, its edges have a rounded shape. If the drill is distinguished by the presence of an impact function, then it is also used for drilling with a drill.

When choosing a particular drill, you should be guided by the size of the hole and its depth. Most often, the diameter of the drill shanks is 1 and 1.8 cm. They have special and standard grooved clamping holes.

If there is a need for through drilling of a wall whose thickness exceeds 60 cm, then several drilling devices are used at once, having different lengths, but the same diameter. Thus, it will be possible to speed up the drilling process and the work will be done safely. For example, at first drilling is carried out using a drill about 15 cm long, the drilling depth is no more than 10 cm. Then, using a long drill, drilling continues and a hole with a depth of about 30 cm is created. At the final stage of the work, a drill whose length is used is 50 cm.

If a drill is used during the work, it must have high productivity and power. Otherwise, the use of a hammer drill is recommended.

Technology for punching holes in a brick wall

Before you start drilling any wall, including brick, you should study the location of the electrical wiring. Since getting into an electrical wire will lead not only to damage to the power supply, but also to electric shock to the person working with the hammer drill.

Initially, inspect the wall for the presence of sockets or switches on its surface. Most often, the wires are located in a vertical position. However, there are cases that to save wire, the wiring is laid in a diagonal direction.

The wires are located at a depth of no more than one centimeter, so they are quite easy to detect. Take a regular screwdriver and use it to pierce the wall at the intended location of the wire. If there are no wires at the drilling site, start working.

If you doubt the absence of wires in a given area, then use a special device that can be used to detect hidden wires. To detect copper wiring, it must be recessed into the wall no more than 1 cm. To detect an electrical wire made of aluminum, you should turn on the metal search mode.

An intermittent beep or a flashing light diode indicates that electrical wiring has been detected in the wall. Only after this, start drilling.

In order to drill into walls made of brick, it is enough to use a drill based on a Pobedit. Determine the drilling location, make a mark, if necessary, and with strong pressure on the drill, drill a hole. The rotation speed of the drill should be low, about 300. However, the impact mode must be turned on. During the drilling process, monitor the temperature of the device, as there is a risk of overheating.

Please note that during long-term drilling, the drill heats up to a certain temperature, so at the end of the work, you should not touch it with your hands. Periodically dip the drill bit into a container of water.

In order to control the depth at which drilling is carried out, special mechanisms called limiters are used. To make them, it is enough to cut off a certain part of the pipe and put it on the drill. If there is no pipe, then it is enough to wrap ordinary polyvinyl chloride tape around the drill.

How to make a hole in a brick wall

Before drilling into a brick wall, you need to check for electrical wiring. Then marking is carried out. You need to decide on the parameters of the recess. Depending on this, drills, drills or crowns will be selected.

Preparing tools

If you plan to use a drill, its power should not be less than 600 W, and the number of revolutions should be approximately 2500 or more. Make sure the equipment has a reverse function so you can adjust the power. Brick is resistant to static loads, so the equipment must have an impact option.

The material should be influenced dynamically, only then will it be possible to achieve results. This is why a household drill is not suitable for the process. If you still decide to take a risk and use such a device, you may be faced with the need to repair the drill, since its motor will certainly overheat and fail.

Preparatory work

In addition to electrical wiring, there should be no fittings in the wall. To find it, you should use a metal detector. If there is no tool to find the wiring, you need to make sure that it does not pass through the seams under the layer of plaster. To do this, before starting drilling, you need to deepen the seams a little.

A little theory

Since ancient times, people have tried to arrange their homes. And if you don’t take into account all sorts of temporary buildings like straw huts and yurts made from wild animals, the dwellings were built quite heavily. A capital wall can be called a wall that is built for a long period of time, can withstand heavy loads, be a support for ceiling or interfloor ceilings, and have a durable structure when a window or doorway is made in it.

From ancient times to this day, such walls have been either wooden or stone. By stone we can also mean a brick or concrete wall. These are simply modifications to the size and structure of the stone.

Perforator device.

Stone or brick walls can withstand loads many times greater than the safety factor of wooden structures. This is due to the hardness and strength of the material. But this same hardness also has a downside. Drilling into brick walls is a big challenge compared to drilling into wood.

Wood is a very soft material, pliable to any tool. Punching a wall from it is possible with many tools: a chainsaw, a drill, a chisel, and even an ax. Shelves and brackets for all kinds of household appliances can be attached to a wooden surface. This can be done using nails, screws, staples, push pins and other things.

The situation is different with brickwork. Here the punching will not be so easy. Both the mortar and the bricks themselves are very hard. The nail cannot be driven into them and bends, the self-tapping screw cannot cut its own thread, and the drill becomes dull. Drilling holes in a brick wall without special tools is not possible.

To drill a brick wall, use a special tool designed for working with concrete, which in most cases has a shank for attaching to a hammer drill.

There are several ways to make a hole in a brick wall, but many of them will require significant expenses if you do not do it yourself.

Drill

Special pobedit drills are the simplest and most affordable tool for drilling holes in any building materials. A standard drill with a Pobedit tip for a household drill can make through holes 150 mm deep; the length and diameter of drills for rotary hammers can be significantly higher - such large-section models are called not drills, but auger drills.

Drilling and gating of ceramic blocks

Despite the fact that houses have been built from warm ceramics for quite a long time, this wall material still remains unclear to some consumers, and many use it with caution.

In Europe, ceramic wall blocks have been successfully used for almost 10 years, but in Ukraine they still look at construction with ceramic blocks with caution.

Builders have a false impression about ceramic blocks; for example, their fragility does not inspire confidence in many craftsmen. But here you just need to know how to work with this building material.

How to make grooves in a ceramic block

The first thing that worries consumers is the cutting of ceramic blocks. Making grooves in ceramics is not difficult, because ceramic blocks are no more susceptible to impact loads than hollow ceramic bricks.

Grooving is performed using a standard wall chaser; impacts on the ceramics should be avoided. To control the material, standards have been developed - the width of the groove is allowed up to 200 mm, the depth of the groove should not exceed 30 mm.

When using power tools, you must use personal protective equipment - a respirator and special glasses. When carrying out work indoors, a construction vacuum cleaner should be connected to the wall chaser.

Working with a wall chaser is quite simple - no great physical effort is required. After working with the tool, it is necessary to remove the core from the groove made in the ceramic block. The block as a whole is not brittle, and it breaks off only in places where the tool is exposed; cracks do not form in other places in the material.

What you shouldn’t be afraid of when working with ceramic block

The second concern is that ceramics are very difficult to drill, and therefore cabinets, water heaters, etc. should be hung on such walls.

But this is not true; the attachments are attached quite tightly. To hold light hanging elements on the wall, a plastic dowel of various diameters (6, 8, 12 mm) is used; a load of up to 50 kg is allowed.

The ceramic block is drilled effortlessly and quickly enough. After drilling, the dowel can be brought down with a hammer - CERAMOBLOK is not afraid of such blows.

The chemical anchor can withstand significant weight - drilling is performed with a conventional drill, without a hammer drill. A paste-like mixture is driven into the drilled hole using a syringe, which hardens there, then any nail can be driven into it or a dowel can be installed.

You can do it another way:

- Drill a hole in the ceramic;

- Install the dowel;

- Squeeze the paste into it and immediately drive the screw into the dowel.

- The chemical anchor hardens at + 25oC for 45 minutes, at + 15oC for about an hour. The lower the temperature, the longer the paste hardens.

Hole Creation Methods

Manual. If you don't have a power tool, you can do the job using a bolt. To do this, a place is marked on the wall and the edges are punched with a punch. Place the bolt at an angle of 90 degrees to the wall and hit it with a hammer. Every three blows we turn it and remove crumbs of brick from the pipe.

Mechanical. Can be done with a hammer drill or impact drill. The hole locations are marked using a tape measure or stencil. Using a core, the center of the hole is knocked out. This is necessary so that the drill does not move during the start of drilling. The tool must be held exactly perpendicular to the wall to avoid breaking the nozzle.

Auto. Diamond drilling can only be performed using professional, expensive equipment with the proper qualifications. It can only be used with the help of specialists with their own tools. Allows you to quickly create holes at any angle, up to 0.4 m deep, with less noise, and an ideal shape without chips or cracks. The drilling process uses water to cool the bit and wash away dust, making this method the cleanest.

Brick drill: how to choose and use?

When a person is faced with the need to pick up a drill, he understands that hard and dusty work awaits him. And if you have to work with a wall, especially a brick one, then the first thing you need to do is select the right drill for the brick, so that during repairs you do not damage the tool and successfully drill through a wall made of brick.

Drilling technology

There are three ways to drill a hole in a brick wall: manual, electromechanical and automatic.

However, before starting work, it is necessary to study the location of the electrical wiring, since accidentally touching the wiring line will not only damage it, but can also electrocute a person. Most often, electrical wiring is located vertically or diagonally relative to sockets and switches. If you have any doubts, you should use a special device to detect hidden wiring. A portable metal detector will help detect aluminum or copper wire located no deeper than 1 cm.

A portable metal detector will help detect hidden communications

Hand Drilling Technology

In the absence of an electric tool, drilling holes can be done using a bolt. To do this, locations are pre-marked by drilling with a punch. After this, the bolt, which is applied to the wall at an angle of 90 degrees, is struck with a hammer. Every three blows, the bolt is rotated, and the remaining bricks are removed from the pipe. Thus, the hole is knocked out until it reaches the required depth.

Electromechanical process

Mechanical drilling is performed with a hammer drill or hammer drill, the process is the same.

First you need to decide on the type (through, not through), depth and diameter of the hole. This is necessary for a properly selected drill or drill. If you have difficulty maintaining the same distance between the holes, you can use a template. The stencil is made from plywood, chipboard, plastic and other available materials. To use it, you need to secure the sandpaper on one side with double-sided tape or glue, then lean it against the wall and drill.

After the type and diameter of the future hole has been determined, markings should be made with a core. The drilling process will be easier if it is done in the seam between the bricks. Notches with a core are made in order to fix the drill and facilitate its entry. When drilling with a drill, the tool must be held perpendicular to the wall, pressing gently on it so as not to break the drill or drill. Periodically, the drill must be taken out for cooling in a container with cold water.

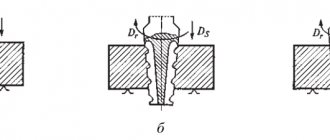

If it is necessary to drill a hole with a diameter greater than 18 cm, a hammer drill with diamond bits is used. If these are not available, you can use Victory drills of regular diameter. For this:

- The location of the future hole is outlined, and its outline is outlined with a pencil.

- Drilling is done along the outside of the line; the number of holes depends on the diameter of the contour. The diameter of the drill itself should be 0.8-1.0 cm, the pitch of the holes along the contour should be 1.0 cm. To do the job more accurately, you can use drills with an even smaller diameter, but then the process will take longer.

- Using a chisel and hammer, a sample is made from the drilled contour.

If you need to drill through a thick wall, you can do this in two stages: first, perform the drilling process as described above on one side of the wall. Then, the center of the resulting hole is drilled through. After this, the required diameter is marked on the other side of the wall around the intended through center, and the process is repeated.

Automatic process

Diamond drilling is carried out using professional, expensive equipment. In this case, it is desirable to have special skills and qualifications. With the help of such a tool, the drilling process is fast, accurate, almost silent, and can be done at different angles to a depth of up to 40 cm, resulting in a smooth hole, without chips or cracks. This method does not create a lot of dust and dirt, since the tool is equipped with an attachment to cool the drill and wash away the dust.

Methods for drilling bricks

Drilling a brick wall can be done in one of three ways:

- manual work method;

- electromechanical tools;

- using automatic drilling technology.

The first method is the simplest, but less technologically advanced. It is used if the master does not have the appropriate equipment. Electromechanical technology allows drilling to be completed in a shorter time. For this purpose, a hammer drill or drill is used. As for automatic drilling, it can be used to make holes of impressive diameter - up to 110 mm.

Manual drilling method

Drilling holes in a brick wall using this technology is carried out if there is no electrical equipment. All you need is a hammer and a bolt. The latter is a metal tube that you can make yourself or purchase ready-made. If you resort to the first solution, you will need to prepare a 30 cm piece. The diameter of such a device should be 25 mm or more. Notches are made at one end.

The technology suggests itself if you imagine these tools: once the location for making the recess has been determined, the bolt is installed at a right angle to the wall, and its other end should be struck with a hammer. The bolt rotates, which will prevent the formation of large amounts of dust.

Electromechanical drilling technology

In order to drill a wall in a shorter time, you should use technology that requires the master to have a drill or hammer drill. In the first case, you need to make sure that the equipment has a shock function. Otherwise, you will have long and monotonous work, which, among other things, may not allow you to achieve a positive result.

The ease of the process will depend on the number of revolutions and power of the tool. The most suitable value for the number of revolutions is considered to be 2000 or more. With an increase in this parameter, you can count on the fact that the hole can be made in the shortest possible time. If you are just planning to purchase a drill, it is important to make sure that it has a keyless chuck and a reverse function. In the first case, you do not have to additionally use a clamping wrench.

Drilling can be done right through the brick. For this purpose, a hammer drill with diamond bits is often used. The working part of the equipment must have rounded edges. This equipment should also have an impact option. In order to avoid placing a large load on the hammer drill and consumables when it is necessary to make holes of impressive diameter, you should start with small drills and finish the work with large ones.

If you have warm ceramics or hollow products, you need to turn off the impact function, as this may destroy the material. If the brick has a high grade and good strength, which also applies to clinker products, the electrical device is set to medium speed, otherwise the equipment may become dull.

Attention! If the wall needs to be drilled for installation of a hood, socket or plumbing system, diamond drilling should be used. For this purpose, a crown with especially strong teeth is selected. If used with the tool in impact mode, it may cause the base to be torn out. In order to eliminate such a nuisance, you need to start drilling from the masonry seam.

Automatic brick drilling

If you need to drill a brick wall in a hard-to-reach place, for example, in a corner, or you need to make a recess of impressive diameter, ordinary tools will not help. Here you should use automatic technology, which involves the use of special installations.

Process of drilling a brick wall

For high-quality drilling, you need a powerful hammer drill, but if you don’t have one, you can get by with a regular drill. Drilling a brick wall does not require special knowledge, however, extreme care and following some recommendations will help you avoid trouble when working with the tool. The drill must be held strictly straight, otherwise there is a chance of breaking the drill bit on the brick and leaving an uneven dent in the wall. When the drill is turned on, it is important to wear safety glasses that will prevent dust and brick fragments from getting into your eyes. Also, when drilling, you need to apply pressure on the drill smoothly and without sudden efforts, ensuring an even load on the surface.

Drilling requires a lot of energy consumption. At high speeds, a huge frictional force arises, which greatly heats the drill, so it must be cooled with cold water as often as possible. Often, when drilling, you can come across burnt bricks, which will not be easy to drill. To understand when such a brick came across, you need to look at the color of its dust, usually it is black.

To successfully drill a hole in a wall covered with burnt brick, you need to set the drill to low speed and turn on the hammer function. You need to press harder on the tool, but control the heating of the drill, preventing it from overheating. A very hot drill quickly wears out the cutting edges, so it is best to use a diamond coating here, which will allow better adhesion to the surface, saving time and effort.

It happens that a hole in a brick wall needs to be made with a considerable diameter. This diameter can serve as a ventilation outlet. For such a procedure, it is unlikely that a conventional drill will be able to drill a hole of large diameter, so a powerful hammer drill and a crown containing a diamond coating are required.

First you need to mark the diameter on the wall and draw a circle on the marked section of the wall. If, for example, a pipe with a diameter of 100 mm, then the hole for the drill must be marked at least 120 mm in order to maintain a margin in case the drill is skewed in the other direction. After this, in the figure you need to mark the points for drilling with a distance every couple of centimeters. Then you need to select a drill of appropriate thickness so that it goes through the entire brick wall.

At the drilling stage, you need to drill the marked points. The drill should go through the wall, remaining on the other side of the wall. After this, there will be a lot of dust, so it is recommended to cover foreign objects with a cloth and put on protection to avoid excessive dust. When finished you should have a large number of drilled points in the circle.

After drilling, use a hammer drill blade to knock out excess pieces of brick. The operation is carried out only in the beating mode; a brick drill is not needed here. When you manage to hollow out the unnecessary brick by going through the tool several times, then you will only be able to make a wide hole in the wall.

Dust-free drilling

If drilling is being done in an already renovated area, you always want to avoid contamination or damage to the finish. This will not happen if you attach a shelf made of the same material to the bottom of your stencil. Your wallpaper or paint will be protected, and dust from drilling will linger on this shelf.

Note! You can use a regular tetra pack (milk carton) by cutting it in half. On one side, you need to cut a little more with scissors so that the paper does not interfere with the drill.

And a few more words about how to make a hole in a large brick wall or create a small niche.

In home repairs, a Pobedit drill can easily cope with this task:

- Mark the outline of the hole on the wall.

- Perform several drillings along the marked line in 10 mm increments.

- Use a hammer and chisel to remove any unwanted material.

If you need to go to a greater depth, and the length of the drill does not allow it, do the work in two or more approaches.

Preparation stage

Drilling a brick wall begins with the preparatory stage. Before making a hole, you need to clearly determine its location. There should be no wiring or water pipes. To do this, use a metal detector to properly exclude obstacles. But even after this, all work is carried out carefully. There are sockets and lamps on the wall, as well as switches from which the electrical wiring runs. For work safety, an initial depth of up to 20 mm is gouged out with a regular screwdriver; a drill is used when there is no risk of damaging communications.

Selecting suitable self-tapping screws for drilling

Self-tapping screws are fasteners in the form of a rod that have a screw thread, a pointed end and a head. The thread holds the screw shaft in the wall, thereby ensuring fixation and immobility. According to the classification, self-tapping screws for drilling are divided into the following types.

To choose the right self-tapping screws for drilling, it is important to consider what metal or alloy they are made of. The scope of application of these products depends on the material of manufacture.

- Stainless steel. A huge advantage is protection from moisture. The presence of metals such as chromium and nickel prevents such screws from rusting.

- Carbon steel. Compared to the previous type, this metal is not protected from moisture, but is more durable.

- Brass self-tapping screws for drilling are a relatively expensive but high-quality material. They can be used in both salty and acidic environments. Brass is resistant to corrosion, but this alloy is soft and deforms under heavy load.

If you choose self-tapping screws for drilling in concrete with a dowel, you need to take into account that the capsule is first hammered into it, and the screw itself is screwed into it. The mechanism is made in such a way that the sharp ends of the capsule dig into the wall as the screw is screwed into the hole, expanding the fastening area for a more durable attachment.

This fastening system, where a plastic sleeve expands the fastening area, is used in the following cases:

- increased load on screws;

- more rigid fixation for cellular concrete;

- the need to eliminate vibrations to prevent screws from unwinding.

If you need to strengthen the structure in a facade building, you can use high-quality MBR-X facade dowels that come with a screw. Such fasteners can be screwed into a brick wall, and they are suitable for both solid and hollow bricks.

In the absence of a dowel, you will also need to drill a small hole for self-tapping screws; it is also better to calculate in advance the length of the screw to be passed through. Otherwise, the self-tapping screw will either not reach the required depth or will sink into the wall. Re-installation may only damage the fragile hole in the concrete.

There are also so-called turbo screws. The advantage of such a screw is the variable thread, which has notches. It has good adhesion to the concrete wall. Such self-tapping screws can be screwed in with a regular drill; they do not require excessive effort. The turboscrew is suitable for cellular and hollow concrete blocks.

The color of the screws is also important. In relation to color, drilling screws are as follows.

- Silver - these screws are suitable for any climatic conditions. Prevents the onset of corrosion. Suitable for work both indoors and outdoors.

- Yellow – covered with a protective zinc coating with an admixture of copper. Are used only for interior work.

- Black – contain an oxide film. Such screws are not suitable in rooms with a high percentage of humidity, for example, in bathhouses and greenhouses it is undesirable to use such fasteners.

Selecting and purchasing a drill

The diameter of drills for making holes in brick usually varies from 6 to 8 mm. This value is average, as is the depth, which is usually 15 cm. To make holes with more impressive parameters, it is better to use a drill. Its length reaches one meter, but it is used in conjunction with a drill and a hammer drill. The first one must have the function of a hammer drill.

When there is a thick wall, it is better to act in several approaches. To begin with, a 20-centimeter drill is used, and the recess is approximately 15 cm. Then the depth should be increased to 40 cm, and at the final stage - to 50 cm. During this process, a hammer drill will be needed.

Attention! The presence of an outlet on the wall will help identify and naturally not affect communications. If you don’t have the appropriate equipment at hand with which you can find out whether the wires are running inside, you can follow the first recommendation. But the electrical wiring must be de-energized in any case.

What drill to use to drill a hole in the wall

You can easily drill a wall or prepare a through hole by choosing the right drill for the equipment you are using, be it a drill or a hammer drill. For any purpose, the hole must have smooth edges and the right size. Accuracy is quite easy to achieve. Let's talk about the right choice of drills and features of drilling walls.

- Concrete, brick, stone

- Tile, glass

- Metal

- Wood, drywall

- Foam concrete

How to drill a brick correctly

- To mark a new hole in the wall, use a core (a tool for marking holes). It will help to leave the core in a specific place, so the drilling will be clear.

- Wear safety glasses and a face shield to protect yourself from dust and debris.

- Place the tool straight, otherwise the drill may break.

- It is necessary to drill so that the pressure on the drill is very soft, and this will ensure a kind of uniformity. The same load will allow the device to cool itself at the right time.

- After work, carefully remove the drill with gloves and place it in water. Or the whole tool is placed in a container, but only at the level of the drill.

- Burnt bricks are more difficult to drill, so if you see a brick that is different (darker than normal), then turn on lower speeds and be careful and gradual. And besides this, the drill should not be allowed to overheat under high pressure.

- If the drill heats up to the limiting temperature, and you notice this, you should never touch it in order to protect yourself from all kinds of injuries and burns.

- An important point also concerns a heated drill, since its edges may become dull due to its sudden cooling.

- For drilling, diamond drilling is often used, which gives good results in a short time, saves time, and the holes are stable.

Also watch videos on how to drill correctly, following the rules and safety precautions.

- For drilling over 30 mm, a core drilling machine is used, which also makes holes very quickly. But working with it requires professional skills.

- If it is necessary to drill a ventilation duct, the hole should be 18-20 cm in diameter. For this purpose, drills made of hard alloys are used. You make holes according to the markings, and then, using a Pobedit drill, hammer and chisel, knock out the remaining bricks from the wall.

How to drill hollow brick?

To do this, you need a special drill for concrete tipped with Pobedit or another hard alloy. Drilling hollow bricks and “warm ceramics” is not allowed in the “perforator” mode - reciprocating movements can destroy the internal cavities of the material. When working with a drill in normal mode, the hole turns out smooth and neat, but the process takes a little longer.

Photo 1. Drilling hollow ceramic products

Drilling solid brick can be done with a hammer drill. When working with high-strength and clinker products, it is recommended to set the drill to medium speed. Otherwise, the drill will quickly become dull, and as a result of excessive heating, the pobedit tip will lose its hardening.