To increase the service life of fasteners and give them a marketable appearance, protective and protective-decorative coatings are used. The following types of coatings are mainly used in TsKI :

- galvanizing;

- phosphating;

- oxidation;

- brass plating;

- nickel plating;

- powder coating;

- nitride titanation (TiN).

Zinc coatings

The most common of them is zinc . It significantly increases the service life of the product, is technologically advanced and inexpensive.

The TsKI assortment includes products galvanized using various technologies:

- electrolytic (galvanic) galvanizing;

- hot galvanizing;

- thermal diffusion galvanizing (sherardization);

- zinc laminate coating.

The protective effect of zinc coating is based on the fact that in the presence of contact with an aggressive environment (for example, a humid atmosphere), corrosion processes preferentially develop on zinc. Thus, corrosion of the base material – iron (steel) – is temporarily suppressed. However, this kind of protection is not very durable - it lasts until the zinc layer on the steel surface is completely oxidized. In mechanical engineering, the thickness of zinc coatings is usually 7-15 microns, in the construction industry - 50-100 microns.

Externally, the corrosion process of galvanized zinc coated in a salt fog chamber (standard test environment) looks like this. A few hours after the start of testing, a white, initially compact, and later loose coating – zinc oxide – appears on the product. Then corrosion of the base metal begins through its pores. It appears in the form of red-brown dots and spots - rust, in those places where the zinc coating has already become permeable.

Electrolytic galvanizing technology is based on the electrolysis process. The setup for electrolysis is very simple.

A steel product (spoon) to be coated and pure zinc plates are placed in a bath of electrolyte. Direct current is supplied to them through special clamps. In this case, “-” is applied to the product (cathode), and “+” is applied to the zinc plates (anodes). Solutions of various acids, alkalis and salts serve as electrolytes. During the electrolysis process, the zinc anode dissolves, its ions are transferred to the cathode - the product, where they are reduced to metal and deposited on the surface of the coated product. It should be borne in mind that simultaneously with the deposition of zinc, hydrogen gas is formed on the same surface. It penetrates the metal, forms gas voids, which rearrange the crystal lattice, thereby reducing the mechanical characteristics of the metal. That is why galvanizing is not recommended for products made of materials with a strength class higher than 8.8.

To increase corrosion resistance and give products an improved decorative appearance, passivation . It consists in the fact that immediately after application and washing, the zinc coating is immersed for 5-10 minutes in a solution of sodium dichromate and sulfuric acid. The zinc coating acquires a greenish-yellow color with rainbow hues. Therefore, in informal communication it is often called “yellow zinc”. If it is necessary to obtain a shiny coating, use another solution containing chromic anhydride, sulfuric and nitric acids. It not only passivates, but also brightens the surface of the product. The protective effect caused by passivation is based on filling the pores of the zinc coating with chromium VI compounds. chromatization is used quite often . In this case, we are talking about coatings obtained by passivation with a composition containing chromium III.

Today, electrolytic galvanizing is the most common method of protecting fasteners from corrosion. This is due to the high productivity of galvanic units, the low cost of the process and a fairly high protective ability.

Another mass application technology for zinc is hot-dip galvanizing . In this case, steel products are immersed in molten zinc at a temperature of 445 to 460°C. In this case, coating formation occurs much faster than with the electrolytic method: the hot-dip galvanizing speed can reach 80 µm/min. This is extremely convenient when coating large parts.

If small parts are processed, excess zinc is removed using a centrifuge, and parts of complex shapes are not allowed to be processed in the melt at all.

The structure of the hot coating consists of two layers. The inner one is an iron-zinc alloy of variable composition (intermetallic compound), and the outer one is the actual metal zinc coating. There are technological techniques that allow you to change the thickness and structure of these layers. And the high speed of coating formation is manifested in the coarse grain of the outer zinc layer.

You can learn more about the technology and properties of hot-dip galvanizing in the technical article. In addition, you can compare the test results of hot-dip galvanized fasteners and galvanized hardware in the TsKI article “Hot-dipped galvanized fasteners.”

Thermal-diffusion galvanizing (sherardization) – saturation of the top layer of a metal product with zinc (thermal-diffuse layer). The technology for applying protection is quite complex and expensive. Produced in heated rotating centrifuges with zinc dust. The temperature in the container reaches 290–450 °C. Sherardization makes it possible to obtain a coating thickness in the range from 6 to 110 microns, and the coating is smooth and non-porous, with high adhesion to the substrate. The protective ability of such a coating is 3–5 times higher than that of galvanic coating and comparable to hot-dip zinc. This method is used to protect special-purpose metal products, for example, for railway transport parts. The disadvantages include low productivity, limited by the volume of galvanizing chambers, limitation of the size of parts by the size of the container and the lack of decorative properties of the diffusion coating (gray tones, lack of shine).

Zinc lamel coating contains up to 80% zinc flakes (lamellas), 10% aluminum and a binder base (acrylic, urethane, epoxy and silicone resins). The microscopic scales are arranged in parallel, so they overlap each other, leaving no “gaps” on the metal surface where oxygen could enter. In addition, the oxidation rate of aluminum is lower than that of zinc, so zinc-aluminum coating is 3 times more resistant to corrosion than standard hot-dip galvanized coating.

Zinc lamel coating can be applied not only to ferrous metal, but also to galvanized steel, nickel, aluminum, copper, stainless steel and other metals. If necessary, additional layers are applied to the base coating, which increase corrosion and chemical resistance, give the desired color and increase wear resistance. As a rule, fasteners are coated with zinc lamella by immersion in a solution, the residues of which are removed in a centrifuge.

Among all types of coating, zinc lamel is noticeably superior to similar ones, winning in terms of physical and aesthetic parameters. Despite the fact that the parts are coated with a thin layer of the composition and completely retain their shape, they are 100% protected from corrosion, and the metal is protected from hydrogen penetration and embrittlement. This coating can withstand the maximum load class - C5. It is easy to apply to parts of complex shapes, and the requirements for the thickness of the base material are minimal. Despite the obvious advantages of zinc-lamella coating, in Russia it is still used by enterprises that can be counted on the fingers of one hand.

There are also numerous options for zinc-based coatings. On SPAX self-tapping screws, after applying galvanic zinc coating, its pores are filled with a fluoroplastic suspension. This increases the corrosion resistance of the system, as well as, equally important, its anti-friction properties.

In practice, zinc coating is applied to fasteners in the vast majority of cases. However, when this is not possible for some reason (for example, due to hydrogenation of high-strength steels) or when any special requirements are imposed on the coating, phosphate and oxide coatings are used.

Processing rules

In order to apply an anti-corrosion coating at home and reliably protect the metal from environmental factors, you need to follow a number of rules:

- A layer of rust, dirt, and plaque is removed from the metal surface.

- The protective layer is applied after degreasing the stripped metal and applying a primer.

Anti-corrosion paint is applied in two layers.

Anti-corrosion coating protects metal products from the destructive effects of moisture and air. To apply it, you need to select a chemical composition and apply the coating correctly.

Phosphate coating

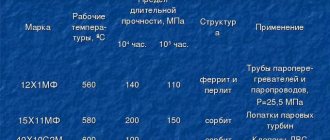

Phosphate coating is the result of phosphating. This is the name given to the process of chemical treatment of steel (as well as other metals and alloys) in solutions of phosphate salts of alkali metals or ammonium. As a result of phosphating, a layer of sparingly soluble salts – iron phosphates – appears on the surface of the product. The coating has a dark gray to black color and a rough surface. The usual thickness of the protective layer is 2-5 microns. It is resistant to the effects of kerosene, lubricating oils, atmospheric oxygen, can withstand short-term heating up to 5000C and cooling down to -750C, but is destroyed by acids and alkalis. Often used as a primer - a coating for painting.

In our range of phosphate coatings you can find:

- on retaining rings

- on self-tapping screws for fastening plasterboard and gypsum fiber boards

What is corrosion?

Corrosion is a process in which metal surfaces are destroyed by environmental factors. If nothing is done, rust will render the product unusable. Long-term exposure to water negatively affects many characteristics of the material:

- appearance of the workpiece surface;

- indicators of hardness, wear resistance;

- structure of the material.

Car parts, tools stored in rooms with high humidity, industrial equipment, and metal structures often suffer from such problems. Anti-corrosion compounds form a protective layer on the metal surface, which increases the protection of the material from environmental factors.

Oxide coating

The oxide coating is the result of oxidation. This is the name of the process of obtaining an artificially formed film on the surface of a product, consisting mainly of oxides of the material being coated. In the case of oxidation of steels and cast irons, a dark film is formed on their surface, consisting conventionally of iron oxide Fe3O4 with a thickness of only a few microns. Among others, the most common method is chemical oxidation. When selling it, the product to be coated is immersed in a boiling solution, most often consisting of alkali and oxidizing agents - nitrates and nitrites. The resulting film is tightly adhered to the base metal and has a black color. To increase corrosion resistance, the film is oiled, due to which its pores are filled and become impenetrable to the external aggressive environment. One of the widespread oxidation options is bluing. The name comes from the color of the coating. It is black with a blue tint, like a raven's wing.

In our range of oxide coatings you can find:

- on products made of steel with a strength class greater than 8.8, to prevent hydrogenation during galvanizing;

- on installation screws, where the use of a soft coating is unacceptable;

- on retaining rings DIN 471 and 472

- on a thrust washer, quick-release DIN 6799.

Varieties, composition and capacity

Based on their composition, non-metallic mixtures are divided into several groups:

- Silicate enamels are in demand for processing elements operating at high temperatures or in chemically aggressive environments. Available in paste or powder form. The processing process is carried out in several stages. Initially, a primer is applied to improve adhesion and reduce thermal or mechanical stress. After the layer has dried, the product is opened with the covering enamel and again heated to a high temperature. The frozen substance forms a thin layer that protects the product well. The coating does not have high strength, since the enamel cracks and crumbles under strong impacts.

- Polymer coatings - most often such compositions contain polyethylene, polyisobutylene, fluoroplastic, polystyrene, polypropylene, epoxy resins. Mixtures can be applied to the surface with a regular brush, by dipping or spraying. After drying, they form a film several elements thick. Polymer substances also include antifriction solid lubricant mixtures. They are similar to paint, but instead of pigments they contain solid lubricants. Most materials are based on graphite, molybdenum disulfite, polytetrafluoroethylene (PTFE) and other solid lubricants. Epoxy, phenolic, acrylic and polyamide-imide resins, polyurethane, titanate and other components are used as binders.

- Paint and varnish coatings - the composition is formed from film-forming substances, pigments, fillers, plasticizers, catalysts and solvents. The products not only protect products, but also provide them with an attractive appearance. When certain particles are added to the composition, the materials acquire special properties. For example, conductivity, heat resistance, increased strength and acidity.

- Gumming is the treatment of pipelines, tanks and reservoirs with rubber or ebonite for transporting aggressive substances. There are hard and soft coatings. The softness of the composition is controlled by mixing sulfur into the mixture. The substance is applied to a clean surface, pre-treated with rubber glue, then vulcanization is carried out.

- Coatings made from pastes and lubricants are used for long-term storage and transportation of metal products and their protection from aggressive environments. Substances are applied by brush or spray method. After drying, a film is created that prevents contact of parts with moisture, dust and various gaseous substances. Lubricants are produced on the basis of mineral oils with particles of waxy components - paraffin, soap, wax. Pastes are made from suspensions of mineral wax, paraffin or rubber, as well as polyisobutylene. Such means are effective provided that the film is not destroyed under mechanical stress.

Protective coatings that do not require mandatory use in production conditions are packaged in small, medium and large volume tanks. In particular, in cans, cans, buckets and barrels with a capacity of up to several hundred liters. Some formulations are produced in aerosol packages for easy treatment of hard-to-reach places.

Brass and nickel plating

Brass plating imparts decorative properties to coated products. Most often used when installing plumbing fixtures. The main components of brass are copper and zinc in different combinations, but in principle copper predominates. Typical brass has a golden color. The common composition of electrolytically deposited brass contains about 60-70% copper and 30-40% zinc.

Brass-plated parts are represented in the TsKI assortment by furniture screws and screws, as well as furniture decorative nuts.

Nickel plating is used to make fasteners more resistant to salt fog. The thickness of the applied coating is usually from 1 to 50 microns. Parts made of steel and alloys based on copper, aluminum, iron are subject to nickel plating, and galvanic nickel plating can be applied to products made of titanium, molybdenum, and tungsten. When nickel plating steel parts, an underlayer of copper is usually applied to them.

In TsKI, rivets are coated with nickel. You can find more details in the “Rivets” section.

Description

Protective coatings are compounds that are used to treat metal parts and other products to protect against oxidation, corrosion, and premature destruction when exposed to external environments. All types of substances are divided into metallic and non-metallic. The first group includes anodic and cathodic coatings, which are applied by thermal spraying, galvanization, dipping, diffusion or cladding.

The second group includes organic and inorganic materials - paint and varnish mixtures, enamels, polymers, sealants, metal oxides, rubber, compounds based on phosphorus and chromium, etc. They form a film on the treated surface that is resistant to external influences, which protects parts from damage. Treatment of products with metallic compounds is possible only in production conditions, while non-metallic coatings can be applied manually or mechanically during operation or maintenance of individual equipment components.

Protective coating by galvanizing method

- ease of use

- relatively low cost

- the surface must be pre-prepared in a special way

- afraid of high temperatures (it is not advisable to use when coating products that are subsequently exposed to high temperatures)

- low periods of anti-corrosion protection

- relatively high corrosion resistance (subject to pre-galvanization)

- complexity of the process

- high cost of technology

- wide operating temperature range (from +50°С to -70°С)

- environmentally inert material

- high adhesion to base coat

- high availability of material (produced in Russia)

- ability to absorb ultraviolet radiation, which leads to color fading

- relatively rough coating

- beautiful shiny appearance and smooth finish

- It is advisable to use in aquatic environments and areas where there are no low temperatures (for example, when forming gabions, Foucault mattresses, etc.)

- narrow operating temperature range (from +50°С to -20°С)

- coating becomes brittle at t=-20°C, cracks and crumbles

- when destroyed, it releases environmentally harmful chloride compounds

- ability to absorb ultraviolet radiation, which leads to color fading

- high cost of material, because raw materials are imported

- can be applied from 3 to 5 layers

- work effectively in unfavorable (including chemical) environments

- complexity of use and coating - strictly limited in time after preparing the mixture

Latest articles

Types of protective coatings for metals

Industrial gates SNK

Fencing of sports grounds - 2019 standards

Industrial gates

A fence made of chain-link mesh - a fence for your dacha with your own hands!

Barrier fencing

Industrial fencing. Typical solution 6

Industrial safety fencing. Typical solution 5

Industrial safety fencing. Typical solution 4

Industrial safety fencing. Typical solution 3

Popular

Fencing in production is an important requirement for occupational safety

In modern conditions of production development, the requirements for the safety of work processes are increasing. One of the elements that ensures a reduction in injuries is the creation of a security zone around moving and rotating parts of mechanisms. Before you start designing, determine the nature of the equipment and its applicability.

Fencing of sports grounds - 2019 standards

What are the requirements for sports fencing? What documents relevant for 2021 need to be studied when starting to design a sports ground so that there are no problems after its construction? We will talk about the most important points in this article.

The higher the fence, the better the neighbors. Which fence to install in 2019?

Guided by the well-known principle “My home is my fortress,” we install powerful entrance doors to apartments, and for our country house, plot or cottage we are looking for a reliable, strong and durable fence. We believe that by choosing a welded fence, you will get the best solution for a country house or cottage. Why? In this article we will compare it with other types and you will see for yourself.

Protective coating by galvanizing method

- attractive (shiny) appearance

- allows you to cover weld seams

- allows galvanizing products of complex shapes

- relatively thin coating and low service life

- relatively time-consuming, complex and not environmentally friendly technology (including the difficulty of cleaning used chemical compounds)

- allows you to produce products in a stream, at high speeds

- difficulty in galvanizing products of complex shape (presence of residual zinc “snot”, sagging)

- increased coating density – increased protection against corrosion

- difficulty in galvanizing products of complex shape (presence of residual zinc “snot”, sagging)

- high density (thickness) of the coating – effective protection against corrosion

- long service life (up to 30-50 years)

- difficulty in galvanizing products of complex shape (presence of residual zinc “snot”, sagging)

- high density (thickness) of the coating – effective protection against corrosion

- long service life (up to 30-50 years)

- has restrictions on the minimum thickness of the metal (warping of structures with different thicknesses and different thermal conductivities)

- presence of residual zinc (snot, deposits)

- high cost due to high zinc consumption and high energy consumption

- effective for small parts with complex shapes (especially fasteners)

- high quality coating due to the penetration of zinc into the metal at the atomic level

- smooth, matte and pore-free finish

- complexity and high cost of the process

- low process performance

- product size limitation

- used to coat products operating in harsh environments

- long service life - more than 50 years

- complexity and high cost of the process

- high price of finished products